A Winter Harvest

| Written by | Saige Jedele |

|---|---|

| Published | 2/20/2014 |

A Winter Harvest

| Written by | Saige Jedele |

|---|---|

| Published | 2/20/2014 |

Ice harvesters guide rafts of cut ice through a channel, probably on Lake St. Clair, Michigan, circa 1905 (THF110292)

It’s been a cold winter at The Henry Ford. Record low temperatures have closed schools and businesses, lengthened commutes, and hardened lakes and ponds across southeast Michigan. Though some schoolchildren, ice skaters, snowmobilers, and ice fishermen may rejoice, it’s difficult to imagine braving these frigid conditions daily as part of a job. But until the 1920s, the nation depended on men who did just that, year after year, to harvest the ice essential to the American way of life.

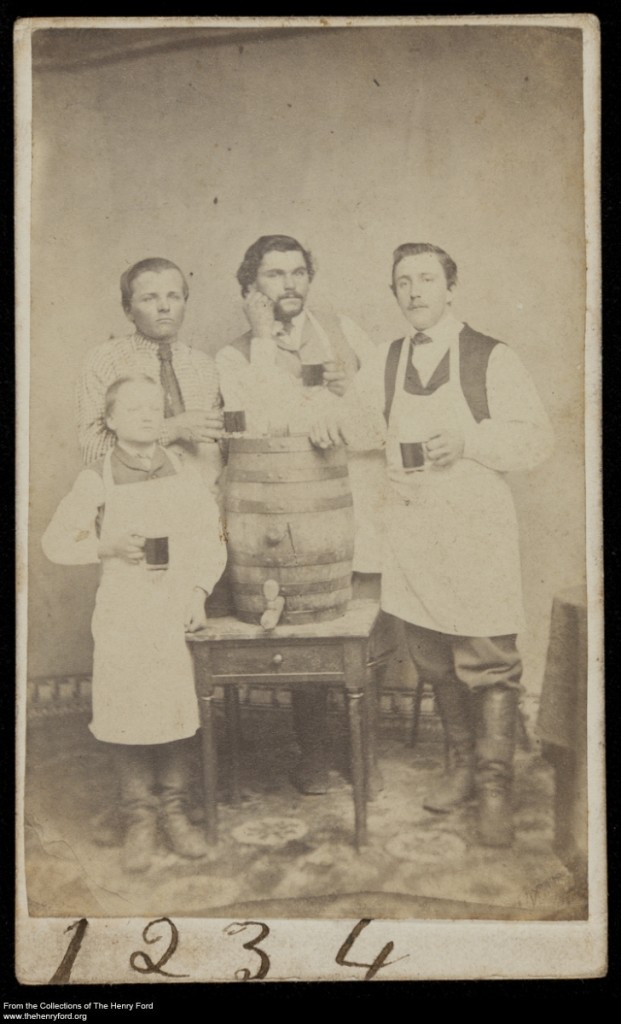

By 1830, foods that required refrigeration were staples of American diets. For decades, rural communities in colder regions of the country had harvested ice to keep certain foods from spoiling during the summer months. But as American cities swelled in the nineteenth century, so did the demand for fresh meat, dairy products, fruits and vegetables, and even beer. Before long, the local, small-scale ice harvest grew into a major industry. Wherever ice on a pond, canal, lake, or reservoir was thick enough, companies deployed teams of men, horses, and machines to harvest it for distribution across the United States.

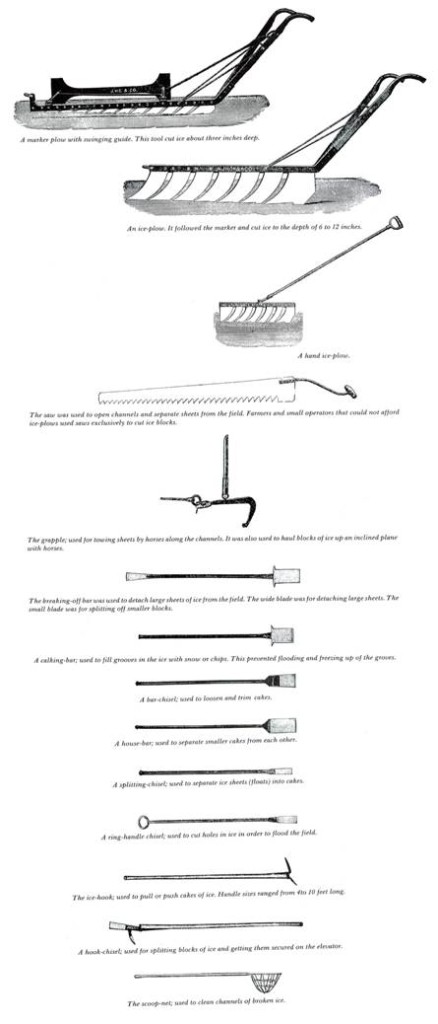

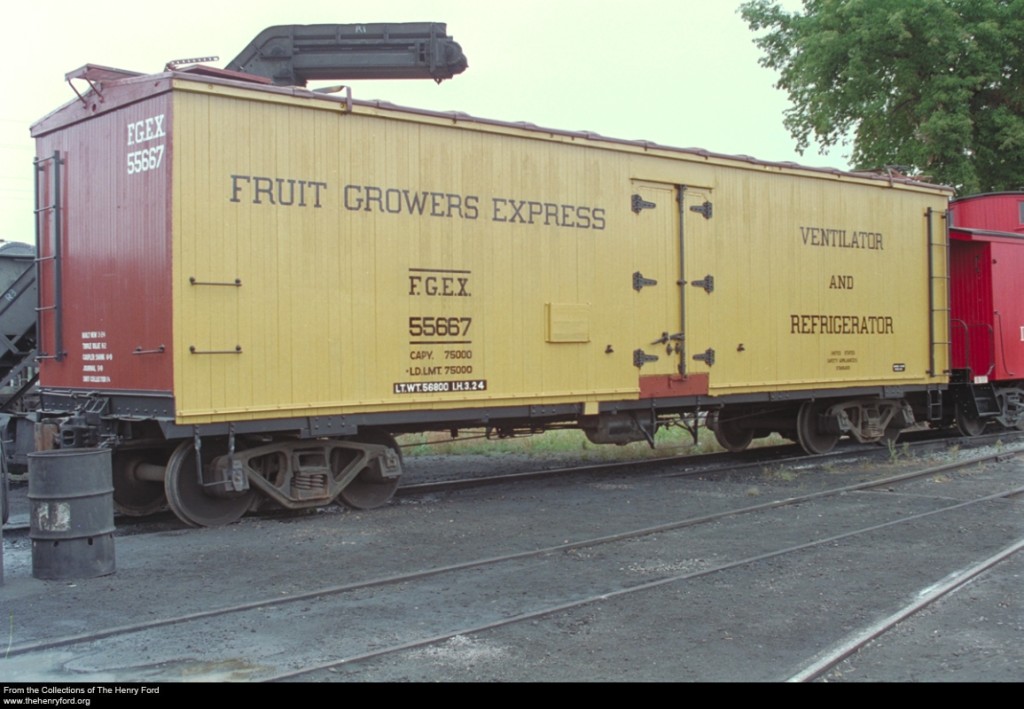

Some of the ice harvesters worked as farmers or fishermen in warmer months; some were imported from nearby cities to work the ice fields. Whatever their makeup, when ice harvesting crews gathered in January and February, they faced a complex and sometimes dangerous challenge. First, the ice had to be scraped clear of snow and, when the surface was too rough to be cut, planed smooth. Workers bored holes to measure the thickness of the ice, and then used a marker or groover to etch a grid of rectangles across the ice field. Next, an ice plow followed these lines, cutting about two-thirds of the way into the ice. If the ice was going to be used locally, the rectangular blocks of ice — called “cakes” — were chipped off and loaded onto wagons or sleighs for direct delivery. Otherwise, harvesters broke off large sections of the grooved ice field using saws and other hand tools. Workers guided these rafts of ice through a channel, where men broke the sheets into individual cakes and fed them up an elevator conveyor into an ice house. There, workers arranged the ice cakes into layers for storage and later delivery. If the ice house was located along the railway – and many were – blocks of ice could be loaded directly into refrigerated rail cars.

Saige Jedele is Associate Curator, Digital Content, at The Henry Ford.

Keywords | |

|---|---|

Themes |