Posts Tagged research

Behind Every Object Is a Story

The author at his desk at The Henry Ford. / Photo by Jeanine Head Miller

I grew up on Detroit’s far west side, just north of Dearborn, during the 1950s and 1960s. History was always my favorite subject, and I fondly remember school field trips to what was then called Henry Ford Museum and Greenfield Village. I can trace my interest in American history to those visits and remember thinking how great it would be to work there someday.

I graduated from the University of Michigan at Ann Arbor in 1975 with a bachelor's degree in history. My original intention was to become a history teacher, but with teaching positions few and far between in those days, I ended up accepting a position in the mortgage department of Comerica Bank and stayed there for nearly 30 years.

I retired in 2008 and became a volunteer at The Henry Ford. After three years of doing computer data entry in the marketing department and helping at special events like Maker Faire, Old Car Festival, and Motor Muster, I met Jeanine Head Miller, Curator of Domestic Life at The Henry Ford. Jeanie was looking for a volunteer curatorial research assistant to work with her in the Historical Resources department. She was willing to take a chance on me, even though my professional life had been spent in banking, not historical research. The learning curve was steep, but with Jeanie’s knowledge and patience, I learned the ropes.

My primary focus as a volunteer has been to research the lives of some of the people who owned, made, or used the objects in The Henry Ford’s collection. Most of them were ordinary people, using these objects as part of their everyday activities.

Uncovering People’s Stories

I first look for clues in the object’s accession file—a file that contains whatever information we know about the object. Sometimes I find letters from the donor, often a descendent of the original owner, providing some family history and information about the maker or owner of the object, or how it may have been used. More often, though, there may be only a few clues—a name or a place. From these clues, I start my search to learn more about the background of the individual or family and the context of the object.

The advent of the Internet and genealogy websites like Ancestry.com—with access to census records, city directories, birth and death records, and other information—make researching the life of someone born more than a hundred years ago much easier. The census records are a particularly valuable tool in my research. They provide information about a person’s occupation, age, place of birth, marital status, immigration status, place of residence, home ownership, and more. The census also lists all the people living in the same home and their relationship to the head of the household.

Sites like Newspapers.com, with its access to many newspapers nationwide, can provide a wealth of information. I often find marriage and birth announcements, obituaries, and other information. Local historical societies are also a great research resource. I encounter other dedicated volunteers willing to search local records for information on people I am searching for—information not available online.

Conrad Hoffman’s Violin

Violin used by Conrad Ambrose Hoffman, 1793. / THF180694

A few years ago, The Henry Ford acquired a violin used by Conrad Ambrose Hoffman (1839–1916), a musician and teacher from Pontiac, Michigan. The violin had been made in 1793 by Czech violin maker Johann Michael Willer (1753–1826). The family not only donated Hoffman’s violin and bow, but also related archival materials, including concert programs, sheet music and librettos, calling cards, and stationery.

These materials helped provide some information about Hoffman. But further research in sources like Ancestry.com, Newspapers.com, and the Palmer Family Papers: 1853–1940 at University of Michigan’s Bentley Historical Library helped me enrich Hoffman’s story.

The United States census records for Conrad Hoffman revealed that he was born in New York in 1839, but moved to Oakland County, Michigan, with his family by 1840. His father, Ambrose D. Hoffman (1806–1881), made his living as a farmer and cooper. The 1870 census revealed that 31-year-old Hoffman was employed as a music teacher and was living at the family home in Pontiac, Michigan, with his parents and two sisters.

Most of the information I discovered about Hoffman’s life as a musician and teacher came from a biography that I found on Google Books, Biographical Sketches of Leading Citizens of Oakland County, Michigan, published in 1903. The account recalled Hoffman’s early interest in music, the musical abilities of his mother and sisters, and his study of the violin as a young boy—including his traveling to Dresden, Germany, to study music at the Dresden Conservatorium.

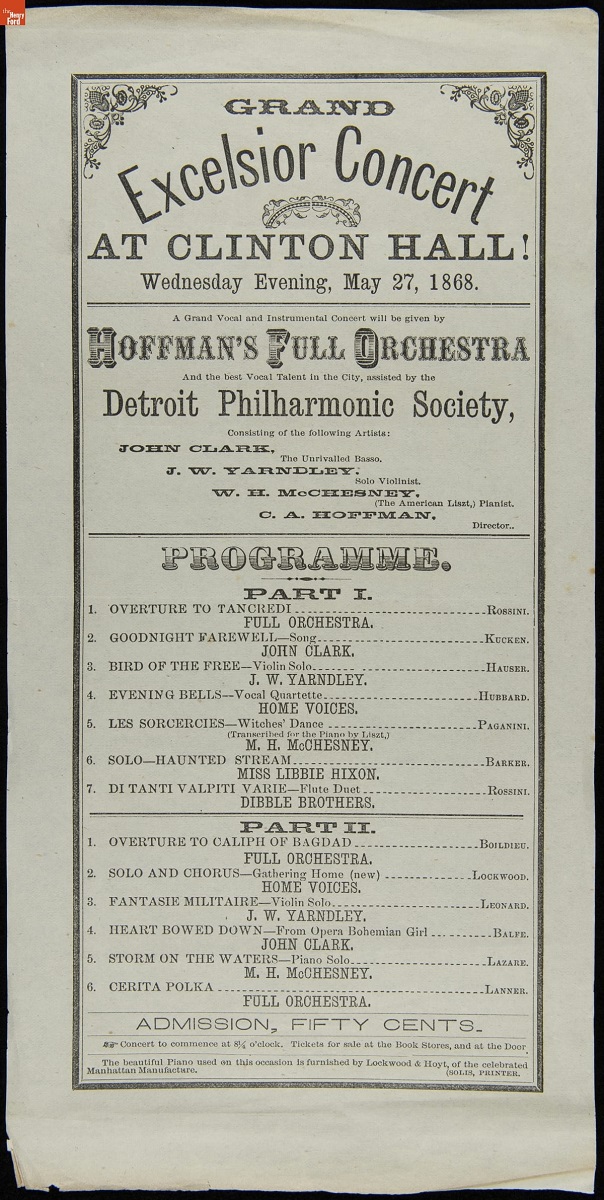

Hoffman and his orchestra performed at Clinton Hall in Pontiac, Michigan, on May 27, 1868. / THF279100

Hoffman’s biography also revealed that he served in the Union Army during the Civil War as a musician with the 15th Michigan Volunteer Infantry. In the years following the war, Hoffman organized an orchestra in the Pontiac area.

Conrad Hoffman performed at this concert at the Music Hall in Holly, Michigan, on May 24, 1866. / THF279106

Concert programs from the 1860s and 1870s document Hoffman’s performances in places like Birmingham, Holly, and Pontiac, Michigan. He performed as a solo violinist, as well as a conductor.

I discovered through a marriage announcement, published in the Detroit Free Press on September 25, 1900, that Conrad Hoffman married for the first time at the age of 60. His bride was childhood friend and pianist Philomela Cowles Palmer (1851–1930). Philomela was the daughter of Charles Henry Palmer (1814–1887) of Pontiac, an entrepreneur who was instrumental in helping develop Michigan’s copper industry.

Conrad Hoffman died in 1916. His obituary, found on Newspapers.com, was published in the Detroit Free Press on December 9, 1916. The obituary described Mr. Hoffman as a well-known violinist, the owner of a collection of old violins, and the instructor of several of the best-known Michigan violinists and violin teachers.

Audrey Wilder’s Dress

Audrey Wilder’s blue 1920s dress is second from the right.

In the fall of 2019, Jeanie Miller asked me to find out what I could about the life of Audrey Kenyon Wilder (1896–1979) of Albion, Michigan. Jeanie planned to use Wilder’s 1920s dress for an exhibit called What We Wore: A Matter of Emphasis in Henry Ford Museum of American Innovation. My task was to find out as much as I could about Wilder to help tell the story of the dress and the woman who wore it.

The donor correspondence in the accession file for Wilder’s dress provided just a few clues—her name and place of residence. I guessed Audrey Wilder’s birth date would be about 1900, based on the age of the dress. I was able to find four-year-old Wilder in the 1900 U.S. Census, living with her parents at the home of her paternal grandparents in Albion, Michigan. Her father was the owner of a lumber yard in Albion.

Yearbooks from high schools and colleges, which I found on Ancestry.com, provided information about Wilder’s education and career. I learned that she graduated from Albion High School in 1914, Albion College in 1918, and earned a master's degree from Columbia University in 1921. Wilder began teaching English at Albion College that same year.

In 1928, Audrey Wilder left Albion College to serve as Dean of Women at Ohio Northern University in Ada, Ohio. I was able to find an article written about her on Google Books, which shed some light on Audrey’s life and activities during this period of her life. The November 1935 issue of her college sorority newsletter, Anchora of Delta Gamma, published a story about Audrey’s life and career, entitled “Audrey Kenyon Wilder, Ohio Northern’s Dynamic Dean.” She is described as a woman “of exquisite grooming” and as having established the first social hall for women on the Ohio Northern campus, providing a setting for the female students on campus to hold teas, receptions, and co-ed dinners.

Dress owned by Audrey Wilder, 1927–1929 / THF177877

Tying an object to the story of its owner is the goal of my research. It is not hard to imagine Audrey Kenyon Wilder, the dynamic dean of exquisite grooming, attending a campus social function wearing the dress which is now part of the collection at The Henry Ford.

“Shopping” for the Collection

At times, I have assisted the curatorial staff in locating items for the museum’s collection. The curators identify a desired object and I then search eBay and other Internet sites to try to locate one in good condition. I then show the possibilities to the curator or curators, who select and acquire the object. These Internet sites make the search easier, but it often requires patient searching—sometimes for months.

Amelia Earhart brand overnight case made by the Orenstein Trunk Company, 1943–1950. / THF169109

One example is an Amelia Earhart brand suitcase. Earhart endorsed various products, including a line of luggage, in order to finance her aviation activities. I searched for six months and found one in like-new condition with the original price tag and keys! Though this example dates from the decade following Earhart’s disappearance, it attests to the staying power of the Earhart brand—this luggage line sold well for decades. This suitcase is on display in the museum’s Heroes of the Sky exhibit, in the section dedicated to Amelia Earhart.

I could not have asked for a more rewarding and interesting way to spend some of my time during my retirement years. I was finally able to find that “job” that I thoroughly enjoy and never get tired of. With millions of artifacts in the collection at The Henry Ford, there is always another life to explore and, for me, another adventure.

Gil Gallagher is Curatorial Research Volunteer at The Henry Ford.

Heroes of the Sky, women's history, Henry Ford Museum, What We Wore, fashion, Michigan, music, musical instruments, violins, The Henry Ford staff, #Behind The Scenes @ The Henry Ford, by Gil Gallagher, research

Moving and Reconstructing Firestone Farm

Firestone Farmhouse and Firestone Barn during reconstruction in Greenfield Village, December 1984. / THF118159

Two centuries ago, in the 1820s, Peter Firestone began the construction of his new farmstead in Columbiana County, Ohio. It eventually comprised a sturdy brick home, a very large barn, and several small outbuildings. The task took him, his family, and numerous local craftsmen many years to complete. The farmhouse alone is said to have taken four years; it is possible the entire complex may have taken as many as ten years.

When The Henry Ford acquired Firestone Farmhouse and Firestone Barn in 1983, the first challenge we faced was moving them to Dearborn, Michigan, from their original location in eastern Ohio—some 200 miles away. We decided the only feasible method was to completely disassemble the buildings, pack the materials into trailers, and transport them to Greenfield Village, where we would reenact Peter Firestone's feat.

Research and Disassembly

Our project commenced in April 1983, when an architectural recording team began to measure the structures to be moved and created drawings that would be used for their reconstruction. The team noted the condition of the buildings, researched their history, and began to develop theories about the changes the structures had gone through over the years. Armed with architectural plans and documentary evidence, we began a careful probing of the buildings to uncover information about their construction.

We took paint samples from wood surfaces and analyzed them microscopically to help identify layers of paint applied over time. We also removed brick and mortar samples for chemical analysis. At this time, we discovered former stair locations, old room partition placements, blocked-up doorways, and the remnants of a fireplace in the farmhouse. Our examination of the barn revealed much about its original form and the changes made to it in the early 20th century. Our team recorded the location of mortises for missing framing members and incorporated patterns of the original construction into the drawings.

In conjunction with this work, we conducted two other types of research—archeological research and architectural field research. Evidence from an archeological dig to locate outbuildings that had once been part of the historic farm proved inconclusive, but we did uncover a large quantity of artifacts that helped establish how the farmhouse had been furnished in the past. As part of our architectural field research, we surveyed more than 200 area farmsteads. After analyzing our material, we went back to conduct an in-depth study of 25 barns resembling Firestone Barn, as well as various other 19th-century outbuildings.

We began disassembling the structures by removing and numbering interior woodwork and doors, which were then packed into trailers. Our team removed plaster and lath from ceilings and partitions. Then, we took up floorboards from all three levels of the farmhouse, numbered them, and placed them into trailers. In this same way, all the elements of the farmhouse interior and roof were disassembled and readied for shipment to Greenfield Village.

Next, restoration specialists took apart the masonry structure of the farmhouse brick by brick. They cleaned the bricks onsite and packed them with straw in shipping crates. As the brick walls came down, we removed window and door units intact. Then, the masonry specialists prepared the farmhouse’s sandstone foundation for disassembly. They numbered each stone on the interior face (which had several layers of whitewash on it) and photographed each wall surface with its numbering pattern showing. As the masons removed the stones, they again numbered each one on its top bedding surface. The stones, too, were cleaned and packed with straw in crates, and the number of each stone was listed on the outside.

Masonry restorers removed each brick from the walls of Firestone Farmhouse. After being cleaned of excess mortar, the bricks were packed with straw in the crates in the foreground. / THF149938

The barn was stripped of its 20th-century additions, siding, and roof to expose the frame of the building for disassembly. The wooden pins anchoring each timber joint had to be driven out so that the posts and beams could be taken apart in the reverse order of their assembly. Prior to removal, each timber was numbered with a color-coded plastic tag that identified its location in the frame. Timbers less than 40 feet long were loaded into trailers. Those that were longer—for example, one floor support beam that measured 68 feet—had to be shipped on a special stretch trailer.

Disassembly of Firestone barn at its original site, Columbiana County, Ohio, 1983. / THF628361, THF628363, THF628367, THF628369

Discoveries

Each stage of disassembly yielded more information about the original construction and subsequent alterations of the buildings.

In the barn we discovered the original granary and hay chute arrangements. Analysis of historic photographs and field data brought to light the "drive-through" equipment shed/corn crib that had been almost obliterated by 20thcentury alterations. We also unveiled early 19th-century changes to the structure, including a tool and storage room on the second level and subdivisions of the stalls on the first level.

The farmhouse continued to divulge more of its secrets. Evidence of major interior and exterior renovations turned up daily, as we found reused materials from the original construction in every conceivable portion of the later construction.

This bedroom doorway, which had been closed off during Firestone Farmhouse’s 1882 renovation, came to light during the disassembly process. / THF149936

We made one very exciting find while moving a section of hand-decorated plaster ceiling above the central stairway. Attached to a framing member associated with the farmhouse’s renovation was a scrap of paper inscribed, “James Maxwell Washingtonville Ohio 1882 / Harvey Firestone Columbiana Ohio 1882.” Aged 12 and 14, respectively, these boys had left a "secret" message, and we had been the lucky finders. Census research established that James Maxwell was the son of a plasterer. He was probably helping his father with interior renovation for the Firestones. Since we knew from the account book of Harvey Firestone’s father, Benjamin, that the renovation of the exterior of the farmhouse had been accomplished in 1882, the note proved conclusively that the interior renovation had been done at the same time. This helped influence our choice of 1882 as the restoration period for the entire farm.

This hidden message enabled us to precisely date Firestone Farmhouse’s 1882 renovation. / THF124772

Firestone Farm in Greenfield Village

While all this work was taking place in Ohio, we transformed Greenfield Village in anticipation of the farm's arrival. Workers cleared a seven-acre area designated as the farm site for development. We moved six buildings to new locations in the Village; eliminated four non-historic buildings from the area; constructed three new buildings for behind-the-scenes activities to replace those displaced by the farm; and relocated a portion of the railroad tracks.

By the end of 1983, four trailers, two large stacks of over-sized beams, and no fewer than 250 crates of brick and stone were all onsite awaiting the spring construction season. While planning for the entire farm restoration continued, workers began to reproduce a substantial portion of the barn that had been lost to 20th-century alterations. We purchased white oak logs, and craftsmen began hand hewing and joining timbers to recreate most of the original ground-floor framing, which had been replaced by modern materials. This process alone, excluding the actual erection of the timbers, took four craftsmen nearly three months to accomplish. Later in the project, additional components had to be created to replace portions of two sheds initially attached to the main barn. These had been drastically altered for 20th-century farming needs. The upper portions of the barn required numerous replacements and repairs, though most of this part of the frame had been unchanged from its original construction.

In May 1984, we broke ground for the foundation of both the farmhouse and barn. Throughout the summer and into the fall, the masonry shell of the farmhouse rose slowly from the foundation toward the roof line, with windows, doors, and floor framing incorporated during the process. The task of restoring each basement stone to its original location and replicating the brick bonding was tedious and time-consuming. To replace damaged bricks, we manufactured replicas in three different shades to match the originals in color variation, as well as in shape and texture. The entire masonry shell of the farmhouse was finally completed late in the fall, just as plunging temperatures threatened to stop the project. Winter weather halted most outdoor activity, and a temporary roof was placed on the building until late the next spring.

Masons set the transported stones back into Firestone Farmhouse’s new foundation. Here, the author assists by referring to composite photographs of each of the basement walls. / THF149926

The largely reproduced lower frame of the barn was erected in the summer, with repairs and minor replacements to the large upper section of the building continuing into the fall. After trial-fitting and adjusting individual portions of the upper stories, workers reassembled them in sections called “bents.” Each bent was lifted into place, then connected to another by struts and top plates to create the full frame. The erection process for the three-tier main frame lasted until December, when production of the attached sheds began. We completed roofing and siding of the main barn in the winter months as work on the remaining portions of the sheds moved offsite and indoors to escape the cold weather.

The author in May 1985 with a portion of the scale model constructed to assist in the restoration of the barn. The ramp side of the nearly completed barn is in the background. / THF149932

We restored the interior of the farmhouse during the first four months of 1985, placing each numbered floorboard, wall stud, wall plank, and door or window trim piece in its original location. At the same time, we repaired or replaced damaged materials using the same type of materials in the original construction. We applied new plaster to lathed stud walls and ceilings, as well as to the brick walls of the interior, then reinstalled additional trimwork that had covered the old plastering. Finish work then began on the interior surfaces of the farmhouse in preparation for whitewashing, painting, and papering. Carpenters moved outside at this time to restore the three porches that had been built in 1882. We finished painting the exterior in early June 1985.

With the coming of spring, we resumed outdoor work on the barn. We completed the attached sheds and massive stone ramp that leads to the upper floor of the barn, then moved our work inside. We attached plank floors with wooden pegs in the threshing area; restored the granary and tool room; and placed packed earth floors in the animal stall area on the ground level. We constructed new doors based on historic photographs, field studies, and an extant door—one of three types used for the barn.

The restoration of the farmhouse and barn did not represent a complete recreation of the Firestone farm. Additional elements helped establish the environment of an operating farm of the 1880s. We reproduced a pump house next to the farmhouse using historic photographs, archeological evidence, and field research data. We also acquired a period outhouse in Ohio, restored it, and placed it in the yard behind the farmhouse. We then erected a chicken house—modeled after examples shown in agricultural literature of the period—adjacent to the barn, as well as a fence enclosure for hogs. To complete the experience, we built more than 7,000 linear feet of fencing to match historic photographs of fields at the farm’s original site.

Over a period of almost two and a half years, we moved the Firestone farm from Ohio to Michigan and meticulously and accurately restored it to its physical condition of a century earlier. The process required an understanding of the historical record, the careful handling of tens of thousands of historic architectural objects, and the reproduction of thousands of missing elements. It may not have equaled Peter Firestone's feat 160 years earlier, but it did honor his effort, as well as that of the millions of 19th-century farmers who contributed to our country's agricultural heritage.

Blake D. Hayes is former Conservator of Historic Structures at The Henry Ford, including during the move and reconstruction of the Firestone farmstead. This post was adapted by Saige Jedele, Associate Curator, Digital Content, at The Henry Ford, from an article in Volume 14, Number 2 of the Henry Ford Museum and Greenfield Village Herald (1985).

Ohio, 1980s, 20th century, research, Greenfield Village history, Greenfield Village buildings, Greenfield Village, Firestone family, farms and farming, conservation, collections care, by Saige Jedele, by Blake D. Hayes, #Behind The Scenes @ The Henry Ford

Deepening Our Understanding of Soybeans

Soybean Processing for Fiber and Oil, Ford Exposition, New York World's Fair, 1939 / THF216213

Soybean Processing for Fiber and Oil, Ford Exposition, New York World's Fair, 1939 / THF216213

A New Partnership

Today, on National Agriculture Day, The Henry Ford is pleased to announce a new partnership with the Michigan Soybean Committee to deepen our understanding of this important crop, from field to factory.

The Michigan Soybean Committee works on behalf of Michigan’s 12,000 soybean farmers to drive demand, fund research advancements, share the story of agriculture, and identify ways to help farmers grow soybeans sustainably for generations to come. Michigan Soybean Committee has a renewed focus on consumer outreach and working with partners to provide information to the public about soybeans and agriculture in the state of Michigan. The collections of The Henry Ford help tell the long history of soy, and especially the launch of the legume in Michigan, a project with a long history dating back to Henry Ford himself. Michigan Soybean Committee is excited to work with The Henry Ford to provide the public with the chance to learn more about agriculture and the innovations that have helped farmers feed the world.

Soybeans Planted in 30-inch Rows / Photo courtesy Michigan Soybean Committee

Why Soybeans?

The soybean (soya bean, Glycine max) moved from relatively obscure forage crop in 1920 to center stage on global markets in 2020. Today soybean farmers in 19 states, including Michigan, raise 96% of the more than 4 billion bushels of beans produced in the United States. Each of those soybeans contains oil, protein, and biomass, attributes that processors use to transform the soybean into valuable products.

Mrs. Hardy Checking Soybean Milk in Ford Lab, March 1944 / THF272478

Today we encounter soybeans in almost every aspect of our daily lives, but we may not recognize the legume, even when we use or consume it. Drink soymilk? Use a non-dairy creamer or whipped topping? Eat chocolate? Use soy oil for cooking? Is your candle made of soy? How about the bioplastic coating your take-out food container or disposable coffee cup? Have you ever filled your vehicle with biodiesel? These products, and many more, likely include ingredients derived from soybeans. The Michigan Soybean Committee recommends the United Soybean Board website https://soynewuses.org/ as a good resource to learn even more about all of the products made with soy.

Presto Whip Building, Dearborn, Michigan, 1976 / THF115752

Why Soybean Stories from The Henry Ford?

Our founder, Henry Ford, was intrigued by and invested in research on the humble soybean, both as a food source and for use in industrial products. Our collections contain much information on these topics. You can read more about “Soybeans: Henry Ford’s Miracle Crop,” or explore related artifacts in this Expert Set that illustrates Henry Ford’s soybean research, some of which took place at the Soybean Laboratory (now the Soybean Lab Agricultural Gallery) in Greenfield Village. A clip from the first season of The Henry Ford's Innovation Nation features host Mo Rocca and Matt Anderson, Curator of Transportation at The Henry Ford, in the Soybean Lab discussing “Different Uses of Soybeans.” Content related to that episode includes a soyfoods Expert Set and one of our most popular research inquiries from guests, information about Henry Ford’s soybean plastic car.

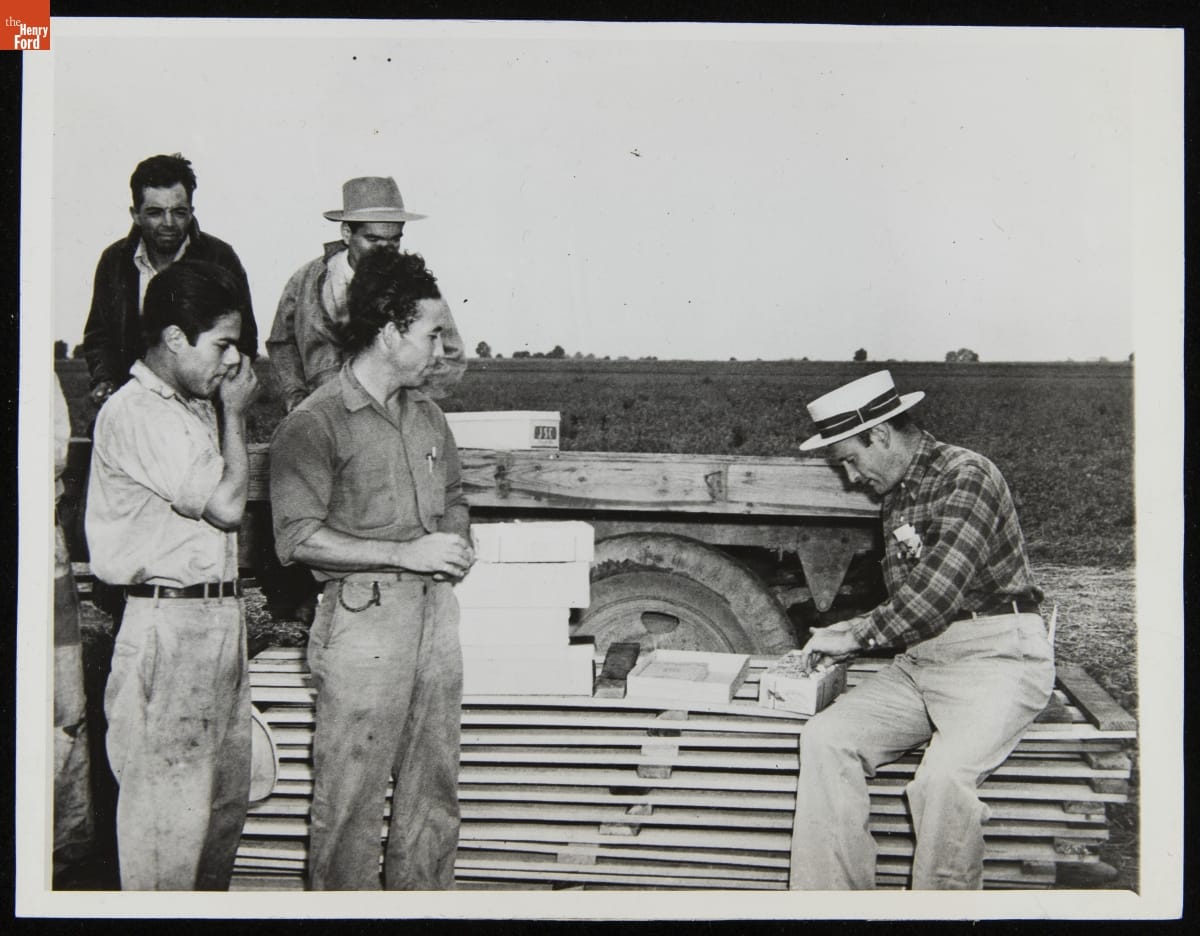

Robert Boyer and Henry Ford in a Soybean Field, 1936 / THF98619

Black chemists contributed to this soybean research. Paul Foster focused on food research. “Paul Foster and Food Research in Henry Ford’s Laboratories, 1930-1942” introduces readers to Foster and explores some of the soy recipes that resulted from research he conducted. George Washington Carver and his assistant, Austin Curtis, Jr., chemists working at Tuskegee Institute in Alabama, shared Henry Ford’s enthusiasm for chemurgy (industrial uses for raw materials). Both Carver and Curtis participated in the third Dearborn Conference on Industry in 1937, featuring lectures by chemists working with farm-grown crops and industrial products, and Curtis even worked one summer in Ford’s Greenfield Village Soybean Lab. Ford expanded soy food research in 1942 with dedication of the Carver Nutrition Laboratory on Michigan Avenue in Dearborn, near Greenfield Village.

Ford Motor Company shared its soybean research at World’s Fairs during the 1930s. The Ford Exposition exhibited the William Ford Barn (now in Greenfield Village) transformed into “the industrial farm of the future” at the 1934 World’s Fair in Chicago. Giveaways included a souvenir box containing items from the Earth (including soybeans) used in Ford manufacturing. At the 1936 Texas Centennial Exposition, Ford Motor Company handed out salt-and-pepper shakers converted from gear shift knobs made from soy products. Ford staff demonstrated chemical experiments used to extract oil and transform it into fiber during the 1939–1940 New York World’s Fair.

Soybean Processing for Fiber and Oil, Ford Exposition, New York World's Fair, 1939 / THF216215

Coming Soon

What do we have in store for this partnership?

We’ll kick things off on March 23 on The Henry Ford’s Facebook page, with an interview with Laurie Isley, Michigan farmer and president of Michigan Soybean Committee. You can get a sneak peek of Isley’s work at the websites for U.S. Soy and the Michigan Agriculture Council.

John Deere Tractor and Planter Planting Soybeans / Photo courtesy United Soybean Board

Our plans for 2022 focus on exploring untold stories, adding to existing stories, and engaging the public in the process. We will explore changes in biological and mechanical technologies between 1920 and 2020, and document agricultural research at Ford farms focused on producing soybeans richer in oil content and better suited to industrial uses. We will deepen existing content on the daily operations of soybean research undertaken at the chemical laboratory constructed by Henry Ford in Greenfield Village in 1928 (still standing today), and in the George Washington Carver Nutrition Laboratory launched by Ford in 1942.

Over the growing season, we’ll explore the year-round work it takes to produce soybeans in Michigan, from planting to growing to harvesting, with the farmers who do this work. This will also involve a collaborative contemporary collecting effort to document Michigan soybean farmers today and add those stories to the permanent collections of The Henry Ford.

Case IH Combine Harvesting Soybeans / Photo courtesy Michigan Soybean Committee

The Michigan Soybean Committee will share its popular teacher resources with The Henry Ford’s learning and engagement staff. This will benefit rising fifth graders in The Henry Ford’s 2022 Growers summer camp, presented by the Michigan Soybean Committee, as they explore soya from bean to bioplastic. From June to August, students in the Growers summer camp will interact directly with Michigan Soybean Committee resources and soybeans growing in Greenfield Village for the first time since the 1940s.

Cultivating and Planting Activity at Soybean Laboratory, Greenfield Village, Dearborn, Michigan, 1937–1950 / THF236443

Both The Henry Ford and Michigan Soybean Committee are eager for this 2022 soybean-knowledge growing season, and we look forward to having you along for the journey.

Debra A. Reid is Curator of Agriculture and the Environment at The Henry Ford. Many thanks to the Michigan Soybean Committee for their collaboration on this post.

Ford Motor Company, world's fairs, African American history, Henry Ford, Greenfield Village, Greenfield Village buildings, food, research, soybeans, philanthropy, agriculture, by Debra A. Reid

Paul Foster storing bread in the Soybean Laboratory in Greenfield Village, Dearborn, Michigan, circa 1935. / THF236481

Paul Foster storing bread in the Soybean Laboratory in Greenfield Village, Dearborn, Michigan, circa 1935. / THF236481

The Soybean Laboratory (now the Soybean Lab Agricultural Gallery) in Greenfield Village buzzed with activity during the 1930s and 1940s. Paul Hunter Foster worked as a waiter in that laboratory in its earliest days, but over time, his responsibilities expanded to include valet to Henry Ford and cook on Henry Ford’s private railroad car, Fair Lane. As these photographs indicate, he tested soy foods and may have fed the laboratory staff in the process.

Paul Hunter Foster was born on June 5, 1900, to a well-connected mixed-race family living in Meridian, Mississippi. His father, William Thomas Foster, sampled cotton and rated bales based on cotton quality. His mother, Alvina (“Vinie”/“Viny”) Lewis Hunter, bore seven and raised five children. Most of them pursued higher education and community service and flourished professionally. Three studied at Tougaloo College in Jackson, Mississippi. One graduated from Fisk University in Nashville, Tennessee, and another from Howard University in Washington, D.C. Two of Paul’s brothers became dentists, and another worked in race relations throughout his career.

Piecing together the details of Paul Foster’s life remains a work in progress, but primary sources confirm that he lived in Washington, D.C., after his father died in 1917. One of his brothers lived there at the time, attending Howard University. Paul worked as a messenger for the U.S. War Department during World War I (per his draft registration card). He was back in Meridian in January 1920 (per the U.S. Census). Then, on July 7, 1920, while still a student, he married Lilybel E. Scott in Detroit, and settled into life at 6081 Whitewood Avenue in Detroit.

Lilybel Scott Foster (left) with Paul Hunter Foster (right) and Georgia Singleton Ralls (center) of Pittsburgh, Pennsylvania, during the dedication of the Stephen Foster Home (now the Sounds of America Gallery/Foster Memorial) in Greenfield Village, July 4, 1935. / THF272761

It remains unclear when Paul Foster joined Henry Ford’s staff, but his work in Greenfield Village and in proximity to Henry Ford’s office at Ford Motor Company’s Oakwood Boulevard headquarters translated into “other duties as assigned.” In 1935, this included escorting a special guest invited to the Stephen Foster Home dedication. A reporter from the Pittsburgh Courier explained on September 21, 1935, that Georgia Singleton Ralls had, as a child, lived in the house in Lawrenceville, Pennsylvania. She provided valuable information about the home interior to Henry Ford via Charles T. Newton. Ford invited her, but the Foster family ensured her personal comfort. She stayed with Paul and Lilybel and their four children during her visit. Ralls described Paul Foster as Henry Ford’s valet.

Detroit newspapers confirm that Paul and Lilybel Foster encouraged education, a love of music and theater, and civic engagement. Lilybel and the four children, Paul H. Foster, Jr., [William] Estus, Jane, and Harris, each received their share of coverage in the Michigan Chronicle social pages. This helped them forge networks with other middle-class Black Detroiters.

In addition, Paul Foster, Sr., developed relationships with other Black Detroiters working in industry. His eldest child, Paul, Jr., listed Bohn Aluminum as his employer on his World War II draft registration card, and his second son, William Estus, listed Ford Motor Company. The elder Foster also listed Ford Motor Company, Oakwood Boulevard, as his employer. The sons listed their mother as the person most likely to know their permanent addresses, but Paul, Sr., listed Frank Davis, a field agent for Detroit Light Company (Detroit Edison Company), instead of his wife. This likely reflected a commitment to class and racial bonds among well-connected Black Detroiters employed in managerial positions by white business owner-operators. Frank Dewitt Davis became the first Black employee in an office position at Detroit Edison according to his obituary (published in the Detroit Free Press, September 19, 1974).

Work in the Soybean Lab

The following provides a snapshot of the chemical laboratory that Henry Ford constructed in Greenfield Village during 1929, and the workspace that Paul Hunter Foster, Sr., occupied.

Henry Ford invested in the chemical laboratory to discover industrial uses of agricultural products. Soybeans, a crop with a long history, became the research focus by 1931. The crop offered much potential. Extracted oil could be refined for multiple uses and the bean residue could be pressed into numerous molded forms. The protein- and oil-rich soybean also addressed the need of many seeking healthier foodstuffs.

Chemical Laboratory in Greenfield Village, 1930 (today known as the Soybean Lab Agricultural Gallery). / THF222341

Foster worked in the lab that undertook food experiments during this early period of exploration and innovation. His workspace consisted of the low-roofed kitchen shown below, divided by a railing. The preparation area included ingredients, storage containers, scales and other data collection instruments, and scientific apparatuses to facilitate testing.

Preparation and testing area of the kitchen laboratory at the Soybean Laboratory in Greenfield Village, Dearborn, Michigan, circa 1935. / THF236497

Staff worked together in this testing kitchen. The photograph below shows Foster at work in the foreground, and another lab technician busy in the background.

Paul Foster making soybean bread inside the Soybean Laboratory in Greenfield Village, Dearborn, Michigan, circa 1935. / THF236493

The cooking area in the kitchen laboratory included a range, a sink, and counter space, as well as measuring cups, pots, pans, and other kitchen implements. It was at a slightly lower level than the preparation area.

Making soybean bread in the Soybean Laboratory in Greenfield Village, Dearborn, Michigan, circa 1935. / THF236485

Food testing occurred in this lab. The results appeared in the booklet “Recipes for Soybean Foods.” It described the work of the laboratory, summarized the benefits of soy-based foods, and consolidated recipes proven in this laboratory.

“Recipes for Soybean Foods,” circa 1931. / THF119278

Cooks had to be aware that preparing soybeans required some extra effort. For example, “the soy bean generally requires a longer time for cooking than does the common bean…. With a pressure cooker, the beans can be cooked in 20 minutes at 20 pounds pressure” (page 2). Paul Foster used a pressure cooker to prepare soybeans in the kitchen workspace.

Lab technician (likely Paul Foster) with a pressure cooker in the Soybean Laboratory in Greenfield Village, circa 1935. / THF236489

Soybeans had a higher protein content than navy beans or lima beans, according to “Recipes for Soybean Foods.” Thus, cooks substituted soybeans to facilitate healthy eating.

An omelette, two baked beans recipes, and two salad recipes in “Recipes for Soybean Foods,” circa 1931, page 9. / THF119283b

Soy flour also offered a higher-protein alternative to wheat flour, and a flour more supportive of diabetic diets and other diets for those intolerant to certain foods. Furthermore, soy flour properties helped bread remain fresher for longer. As “Recipes for Soybean Foods” explains, breads that incorporated 5% soy flour and 95% wheat flour produced a loaf of bread that kept longer than bread made without soy flour. Combining flours at a ratio of 20% soy and 80% wheat resulted in a bread loaf with 40% more protein than wheat flour alone (page 2). Such persuasive arguments converted some to soy.

The photographic print below shows Paul Foster preparing dough for soybean bread in the kitchen workspace.

Making soybean bread inside the Soybean Laboratory in Greenfield Village, Dearborn, Michigan, circa 1935. / THF236491

After baking, storing the bread in a wire-enclosed wood-frame container was the next step in the longer process of documenting drying rates for different types of bread loaves.

Storing bread in the Soybean Laboratory in Greenfield Village, Dearborn, Michigan, circa 1935. / THF236483

A closer look at Foster and his bread loaves, in the photo at the very top of this post, shows him in the process of loading the loaves into the food safe (a term used for similar wire-sided storage cabinets). The experiments in the test kitchen continued with rotation of loaves and measuring rates of dryness.

Interested in trying the recipe for the soybean bread baked in the laboratory in Greenfield Village? Check out page 4 of Recipes for Soybean Foods, or explore these and other recipes in the Ford Motor Company bulletin, published around 1939 (and two pages longer). Be mindful of inconsistencies. In both, on page 2, the directions indicate that the pressure cooker should be set at 20 pounds pressure, but page 16 in the earlier booklet, and page 18 in the 1939 version, states that soybeans should be cooked for 20 minutes at 25 pounds.

“Recipes for Soy Bean Foods,” Ford Motor Company, circa 1939. / THF223249

Foster remained visible in Soybean Laboratory research through the visit of George Washington Carver in July 1942. During this visit, Henry Ford dedicated a nutrition laboratory on Michigan Avenue, adjacent to Greenfield Village, named for Carver. It included an experimental kitchen described as “the dominion of Mr. Paul Foster” (Herald, August 14, 1942, page 12).

George Washington Carver (seated) at the dedication of Carver Nutrition Laboratory, Dearborn, Michigan, July 21, 1942. Paul Foster is standing in the foreground to the right. / THF214097

Foster apparently had full authority over the kitchen in the Carver Nutrition Laboratory: “Here this master of the culinary art will hold forth, concocting delicious morsels” (Herald, page 12). Carver credited Foster with the “weed sandwiches” sampled during the Nutrition Lab dedication (Herald, page 14). Carver appreciated such ingenuity, given his recent bulletin Nature’s Garden for Victory and Peace (March 1942). Foster’s sandwich spread of “nature’s vegetables” consisted of ground dandelion, purslane, curly dock, plantain, chickweed, lamb’s quarters, bergamot, oxalis, and radish seed pods with salt, lemon juice, and mayonnaise added. Served on soybean bread, such a mixture could have a wonderful flavor and “contain the equivalent in vitamins and minerals to the average person’s monthly diet of vegetables.” So explained Edison Institute student Robert Cavanaugh, who reported on “The Development of a New Laboratory” (Herald, page 12). A photograph of Foster, preparing vegetable sandwiches, illustrated the story.

Documenting Paul Foster’s role in research in either laboratory after 1942 remains a work in progress. Consider this a first installment as we continue to learn more about the scientists who worked at the Soybean Laboratory in Greenfield Village, and at the nearby Carver Nutrition Laboratory on Michigan Avenue.

Debra A. Reid is Curator of Agriculture and the Environment at The Henry Ford. She thanks Saige Jedele and Sophia Kloc for feedback that improved this blog.

Washington DC, 1940s, 1930s, 20th century, soybeans, research, recipes, Michigan, Henry Ford, Greenfield Village buildings, Greenfield Village, food, Detroit, Dearborn, by Debra A. Reid, African American history

The History of Historic Base Ball in Greenfield Village

In 1993, inspired by a handful of century-old newspaper references, nine employees volunteered to form The Henry Ford’s first historic base ball club. What started small has become a grand and beloved Greenfield Village tradition, guided—as it was from the beginning—by a passion for authenticity.

The Greenfield Village Lah-De-Dahs and the general store that spurred the club’s formation, 1994. / THF136301

Beginnings

It all began with Greenfield Village’s general store. New research in the 1990s initiated a more accurate historical interpretation of the J.R. Jones General Store as it existed in Waterford, Michigan, during the 1880s. It also turned up references to a local amateur base ball club—the Lah-De-Dahs—in period newspapers. Employees eagerly set about reviving the Lah-De-Dahs as a historic base ball club. A clue about the original uniform came from a colorful report on the Lah-De-Dahs’ poor showing in a summer 1887 game:

As the contest went on, slowly but surely dawned upon the minds of all the truth that a fine uniform does not constitute a fine pitcher, nor La-de-dahs in their mammas’ red stockings make swift, unerring fielders. —Pontiac Bill Poster, September 14, 1887

The revived Lah-De-Dahs of Greenfield Village wore white base ball shirts with a red script “L” and, at first, nondescript white painter’s pants. (The Henry Ford’s period clothing studio soon produced matching, knickers-style bottoms.) That first season, the Lah-De-Dahs played a handful of matches with rules pieced together from various historical interpretations. At Firestone Farm, the club challenged farmhands in the harvested wheat field before whatever crowd gathered along the lane. The Lah-De-Dahs also hosted a few outside historic base ball clubs at their future home field, Walnut Grove.

Structure

Historic base ball in Greenfield Village quickly assumed a more structured form that incorporated thoughtful details rooted in history—beginning with the name of the sport itself. Virtually all of the earliest references to this style of bat-and-ball game in England and the United States used the hyphenated name, “base-ball.” By the late 1830s and into the 1840s, likely due to simple changes in typesetting practices, the two-word spelling, "base ball," had begun to replace "base-ball." Conventions continued to shift, with the hyphenated version reemerging in the mid-late 19th century and receiving formal backing from the U.S. Government Printing Office in 1896. But years earlier, in 1884, the New York Times had explicitly changed its style guide away from "base-ball" to "baseball"—an early move toward the one-word convention that would stick. To highlight overlapping customs in the sport’s formative decades, The Henry Ford emphasizes the two-word spelling in its historic base ball program.

Henry Chadwick’s 1867 Base Ball Player's Book of Reference, the first reference book designed to teach the game of base ball, from which the current rules of play in Greenfield Village were drawn. / THF214794

For demonstration in Greenfield Village outside of Lah-De-Dahs matches, a set of rules, known as “Town Ball” or “Massachusetts Rules,” was selected from the 1860 Beadle’s Dime Base Ball Player. Written by Henry Chadwick, a sports journalist and leading promoter of base ball, this book included early rules of the game we know today, as well as the alternative “Massachusetts Rules” version of the game. This early version of baseball requires minimal equipment, calls for a soft ball, and features chaotic rules, making it a perfect choice for guests of Greenfield Village to try.

Elements added for the comfort and enjoyment of spectators on Walnut Grove appropriately reflect the 1860s setting. On select dates, the Dodworth Saxhorn Band provides musical accompaniment representing that of a period brass band. (Much of the music commonly associated with the professional game of baseball in America—including its unofficial anthem, “Take Me Out to the Ball Game”—was published two generations later.) Refreshments are served from contextual, temporary structures fitting the rural environments where 1860s base ball was played. And a uniquely designed sound system—disguised by several strategically placed waste receptacles—allows the umpire and scorekeeper to present a real-time account of the game via concealed cordless microphones. The live music and play-by-play, combined with the unpredictability of the game, make for an entertaining afternoon.

The Dodworth Saxhorn Band during the World Tournament of Historic Base Ball, 2007, photographed by Michelle Andonian. / THF52297

Expansion

The Lah-De-Dahs’ roster grew to 25 players over the club’s second and third seasons. They wore handmade uniforms for matches, which were held whenever visiting clubs could make the trip to Greenfield Village. By 2002, the season consisted of a dozen games played on select Saturdays throughout the summer. After nearly a decade of play, the Lah-De-Dahs had attracted a dedicated fan base, and spectators increasingly requested a regular schedule with more games.

The reopening of Greenfield Village in 2003 after a massive restoration project heightened expectations for the historic base ball program. With financial support from Edsel and Cynthia Ford, The Henry Ford delivered an entire summer of base ball with expanded offerings: daily period base ball demonstrations, formal games on Saturdays and Sundays—now played by the “New York rules” specified in Henry Chadwick’s 1867 Base Ball Player's Book of Reference (which were more familiar to spectators than the Massachusetts Rules game)—and the development of the World Tournament of Historic Base Ball.

The Henry Ford’s World Tournament of Historic Base Ball pays homage to the original “World's Tournament of Base Ball” hosted in August 1867 by the Detroit Base Ball Club. Though organizers ultimately failed to attract the world-famous clubs of the day, they managed to stage a remarkable, one-of-a-kind event. The trophy bat awarded to the Unknown Base Ball Club of Jackson, Michigan—winners of the first-class division of the 1867 tournament—is now in The Henry Ford’s collections. It is displayed each year in Greenfield Village during the World Tournament of Historic Base Ball.

Trophy bat awarded at the 1867 World's Tournament of Base Ball. / THF8654

For 2004, the Lah-De-Dahs’ season expanded from 12 to 30 games, and its roster swelled to 42 players. To make sure they always had an opponent, The Henry Ford created a second club. The National Base Ball Club takes its name from a competitor in the 1867 World's Tournament of Base Ball. New uniforms purchased for both clubs added to the already vibrant atmosphere during matches, with the Lah-De-Dahs in their now-familiar red and white and the Nationals in striking dark blue and gold. At first, many considered the Lah-De-Dahs to be Greenfield Village’s “home” club, but displays of sportsmanship and close games going to either side have endeared fans to both.

One of the close plays that have helped endear fans to both Greenfield Village clubs.

Over time, baseball became “America’s pastime,” an enduring cultural touchstone—and a multibillion-dollar business. Historic Base Ball in Greenfield Village (and also played in many other venues around the country) showcases an early form of the sport, from a time when amateurs played for recreation and innocent amusement—for the love of the game!

Brian James Egen is Executive Producer and Head of Studio Productions at The Henry Ford and Marcus W. Dickson is Professor of Industrial/Organizational Psychology at Wayne State University. This post was prepared for the blog by Saige Jedele, Associate Curator, Digital Content, at The Henry Ford.

Additional Readings:

research, Historic Base Ball, by Saige Jedele, by Marcus Dickson, by Brian James Egen, #Behind The Scenes @ The Henry Ford, Greenfield Village, events, sports, baseball

Piecing Together Black History: A Case Study

For centuries in America, Black history has been relegated to the margins, with stories of Black lives only recorded by those who had the means or the motivation—or perhaps the hope that future generations would value them. The second-class treatment of Black history, the result of entrenched sociocultural discrimination, is painfully obvious to historical professionals looking to the written record for answers about the past lives of Black Americans.

While a major discrepancy still exists between the quality and quantity of Black historical records when compared to white counterparts, scholarship and re-examination, aided by new technologies, have helped in making new and old information alike more accessible. With barriers to information accessibility lessened to some degree, assembling these pieces of information into individual stories remains the biggest and most puzzling challenge. A prime example of this challenge can be found in the analysis of a document from The Henry Ford’s Digital Collections—an 18th-century apprenticeship contract.

This apprenticeship document was gifted to Henry Ford in 1928 by William Van Rensselaer Abdill of Titusville, New Jersey. Abdill was a well-known collector whom Ford and others called upon to locate certain objects from history. This item was most likely part of a larger document collection that Abdill had amassed. / THF129623

On the surface, this apprenticeship document shows no indications of being related to Black history, but a careful examination proves otherwise. To start, there’s a name, “John Thompson” (or “John Thomson,” as signed at the bottom); there’s an age, “fourteen years, eight months, twenty-seven days”; and there’s a date, September 11, 1794. Other information from the document tells us that John Thomson was from Salem, Massachusetts, and was apprenticing to be a “mariner.” A careful sifting of this information through genealogical resources reveals that in May of 1809, this same John Thomson applied for a Seamen’s Protection Certificate. The application confirmed Thomson’s birth in 1780 in Salem, Massachusetts, and described him as a “negro, born-free.”

John Thomson’s application for a Seamen’s Protection Certificate included identifying information. The document states he was about five feet, three inches, in height and had several scars above his left eyebrow, as well as a scar from a smallpox inoculation on his left elbow and marks from a dog bite on his left arm. / Citation: The National Archives and Records Administration; Washington, D.C.; Proofs of Citizenship Used to Apply for Seamen's Certificates for the Port of Philadelphia, Pennsylvania, 1792-1871

Further historical context helps illuminate John Thomson’s life and experiences. During the “Age of Sail,” when global commerce was facilitated by sailing ships, the city of Salem, Massachusetts, was a bustling international port. In the centuries before Thomson’s apprenticeship, slavery played a major role in Salem’s maritime economy, not only in the city’s involvement in the slave trade, but in the lives of those who worked its ships and docks. Even after Massachusetts became the first state to abolish slavery in 1783, slavery’s discriminatory legacy continued. As one of the few occupations open to them, free Blacks found life on the sea as a sailor to be a more integrated and less racially tense working environment. In port cities like Salem, these kinds of employment opportunities helped lay the foundation for Black communities in the early years of America.

John Thomson’s 1794 contract also reveals clues about how the then-14-year-old spent the next six years of his work life apprenticed to Captain Robert Emery on the ship Diana. Information on the ship and its captain (in contrast to Thomson) is plentiful. We know that the Diana was built in 1790 up the coast in Amesbury, Massachusetts, and was used to carry trade with Europe. Sometime in 1793, a change of ship masters occurred in New York City and the Diana was transferred to Emery, who was merely 20 years of age at the time.

Information from the first part of the document tells us that Robert Emery was the master of the ship Diana (whose owners were based in Boston), and that John Thomson’s apprenticeship would last just over six years. / THF129623, detail

In 1794, Emery was hiring a crew for an upcoming trip to Bristol, England, and needed an apprentice. Apprenticeships were standard in a variety of trades during this period of American history. Usually, a boy of about 13 or 14 would be indentured to a master until he reached the age of 20 or 21. In return, the master would provide food, clothing, shelter, and, most importantly, training. For Black adolescents like John Thomson, whose opportunities were limited, a stable source of food, clothing, and training could be life changing. Racially integrated crews were common for ships sailing out of Northern port cities. In 1805, five years after Thomson’s apprenticeship ended, Emery hired another racially integrated crew to sail out of Salem for India aboard the vessel Golden Age. Among the group were two local Black men: a “first mate” (next rank under captain) and a “boy” (another name for an apprentice).

As part of the agreement, John Thomson would be provided “meat, drink, apparel, washing and lodging” during his apprenticeship. / THF129623, detail

Threats abounded for Black sailors when John Thomson agreed to his apprenticeship contract in 1794. A year earlier, the 1793 Fugitive Slave Act was passed, giving slaveholders the right to recover an escaped slave. Abuse of the law began immediately, as it offered no procedural protections for free Blacks to avoid being seized as slaves—no right to a lawyer or a trial by jury, or even to speak on their own behalf. Furthermore, the British were struggling to staff a massive navy and actively forced thousands of unwilling American sailors into service. In an effort to stop illegal impressment by the British, Congress began issuing Seamen’s Protection Certificates in 1796, which worked as identification papers and proof of a sailor’s American citizenship. These kinds of papers would have been doubly important to Black sailors who were also under constant threat of being enslaved.

“J.W. Keese” of the “City of New York” notarized the agreement at some point in time. / THF129623, detail

In the years preceding Seaman’s Protection Certificates, around the mid-1780s sailors began carrying papers that helped prove their identity. These could have been copies of parish or town records or a notarized statement by a reputable person who could attest to the bearer’s American citizenship. Notarizing this apprenticeship document, most likely Thomson’s only proof of identification, would have been vitally important. The writings along the side of the document speak to this, as they show that this document was notarized by John Keese of New York City—a notary public, attorney, and founding member of the New York Manumission Society. As New York was a major port city, it’s likely Thomson would have been there at some point, and while the Manumission Society played a paternalistic guardian role in lives of New York’s slaves and free Blacks, it would have been one of the only groups advocating for Black rights in general. For free Blacks like John Thomson, having Keese’s name on the document carried weight if anyone questioned his identity.

The reverse side of the agreement confirms Thomson finished his apprenticeship in Salem on October 8, 1800. / THF129624

We know little about Thomson’s time on the Diana, except for the fact that at some point in the late 1790s, Emery armed the ship for protection against the French. According to the reverse of the contract, Thomson’s apprenticeship ended in Salem in 1800. Details about the remainder of Thomson’s life and career remain lost (or at least very well hidden) to history—whether or not he had a family (some sources suggest he married Violet Wilkins in 1817), if he joined fellow Black sailors in defending the nation during the War of 1812, or even when he died. What has endured though, are the pieces of information that provide enough clues to tell a meaningful part of Thomson’s story—and offer an important lens into the lives of early Black Americans.

Ryan Jelso is Associate Curator, Digital Content, at The Henry Ford. He would like to point out that numerous digital resources were used in the researching of this blog—from genealogical resources like Ancestry.com and academic resources like JSTOR, to the digitized collections of many other institutions.

Searching for Dr. Howard

Photograph of Dr. Alonson B. Howard, Jr., 1860s. / THF237208

How do we uncover the stories of the people who lived and worked in the buildings that come to Greenfield Village? Usually, there are no books written about them, unless they were famous—like Abraham Lincoln or the Wright Brothers. To piece together the stories of these people, we have to look at archival documents, images, and artifacts—which offer a firsthand account or a direct reference to the people and their stories. These primary sources—like census records, business records, and personal reminiscences—each provide clues. But they can be hard to interpret and difficult to piece together. Moreover, they are sometimes inaccurate and can even contradict each other. We must constantly assess the value and accuracy of each source and compare it with others.

We delved into many of these types of sources to prepare for an episode of The Henry Ford’s Innovation Nation featuring Dr. Alonson B. Howard, Jr.—whose mid-19th-century office now resides in Greenfield Village. Many of our findings are summarized in the blog post, “Dr. Howard, A Country Doctor in Southwest Michigan.” Where did we go in our search to uncover clues to Dr. Howard’s background and medical practice? Here are some of the sources that helped us out.

First, Our Own Archival Records

First page from great-grandson Howard Washburn’s write-up on Dr. Howard, May 25, 1962. / THF627447

The first place we look when we explore the stories of Greenfield Village buildings and the people related to them is our own Edison Institute (or EI) archives. Beginning at the time that each building is first acquired and brought to Greenfield Village, the majority of the records collected by the museum for that building are kept in the archival accession EI.186—or what we familiarly call the “Building Boxes.” We were lucky that in the case of Dr. Howard’s Office, we found in this accession two folders entitled “Family History.”

These folders contain numerous typed reports, the result of years of tedious research undertaken by Dr. Howard’s great-grandson, Howard Washburn. Washburn’s study of Dr. Howard began in 1935, from which time he developed a steadily expanding notebook on the subject. In January 1946, he and his mother purchased and came to live on the family farm, “Windfall,” where the office was located. Washburn’s interest in his great-grandfather’s life and medical practice deepened in the 1950s and 1960s, involving both sifting through the materials that were still in the office and collecting numerous reminiscences about Dr. Howard from his by-then elderly family members, friends, and neighbors.

Dedication of Dr. Howard’s Office in Greenfield Village, with Howard family descendants, October 1963. / THF20847

Washburn found some wonderful primary sources of his own in his search, like the extensive entry about Dr. Howard’s life that was handwritten in the Howard family Bible by his son, Camer. But most of Washburn’s material came from those previously mentioned personal reminiscences. We know that people’s long-term memories can be sketchy, especially when decades have gone by (Dr. Howard passed away in 1883). So, we planned to compare these reminiscences with other types of sources (see section below on genealogical records).

Photograph of office interior, taken at the building’s original site near Tekonsha, Michigan, before removal to Greenfield Village, March 1956. / THF237188

The Building Boxes in our archives also house numerous photographs that document each Greenfield Village building, especially photographs relating to each building on its original site just before its removal to Greenfield Village. Howard Washburn’s reports informed us that when Dr. Howard passed away in 1883, his wife Cynthia padlocked his office with most of its contents intact. Sure enough, photographs of the building’s interior that were taken when Henry Ford’s assistants came to look at the building in the 1950s reveal a huge array of original furniture, bottles, casks, business records, and medical books. These came with the building to Greenfield Village. They not only helped us later recreate the building’s interior as close as possible to the original, but also furthered our knowledge about many aspects of Dr. Howard’s medical practice.

A homeopathic medical publication from July 1868, found amongst the contents of Dr. Howard’s Office when it was brought to Greenfield Village. / THF627467

Dr. Howard’s business records and medical books (all paper items that were later removed from the building because of their fragility) were put together with other family documents to make up another accession in our archives—the Howard Family Papers. These materials particularly reveal Dr. Howard’s increasing interest in adapting a range of different approaches to treating patients.

Letter from Isaac Haines to Dr. Howard, April 18, 1877, inquiring about how to get to the doctor’s office from Fort Wayne, Indiana. / THF627457

Some particularly interesting letters from patients in the Howard Family Papers contain descriptions of ailments that people asked Dr. Howard to diagnose for them. Another of these letters, from 1877, even came from a man in Fort Wayne, Indiana, who requested directions to his office (about 75 miles away!) so he could make a personal visit.

Two pages from Dr. Howard’s 1849–1853 account book. / THF627454

The Howard Family Papers also contain Dr. Howard’s account books, dating all the way from 1849 to 1881. These primarily record his visits to or from patients and the amount that he charged them. Unfortunately, most of the patients’ names are difficult to read. However, the 1878 account book does contain several neatly handwritten pages of patients, listed in alphabetical order, at the front—many of which are indeed legible. Some of these even mention the patients’ hometowns, including Tekonsha, Michigan (where his office was located), as well as nearby Burlington (about five miles away) and Union City (about nine miles away). We hope to delve more deeply into the backgrounds of some of these patients through genealogical records, to get an idea of their ages, occupations, and backgrounds.

Invoice from Farrand, Williams & Co., from February 15, 1881, for Dr. Howard’s purchase of medical equipment, supplies, and ingredients. / THF620458

The Howard Family Papers also contain several invoices sent to Dr. Howard from a chemical supply company in Detroit, Michigan, dated 1881. These provide valuable clues to the types of medicinal ingredients that Dr. Howard purchased to create his pills and concoctions—and help to break down the stereotype that everything he used was botanical (i.e., natural materials like plants and herbs) and homegrown or locally obtained. The invoices contain not only dried herbs and plants but also such non-botanical ingredients as quinine and alum that relate to more conventional Western medical practice.

Dr. Howard’s “recipe” for cough syrup, from his 1864 handwritten receipt book. / THF620470

One of the most valuable items in this collection—originally donated with the building—is Dr. Howard’s own handwritten book of receipts (or recipes) for remedies from 1864. Like the account books, the pages are difficult to decipher without some concentrated effort. But it is possible to get an idea of the types of illnesses he was trying to treat and the combination of purchased and locally available ingredients he combined in creating his remedies.

Genealogical Records

The four children of Dr. Howard and his second wife, Cynthia, about 1870. Front, left to right: Mattie, Camer, and Letitia; rear: Manchie. / THF109605

As mentioned before, it is important to verify the stories gleaned from personal reminiscences. So, for Dr. Howard’s background and family history, we also consulted census and other genealogical records (many, thankfully, online on websites like ancestry.com). Here we could verify the dates of the Howard family’s move to Michigan, as well as the names, birth and death dates, and places of origin of his parents, siblings, and two wives (Letitia, his first wife, passed away in 1857; he married his second wife, Cynthia, a year later), and children with each wife), as well as other interesting information, like the fact that his father, Alonson B. Howard, Sr., served in the War of 1812.

Photograph of Dr. Howard’s father, Alonson B. Howard, Sr., about 1860. / THF237220

We also learned through census records that Dr. Howard listed his occupation in three different ways over the years—as a farmer in 1850 and 1860, as a physician in 1870, and as both a physician and surgeon in 1880.

Local History Records

Dr. Howard’s office on its original site near Tekonsha, Michigan, situated along the road at the front of “Windfall,” the family farm, March 1956. / THF237150

It is important for us to remember that, although a building and its story might reside in Greenfield Village today, it originally came from another place. This larger context is crucially important to creating an accurate picture in our interpretation of that building and the people related to it. Dr. Howard’s office was originally located just outside the village of Tekonsha, Calhoun County, in south central Michigan. The Howard family settled there in the 1840s, when Alonson, Jr. was 17 years old, during a period of great migration into Michigan by white settlers. A majority of settlers, including the Howard family, came from upstate New York.

Road sign near original site of Dr. Howard’s office, August 1959. / THF237152

To find out more about Tekonsha in the 1840s, we consulted the voluminous History of Calhoun County from 1877. We know that the numerous county histories that were published across the country around the time of America’s centennial in 1876 are among the best sources for recounting minute details of the early settlement of various communities. Indeed, the Calhoun County history provided several valuable bits of information. But, of course, in the end, it is essentially the story of white settlers. About Native Americans, who had recently occupied the area and some of whom still lived there during Dr. Howard’s time, this county history ranged from sketchy to dismissive to outright racist.

We found in our research that self-emancipated orator Sojourner Truth was perhaps Calhoun County’s best-known African American resident at the time. She lived in Harmonia (Bedford Charter Township, now part of Battle Creek) from 1857 until her death in 1883. Residents in Tekonsha, located about 25 miles down the road, would have undoubtedly heard of or read about her. / THF121160

African Americans were similarly dismissed from the historical record in this county history, except as “runaways” on the Underground Railroad who were “saved” by white “conductors.” To create a more accurate picture of these marginalized groups, we pursued additional research in scholarly books and trustworthy websites. Potawatomi tribal history was particularly important for us to understand because according to Howard Washburn, Dr. Howard had a friendly relationship with members of this group and even named two of his children after “Indian” friends of his (see “Dr. Howard: A Country Doctor in Southwest Michigan” for more detail on this history).

Oral Histories

Five descendants of Dr. Howard standing in front of his office in Greenfield Village in June 2013. From left to right: Corey Washburn (North Dakota); Sue Gillies (Australia); Dawn Gunther (California); Fiona Lynton (Australia); and Angela Karaca (Australia). / Photograph by Donna Braden.

Oral histories involve the systematic collecting and recording of personal reminiscences through live interviews. They can convey a level of detail not available in other sources, and can be informative, vivid, and colorful—often with a touch of humor and a wellspring of emotion.

In 2013, we were treated to a visit from five descendants of Dr. Howard, on a pilgrimage from their homes in North Dakota, California, and even Australia, to visit the sites related to their ancestor. During a lively oral history session with us, they filled in gaps in our knowledge about the family tree of Dr. Howard’s descendants, as well as regaling us with stories they had researched and collected themselves (see “A Visit from Dr. Howard’s Descendants”).

The Building and Its Contents

Dr. Howard’s office as it looks in Greenfield Village today. / THF1696

Since we know that Dr. Howard was the first and only individual to use this space as a doctor’s office, the actual building additionally becomes a unique primary source of its own for providing clues. The building spaces reveal that he divided what had originally been a schoolhouse into several partitioned rooms: a public waiting room, a private office, a working laboratory (where he mixed his own concoctions), and a pill-rolling room (where he hand-rolled his own pills).

Dr. Howard’s desk, in one of several photographs taken of the building’s interior on its original site before removal to Greenfield Village. The desk is on display in the refurbished building in Greenfield Village today. / THF237200

The original furnishings that were donated with the building—e.g., the cast-iron stove, a wooden storage trunk, Dr. Howard’s desk, chairs, and a daybed—provide further concrete evidence of his use of the building and its specific spaces. Finally, the wooden casks for holding extracts and the approximately 250 bottles and jars that came with the building—most with their original labels and some with their contents intact—greatly helped to supplement our knowledge about the ingredients that Dr. Howard used and the concoctions he created to treat patients (see “Dr. Howard’s ‘Medicine Cabinet’” for more on this).

Conclusion

We have described some of the sources we look at when researching the people related to our Greenfield Village buildings, and, specifically, some of our most helpful finds in piecing together the story of country doctor Alonson B. Howard, Jr. There are always more clues to be unearthed. The research on each Village building is never-ending, and we look forward to deepening and enriching the stories of Dr. Howard and other people who once inhabited buildings now in Greenfield Village.

Donna R. Braden is Senior Curator and Curator of Public Life at The Henry Ford. She would like to thank Associate Curator Ryan Jelso for his assistance in doing the genealogical research on the Howard family.

healthcare, Michigan, The Henry Ford's Innovation Nation, Greenfield Village buildings, Greenfield Village, Dr. Howard's Office, #Behind The Scenes @ The Henry Ford, by Donna R. Braden, research, archives

"The Busy World" Automaton

“The Busy World” automaton, 1830–1850. / THF187282

“The Busy World” automaton, 1830–1850. / THF187282

I was about nine years old when I first saw it. My family and I were visiting Henry Ford Museum when I spotted “The Busy World”—an intriguingly detailed and well-populated automaton displayed along the museum’s Street of Shops displays. I was entranced. “The Busy World” would remain among my most vivid memories of this visit. Little did I know that many years later I would be involved in further research on this fascinating, whimsical object.

An automaton is a non-electric moving machine that performs a predetermined set of operations. With approximately 300 moving figures, “The Busy World” automaton is a kind of mechanized diorama with six individual platforms powered by gears, belts, and pulleys. When the automaton is cranked, the figures go into motion.

1869 Beers Atlas map of Delaware County, New York. / Image courtesy of the Delaware County Historical Association

Delaware County in upstate New York—where “The Busy World” was likely built and spent much of its working life—was a place of farms and small villages during the 19th century. The wagon's lively, hand-cranked animations would have had tremendous popular appeal for adults and children alike at country fairs and small exhibitions.

“The Busy World” features six different animated scenes. Click on the links under the scenes below to see those images in our Digital Collections, where you can zoom in on the details.

Left section of “The Busy World.” / THF187276, detail

At the upper left, figures perform activities of everyday life, including rocking a baby, getting warm by the stove, chopping food, spinning thread, churning butter, and sharpening a tool.

In the scene at lower left, people attend a ballroom dance while musicians play. At the left of the dance scene are caricatured figures of African Americans. This “Busy World” scene reflects not only the activities of the time period but also the racism of the era.

Center section of “The Busy World.” / THF187277, detail

The scene at upper center shows men making rakes and grain cradles in a factory. Delaware County had at least one rake factory. During the early 19th century, New York was the grain belt of the United States. Wooden rakes were essential tools on farms.

Biblical scene from “The Busy World.” / THF125152

At lower center, a small revolving “stage” features eight Biblical stories.

Right section of “The Busy World.” / THF187278, detail

At upper right, soldiers in uniform promenade with ladies.

The scene at lower right features a regiment of soldiers parading in formation to the “sounds” of a military band.

“The Busy World” Comes to The Henry Ford

“The Busy World” came to The Henry Ford in 1963. The museum purchased the automaton from Janos and Mary Williams of Stone Henge Antiques in Sidney, New York. Where was it before that? Well, we know part of the story.

The Williamses had acquired “The Busy World” from a man named David Smith. About 1944, David Smith (1923–2002) saw an ad in a Walton, New York, newspaper offering “The Busy World” for sale: “Will sell cheap, if sold this week, ONE busy world.” Twenty-one-year-old Smith, who lived in nearby Delhi, New York, couldn’t resist. He drove the 17 miles to Walton to take a look. Amazed and delighted with what he saw, Smith purchased the automaton with his own savings, over the objections of his family. For the first seven years that he owned it, Smith stored “The Busy World” in his family’s barn in Delhi. David Smith got it to run, at least sporadically.

It wasn’t until September 1951 that “The Busy World” once again had a public showing. David Smith’s mother had offered the family barn to the Delaware County Horticultural Society as a place to hold their annual Harvest Show. “The Busy World” delighted local people who came to see the choice vegetables, flower arrangements, and potted plants on display there. Some of those attending recalled 30 or so years before when the automaton had appeared at county fairs in the area.

Next stop for “The Busy World”? David Smith opened an antique store in his hometown of Delhi, where he displayed the automaton. The name of the shop? Busy World Antiques.

David Hoy Takes “The Busy World” on the Road