Building and Operating a Highland Park Plant for the Digital Age

| Written by | Brian Wilson |

|---|---|

| Published | 11/22/2020 |

Building and Operating a Highland Park Plant for the Digital Age

| Written by | Brian Wilson |

|---|---|

| Published | 11/22/2020 |

Exterior View, Ford Highland Park Plant, 30 March 1932; Object P.833.56894.1 / THF237509

When Ford Motor Company engineers developed the assembly line at the Highland Park Plant back in 1913, they were seeking to increase production volume in order to provide more automobiles to the general public at a reasonable cost, and in a reasonable time.

Move ahead more than 100 years to 2020, where the staff of The Henry Ford and the Benson Ford Research Center (BFRC) are operating a modern assembly line to digitize images and documents from our collections and make them available online.

By some estimates, The Henry Ford holds roughly 26 million 2D and 3D objects, with the majority of that total – some 25 million items – contained within the archival collections at the BFRC. Clearly, there’s a lot to move down our “assembly line”!

As is the case with auto assembly, there are a number of stations along our line, beginning with material selection, then material retrieval, cataloging, imaging, storage, import, export, and finally ending with online display. Improvements made to the speed and efficiency at each of these stations can lead to gains in the production rate of the entire line.

This graphic shows where Rapid Capture imaging fits into The Henry Ford's overall digitization process.

To bring that speed and efficiency to archival imaging, the BFRC uses a process we refer to as Rapid Capture digitization. Developed by several institutions as an approach to increasing the scale of digitization, Rapid Capture is part technology, part process, and part philosophy.

Technically, Rapid Capture is rather simple. The equipment consists of a copy stand, lighting, a digital single lens reflex (DSLR) camera, and a computer equipped with photo editing software.

Rapid Capture station.

The important feature of the camera is its full-frame sensor, which can create a 400-pixel-per-inch image of an item as large as 9 × 14 inches, allowing us to provide users with high-quality images for the majority of our archival materials, which can be easily viewed, downloaded, and used for presentations or reports.

At the click of the shutter button, the camera can record an entire image – perhaps an 8 × 10 photographic print – without the cycle time of a more traditional flatbed scanner. If you’ve used a digital camera or a camera phone to take personal photographs, then you know how quickly you can take tens or even hundreds of snapshots. The same holds true for Rapid Capture, with the limit on imaging rate being the safe and proper handling of the archival material, not the time spent waiting for the scanner to make a pass.

On certain projects, we are able to capture both sides of a photographic print in less than 60 seconds, translating to nearly 500 prints imaged in a single day. Our flatbed scanner can produce 10-12 images per hour, or both sides of just 48 prints per day. Starting with a single Rapid Capture workstation in February 2011 and now utilizing two workstations, we have produced nearly 100,000 production images since the launching the process.

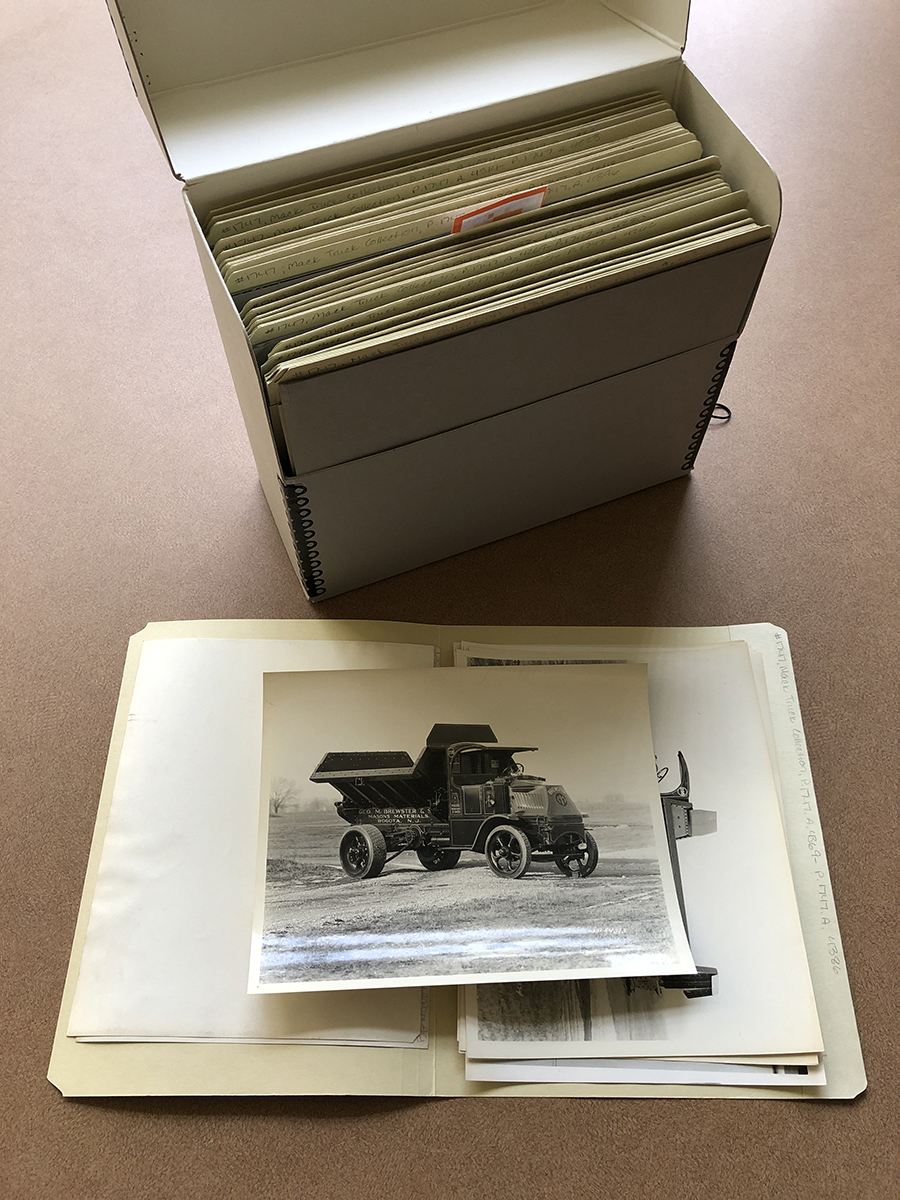

Process, or efficiency in process, is also an important part of Rapid Capture. For example, since material handling is one of the keys to the speed of Rapid Capture, we work to select and schedule material in groups having similar sizes or formats and that are located together physically, such as the box of 8 × 10 photographic prints shown below.

8 x 10 photographs from our collection foldered within an archival box.

Another example occurs in the post-processing of images, which can also be done in a batch manner, including exposure correction, cropping, and derivative image creation. By using automated scripts, much of this work can be done unattended, and in the case of large batches, performed in the overnight hours.

Finally, Rapid Capture is in some ways a philosophy. Rapid Capture puts a premium on user access to large numbers of images, and in doing so forces trade-offs in areas such as perceived image quality and image resolution. An example of this trade-off can be seen in some of our Rapid Capture images, which appear slightly tilted, such as this image from the Detroit Publishing Company Collection.

Railway Station at Haines Corners, Catskill Mountains, New York, circa 1902; Object P.DPC.014510 / THF204908

Rather than spend additional time on each image to create a perfect alignment, we’ve chosen to spend that additional time producing more images, with the assumption that you, our users, would want to see more “stuff,” and can accept some imperfection.

A second compromise involves image resolution. While the camera can produce images sufficient for online viewing and use in presentations, the images may not be adequate for advertising or commercial publication. We’ve accepted that a certain number of items may need to be reimaged at some point for publication use, but that the potential rescanning effort is outweighed by the ability to both produce and store more lower-resolution images.

Our implementation of Rapid Capture has proven to be very successful. In nearly 10 years of operation, we’ve created a large number of images that meet our goals for quality, usefulness, production time, and cost. And, as we celebrate our #digitization100K milestone of 100,000 digitized objects on our Digital Collections, we can also point to the more than 38,500 objects that are illustrated using Rapid Capture images as another measure of that success.

| The Henry Ford is facing unprecedented financial challenges due to the impact of our 16-week closure and reduced operations. We need your help in securing our future. Love the Henry Ford? Please support all that we treasure—including our digitization program. Longtime supporters of The Henry Ford will match your donation dollar for dollar, so your contribution will have double the impact. |

Brian Wilson is Sr. Manager of the Archives and Library at The Henry Ford. A version of this post originally appeared on The Henry Ford’s blog on February 9, 2012.

Keywords | |

|---|---|

Themes |