The Henry Ford’s Ingersoll Milling Machine and Mass Production at Highland Park

| Published | 4/25/2020 |

|---|

The Henry Ford’s Ingersoll Milling Machine and Mass Production at Highland Park

| Published | 4/25/2020 |

|---|

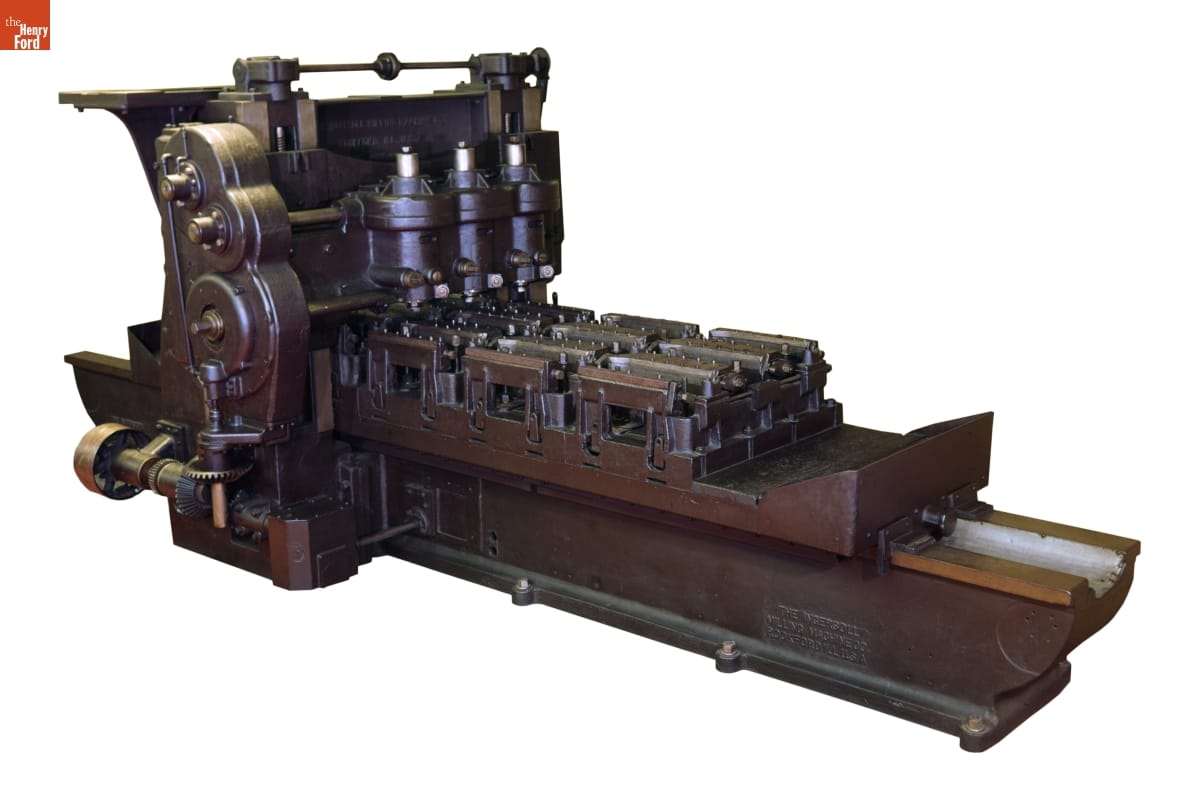

THF129649

What are the icons of the Industrial Revolution—steam engines, printing presses, combine harvesters, textile machinery? Any such list would surely include Ford’s Model T. Like the other machines that would make the grade it too was a complex mechanism, but it was also a beloved consumer product rooted in personal practical everyday use, and it was a design icon—in its day a symbol of absolute modernity.

The T’s success came about through two revolutions within the Industrial Revolution—those of power generation and distribution, and precision production manufacturing. Developments in the electrical industry liberated Henry Ford and his production experts from the constraints of mechanical power distribution. Earlier systems dictated where machinery was placed based on long straight runs of shafts and associated pulleys. Electric motors powering first groups and then individual machines enabled Ford’s engineers to position machine tools where the production process dictated. It was the incredible machines developed specifically for that process that were crucial to the speed and quality of Model T production.

Henry Ford and his assistants developed a system of mass production at Ford Motor Company’s Highland Park plant that was based on moving components through a refined sequence of manufacturing, machining and assembly steps. Launched in October 1913, Ford’s new system ultimately reduced the time of producing Model Ts from about 12½ man-hours to only 1½ man-hours.

Model Ts contained more than ten thousand parts. Ford’s moving assembly line required that each one of these parts be manufactured to exacting tolerances (the acceptable amount of variation) and be fully interchangeable with any other part of its kind. By organizing the automobile’s construction into a series of distinct small steps and using precision machinery, the assembly line generated enormous gains in productivity.

This is the only survivor of the vast range of custom-designed high-production machine tools used at Ford’s Highland Park plant. THF129616

Machines like this 1912 Ingersoll milling machine were crucial to the high production levels attained at Highland Park. Milling machines are machine tools that rotate cutters to plane or shape surfaces. Teams of Ford specialists collaborated with machine tool designers to develop and continually improve machinery for Highland Park, resulting in milling machines that were capable of undertaking highly accurate, multiple cutting operations on many components at the same time.

One of six similar machines in a careful arrangement of machine tools in Highland Park’s cylinder finishing shop, this planer-type milling machine – both a vertical and a horizontal miller – simultaneously milled the underside and main bearing holders of Model T engine blocks. Cutters on the horizontal spindle shaped the bearing holders, while large cutters on vertical spindles milled the bottom surface of the blocks flat. The machine could mill 15 engine blocks in one batch—loaded and unloaded by semi-skilled labor. The work was physically demanding, and while it did not demand the skills of a trained machinist, it did require dexterity and attention to detail in addition to stamina.

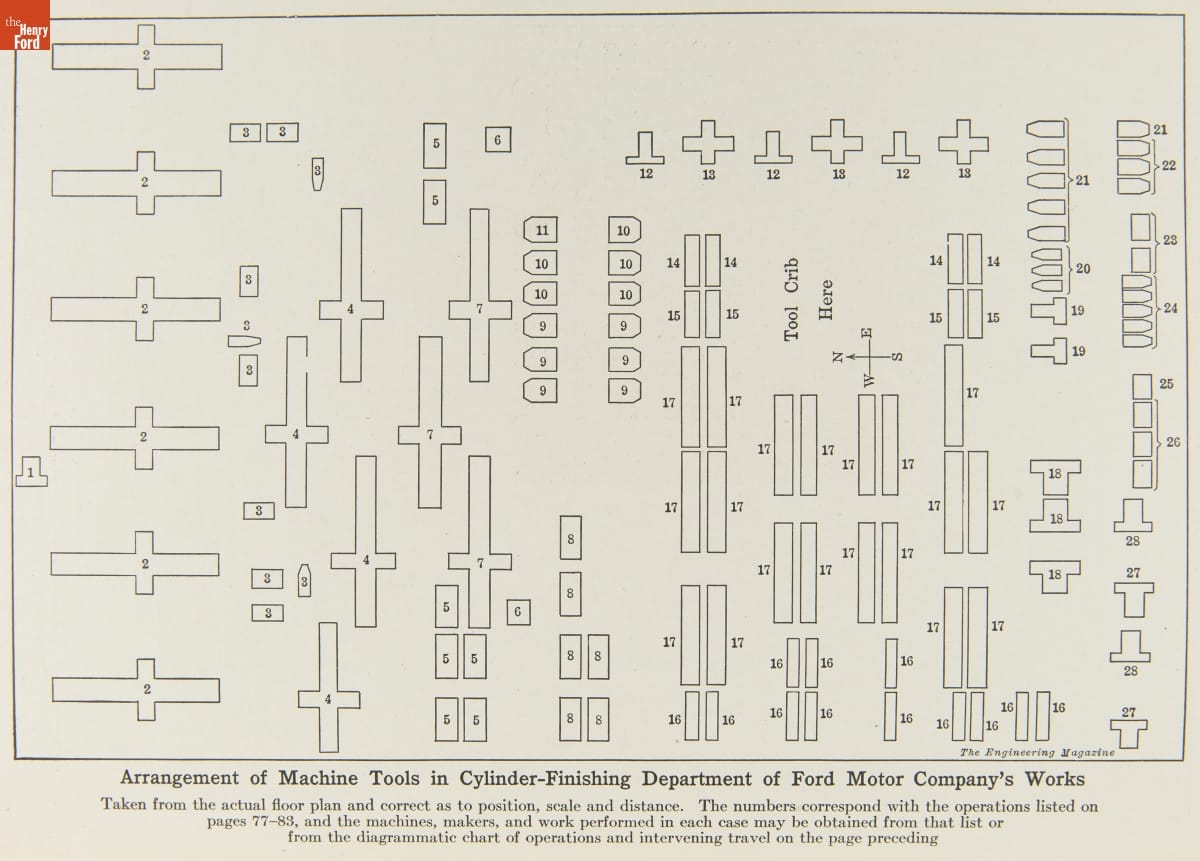

The Henry Ford’s Ingersoll milling machine is represented by one of the six horizontal cross shapes labeled #2 on the left of this diagram, which shows the arrangement of machine tools in the cylinder block machining shop at Highland Park. THF300582

The Ingersoll milling machine first arrived at Ford’s Highland Park plant in December 1912. It was just one of a vast range of new, specialized machines that enabled Ford to mass produce quality, affordable vehicles – and capture 50% of the American market! Today, it is exhibited in Henry Ford Museum of American Innovation as the only survivor of the custom-designed high-production machine tools used at Highland Park. Twenty-one feet long and eight feet high, the machine is an imposing presence and a compelling reminder of Ford’s moving assembly line—as important a development as the Model T itself.

Additional Readings:

- Steam Engine Lubricator, 1882- “Female Operatives Are Preferred”: Two Stories of Women in Manufacturing

- The Changing Nature of Sewing

- Collecting Mobility: Insights from Hagerty

Keywords | |

|---|---|

Themes |