Search

- Two Women Posing with Textileworking Tools, circa 1892 - Tintypes, the popular "instant photographs" of the 19th century, could be produced in a matter of minutes at a price most people could afford. Tintypes democratized photography. Beginning in the mid-1850s, they gave more people than ever before the chance to have a real likeness of themselves--capturing unique glimpses of how everyday Americans looked and lived.

- circa 1892

- Collections - Artifact

Two Women Posing with Textileworking Tools, circa 1892

Tintypes, the popular "instant photographs" of the 19th century, could be produced in a matter of minutes at a price most people could afford. Tintypes democratized photography. Beginning in the mid-1850s, they gave more people than ever before the chance to have a real likeness of themselves--capturing unique glimpses of how everyday Americans looked and lived.

- Miniature Tool Chest with Woodworking Tools, Presented to Henry Ford, 1938 -

- 1935

- Collections - Artifact

Miniature Tool Chest with Woodworking Tools, Presented to Henry Ford, 1938

- Brewery Workers, "The Bear Brewists," Buffalo, New York, circa 1865 - This carte-de-visite, made in an unknown photographer's studio around 1865, shows four brewery workers from Buffalo, New York. Cartes-de-visite were small, professional photographic prints on cardboard stock. Americans often collected cartes-de-visite, which remained popular in the United States from the Civil War in the 1860s through the 1880s, to help them remember places, celebrities, or family members.

- circa 1865

- Collections - Artifact

Brewery Workers, "The Bear Brewists," Buffalo, New York, circa 1865

This carte-de-visite, made in an unknown photographer's studio around 1865, shows four brewery workers from Buffalo, New York. Cartes-de-visite were small, professional photographic prints on cardboard stock. Americans often collected cartes-de-visite, which remained popular in the United States from the Civil War in the 1860s through the 1880s, to help them remember places, celebrities, or family members.

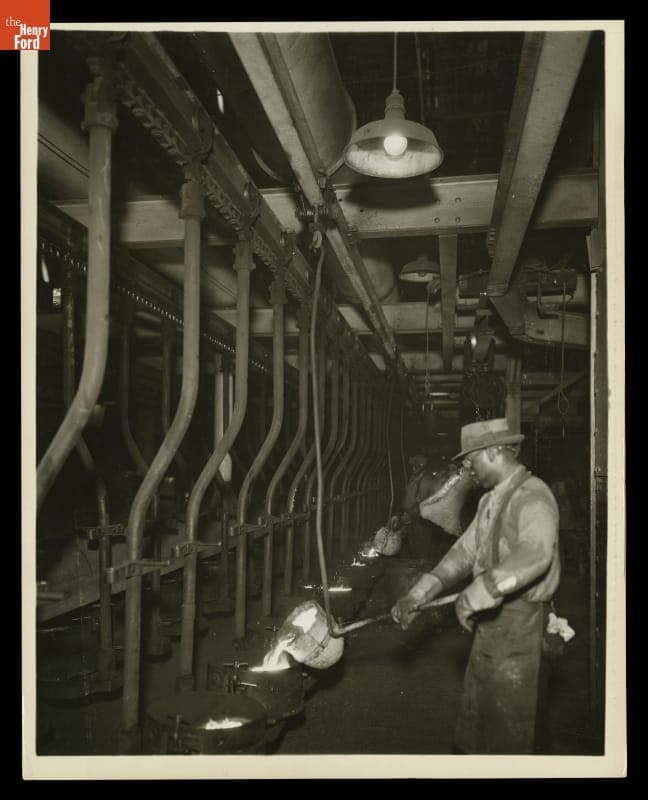

- Foundry Workers at Ford Rouge Plant, 1936 - Workers at the Ford Rouge plant's foundry poured a molten mixture of metal, coke, and limestone into molds to create cast-metal engine blocks and parts. Once "shaken out" of their molds, castings were roughly machined before heading elsewhere for finishing and assembly. The Rouge foundry set an industry benchmark in 1932 by successfully casting Ford's intricate, single-piece V-8 engine block.

- 1936

- Collections - Artifact

Foundry Workers at Ford Rouge Plant, 1936

Workers at the Ford Rouge plant's foundry poured a molten mixture of metal, coke, and limestone into molds to create cast-metal engine blocks and parts. Once "shaken out" of their molds, castings were roughly machined before heading elsewhere for finishing and assembly. The Rouge foundry set an industry benchmark in 1932 by successfully casting Ford's intricate, single-piece V-8 engine block.

- Foundry Workers at Ford Rouge Plant, 1933 - Workers at the Ford Rouge Plant foundry poured a molten mixture of metal, coke, and limestone into molds to create engine blocks. Once "shaken out" of their molds, castings were roughly machined before heading elsewhere for finishing and assembly. The Rouge foundry set an industry benchmark in 1932 with the successful casting of Ford's intricate, single-piece V-8 engine block.

- July 22, 1933

- Collections - Artifact

Foundry Workers at Ford Rouge Plant, 1933

Workers at the Ford Rouge Plant foundry poured a molten mixture of metal, coke, and limestone into molds to create engine blocks. Once "shaken out" of their molds, castings were roughly machined before heading elsewhere for finishing and assembly. The Rouge foundry set an industry benchmark in 1932 with the successful casting of Ford's intricate, single-piece V-8 engine block.

- Assembly Line Workers, Ford Rouge Plant, 1932 - Ford Motor Company's system of mass production depended on the smooth flow of parts and materials to workers. Ford engineers designed the buildings and facilities at the company's massive Rouge plant with this in mind. The "B" Building, where vehicle assembly took place, included extensive conveyer systems to accommodate the continuous movement of parts and processes.

- June 30, 1932

- Collections - Artifact

Assembly Line Workers, Ford Rouge Plant, 1932

Ford Motor Company's system of mass production depended on the smooth flow of parts and materials to workers. Ford engineers designed the buildings and facilities at the company's massive Rouge plant with this in mind. The "B" Building, where vehicle assembly took place, included extensive conveyer systems to accommodate the continuous movement of parts and processes.

- Assembly Line Workers, Ford Rouge Plant, 1932 - Ford Motor Company's system of mass production depended on the smooth flow of parts and materials to workers. Ford engineers designed the buildings and facilities at the company's massive Rouge plant with this in mind. The "B" Building, where vehicle assembly took place, included extensive conveyer systems to accommodate the continuous movement of parts and processes.

- June 28, 1932

- Collections - Artifact

Assembly Line Workers, Ford Rouge Plant, 1932

Ford Motor Company's system of mass production depended on the smooth flow of parts and materials to workers. Ford engineers designed the buildings and facilities at the company's massive Rouge plant with this in mind. The "B" Building, where vehicle assembly took place, included extensive conveyer systems to accommodate the continuous movement of parts and processes.

- Workers in Ford Rouge Plant Cyanide Foundry, 1931 - By 1931, Ford Motor Company was the largest employer of African-American workers in the country. Henry Ford was closely tied to leaders in Detroit's African-American community, especially with the pastors of two of the city's largest churches, Rev. Robert Bradby of 2nd Baptist and Rev. Everard Daniel of St. Matthew's Episcopal Church. Through these men, many recent arrivals were directed to the Ford Employment Office. Although Ford employed large numbers of African Americans, there were limits to how far most could advance. Many African-American workers spent their time in lower paying, dirty, dangerous, and unhealthy jobs in places like this Cyanide Foundry that used potassium cyanide, a key material in hardening steel.

- February 10, 1931

- Collections - Artifact

Workers in Ford Rouge Plant Cyanide Foundry, 1931

By 1931, Ford Motor Company was the largest employer of African-American workers in the country. Henry Ford was closely tied to leaders in Detroit's African-American community, especially with the pastors of two of the city's largest churches, Rev. Robert Bradby of 2nd Baptist and Rev. Everard Daniel of St. Matthew's Episcopal Church. Through these men, many recent arrivals were directed to the Ford Employment Office. Although Ford employed large numbers of African Americans, there were limits to how far most could advance. Many African-American workers spent their time in lower paying, dirty, dangerous, and unhealthy jobs in places like this Cyanide Foundry that used potassium cyanide, a key material in hardening steel.

- Foundry Workers at the Ford Rouge Plant, 1934 - Workers at the Ford Rouge plant's foundry poured a molten mixture of metal, coke, and limestone into molds to create cast-metal engine blocks and parts. Once "shaken out" of their molds, castings were roughly machined before heading elsewhere for finishing and assembly. The Rouge foundry set an industry benchmark in 1932 by successfully casting Ford's intricate, single-piece V-8 engine block.

- 1934

- Collections - Artifact

Foundry Workers at the Ford Rouge Plant, 1934

Workers at the Ford Rouge plant's foundry poured a molten mixture of metal, coke, and limestone into molds to create cast-metal engine blocks and parts. Once "shaken out" of their molds, castings were roughly machined before heading elsewhere for finishing and assembly. The Rouge foundry set an industry benchmark in 1932 by successfully casting Ford's intricate, single-piece V-8 engine block.

- Foundry Workers at Ford Rouge Plant, April 28, 1936 - Workers at the Ford Rouge plant's foundry poured a molten mixture of metal, coke, and limestone into molds to create cast-metal engine blocks and parts. Once "shaken out" of their molds, castings were roughly machined before heading elsewhere for finishing and assembly. The Rouge foundry set an industry benchmark in 1932 by successfully casting Ford's intricate, single-piece V-8 engine block.

- April 28, 1936

- Collections - Artifact

Foundry Workers at Ford Rouge Plant, April 28, 1936

Workers at the Ford Rouge plant's foundry poured a molten mixture of metal, coke, and limestone into molds to create cast-metal engine blocks and parts. Once "shaken out" of their molds, castings were roughly machined before heading elsewhere for finishing and assembly. The Rouge foundry set an industry benchmark in 1932 by successfully casting Ford's intricate, single-piece V-8 engine block.