American Tinsmithing Machines: Revolutionizing an Industry

| Written by | Donna R. Braden |

|---|---|

| Published | 1/9/2023 |

American Tinsmithing Machines: Revolutionizing an Industry

| Written by | Donna R. Braden |

|---|---|

| Published | 1/9/2023 |

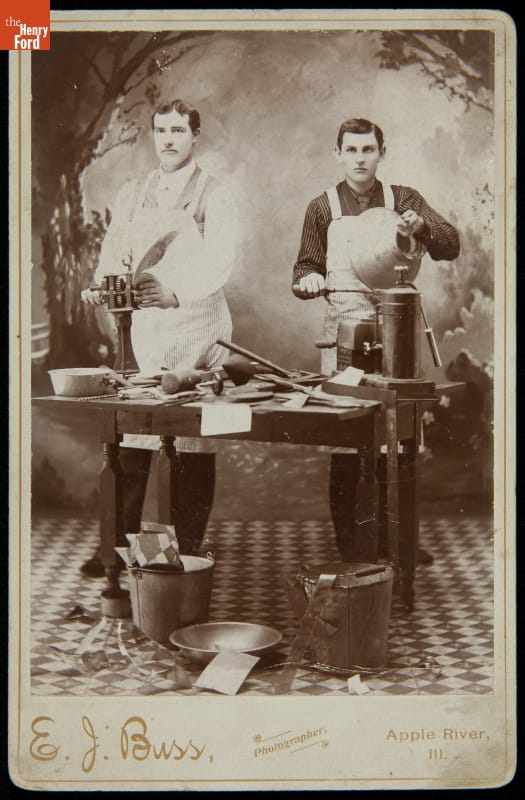

Tinsmiths pose with hand tools, machines, sheets of tinplate and examples of tinware, circa 1875. / THF228486

Until the first decade of the 19th century, tinsmiths in both Europe and America manufactured virtually all tinware by hand, using a wide range of specialized tools. But as tinware became more popular, American tinsmiths developed a unique set of equipment that included patented cast-iron geared machines.

American tinsmithing began in the 18th century, but the production of tinware really took off after the War of 1812, when American tinsmiths could finally obtain a constant supply of tinplate (or tin-coated iron, the material tinsmiths use to make their wares) from England and Wales. (These countries dominated the tinplate industry through most of the 19th century.) The influx of imported tinplate, as well as the immigration of skilled English and Welsh tinsmiths, contributed to the tremendous popularity of tinware in 19th-century America.

This circa 1840 lithograph depicts the hand process of producing tinware, as well as several hand tools and examples of finished goods. / THF626375

Tinplate was a stiff but pliable material, shaped by cutting, bending, crimping (to create folds or pleats), hammering and soldering joints together. Tinsmiths needed training and skill to accomplish these tasks. Overheating could destroy the tin coating. Over-hammering could break the coating. Joints had to be carefully soldered with soldering irons heated over charcoal stoves or braziers. Tinsmiths generally developed their own wooden patterns to help reduce variation and error, but handwork still took much practice.

Increasing American demand for tinware led to the development and enthusiastic embrace of numerous patented hand-powered machines that saved time and labor, making it possible for tinsmiths to produce the same items in quantity in less time and at a lower cost. When they could afford them, American tinsmiths eagerly added these machines to their more traditional sets of hand tools.

.png?sfvrsn=4c02622f_0)

This 1874 image depicts a tin shop that utilized traditional hand tools as well as at least one hand-cranked machine, visible just behind the tinsmith at center. / THF626434

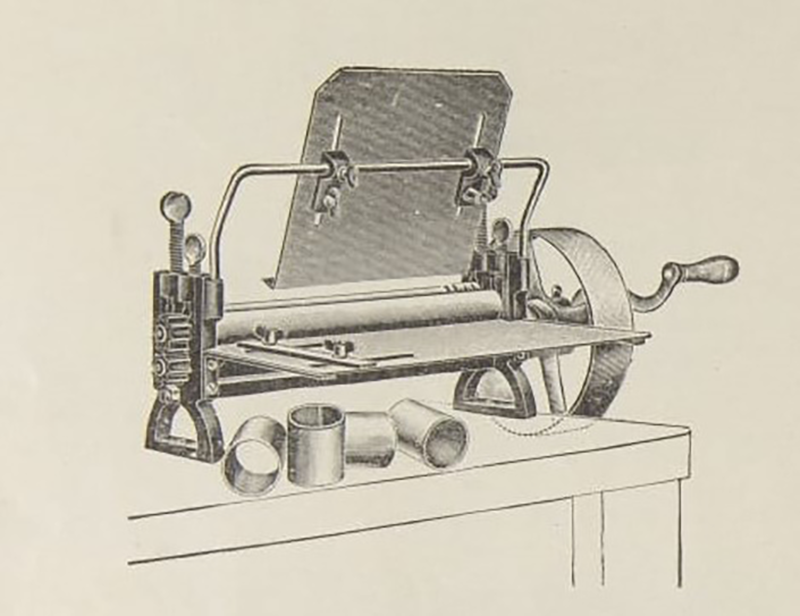

A unique American characteristic of many crafts and trades in 19th-century America — tinsmithing being no exception — was the preference for speed and uniformity over European traditions of personal, individualized workmanship. Hand-cranked machines revolutionized American tinsmithing by replacing old hand methods — like crimping, bending and locking edges, cutting, forming, slitting, cutting circles, stamping and rolling — with quicker, more efficient steps to produce greater quantities of uniform pieces in less time. And as American tinsmiths embraced machines, their assistants required less training.

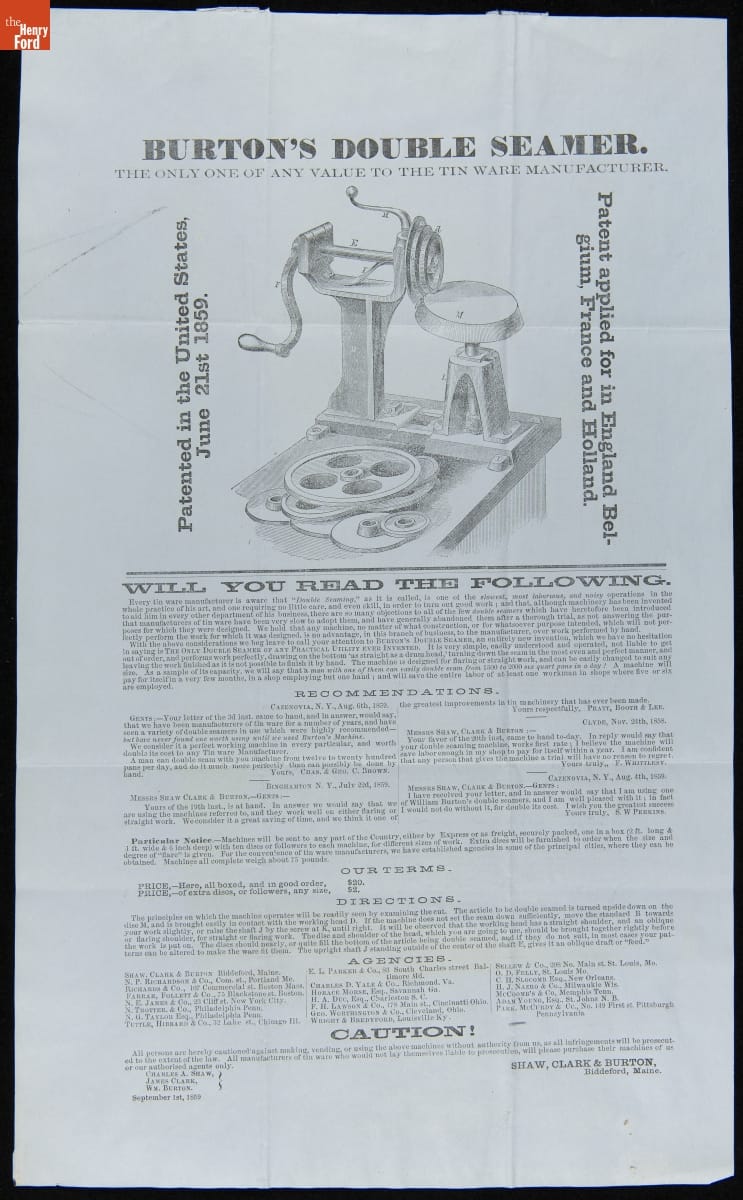

The manufacturer of Burton’s Double Seamer, patented in 1859 and illustrated here sealing the bottom of a round pan, advertised it as “the only one of any value to the tinware manufacturer.” Early hand-cranked machines led to a plethora of patented machines developed by American blacksmiths, toolmakers and machinists throughout the 19th century. / THF626369

This hand-cranked circle shear, patented in 1860, allowed tinsmiths to cut circles of tinplate up to 20 inches in diameter. / THF705411

Tinsmiths used hand-cranked forming machines, like this one depicted in a circa 1895 Peck, Stow & Wilcox Co. trade catalog, to create cylindrical shapes. / Detail, THF626395

By the 1850s, a range of patented geared machines could be found in an increasing number of tin manufactories, which employed up to 30 people and turned out dozens of uniformly made items. The longtime use of precut patterns or templates led, by the late 19th century, to the use of published pattern books, further helping to ensure uniformity. Small tin shops, which persisted into the early 20th century (particularly in rural and remote areas), could order parts – such as lids or bucket handles – from these establishments and pair them with or attach them to their own forms, to avoid purchasing the expensive specialized equipment needed to produce them. See our blog for more on the history of tinsmithing and tinware.

Donna R. Braden is senior curator and curator of public life at The Henry Ford. This post was adapted for the blog by Saige Jedele, associate curator, digital content.

Keywords | |

|---|---|

Themes |