Search

- Employee Placing Pork into Cans, H. J. Heinz Company, Pittsburgh, Pennsylvania, circa 1915 - Before complete mechanization of the manufacturing process, many tasks at the Heinz factory were done by hand. The H. J. Heinz Company documented the many departments of the manufacturing process through photographs. This photograph shows an employee placing a hand-picked piece of pork into cans for baked bean products.

- circa 1915

- Collections - Artifact

Employee Placing Pork into Cans, H. J. Heinz Company, Pittsburgh, Pennsylvania, circa 1915

Before complete mechanization of the manufacturing process, many tasks at the Heinz factory were done by hand. The H. J. Heinz Company documented the many departments of the manufacturing process through photographs. This photograph shows an employee placing a hand-picked piece of pork into cans for baked bean products.

- Employees Filling and Weighing Cans, H. J. Heinz Company, Pittsburgh, Pennsylvania, circa 1900 - Before complete mechanization of the manufacturing process, many tasks at the Heinz factory were done by hand. The H. J. Heinz Company documented the many departments of the manufacturing process through photographs. This photograph shows employees filling and weighing cans of beans to ensure accuracy and consistency.

- circa 1900

- Collections - Artifact

Employees Filling and Weighing Cans, H. J. Heinz Company, Pittsburgh, Pennsylvania, circa 1900

Before complete mechanization of the manufacturing process, many tasks at the Heinz factory were done by hand. The H. J. Heinz Company documented the many departments of the manufacturing process through photographs. This photograph shows employees filling and weighing cans of beans to ensure accuracy and consistency.

- Tomatoes Coming into the H. J. Heinz Main Plant, Pittsburgh, Pennsylvania, circa 1920 - Entrepreneur H.J. Heinz recognized that producing the highest quality products began with where the ingredients were grown and how they were harvested. He took great care in managing every aspect of the process to ensure the best ingredients for his line of pickled foods, preserves, and condiments. This photograph shows one step in the tomato harvesting process.

- circa 1920

- Collections - Artifact

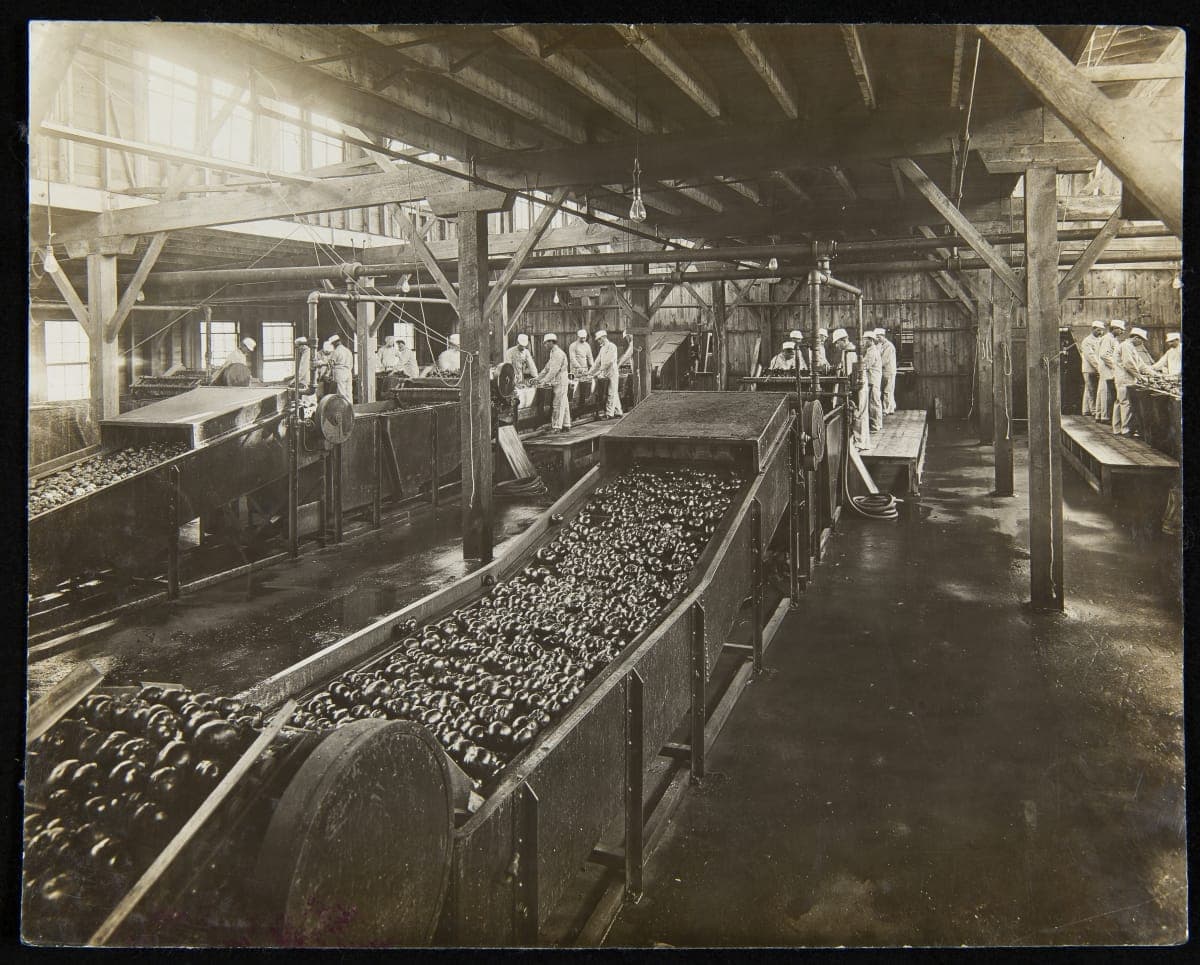

Tomatoes Coming into the H. J. Heinz Main Plant, Pittsburgh, Pennsylvania, circa 1920

Entrepreneur H.J. Heinz recognized that producing the highest quality products began with where the ingredients were grown and how they were harvested. He took great care in managing every aspect of the process to ensure the best ingredients for his line of pickled foods, preserves, and condiments. This photograph shows one step in the tomato harvesting process.

- Employees Filling Cans, H. J. Heinz Company, Pittsburgh, Pennsylvania, circa 1900 - Before complete mechanization of the manufacturing process, many tasks at the Heinz factory were done by hand. The H.J. Heinz Company documented the many departments of the manufacturing process through photographs. This photograph shows employees operating the machines that filled canned products.

- circa 1900

- Collections - Artifact

Employees Filling Cans, H. J. Heinz Company, Pittsburgh, Pennsylvania, circa 1900

Before complete mechanization of the manufacturing process, many tasks at the Heinz factory were done by hand. The H.J. Heinz Company documented the many departments of the manufacturing process through photographs. This photograph shows employees operating the machines that filled canned products.

- Automatic Gravity Conveyor Used during Helmet Painting Process, Ford Motor Company Philadelphia Plant, 1917-1918 - When the United States entered World War I, American automobile companies turned some of their manufacturing capacity to the production of war materiel. Ford Motor Company received a contract to paint, assemble, and crate steel helmets for American soldiers. Altogether, Ford's Philadelphia plant processed more than 2.7 million helmets at a rate as high as 40,000 each day.

- circa 1918

- Collections - Artifact

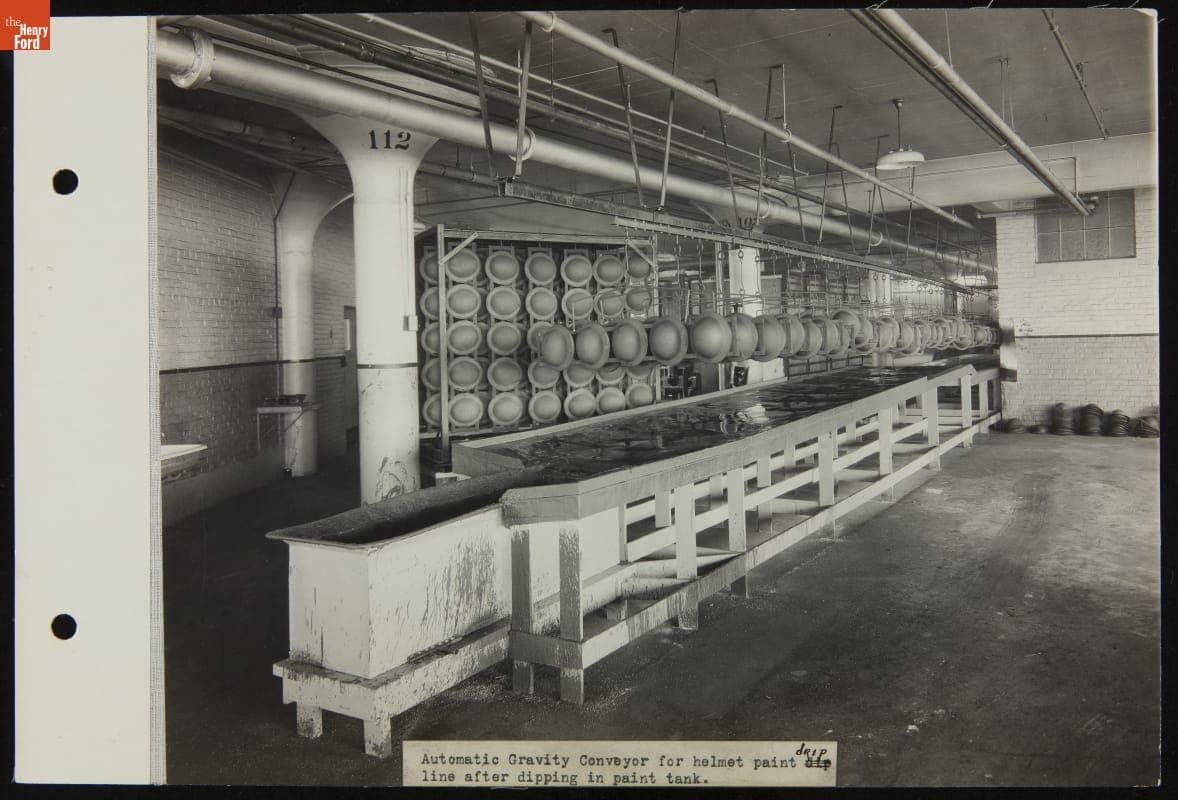

Automatic Gravity Conveyor Used during Helmet Painting Process, Ford Motor Company Philadelphia Plant, 1917-1918

When the United States entered World War I, American automobile companies turned some of their manufacturing capacity to the production of war materiel. Ford Motor Company received a contract to paint, assemble, and crate steel helmets for American soldiers. Altogether, Ford's Philadelphia plant processed more than 2.7 million helmets at a rate as high as 40,000 each day.

- Charcoal Briquet Production at the Ford Iron Mountain Plant, Moving Hot Dried Wood to Retorts, 1935 - Ford Motor Company made charcoal from wood wastes produced by its Michigan lumber mills. Wood chips were collected, dried and burned in retorts. These special ovens captured the combustion gases so that they could be used to generate some of the energy needed to run the plant. The resulting char was crushed, mixed with starch and compressed into usable briquettes.

- April 25, 1935

- Collections - Artifact

Charcoal Briquet Production at the Ford Iron Mountain Plant, Moving Hot Dried Wood to Retorts, 1935

Ford Motor Company made charcoal from wood wastes produced by its Michigan lumber mills. Wood chips were collected, dried and burned in retorts. These special ovens captured the combustion gases so that they could be used to generate some of the energy needed to run the plant. The resulting char was crushed, mixed with starch and compressed into usable briquettes.