Conservation Spotlight: 19th Century Passenger Cars

| Written by | Marlene Gray |

|---|---|

| Published | 1/15/2025 |

Conservation Spotlight: 19th Century Passenger Cars

| Written by | Marlene Gray |

|---|---|

| Published | 1/15/2025 |

If you had a chance to visit the Henry Ford Museum of American Innovation in 2024, you may have seen a few members of our conservation team working by the legendary Allegheny, on the three cars attached to the replica DeWitt Clinton locomotive. For a few months, we chatted with visitors about conservation and our preservation efforts on these artifacts. Let's look at the full process now that conservation work is complete!

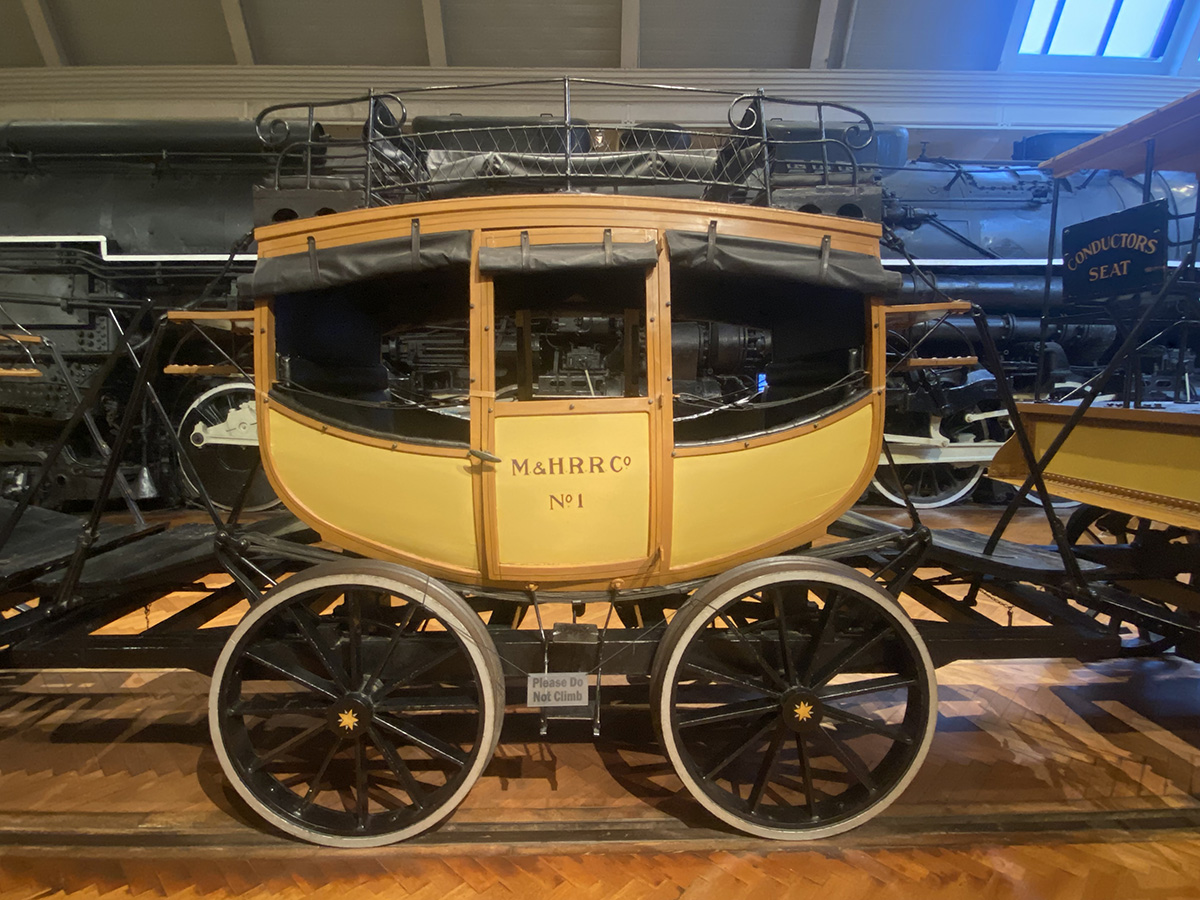

First car

Made in 1893 by the New York Central Railroad for the World’s Columbian Exhibition in Chicago and various promotional events, the locomotive and passenger cars are replicas of the 1831 DeWitt Clinton. Henry Ford acquired the replica locomotive and carriages in the 1930s, which are now displayed on railroad tracks as if ready for their next journey.

Second car

Both their days of use and time on display have contributed to the wear and tear on the locomotive and its cars. Our fabulous clean team documents changes to the artifacts to report to Conservation. For the replica DeWitt Clinton passenger cars, the clean team noticed broken leather straps, lost paint, torn leather cushions, and a missing seat cushion.

Third car

This year, we made it a priority to give the cars conservation attention. Since these are large artifacts, instead of moving them to the conservation lab, cleaning and repairs were done on the museum floor.

Broken leather strap on one of the cars

First, broken and brittle leather belt straps in the windows of each car were removed for replication by a local leather worker. The straps were measured and fabricated to match the full length and appearance of the original straps in completed form. The original metal buckles were saved to fit the straps back to the windows.

Surface grime on car exteriors visible around the lettering

The exteriors of the cars were cleaned to remove surface grime and expose the richness of the bright mustard and reddish-brown paints. At this stage, it allows us to see other issues that we may have missed upon the first examination. Not only were paint losses visible on the surface, but losses in the wood frame were found on the rear car.

Filled losses with gesso to create even layer before painting

The unstable paint was carefully adhered back in place and large losses filled with gesso or wood putty before painting to match the rest of the car.

Wood putty fill in center

Pinstripes and lettering on the car doors were also touched up. If there was structural damage, strong wood putty was used, otherwise the gesso was used for shallow fills.

Large paint loss on side panel

Otherwise, after concocting just the right proportions of pigments, wax fills were chosen to provide good color match for shallow surface damages. Smaller losses were filled with the pigmented waxes applied vertically using a warm tacking iron, mindful not to drip wax everywhere!

Torn leather on cushion

Tufted seat cushions with torn leather were removed from the cars and taken to the conservation lab. The tears were mended with adhesive film activated by heat. Any gaps in the lost leather were filled with pigmented wax. The buttons were re-secured where necessary with stronger twine.

Cushion after stabilization

The missing seat cushion on one of the cars was recreated by a local car upholsterer. See if you can spot the new one! We make sure new materials added to artifacts are documented in condition and treatment reports for future conservators to know what is original versus a replication.

Each car's leather armrests had been previously repaired with tape strips to cover lost material or insecure leather. Over time the tape started to peel away, drawing more attention to these damaged areas.

Adding leather tape patches to losses on armrests

We removed the old tape and adhesive before attaching leather tape patches cut for specific loss areas instead of covering the entire armrest.

Applying wax to small losses on armrests

As seen with the seat cushions, pigmented wax was applied to the gaps between the original leather and the new patches to create as seamless a finish as possible while securing the edges of the tape to the armrests.

3D-printed tacks ready for attachment

Final additions involved replicating lost tacks around the window shades and interior leather panels of each car. Example tacks were scanned to create digital models for 3D printing. Close to 100 printed tack models were then painted to look like corroded metal or leather covers for the tack heads and secured with adhesive. Once the last tack was attached, our rejuvenating treatment was complete!

View of all three cars from the Allegheny

We heard many visitors standing in awe of the replica DeWitt Clinton and what must have been quite the experience of riding these passenger cars long ago. This behind-the-scenes look at what it takes to preserve some of the larger items in our collection gives a taste of the detailed work our conservation team does every day to continue the legacy of these historical artifacts.

Marlene Gray is a senior conservator at The Henry Ford. Huge thanks to conservation specialists Fatima Sow, Julia Fahling, Scott Powers, and senior conservator Cuong Ngyuen for their work on the passenger cars.

Themes |

|---|