Search

- Ford Motor Company Manual Containing Material Control Flow Chart for the Willow Run Bomber Plant, 1944 - Building something as complex as a B-24 bomber on an assembly line was no easy task. Ford Motor Company officials methodically divided the complicated airplane into 11 major assemblies, and then further split these into 69 subassemblies. By April 1944, Willow Run employees completed B-24 airplanes at the rate of one every 63 minutes.

- 1944

- Collections - Artifact

Ford Motor Company Manual Containing Material Control Flow Chart for the Willow Run Bomber Plant, 1944

Building something as complex as a B-24 bomber on an assembly line was no easy task. Ford Motor Company officials methodically divided the complicated airplane into 11 major assemblies, and then further split these into 69 subassemblies. By April 1944, Willow Run employees completed B-24 airplanes at the rate of one every 63 minutes.

- Flow Chart for B-24 Production at the Willow Run Bomber Plant, 1944 - During World War II, Ford built 8,685 B-24 Liberator bombers at Willow Run. Fuselages were joined to center wing sections and landing gear, after which the airplanes moved along four parallel assembly lines where noses and tails were added. These lines merged into two for the installation of wingtips, engines, and other components. A single final line handled finishing steps and fueling.

- September 01, 1944

- Collections - Artifact

Flow Chart for B-24 Production at the Willow Run Bomber Plant, 1944

During World War II, Ford built 8,685 B-24 Liberator bombers at Willow Run. Fuselages were joined to center wing sections and landing gear, after which the airplanes moved along four parallel assembly lines where noses and tails were added. These lines merged into two for the installation of wingtips, engines, and other components. A single final line handled finishing steps and fueling.

- Design Procedure Flow Chart, Drawn by John Najjar, July 25, 1962 - Designer John Najjar spent more than 40 years at Ford Motor Company. He made significant contributions to the styling of the 1957 and 1958 Lincolns, the 1961 Lincoln Continental and the 1961 Ford Thunderbird. Najjar also supervised design of the 1962 Mustang I concept car, and he headed interior design on the 1965 Ford Mustang production car.

- July 25, 1962

- Collections - Artifact

Design Procedure Flow Chart, Drawn by John Najjar, July 25, 1962

Designer John Najjar spent more than 40 years at Ford Motor Company. He made significant contributions to the styling of the 1957 and 1958 Lincolns, the 1961 Lincoln Continental and the 1961 Ford Thunderbird. Najjar also supervised design of the 1962 Mustang I concept car, and he headed interior design on the 1965 Ford Mustang production car.

- Material Control Flow Chart, Ford Motor Company Willow Run Bomber Plant, April 1944 - Building something as complex as a B-24 bomber on an assembly line was no easy task. Ford Motor Company officials methodically divided the complicated airplane into 11 major assemblies, and then further split these into 69 subassemblies. By April 1944, Willow Run employees completed B-24 airplanes at the rate of one every 63 minutes.

- April 01, 1944

- Collections - Artifact

Material Control Flow Chart, Ford Motor Company Willow Run Bomber Plant, April 1944

Building something as complex as a B-24 bomber on an assembly line was no easy task. Ford Motor Company officials methodically divided the complicated airplane into 11 major assemblies, and then further split these into 69 subassemblies. By April 1944, Willow Run employees completed B-24 airplanes at the rate of one every 63 minutes.

- Material Control Flow Chart for B-24-M and B-24-N Airplanes Built at Ford Motor Company Willow Run Bomber Plant, June 1945 - Building something as complex as a B-24 bomber on an assembly line was no easy task. Ford Motor Company officials methodically divided the complicated airplane into 11 major assemblies, and then further split these into 69 subassemblies. By April 1944, Willow Run employees completed B-24 airplanes at the rate of one every 63 minutes.

- June 01, 1945

- Collections - Artifact

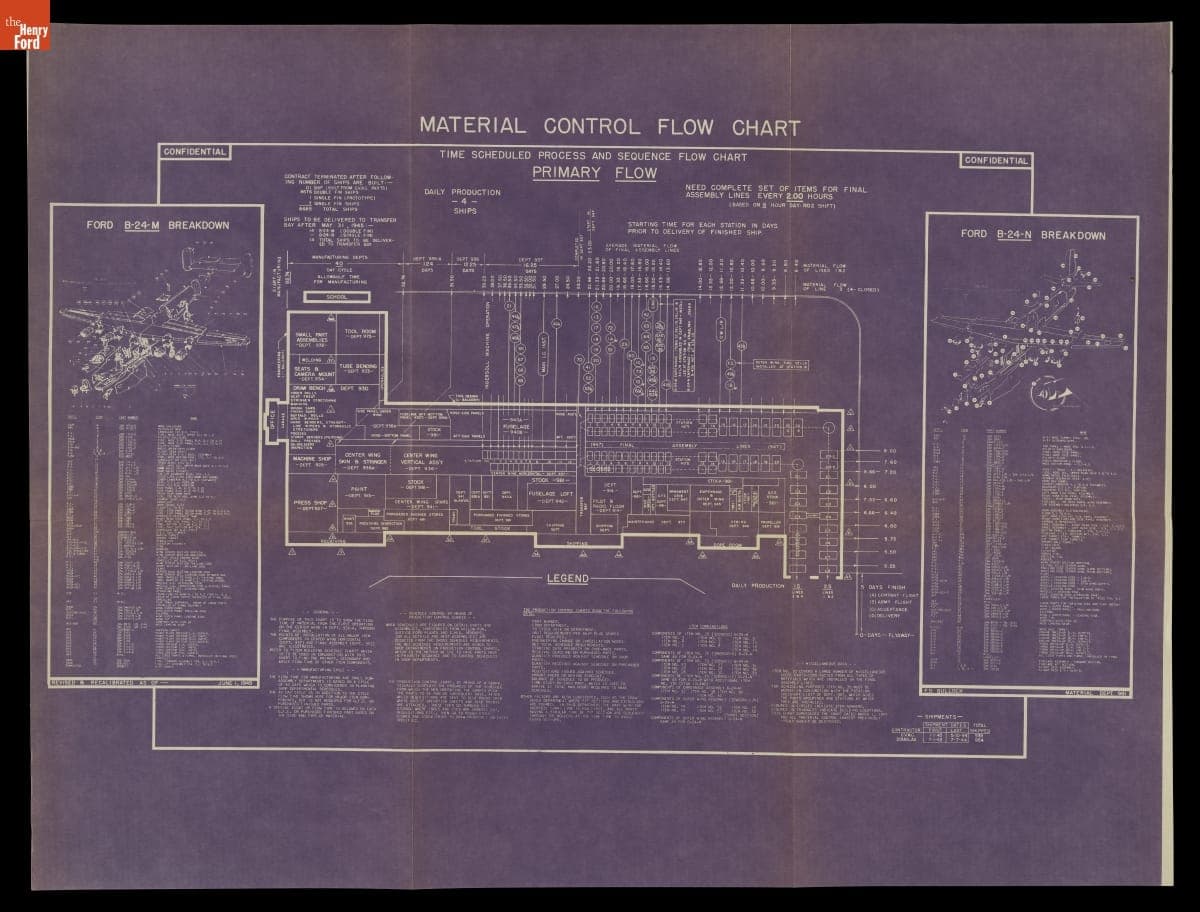

Material Control Flow Chart for B-24-M and B-24-N Airplanes Built at Ford Motor Company Willow Run Bomber Plant, June 1945

Building something as complex as a B-24 bomber on an assembly line was no easy task. Ford Motor Company officials methodically divided the complicated airplane into 11 major assemblies, and then further split these into 69 subassemblies. By April 1944, Willow Run employees completed B-24 airplanes at the rate of one every 63 minutes.