Suits for the Stars: Spacesuits of Yesterday, Today, and Tomorrow

| Written by | Fedor Kossakovski |

|---|---|

| Published | 2/24/2022 |

Suits for the Stars: Spacesuits of Yesterday, Today, and Tomorrow

| Written by | Fedor Kossakovski |

|---|---|

| Published | 2/24/2022 |

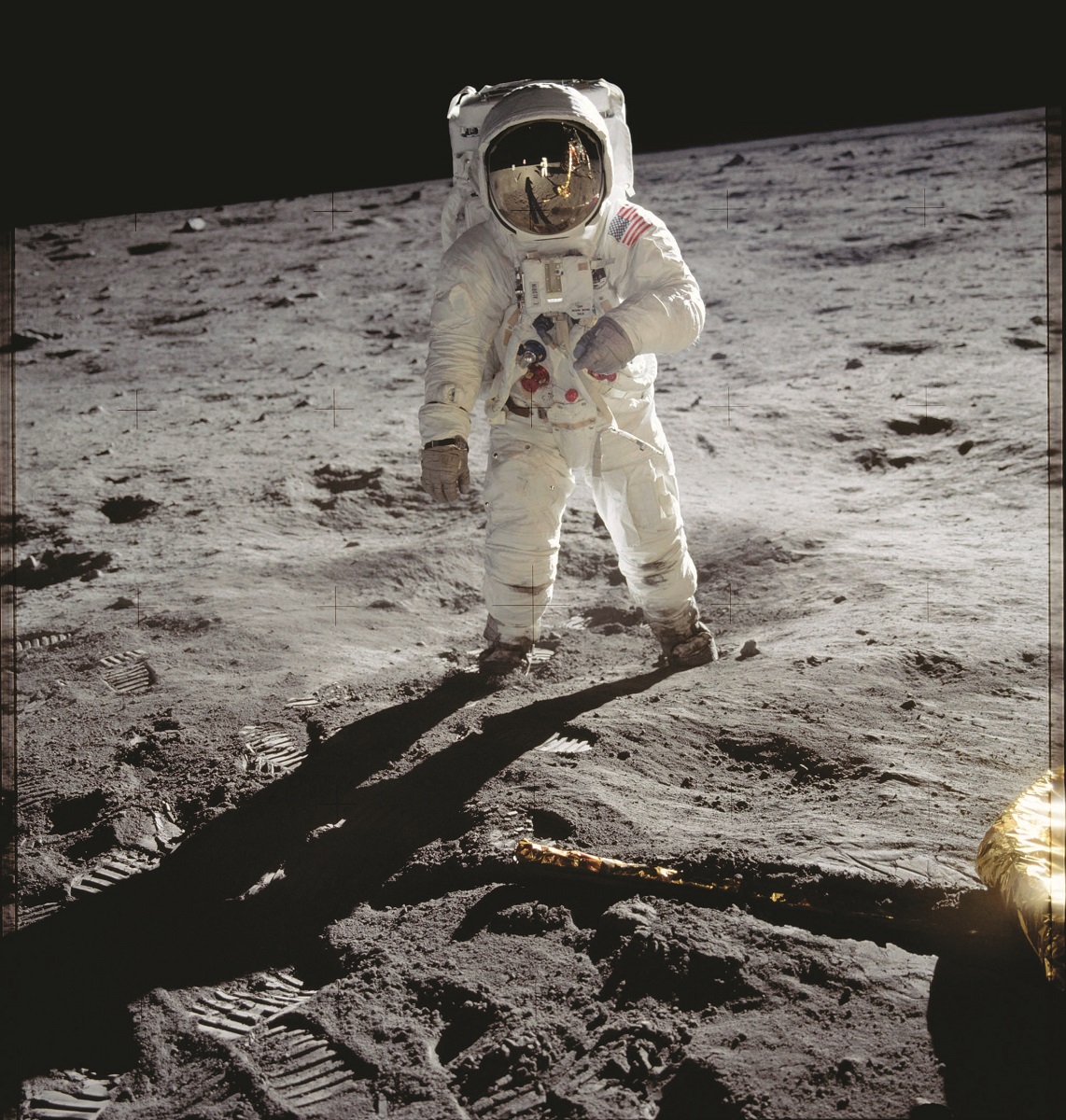

Cocooned within 21 layers of synthetics, neoprene rubber, and metalized polyester films, Apollo 11 astronaut Buzz Aldrin was well protected from the airless moon’s extremes of heat and cold, deadly solar ultraviolet radiation, and even the off chance of a hurtling micrometeorite. / Photo by Neil Armstrong/NASA

Cocooned within 21 layers of synthetics, neoprene rubber, and metalized polyester films, Apollo 11 astronaut Buzz Aldrin was well protected from the airless moon’s extremes of heat and cold, deadly solar ultraviolet radiation, and even the off chance of a hurtling micrometeorite. / Photo by Neil Armstrong/NASA

It’s possibly the most recognizable image in all of human history: Buzz Aldrin on the surface of the moon, his left arm drifting up as if checking the time during a stroll through the park.

The photo sticks in the imagination more than any image of sleek rockets on the launchpad or metallic modules landing on an inhospitable world. Perhaps it’s the casual, individual bravado oozing off Aldrin’s puffed-up frame that truly captures the essence of humans pushing past the ultimate boundary: space.

And yet the spacesuit is rarely the star of the human spaceflight epic. Which is a shame, since this was the most intimate component of the engineering endeavor that landed man on the moon 50 years ago—intimate also because the surprising winner of NASA’s spacesuit contract was a spinoff of Playtex, the underwear manufacturer which still makes items from bras to feminine products to this day.

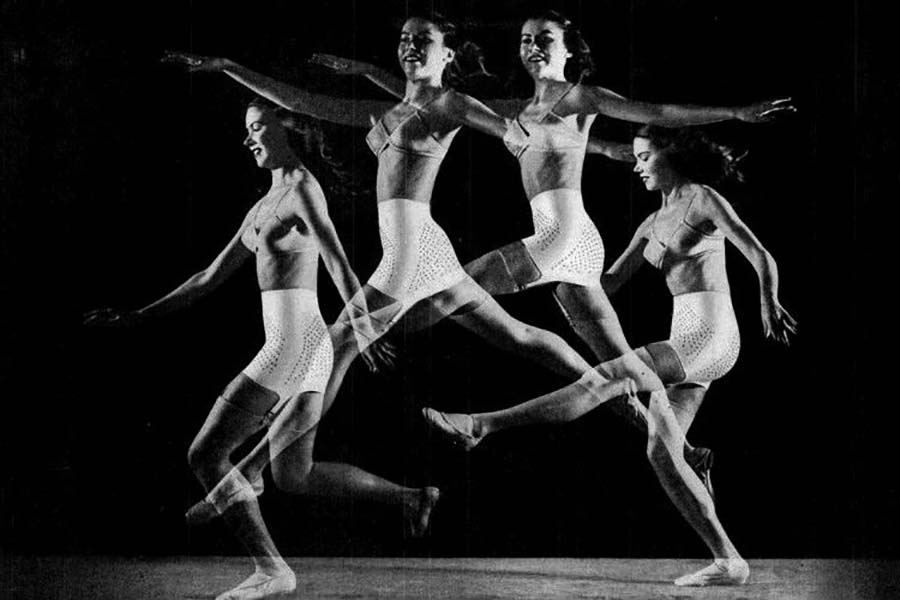

Playtex made everyday women’s girdles like those shown in this ad before making an unlikely jump to producing clothing for space travel to the moon in the 1960s. / Photo courtesy of Wikimedia Commons

“The suits that other companies provided were stiff, they were bulky, they couldn’t fit the narrow confines of the mission parameters,” said Nicholas de Monchaux, professor of architecture at University of California Berkeley’s College of Environmental Design and writer of a deeply researched book called Spacesuit: Fashioning Apollo.

At the core is the idea of the “human factor,” often overlooked by engineers in their quest to reach the lunar surface. The Saturn V rocket and the lunar module were exquisitely engineered, with sharp, clean lines governed by the unchanging forces of physics: thrust, gravity, air resistance. But the same equations are blurred when dealing with the human form. “The human body doesn’t operate from first principles,” said de Monchaux.

In the race to win the initial suit contract, companies such as David Clark Company, which made the Mercury mission spacesuits, and Hamilton Standard, a division of conglomerate United Aircraft, produced concepts informed by their decades-long experience with high-altitude pressure suits. These options proved much more difficult to maneuver than the suit produced by ILC Dover, the Playtex spinoff whose patented “convolutes” included rubber identical to that filling Playtex’s girdle molds, as well as nylon tricot and webbing taken from the supplies feeding its brassiere assembly lines.

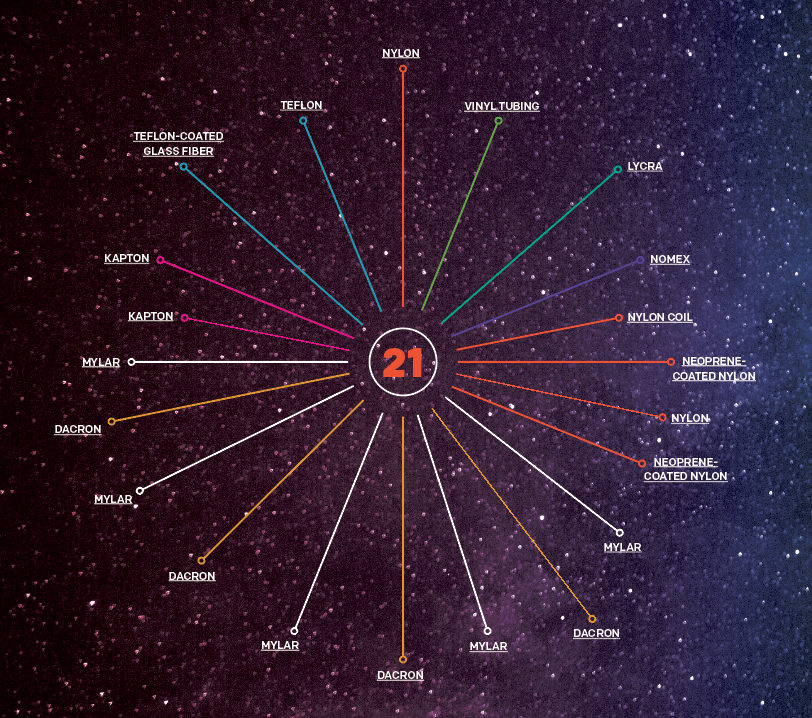

The Apollo spacesuit designed by ILC Dover and worn on the moon had 21 layers, 20 of which were created with synthetics made by chemical giant DuPont. Familiar household names like nylon, Lycra, and Teflon were found in various layers, a fact DuPont proudly advertised at the time.

In 1966, events came to a head when a new ILC spacesuit had to compete once more against prototypes from Hamilton Standard and David Clark. Test subjects using the competing suits had trouble moving around, operating switches, and fitting in and out of the mock landing module. Imagine if Aldrin and Neil Armstrong had touched down successfully on the moon only to not fit through the hatch to step on the surface!

Though each competing suit was custom fitted, only the 21-layer ILC Dover soft suit was sewn by hand by a hotshot crew of the best seamstresses taken from Playtex’s sewing floor—eschewing paint-by-numbers engineering in favor of highly personalized, artisanal craftsmanship. Each spacesuit created by the ILC Dover team bore a laminated photograph of the astronaut it belonged to in order to create a connection to the person whom they were literally keeping alive with their craftsmanship.

Arlene Thalene of ILC Dover inspects a spacesuit’s mylar insulation layers. / Photo courtesy of ILC Dover, LP

Their knowledge, gained by fashioning bras and girdles for women’s activewear, proved indispensable to creating a superior product. The material itself was co-opted: “The rubber that made the suit was literally from the same tank that was, originally at least, supplying the girdle-making that had made Playtex’s fortune,” said de Monchaux.

ILC Dover employee Velma Breeding installs a bladder into a boot. / Photo courtesy of ILC Dover, LP

The ILC Dover suit bested the others in official NASA tests, but the systems-engineering bureaucracy of the Apollo program was still skeptical of an untested spinoff holding such a critical contract. When again faced with competition for the last phase of Apollo’s missions (numbers 14-17), the ILC Dover team even resorted to filming a test subject playing football in a pressurized suit for several hours. “And, as became clear on watching the films, the suited subject’s attempts were at the very least equivalent to those of an engineer in shirtsleeves and slacks who joined him on the field,” wrote de Monchaux. “ILC Dover, née Playtex, had won the Apollo game.”

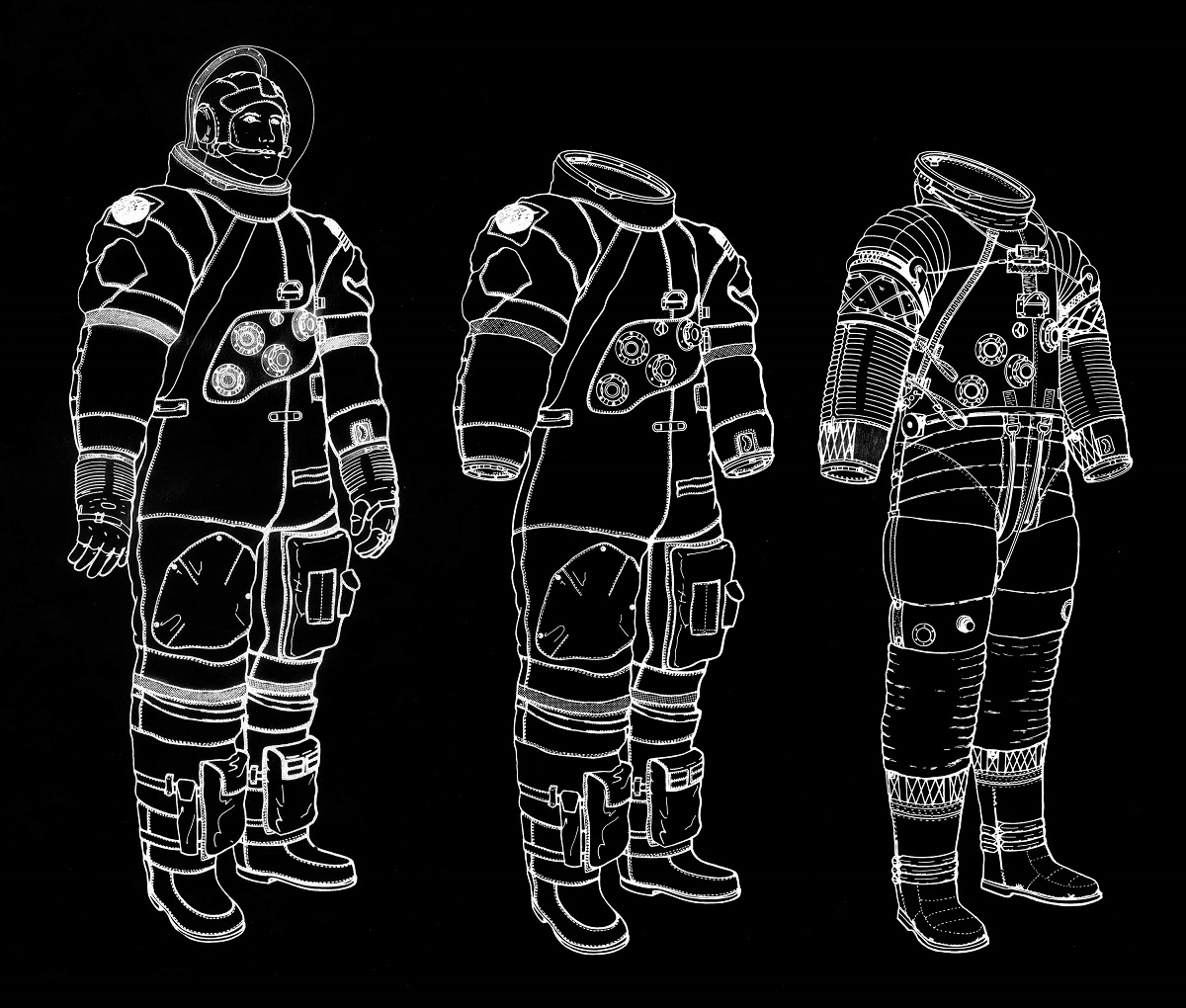

A composite of the final drawings from ILC Dover depicts (from right to left) an Apollo 11 spacesuit’s pressure garment assembly, a suit with its Thermal Micrometeoroid Garment (TMG) attached, and an astronaut wearing a suit with TMG outer cover, gloves, and helmet. Once securely attached to the spacesuit’s inner pressure garment, the multilayered TMG protected astronauts against micrometeoroid impacts, solar and galactic radiation, thermal conduction, and abrasion, and also provided fire protection. / Drawings courtesy of ILC Dover, LP

Dressed for Health

More than 50 years after the Apollo 11 astronauts donned their spacesuits on the moon, I’m sitting in an office at hygiene and health giant Essity’s facility in North Carolina trying to pull on what looks like your average thick knee-high black socks. Kevin Tucker, the global technical innovations manager for a division of Essity, chuckles while I struggle with the fabric as it tightens like a vice. Tucker is in charge of the company’s work with NASA to develop a compression suit for astronauts returning from space. He points out as he puts the socks away that future NASA astronauts will wear something with twice the compression power.

Essity’s bread and butter is making compression garments for people with venous and lymphatic diseases. That’s when the body has issues with pumping fluids against the pull of gravity, causing symptoms from lack of feeling in extremities to loss of consciousness. It’s something we have all experienced to some degree, said Tucker. “If you’re sick in bed with the flu and you’re lying down for a long period of time and you have to go run to the bathroom, the first step you usually take you end up on your nose.”

Astronauts also have trouble with fluid control. When they first get up into space and gravity is no longer a factor, fluids are pumped more into their torso and head. That’s why new arrivals to the International Space Station have puffy faces. After a while, the body adjusts and pumps less to accommodate the lack of gravity. But the problem rears its head again upon re-entry and the rapid reintroduction to gravity. At that point, the body’s fluid pumping is weakened, and astronauts often have to be carried out of the capsule. “This sudden rush of fluid away from the head and heart down into the legs can affect your consciousness,” said Tucker. That’s something his team is trying to change.

To help NASA, Essity is applying its expertise in designing compressive socks, sleeves, and girdles to create a compression suit future astronauts would wear on re-entry to prevent or avoid the sudden redistribution of fluids to the lower extremities upon return to Earth’s gravity. When Tucker lays out the current design on a table, it’s a crisscross of tight black fabric and a few zippers, woven in a way reminiscent of those fancy yoga pants that have sheer patterns.

Health giant Essity is currently working with NASA to create a compression suit that astronauts will wear upon re-entry to Earth. The garments, shown separately here for illustrative purposes, will prevent or avoid the sudden redistribution of fluids to the lower extremities upon return to Earth’s gravity. / Photo courtesy of Essity

It’s slated to be the first layer of gear NASA astronauts will put on as they prepare to splash down—so getting stuck as you pull on the suit is simply not an option. Another “soft” consideration is that the astronauts will have to wear these for hours in a seated, upside-down position, and tests of earlier designs irritated subjects’ bent knees. The newest version of the compression suit comes slightly pre-bent at the joint, making it more comfortable.

The Human Factor and What’s Next

The human body was not meant for space travel, and the soft problems it presents require innovative solutions with intimate knowledge of the human body. Some of those challenges (and ways suits can help) are listed below.![]()

Vacuum: Exposed to the vacuum of space, a body’s fluids would start boiling away as the body puffs up. A spacesuit protects you—but, be warned, it will puff up, too.![]()

Temperature: Outside the International Space Station, the temperature swings wildly from 250 to -250 degrees Fahrenheit. But with no atmosphere to transfer heat or cold, a well-insulated spacesuit keeps you comfy.![]()

Radiation: Above the protection of the Earth’s atmosphere and magnetic field, cosmic radiation is the most consistent health concern. A spacesuit provides very limited protection—as does the space station.![]()

Lack of Gravity: Low or no gravity makes muscles atrophy, bones lose density, and fluids redistribute. NASA is working on it.

Unfortunately, the human body is not always something the engineering culture of rocket scientists takes into account. “We’re still thinking about the engineering and the propulsion systems and the vehicle, but we’re not thinking enough about the pink, squishy things that are in the middle of that vehicle,” said Diana Dayal, who did a year-long apprenticeship at the National Space Biomedical Research Institute (NSBRI). Funded by NASA’s Human Research Program, NSBRI, which closed in 2017, was NASA’s lead partner in space biomedical research and provided hands-on lab opportunities for young scientists, engineers, and physicians such as Dayal to access careers in human spaceflight.

On future, longer space missions, the human factor will be amplified. New challenges will arise from the long stint in low gravity. “The deconditioning of your bones and muscles is going to be an unavoidable problem on a three-year Mars mission,” said Dayal. “How are you supposed to send people to Mars and expect them to set up a habitat?”

Astronaut Neil Armstrong—shown here aboard the Apollo 11 Lunar Module Eagle, the first crewed vehicle to land on the moon—later quipped that his spacesuit was one of the most widely photographed spacecrafts in history. Decades later, he sent a note to the team that designed the spacesuit, complementing it and calling it “tough, reliable and almost cuddly.” You can see the “cuddly” spacesuit worn by Armstrong, held by the Smithsonian National Air and Space Museum, on their collections website. / Photo by NASA / Edwin E. Aldrin Jr.

One of the solutions being explored is enhancing the spacesuit with an exoskeleton—essentially empowering the humans by linking them to a stronger robotic carapace. This is a good idea, but the prototype Dayal saw at NASA’s Johnson Space Center was so large and cumbersome, it was hard to imagine it on an average person.

“It’s so cool that you basically have all this circuitry that simulates nerves, but at the same time, who did you build this for? Who’s going to wear it?” They were questions posed by Dayal’s group, she said, pointing out that current designs lack sufficient modularity to adjust to different body types.

While the lessons learned in developing the soft Apollo spacesuit decades earlier may have to be revisited as we look to longer missions, it’s also an opportunity to push the boundaries of design. “All of your constraints are out the window; everything is a variable,” said Dayal. “If anything, designing for space should help us better design for Earth.”

Fedor Kossakovski is a freelance science writer and producer. This post was adapted from an article in the June–December 2019 issue of The Henry Ford Magazine.

Keywords | |

|---|---|

Series | |

Themes |