Posts Tagged #behind the scenes @ the henry ford

First Quarter IMLS Grant Update for 2023

To celebrate the completion of the first six months of work on our 2022-2024 IMLS Museums for America – Collections Stewardship Program, the Conservation staff are highlighting some standout objects we have cleaned and repaired. This grant began late last year as part of a two-year project to conserve, rehouse, relocate and create fully digital catalog records for 1,800 objects related to agriculture and the environment that have resided in the Collections Storage Building. Many of these objects will be used to support our Edible Education and Green Museum initiatives.

Stop by the back of the museum, near the steam engines, to get a peek through the windows of the Conservation lab and see what staff are currently conserving.

One of the first objects chosen for the grant was this entertaining dolphin-patterned culinary mold that received a thorough cleaning. The image above was taken during cleaning.

The inscription reads: “OF ALL Y FISHES IN Y SEA / I AM DOLPHIN EAT OF ME” / THF192318

This glass washboard was cracked in nine places and previously mended, but the glue was discolored from aging. The tin soap tray mounted in the wooden frame was corroded.

Continue Reading

Electric Mower with 74-Inch Cut Comes to The Henry Ford

The Henry Ford has a grounds crew that works year-round to keep the expansive lawns in tip-top condition. Green practices have driven much of the care from the beginning. The millponds in Liberty Craftworks and behind A Taste of History are all part of a natural water filtration system that allows residue to settle out of rainwater runoff before it enters the Rouge River. That’s just one part of water management at The Henry Ford, however, because that water is also reused to irrigate the lawns.

The irrigation system keeps the yards lush. Thus, mowing consumes many an hour in the grounds crew’s schedule. A grant from the Aptiv Foundation Inc. funded purchase of a new Evo electric zero-turn riding mower. The 74-inch width means the grounds crew can cut more grass in a day (and the battery will power up to 8 hours of work on a single charge).

Continue Readinglawn care, nature, Greenfield Village, by Debra A. Reid, #Behind The Scenes @ The Henry Ford

Lillian Schwartz Collection: Beginning the Journey

In 2021, The Henry Ford acquired the papers of noted computer-generated film and new media artist Lillian F. Schwartz as part of the larger Lillian F. Schwartz & Laurens R. Schwartz Collection.

The papers, perhaps the most complex set of materials ever brought into the holdings of the archives and library at The Henry Ford, contain multiple formats, including documents, graphics, audio, still and moving images, and books in both physical and digital forms.

In addition to the archival and library materials, the larger collection includes many three-dimensional items, such as sculpture, clothing, and large framed artworks, with our collections management and registrar staff being responsible for the care of those items.

The collection’s journey to the archives and library began by receiving the shipment into a large project area in Henry Ford Museum of American Innovation, and then unwrapping and unloading pallets.

Photo by Brian Wilson

Photo by Brian Wilson

Boxes were sorted so that we could check them against existing inventory lists and create additional inventories if needed. Any unlabeled boxes were given temporary paper labels so that they could be tracked.

As the inventories were reviewed, determinations were made about where materials would be stored in the Benson Ford Research Center (BFRC). Storage locations were specified based on the format of the material with, for example, film being placed in cold storage, and books being transferred to library storage.

Once we understood how much we had and where we wanted to put it, we began making shelf space in the BFRC. Many existing collections had to be relocated to create room, with location data for each of those collections requiring updates in our collections management system. In several cases, moving a collection required moving one, two, or three other collections to make efficient use of available shelving. In the end, we made 95 shelves and 16 flat file drawers available for the Schwartz papers. With each shelf being 40 inches wide, this added up to over a football field in length of shelving!

Photo by Brian Wilson

Photo by Brian Wilson

The newly cleared shelves and drawers were slowly filled with boxes and folders over several weeks as the materials were moved from the museum to the BFRC.

Photo by Brian Wilson

Photo by Brian Wilson

In addition to storing the physical materials, we’ve also been reviewing the electronic data included in the papers. Located on multiple “carriers,” including computers, external hard drives, and backup disks, the data includes thousands of text, image, and video files. We’re noting the type, storage size, manufacturer, and part and serial number for each carrier and have created disk images of the most recently used hard drive to improve access to and preserve that data.

Our next steps in this journey will be to expand and refine the original inventories by reviewing the entire collection in the BFRC box-by-box, folder-by-folder, and hard-drive-by-hard-drive with the goal of creating a single master inventory. This inventory will become the starting point for access to the papers for our staff and researchers.

Be sure to visit our Digital Collections to see items from the entire collection that have already been digitized, and contact the archives and library at research.center@thehenryford.org if you’d like more information on this collection—or any of the hundreds of others in our holdings.

Brian Wilson is Senior Manager of Library and Archives at The Henry Ford.

2020s, 21st century, women's history, technology, Michigan, drawings, Dearborn, computers, collections care, by Brian Wilson, art, archives, #Behind The Scenes @ The Henry Ford

Behind Every Object Is a Story

The author at his desk at The Henry Ford. / Photo by Jeanine Head Miller

I grew up on Detroit’s far west side, just north of Dearborn, during the 1950s and 1960s. History was always my favorite subject, and I fondly remember school field trips to what was then called Henry Ford Museum and Greenfield Village. I can trace my interest in American history to those visits and remember thinking how great it would be to work there someday.

I graduated from the University of Michigan at Ann Arbor in 1975 with a bachelor's degree in history. My original intention was to become a history teacher, but with teaching positions few and far between in those days, I ended up accepting a position in the mortgage department of Comerica Bank and stayed there for nearly 30 years.

I retired in 2008 and became a volunteer at The Henry Ford. After three years of doing computer data entry in the marketing department and helping at special events like Maker Faire, Old Car Festival, and Motor Muster, I met Jeanine Head Miller, Curator of Domestic Life at The Henry Ford. Jeanie was looking for a volunteer curatorial research assistant to work with her in the Historical Resources department. She was willing to take a chance on me, even though my professional life had been spent in banking, not historical research. The learning curve was steep, but with Jeanie’s knowledge and patience, I learned the ropes.

My primary focus as a volunteer has been to research the lives of some of the people who owned, made, or used the objects in The Henry Ford’s collection. Most of them were ordinary people, using these objects as part of their everyday activities.

Uncovering People’s Stories

I first look for clues in the object’s accession file—a file that contains whatever information we know about the object. Sometimes I find letters from the donor, often a descendent of the original owner, providing some family history and information about the maker or owner of the object, or how it may have been used. More often, though, there may be only a few clues—a name or a place. From these clues, I start my search to learn more about the background of the individual or family and the context of the object.

The advent of the Internet and genealogy websites like Ancestry.com—with access to census records, city directories, birth and death records, and other information—make researching the life of someone born more than a hundred years ago much easier. The census records are a particularly valuable tool in my research. They provide information about a person’s occupation, age, place of birth, marital status, immigration status, place of residence, home ownership, and more. The census also lists all the people living in the same home and their relationship to the head of the household.

Sites like Newspapers.com, with its access to many newspapers nationwide, can provide a wealth of information. I often find marriage and birth announcements, obituaries, and other information. Local historical societies are also a great research resource. I encounter other dedicated volunteers willing to search local records for information on people I am searching for—information not available online.

Conrad Hoffman’s Violin

Violin used by Conrad Ambrose Hoffman, 1793. / THF180694

A few years ago, The Henry Ford acquired a violin used by Conrad Ambrose Hoffman (1839–1916), a musician and teacher from Pontiac, Michigan. The violin had been made in 1793 by Czech violin maker Johann Michael Willer (1753–1826). The family not only donated Hoffman’s violin and bow, but also related archival materials, including concert programs, sheet music and librettos, calling cards, and stationery.

These materials helped provide some information about Hoffman. But further research in sources like Ancestry.com, Newspapers.com, and the Palmer Family Papers: 1853–1940 at University of Michigan’s Bentley Historical Library helped me enrich Hoffman’s story.

The United States census records for Conrad Hoffman revealed that he was born in New York in 1839, but moved to Oakland County, Michigan, with his family by 1840. His father, Ambrose D. Hoffman (1806–1881), made his living as a farmer and cooper. The 1870 census revealed that 31-year-old Hoffman was employed as a music teacher and was living at the family home in Pontiac, Michigan, with his parents and two sisters.

Most of the information I discovered about Hoffman’s life as a musician and teacher came from a biography that I found on Google Books, Biographical Sketches of Leading Citizens of Oakland County, Michigan, published in 1903. The account recalled Hoffman’s early interest in music, the musical abilities of his mother and sisters, and his study of the violin as a young boy—including his traveling to Dresden, Germany, to study music at the Dresden Conservatorium.

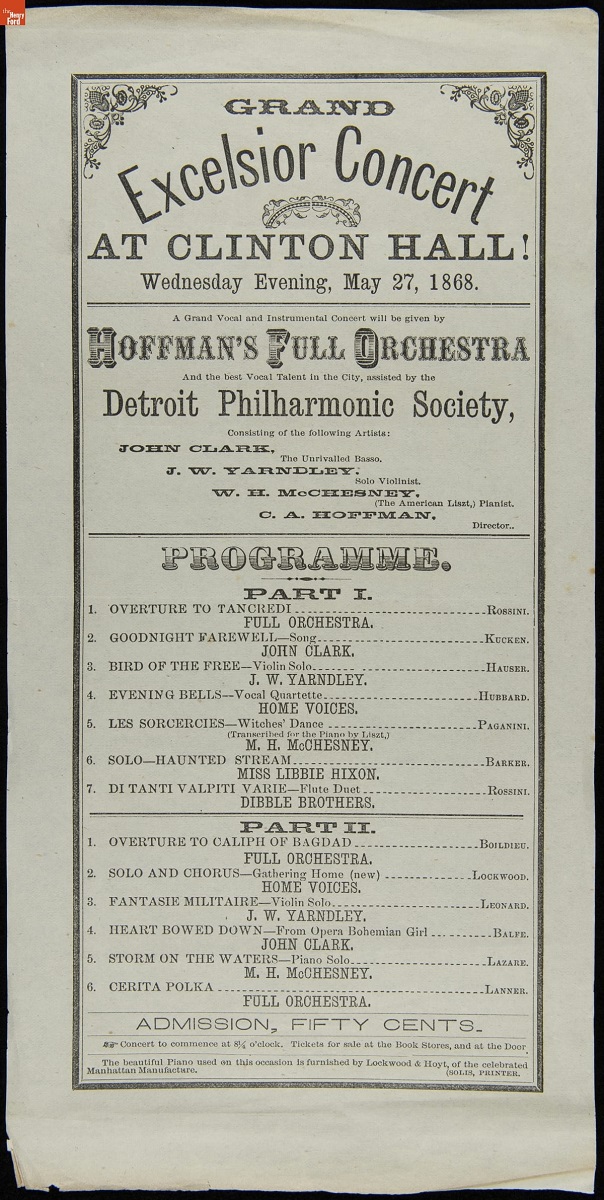

Hoffman and his orchestra performed at Clinton Hall in Pontiac, Michigan, on May 27, 1868. / THF279100

Hoffman’s biography also revealed that he served in the Union Army during the Civil War as a musician with the 15th Michigan Volunteer Infantry. In the years following the war, Hoffman organized an orchestra in the Pontiac area.

Conrad Hoffman performed at this concert at the Music Hall in Holly, Michigan, on May 24, 1866. / THF279106

Concert programs from the 1860s and 1870s document Hoffman’s performances in places like Birmingham, Holly, and Pontiac, Michigan. He performed as a solo violinist, as well as a conductor.

I discovered through a marriage announcement, published in the Detroit Free Press on September 25, 1900, that Conrad Hoffman married for the first time at the age of 60. His bride was childhood friend and pianist Philomela Cowles Palmer (1851–1930). Philomela was the daughter of Charles Henry Palmer (1814–1887) of Pontiac, an entrepreneur who was instrumental in helping develop Michigan’s copper industry.

Conrad Hoffman died in 1916. His obituary, found on Newspapers.com, was published in the Detroit Free Press on December 9, 1916. The obituary described Mr. Hoffman as a well-known violinist, the owner of a collection of old violins, and the instructor of several of the best-known Michigan violinists and violin teachers.

Audrey Wilder’s Dress

Audrey Wilder’s blue 1920s dress is second from the right.

In the fall of 2019, Jeanie Miller asked me to find out what I could about the life of Audrey Kenyon Wilder (1896–1979) of Albion, Michigan. Jeanie planned to use Wilder’s 1920s dress for an exhibit called What We Wore: A Matter of Emphasis in Henry Ford Museum of American Innovation. My task was to find out as much as I could about Wilder to help tell the story of the dress and the woman who wore it.

The donor correspondence in the accession file for Wilder’s dress provided just a few clues—her name and place of residence. I guessed Audrey Wilder’s birth date would be about 1900, based on the age of the dress. I was able to find four-year-old Wilder in the 1900 U.S. Census, living with her parents at the home of her paternal grandparents in Albion, Michigan. Her father was the owner of a lumber yard in Albion.

Yearbooks from high schools and colleges, which I found on Ancestry.com, provided information about Wilder’s education and career. I learned that she graduated from Albion High School in 1914, Albion College in 1918, and earned a master's degree from Columbia University in 1921. Wilder began teaching English at Albion College that same year.

In 1928, Audrey Wilder left Albion College to serve as Dean of Women at Ohio Northern University in Ada, Ohio. I was able to find an article written about her on Google Books, which shed some light on Audrey’s life and activities during this period of her life. The November 1935 issue of her college sorority newsletter, Anchora of Delta Gamma, published a story about Audrey’s life and career, entitled “Audrey Kenyon Wilder, Ohio Northern’s Dynamic Dean.” She is described as a woman “of exquisite grooming” and as having established the first social hall for women on the Ohio Northern campus, providing a setting for the female students on campus to hold teas, receptions, and co-ed dinners.

Dress owned by Audrey Wilder, 1927–1929 / THF177877

Tying an object to the story of its owner is the goal of my research. It is not hard to imagine Audrey Kenyon Wilder, the dynamic dean of exquisite grooming, attending a campus social function wearing the dress which is now part of the collection at The Henry Ford.

“Shopping” for the Collection

At times, I have assisted the curatorial staff in locating items for the museum’s collection. The curators identify a desired object and I then search eBay and other Internet sites to try to locate one in good condition. I then show the possibilities to the curator or curators, who select and acquire the object. These Internet sites make the search easier, but it often requires patient searching—sometimes for months.

Amelia Earhart brand overnight case made by the Orenstein Trunk Company, 1943–1950. / THF169109

One example is an Amelia Earhart brand suitcase. Earhart endorsed various products, including a line of luggage, in order to finance her aviation activities. I searched for six months and found one in like-new condition with the original price tag and keys! Though this example dates from the decade following Earhart’s disappearance, it attests to the staying power of the Earhart brand—this luggage line sold well for decades. This suitcase is on display in the museum’s Heroes of the Sky exhibit, in the section dedicated to Amelia Earhart.

I could not have asked for a more rewarding and interesting way to spend some of my time during my retirement years. I was finally able to find that “job” that I thoroughly enjoy and never get tired of. With millions of artifacts in the collection at The Henry Ford, there is always another life to explore and, for me, another adventure.

Gil Gallagher is Curatorial Research Volunteer at The Henry Ford.

Heroes of the Sky, women's history, Henry Ford Museum, What We Wore, fashion, Michigan, music, musical instruments, violins, The Henry Ford staff, #Behind The Scenes @ The Henry Ford, by Gil Gallagher, research

Moving and Reconstructing Firestone Farm

Firestone Farmhouse and Firestone Barn during reconstruction in Greenfield Village, December 1984. / THF118159

Two centuries ago, in the 1820s, Peter Firestone began the construction of his new farmstead in Columbiana County, Ohio. It eventually comprised a sturdy brick home, a very large barn, and several small outbuildings. The task took him, his family, and numerous local craftsmen many years to complete. The farmhouse alone is said to have taken four years; it is possible the entire complex may have taken as many as ten years.

When The Henry Ford acquired Firestone Farmhouse and Firestone Barn in 1983, the first challenge we faced was moving them to Dearborn, Michigan, from their original location in eastern Ohio—some 200 miles away. We decided the only feasible method was to completely disassemble the buildings, pack the materials into trailers, and transport them to Greenfield Village, where we would reenact Peter Firestone's feat.

Research and Disassembly

Our project commenced in April 1983, when an architectural recording team began to measure the structures to be moved and created drawings that would be used for their reconstruction. The team noted the condition of the buildings, researched their history, and began to develop theories about the changes the structures had gone through over the years. Armed with architectural plans and documentary evidence, we began a careful probing of the buildings to uncover information about their construction.

We took paint samples from wood surfaces and analyzed them microscopically to help identify layers of paint applied over time. We also removed brick and mortar samples for chemical analysis. At this time, we discovered former stair locations, old room partition placements, blocked-up doorways, and the remnants of a fireplace in the farmhouse. Our examination of the barn revealed much about its original form and the changes made to it in the early 20th century. Our team recorded the location of mortises for missing framing members and incorporated patterns of the original construction into the drawings.

In conjunction with this work, we conducted two other types of research—archeological research and architectural field research. Evidence from an archeological dig to locate outbuildings that had once been part of the historic farm proved inconclusive, but we did uncover a large quantity of artifacts that helped establish how the farmhouse had been furnished in the past. As part of our architectural field research, we surveyed more than 200 area farmsteads. After analyzing our material, we went back to conduct an in-depth study of 25 barns resembling Firestone Barn, as well as various other 19th-century outbuildings.

We began disassembling the structures by removing and numbering interior woodwork and doors, which were then packed into trailers. Our team removed plaster and lath from ceilings and partitions. Then, we took up floorboards from all three levels of the farmhouse, numbered them, and placed them into trailers. In this same way, all the elements of the farmhouse interior and roof were disassembled and readied for shipment to Greenfield Village.

Next, restoration specialists took apart the masonry structure of the farmhouse brick by brick. They cleaned the bricks onsite and packed them with straw in shipping crates. As the brick walls came down, we removed window and door units intact. Then, the masonry specialists prepared the farmhouse’s sandstone foundation for disassembly. They numbered each stone on the interior face (which had several layers of whitewash on it) and photographed each wall surface with its numbering pattern showing. As the masons removed the stones, they again numbered each one on its top bedding surface. The stones, too, were cleaned and packed with straw in crates, and the number of each stone was listed on the outside.

Masonry restorers removed each brick from the walls of Firestone Farmhouse. After being cleaned of excess mortar, the bricks were packed with straw in the crates in the foreground. / THF149938

The barn was stripped of its 20th-century additions, siding, and roof to expose the frame of the building for disassembly. The wooden pins anchoring each timber joint had to be driven out so that the posts and beams could be taken apart in the reverse order of their assembly. Prior to removal, each timber was numbered with a color-coded plastic tag that identified its location in the frame. Timbers less than 40 feet long were loaded into trailers. Those that were longer—for example, one floor support beam that measured 68 feet—had to be shipped on a special stretch trailer.

Disassembly of Firestone barn at its original site, Columbiana County, Ohio, 1983. / THF628361, THF628363, THF628367, THF628369

Discoveries

Each stage of disassembly yielded more information about the original construction and subsequent alterations of the buildings.

In the barn we discovered the original granary and hay chute arrangements. Analysis of historic photographs and field data brought to light the "drive-through" equipment shed/corn crib that had been almost obliterated by 20thcentury alterations. We also unveiled early 19th-century changes to the structure, including a tool and storage room on the second level and subdivisions of the stalls on the first level.

The farmhouse continued to divulge more of its secrets. Evidence of major interior and exterior renovations turned up daily, as we found reused materials from the original construction in every conceivable portion of the later construction.

This bedroom doorway, which had been closed off during Firestone Farmhouse’s 1882 renovation, came to light during the disassembly process. / THF149936

We made one very exciting find while moving a section of hand-decorated plaster ceiling above the central stairway. Attached to a framing member associated with the farmhouse’s renovation was a scrap of paper inscribed, “James Maxwell Washingtonville Ohio 1882 / Harvey Firestone Columbiana Ohio 1882.” Aged 12 and 14, respectively, these boys had left a "secret" message, and we had been the lucky finders. Census research established that James Maxwell was the son of a plasterer. He was probably helping his father with interior renovation for the Firestones. Since we knew from the account book of Harvey Firestone’s father, Benjamin, that the renovation of the exterior of the farmhouse had been accomplished in 1882, the note proved conclusively that the interior renovation had been done at the same time. This helped influence our choice of 1882 as the restoration period for the entire farm.

This hidden message enabled us to precisely date Firestone Farmhouse’s 1882 renovation. / THF124772

Firestone Farm in Greenfield Village

While all this work was taking place in Ohio, we transformed Greenfield Village in anticipation of the farm's arrival. Workers cleared a seven-acre area designated as the farm site for development. We moved six buildings to new locations in the Village; eliminated four non-historic buildings from the area; constructed three new buildings for behind-the-scenes activities to replace those displaced by the farm; and relocated a portion of the railroad tracks.

By the end of 1983, four trailers, two large stacks of over-sized beams, and no fewer than 250 crates of brick and stone were all onsite awaiting the spring construction season. While planning for the entire farm restoration continued, workers began to reproduce a substantial portion of the barn that had been lost to 20th-century alterations. We purchased white oak logs, and craftsmen began hand hewing and joining timbers to recreate most of the original ground-floor framing, which had been replaced by modern materials. This process alone, excluding the actual erection of the timbers, took four craftsmen nearly three months to accomplish. Later in the project, additional components had to be created to replace portions of two sheds initially attached to the main barn. These had been drastically altered for 20th-century farming needs. The upper portions of the barn required numerous replacements and repairs, though most of this part of the frame had been unchanged from its original construction.

In May 1984, we broke ground for the foundation of both the farmhouse and barn. Throughout the summer and into the fall, the masonry shell of the farmhouse rose slowly from the foundation toward the roof line, with windows, doors, and floor framing incorporated during the process. The task of restoring each basement stone to its original location and replicating the brick bonding was tedious and time-consuming. To replace damaged bricks, we manufactured replicas in three different shades to match the originals in color variation, as well as in shape and texture. The entire masonry shell of the farmhouse was finally completed late in the fall, just as plunging temperatures threatened to stop the project. Winter weather halted most outdoor activity, and a temporary roof was placed on the building until late the next spring.

Masons set the transported stones back into Firestone Farmhouse’s new foundation. Here, the author assists by referring to composite photographs of each of the basement walls. / THF149926

The largely reproduced lower frame of the barn was erected in the summer, with repairs and minor replacements to the large upper section of the building continuing into the fall. After trial-fitting and adjusting individual portions of the upper stories, workers reassembled them in sections called “bents.” Each bent was lifted into place, then connected to another by struts and top plates to create the full frame. The erection process for the three-tier main frame lasted until December, when production of the attached sheds began. We completed roofing and siding of the main barn in the winter months as work on the remaining portions of the sheds moved offsite and indoors to escape the cold weather.

The author in May 1985 with a portion of the scale model constructed to assist in the restoration of the barn. The ramp side of the nearly completed barn is in the background. / THF149932

We restored the interior of the farmhouse during the first four months of 1985, placing each numbered floorboard, wall stud, wall plank, and door or window trim piece in its original location. At the same time, we repaired or replaced damaged materials using the same type of materials in the original construction. We applied new plaster to lathed stud walls and ceilings, as well as to the brick walls of the interior, then reinstalled additional trimwork that had covered the old plastering. Finish work then began on the interior surfaces of the farmhouse in preparation for whitewashing, painting, and papering. Carpenters moved outside at this time to restore the three porches that had been built in 1882. We finished painting the exterior in early June 1985.

With the coming of spring, we resumed outdoor work on the barn. We completed the attached sheds and massive stone ramp that leads to the upper floor of the barn, then moved our work inside. We attached plank floors with wooden pegs in the threshing area; restored the granary and tool room; and placed packed earth floors in the animal stall area on the ground level. We constructed new doors based on historic photographs, field studies, and an extant door—one of three types used for the barn.

The restoration of the farmhouse and barn did not represent a complete recreation of the Firestone farm. Additional elements helped establish the environment of an operating farm of the 1880s. We reproduced a pump house next to the farmhouse using historic photographs, archeological evidence, and field research data. We also acquired a period outhouse in Ohio, restored it, and placed it in the yard behind the farmhouse. We then erected a chicken house—modeled after examples shown in agricultural literature of the period—adjacent to the barn, as well as a fence enclosure for hogs. To complete the experience, we built more than 7,000 linear feet of fencing to match historic photographs of fields at the farm’s original site.

Over a period of almost two and a half years, we moved the Firestone farm from Ohio to Michigan and meticulously and accurately restored it to its physical condition of a century earlier. The process required an understanding of the historical record, the careful handling of tens of thousands of historic architectural objects, and the reproduction of thousands of missing elements. It may not have equaled Peter Firestone's feat 160 years earlier, but it did honor his effort, as well as that of the millions of 19th-century farmers who contributed to our country's agricultural heritage.

Blake D. Hayes is former Conservator of Historic Structures at The Henry Ford, including during the move and reconstruction of the Firestone farmstead. This post was adapted by Saige Jedele, Associate Curator, Digital Content, at The Henry Ford, from an article in Volume 14, Number 2 of the Henry Ford Museum and Greenfield Village Herald (1985).

Ohio, 1980s, 20th century, research, Greenfield Village history, Greenfield Village buildings, Greenfield Village, Firestone family, farms and farming, conservation, collections care, by Saige Jedele, by Blake D. Hayes, #Behind The Scenes @ The Henry Ford

The Henry Ford’s Innovation Nation: 200 Episodes and Counting

During the filming of a segment on tintype photography in September 2019, the film crew of The Henry Ford's Innovation Nation had their own tintype taken in Greenfield Village. / THF141945

This week, we are happy to celebrate the 200th episode of our television show, The Henry Ford’s Innovation Nation! In honor of this milestone, we wanted to share some fun trivia that even our superfans might not know, reveal some of the behind-the-scenes work that goes into the show, and point viewers to additional resources to allow them to further explore the buildings, artifacts, and stories shared on each and every episode.

When did The Henry Ford’s Innovation Nation first air?

Patricia Mooradian, President & CEO of The Henry Ford, first announced the new show on June 4, 2014. The very first episode aired on CBS that fall: September 27, 2014.

What was featured on the very first episode?

The first episode featured a special steering wheel to prevent distracted driving, the ways in which drones are becoming part of our everyday lives, micro windmills, and The Henry Ford’s own Menlo Park Laboratory, where Thomas Edison once worked. Check out the trailer for the first episode below—or watch the whole episode for free (and without an account) on PlutoTV.

Continue Reading

TV, by Ellice Engdahl, #Behind The Scenes @ The Henry Ford, The Henry Ford's Innovation Nation

Reading an Artifact: The Reconstructed Detroit Central Market Vegetable Shed

Panoramic view of the reconstructed vegetable shed from Detroit Central Market on April 10, 2022. The entrance that originally faced south is front and center in this view. / Compiled from two photographs taken by Debra A. Reid

Panoramic view of the reconstructed vegetable shed from Detroit Central Market on April 10, 2022. The entrance that originally faced south is front and center in this view. / Compiled from two photographs taken by Debra A. Reid

The vegetable shed from Detroit Central Market, opening this week in Greenfield Village, provides the perfect opportunity to be a building detective! You can practice your powers of observation as you explore this open-sided structure. In the process, you can become a more informed observer of the built environment around you.

The following highlights should whet your appetite to learn more about this “shed.” Originally, it sheltered vendors who helped feed hungry Detroiters for more than 30 years, from April 1861 to February 1894. Then it spent 110 years on the upper end of Belle Isle sheltering horses, operating as a public riding stable, and as a storage facility for the City of Detroit. The Henry Ford acquired it in 2003, saving it from demolition. Then, between 2003 and 2021, we conducted research and raised funds to reconstruct it in Greenfield Village. Now you can explore the reconstructed Detroit Central Market shed starting its new life in the heart of Greenfield Village.

Is This Building a Reconstruction?

Rudy Christian, a traditional timber-frame expert and principal of Christian & Son, Inc., describes the Detroit Central Market shed as a reconstruction. He bases this on his experiences dismantling the structure in 2003, advocating for use of original materials and prepping the timber-frame elements, and reassembling the roof system during reconstruction in Greenfield Village during 2021.

The Secretary of the U.S. Department of the Interior (DOI) first defined “reconstruction” in 1978 as “the act or process of reproducing by new construction the exact form and detail of a vanished building, structure, or object, or a part thereof, as it appeared at a specific period of time” (Federal Register, Vol. 43, No. 236, December 7, 1978, page 57251). You can read more about the DOI’s standards for the treatment of historic buildings and landscapes here, including more about reconstruction and the other three standards: preservation (when the property retains distinctive materials and thus conveys historic significance without extensive repair or replacement), restoration (removal of features to return a property to an appearance of a particular time in the past), and rehabilitation (retention of a property’s historic character, but modifications may occur given ongoing use).

What Percentage of the Building Is Original?

The Detroit Central Market vegetable shed, while “new construction,” is authentic because of the significant percentage of original material incorporated into the reconstruction. Fifty percent of the columns (16 of 32) are original. The 16 originals are distinctive because of acanthus-leaf details on the bases, a spiral design, and capitals onto which cast S-scroll leaf ornaments are mounted.

Architectural S-scroll leaf ornament from the Detroit Central Market, 1860. / THF177806

These original cast-iron columns, however, are brittle. It is impossible to calculate their tensile strength—that is, the maximum stress that the cast iron can stand when being stretched or pulled before breaking. Modern code requires structural materials to meet tensile-strength specifications. This posed a significant challenge.

How Can We Meet Modern Building Codes with an Historic Structure?

The facilities team at The Henry Ford contracted with O’Neal Construction, Inc., of Ann Arbor, Michigan, on the reconstruction of the Detroit Central Market building. They were involved in all phases of the planning process and oversaw reconstruction from 2021 to its completion. The team considered different options to support the building, but ultimately selected an innovative solution that exceeds code requirements. In effect, the solution involved flipping the structural support upside down.

Alec Jerome, Director of Facilities at The Henry Ford, explaining the invisible framing system that anchors the vegetable shed on August 26, 2021. / Screenshot from THF Conversations: A Market Shed in its 160th Year

Ensuring guest safety required construction of an underground “moment frame” that anchors the structure and prevents it from acting like a huge umbrella on a windy day. The above screenshot shows the system of rebar that runs between the 48-inch-deep footers. The footers extend up to octagonal bases, or piers. These footers also accommodate modern infrastructure—specifically, electrical conduit that runs underground and up into the piers. All 32 columns are attached to the individual piers with anchor bolts, but 16 of the 32 columns are steel and specially designed extensions of the moment frame. As a whole, the moment frame ensures that the structure will remain on the ground and standing in perpetuity.

The entrance that originally faced north on April 10, 2022, now behind Hanks Silk Mill in Greenfield Village. There are original columns at both sides of the side-entrance gable, but rows of specially designed columns, integral to the moment frame, visible to both the left and right of this side-entrance. / Photograph by Debra A. Reid

The 16 new columns are distinctive from the originals in several ways. They are smooth, not spiral. They have fluted gussets (brackets) at the top, instead of capitals. Finally, they are larger in diameter than the originals. These distinctions make clear which columns are original and which are not, to inform guests of the innovation required to ensure their safety.

How Does the New Footprint Compare to the Original?

What was originally the west entrance, now facing State Street in Greenfield Village, on April 10, 2022, with original columns as well as additional columns installed in two rows in front of the structure. This gives guests a better impression of the original building footprint, though an additional eight columns would be required to mimic the full original size of 11 bays and 242 feet in length. / Photograph by Debra A. Reid

The reconstructed vegetable shed is 7/11ths as long as the original. Why 7/11ths? The original structure was three bays wide by eleven bays long. A bay is the space between architectural elements. You can see the eleven bays visible on the south side of the structure in the detail below from a late-1880s photograph—five bays from the east-facing entrance to the south-facing entrance, with that entrance bay being the sixth bay, and then five bays beyond it to the west-facing entrance (less easy to see given the perspective). The Central Market building towers in the distance.

Detail of the vegetable shed from the Detroit Central Market, circa 1888. / THF200604

The reconstructed Detroit Central Market vegetable shed in Greenfield Village includes only seven of the eleven original lengthwise bays—three on each side of the side-entrance bay. Thus, the reconstruction is 7/11ths the length of the original. Jim McCabe, former collections manager and buildings curator at The Henry Ford, deserves credit for this specification, as he spent nearly two decades working on the project between 2003 and 2022.

The reconstruction is true to the width of the original, three bays total—one on each side of the central entrance, which is also a bay. You can see these bays most clearly in this July 6, 2021, photograph below, showing columns in place and the roof structure in process.

Detroit Central Market reconstruction in process on July 6, 2021, showing the three-bay width and the seven-bay length. / Photograph by Debra A. Reid

How Much of the Timber-Frame Roof Is Original?

The timber-framing system is clearly visible inside the structure. Just walk in and look up! Approximately 80% of the original old-growth white pine was reused in the reconstruction. This resulted from careful detective work during the quick dismantling process.

The Henry Ford contracted with Christian & Son, Inc., to number and measure the original structural and decorative woodwork elements, photograph them, and prep the material for storage. Then we contracted with Jeff DuPilka and West Shore Services, Inc., to disassemble the structure. West Shore, Christian & Son, and staff from The Henry Ford accomplished this in 10 to 12 weeks during the summer of 2003.

Woodwork in one of four outside corners, original to the vegetable shed at Detroit Central Market and still intact after it served as the riding stable at Belle Isle, Detroit, Michigan (photographed in 2003). / THF113493

Christian & Son, Inc., documented all original wooden elements, including those in the section of the building that was fire-damaged due to a car wreck (visible in the photograph below). They believed that documenting the whole required documentation of all parts, so they took as much care tagging, measuring, and dismantling this burned section as they did with the other sections. In fact, timbers from the charred section were reused in the reconstruction and are visible on the exterior of the originally east-facing entrance (the entrance now facing the Detroit Toledo & Milwaukee Roundhouse in Greenfield Village).

West Shore Services, Inc., crane in action, removing a piece of the original timber-frame roof system from the former riding stable (and originally the Detroit Central Market vegetable shed) on Belle Isle, Detroit, Michigan, 2003. / THF113575

What Are Some Notable Details?

The reconstruction of the Detroit Central Market vegetable shed in Greenfield Village includes ornamental woodwork throughout. The following rendering by architecture firm Quinn Evans itemizes seven distinctive brackets, each designed for a specific location in the building, and one “drop,” an accessory at all four gable entrances and used with the decorative fascia along the eaves.

Decorative wood details of the Detroit Central Market vegetable shed, prepared by Quinn Evans, Ann Arbor, Michigan, for The Henry Ford. / Courtesy of The Henry Ford’s facilities team

These decorative elements were all hand-carved during the original construction in 1860. Not all of the decorative elements survived the move to Belle Isle. The elaborate crests atop each of the four gable entrances on the Detroit Central Market vegetable shed, for example, were not included when it served as the horse shed on Belle Isle, as the illustration of it in Seventy Glimpses of Detroit indicates. Missing pieces were replicated to complete the structure’s appearance during its heyday as a public market.

Jim Johnson, Director of Greenfield Village & Curator of Historic Structures and Landscapes at The Henry Ford, starting to inventory architectural elements from the Detroit Central Market vegetable shed not used in the reconstruction, February 8, 2022. / Photograph by Debra A. Reid

What Style Is the Building?

Each of the ornamental elements was part of a stylistic whole that the reconstruction faithfully conveys. If it reminds you of a Swiss chalet, you have an astute eye for style. John Schaffer, the architect, trained in Munich, Bavaria, and incorporated Schweizerstil (Swiss-chalet style) details into his plans, drafted in 1860. Thus, this structure likely introduced that aesthetic to Detroiters. His plans included gently sloping gabled roofs with wide eaves, large brackets, and decorative fretwork, all details common to Swiss-style architecture. Additional Swiss features included sawtooth siding, scroll-sawn fascia, and the elliptical design of the siding at each gable-end.

The Detroit Central Market vegetable shed has so much to teach. Learning to read the details of this addition to Greenfield Village is an important first step on the journey. Learn even more by checking out additional blog posts and artifacts related to Detroit Central Market.

Debra A. Reid is Curator of Agriculture and the Environment at The Henry Ford. Comments from Rachel Yerke, Curatorial Assistant at The Henry Ford, improved this post.

Additional Readings:

- Farmers Market

- Bring the Detroit Central Farmers Market to Greenfield Village

- Detroit Central Market Coming to Life

- Greenfield Village Reopens for 2022 Season April 16 with First Permanent Addition in More Than 20 Years

#Behind The Scenes @ The Henry Ford, collections care, making, design, Michigan, Detroit, Detroit Central Market, by Debra A. Reid, Greenfield Village buildings, Greenfield Village

The Hidden Painting of Robert Frost Home

Unknown artist, “Lady in a Lace Bonnet,” located in Robert Frost Home in Greenfield Village, before conservation. / Photo by Marlene Gray

The same painting, after conservation. / Photo by Marlene Gray

It is that time again, as Greenfield Village opens this week for another exciting season! While you were away, staff at The Henry Ford have been busily cleaning and repairing objects throughout the village buildings. During the winter months, conservation staff move artifacts in need of repair back to our labs for a bit of TLC. Some of these objects are on full display while others hardly ever get the spotlight. One of the latter objects is a painting rarely seen by visitors.

View of Robert Frost Home with the parlor on the right. / THF1883

Within the Porches and Parlors district of Greenfield Village is the home of American poet Robert Frost. Originally located in Ann Arbor, Michigan, the house was moved to the village by Henry Ford in the 1930s. As you enter the house, a parlor is on the immediate right. If you look inside on the left, you will see a frame on the wall. There hangs a portrait of a woman, “Lady in a Lace Bonnet.” During routine maintenance, our dedicated clean team noticed the painting had some paint losses, which you typically find with old paintings. The paint losses at the top and bottom of the painting were the most obvious. These types of losses can occur when the painting is roughly handled during framing.

Image courtesy of clean team member Teresa McCloud, who noted the damage.

Conservation staff then brought the artwork to the lab to give this hidden painting some much needed attention. Once the painting was removed from the frame, the next step was a good cleaning. Paintings trap abrasive dust and debris, both on the canvas behind and the painted surface. After vacuuming to remove the larger debris, a very mild cleaning agent was used to remove the surface grime collected over the years. What a drastic change that made!

Grime cleaning, with right side cleaned. / Photo by Marlene Gray

Still, the portrait had a yellow tint, visible in the sitter’s face, which is a tell-tale sign of an aged varnish. Various solvents were tested to see what worked best at removing the old varnish, and we selected one that did not cause harm to the paint surface. After the varnish was removed, the portrait looked much brighter and fresher.

Varnish removal, with left side cleaned. / Photo by Marlene Gray

Once our lady was cleaned, it was time to tackle the paint losses. Color-matching the surrounding paint is tricky and takes patience to get right, but when we do, it is so rewarding to see the complete image. Last but certainly not least, a new coat of varnish with stabilizers that resist the harmful effects of ultraviolet radiation was added to protect the painting from light from the window on the other side of the parlor.

After securing the painting back inside the frame (being sure not to scratch the surface), we whisked it back to Frost home, tucked into its “hidden” spot. Now you know what hangs on the wall, and you may even be able to get a little peek from outside the parlor window on your next visit. The lady will be happy to show off her fresh appearance!

“Lady in a Lace Bonnet” returned home. / Photo by Marlene Gray

Marlene Gray is Senior Conservator at The Henry Ford.

collections care, conservation, Greenfield Village buildings, Greenfield Village, #Behind The Scenes @ The Henry Ford, by Marlene Gray, art, paintings

Ackley Covered Bridge in Greenfield Village. / THF1914

Guests visiting Greenfield Village in the spring of 2001 encountered a newly transformed Ackley Covered Bridge. The landmark structure—one of the most recognizable, most photographed sites on the grounds—had been completely repaired and restored. While the bridge’s resurrection may have seemed to have happened miraculously, it was—as with all our restoration efforts—the result of meticulous planning and careful completion of a well-defined project.

Originally constructed in 1832 in southwestern Pennsylvania, the single-span, 80-foot bridge’s design dates back to 16th-century Italy and was adapted in a uniquely American way in the early 1800s. It is referred to as a multiple kingpost truss: a series of upright wooden posts, with all braces inclined from the abutments and leaning towards the center of the “kingpost.”

Ackley Covered Bridge was originally a community project, built by more than 100 men on land owned and with materials donated by brothers Daniel and Joshua Ackley. By the mid-1930s, it had fallen into serious disrepair, and when a modern bridge was constructed to replace it, the granddaughter of one of the builders purchased the hundred-year-old Ackley structure for about $25 and donated it to Henry Ford.

Views of Ackley Covered Bride on Wheeling Creek near West Finley, Pennsylvania, 1937. Browse more photos of the bridge on its original site in our Digital Collections. / THF235241, THF132888, THF235221

Simple and classic in its construction, the bridge was dismantled at its original location in late 1937 and shipped by rail to Dearborn. Modifications were made to ensure its longevity, and a number of basic preservation chores were undertaken in the six months between its arrival and the completion of reconstruction in July 1938. (You can view photos of the bridge’s reconstruction and dedication in our Digital Collections.)

Ackley Covered Bridge after reconstruction in Greenfield Village, June 30, 1938. / THF625902

“Even in the 1930s, the Ackley Covered Bridge was clearly an architectural treasure, and Ford and his designers knew its importance and placed it at the heart of the Village,” said Lauren B. Sickels-Taves, architectural consultant for the restoration project. The bridge was back in its prime, spanning a pond designed specifically for it.

Taking photographs near Ackley Covered Bridge in Greenfield Village, 1958. / THF625878

“Unfortunately, the pond was standing rather than flowing water, and the water level had the ability to rise and fall,” she said. “The chords and four end trusses of the bridge (basically, its feet) were exposed to extreme wet/dry cycles, and rot was imminent. By 1974 the bridge was structurally unsound, and dangerous.”

While repairs were undertaken then, nothing was done to regulate the level of the pond, and by the spring of 1999, one truss end was found to be rotting. Closer examination revealed that the bridge was once again structurally unsafe.

Alec Jerome, then part of the facilities management team he now leads at The Henry Ford, was designated as project leader to bring Ackley Covered Bridge back to stability. David Fischetti, a historical structural engineer from North Carolina with a background in covered bridges, was brought in to develop a plan to properly restore the bridge, and Arnold Graton of New Hampshire, one of the country’s leading covered bridge timberwrights, was selected to lead the stabilization and restoration work.

“First,” said Jerome, “the pond had to be drained to expose areas that needed repair. The conditions that we discovered led to some serious revisions in our original project plan—every beam touching the ground was rotting and needed to be replaced.”

Views showing restoration of Ackley Covered Bridge in Greenfield Village, September and October 2000. / THF628587, THF628611, THF628525

The dry rot portion of the original trusses was removed and new support beams were spliced on. The refurbished trusses were then seated on stainless steel plates to prevent moisture from wicking up into the wood. Also, a turnbuckle system was implemented in the upper beams of the bridge, which had become separated over time, to ensure stability. Many of the connectors holding the bridge beams together were replaced, and ultimately a bolster was laid to eliminate any conditions that would promote rot in the floor beams and allow that devastating wet/dry cycle of rot to begin again.

“Our main concerns were the extensive amount of rot over and above the original expectations, the short time period between Village programs in which we had to complete the work, and weather conditions getting in our way,” Jerome said. Work began the day after Old Car Festival in September, and lasted through the day before the start of the evening program, The Legend of Sleepy Hollow, the second week of October. “The project could not have been completed without the assistance of the Museum’s carpentry department and our welder,” Jerome said. “These people assisted with every facet of this restoration.” See more photographs from the restoration project in our Digital Collections.

According to conservator Sickels-Taves, research determined that Ackley Covered Bridge was the oldest multiple kingpost truss bridge and the sixth-oldest covered bridge in the nation. While the cost of its restoration after a century and a half of decline was substantial, its preservation for the future was priceless—without such key commitments of resources, important structures like Ackley Covered Bridge would be lost forever. “The bridge is unquestionably important,” Sickels-Taves said. “We should be proud, and not hesitate to brag that we are the steward of one of the earliest forms of original American architecture.”

A version of this post originally ran in the Spring/Summer 2001 issue of The Henry Ford’s former publication, Living History. It was edited for the blog by Saige Jedele, Associate Curator, Digital Content, at The Henry Ford.

roads and road trips, Greenfield Village buildings, Greenfield Village, collections care, by Saige Jedele, Ackley Covered Bridge, #Behind The Scenes @ The Henry Ford

Discovering the Secrets of a Suit

Men’s Suit, circa 1800. / THF29848

Textiles are some of the least durable artifacts that we have in the collections of The Henry Ford. Early textiles are usually made from the “big four”—cotton, linen, silk, and wool. All these materials can disintegrate, be eaten by insects, make homes for mice, and be degraded by mold and mildew. In addition, heat and light affect the color and the integrity of the fabrics. Here at the museum, we are fortunate to have a representative sampling of garments and textiles from the 18th century to modern times.

What We Know about Our Suit

Even though we don’t know who wore the suit or exactly when, it still directs us to a point in time.

This suit has no known provenance (specific history), having been acquired from Anna Brix, an antiques dealer who lived in Philadelphia. The suit is believed to be French or British, but we have no records linking it to a person or even a family. We don’t know exactly when it was made, but this style lasted through the 18th century. By comparing it with similar garments, we can agree that it was probably worn for the first time in the late 18th century. We can tell it is a late-18th-century jacket because the fit is slim, the front is worn unbuttoned and curves to the back, and overall the cut is shorter than in previous decades. It was likely worn to court, or at least to very formal occasions. A suit such as this would have been worn with a highly decorated waistcoat, silk stockings, a cotton or linen shirt with fancy cuffs, and a jabot (frill or ruffle). The back has dual tails and three vents, making it easier and more stylish to wear when mounted on a horse. The colors are all natural dyes and have held up well with age.

Close-up of embroidery. / Photo by Joan Sheridan

The Making of the Suit Coat

Suits such as this were made to attend court and other high occasions, often mere days before they were needed. Hence, the use of embroidered panels, which reduced the time the tailor needed.

Embroidered panel for a different waistcoat, uncut. / From the collections of Cooper-Hewitt, Smithsonian Design Museum (1962-54-31)

The coat is made of silk taffeta and was embroidered before the suit was made with silk threads using French knots, satin stitch, and stem stitch. Well-to-do men would visit a merchant to select a color and embroidery pattern, often from the shelf. The merchant would then coordinate with a tailor to custom-make the suit. The embroidered fabric, shown in the example above, even included embroidered rounds that would be crafted into fabric covered buttons by the tailor.

Showing cut to shorten jacket at the top right of the pocket. / Photo by Joan Sheridan

The embroidered silk was originally made for a taller man than ours. If you look carefully at the image above, you can see where the embroidery was shortened at pocket height. It is blunt cut—sometimes the embroiderers were brought in to camouflage the adjustment and make it less visible, but not in this case. This is the normal position for a height adjustment, as when the wearer stood with their hands clasped in front of them, the seam was covered.

Embroidery on buttons on back of coat. / Photo by Joan Sheridan

Additional piecing is visible on the back of the garment at the top of the side vents where curved embroidered pieces back the accent buttons.

Discovering the Secrets of the Suit

Being able to look closely at the suit, both inside and out, was a rare treat.

Markings from original button placement are visible above top of cuff; also, the slightly lighter color of silk shows the depth of lengthening. / Photo by Joan Sheridan

Upon closer examination, the outside of the suit tells us even more. The jacket sleeves have been made about two inches longer. There is less wear above the cuff and pin pricks can be seen where the buttons were originally located. It is interesting that the cuffs both show significant wear at the bottom from before and after remodeling.

The knee breeches were refitted to accommodate a larger person. Each side seam was let out, and there, similar to above the coat cuffs, you can see lighter silk with less wear. Finally, the back of the breeches have a wedge of silk inserted to give more room. Small areas of stress at the waist and the drop flap were mended to provide strength, but the breeches are in good condition structurally.

Weighted Silk Is Fragile

Silk has a long and harrowing history, and this suit is a good example of why the use of weighted silk has been greatly reduced in the last century.

Shattered silk at the right shoulder and collar. / Photo by Joan Sheridan

We estimate that the coat was relined in the mid-to-late 1800s, as the lining was shattered throughout because it was made using weighted silk. Then and now, silk was sold by weight. When raw silk is processed, up to 30% of its weight is lost when the sericin (the protein that holds silkworm cocoons together) is cleaned from the tough but delicate fibers. Manufacturers compensate for that loss by adding metal salts to the silk, which adhere to the fabric, causing it to weigh more. What they didn’t know then is that this will forever damage the fabric. Shattered silk cannot be repaired and continues to disintegrate with age. The practice of weighting was regulated by the Federal Trade Commission in 1938 to require labeling of silks containing more than 10% metal salts (15% for silk colored black).

The suit’s shattered lining was in poor condition (see image above) and we decided that it should be replaced with modern, non-weighted silk in a matching color. This also allowed us to see what was inside the garment—where the story continues.

A Rare Treat: Viewing the Inside

Seeing the internal structure produced answers and questions.

A quilt of patches, buckram, and pocket provides insight into the speed with which the coat was made. / Photo by Joan Sheridan

Suits such as these were often hastily made. The outside was sumptuously beautiful with even, neat stitches, but the inside, not so much! The inside would never be seen.

It took many hours to extract the lining from the suit. The stitches that attached the lining to the coat were exceptionally fine and firm. Removing them took small scissors, tweezers, and, at times, a magnifying glass. With the lining separated from the jacket, more interesting things were revealed. It isn’t often that you get to see the original inner-workings of an 18th-century tailor’s creation (see image above).

Mildew and fibers from wear prior to vacuuming. / Photo by Joan Sheridan

One thing that was immediately noticeable was that the light blotches on the outside of the garment were caused by mildew. At some point, the suit was stored in a humid environment. The mildew was an old problem, since our museum storage is climate controlled, but the residue still had to be removed. Since a liquid cleaner could not be applied to the silk, the inside of the coat was vacuumed through a screen, then a stubby paintbrush was used to lift mildew spores before vacuuming again. This treatment made a noticeable difference in appearance.

Buckram stiffens the inside of the front of the coat. / Photo by Joan Sheridan

Inside we see the use of buckram as a stiffener around the edges of the front, much as interfacing would be used today. Buckram was and is made of a coarse hemp, linen, or cotton fabric. The buckram was pieced, perhaps because it was scraps, or perhaps that was how wide the fabric was. Cream-colored silk had been sewn over the buckram from the pocket level to the collar, possibly to reduce friction between the silk and the stiffening fabric (see below).

The left shoulder linen tow shoulder pad covered with the original silk. / Photo by Joan Sheridan

Linen tow was used as padding to create the sloped shoulder shape popular in the late 18th century. This linen waste is full of bits of the stem of the flax plant and it has held together and done its job for over 200 years. The tow was—and is—partially covered by the original white silk lining.

A History Mystery

Anytime we deal with historic objects, there are often more questions than answers. It is interesting to try to suss out the “why?” and apply what we know to arrive at possible solutions. However, some mysteries will always remain mysteries.

Squiggles on the right pocket—partially for mending, but they beg the question, why? / Photo by Joan Sheridan

The stitching used inside the coat is often coarse. A larger thread was used to bind seams, keep the shoulder pads in place, and attach silk to the buckram. Inside is a patchwork of fabric. The linen pocket linings revealed another interesting find. Both pockets had holes that were inexpertly darned with a snakelike pattern that continues from the darning. We can surmise that the original wearer of the suit was right-handed because the right pocket is very stained—by tobacco or a handkerchief, perhaps?

Replacing the Lining

The lining adds support to the garment, transferring stress to itself and away from the fragile and elaborate embroidery and construction.

Pattern making from the shattered silk lining. / Photo by Joan Sheridan

Once removed, the fragile lining was separated into pieces to be used for making a new pattern. From the pattern a polyester sample lining was made and fitted into the jacket. Adjustments were noted on the paper pattern and revisions made until it was as close as it could be. Polyester is not a substitute for silk, as it behaves differently, but it did serve a purpose—knowing that the pattern was close enough.

Small tools and thread are less likely to damage the delicate fabric. / Photo by Joan Sheridan

With the modified pattern in hand, the cream silk was cut and sewn in with a few minor modifications. The lining was attached using a long blind stitch, unlike the original whip stitching. Changing the stitch type reduced the number of holes that had to be put into the garment, and fewer stitches mean less damage to the original green fabric.

The finished collar and newly lined coat, before pressing. / Photo by Joan Sheridan

With the body lining sewn in, the neck lining was next. The edge of the collar was quite worn and treatment was required. A piece of bronze tulle (fine netting) was sewn to the outside edge of the collar next to the main body of embroidery, but not over it. It was then stretched over the damaged area and attached to the inside of the collar. The collar lining was cut freehand because the original is in many pieces. Once the lining was in place, the tulle mend became nearly invisible.

Finishing the Work

The sleeves are very of-the-period. They are curved in shape and tell the story of a suit that was worn often and remodeled in its second life. The sleeve remodeling was likely done at the time the lining was replaced in the mid-1800s.

Two levels of wear are evident on the sleeves. / Photo by Joan Sheridan

Conservation Specialist Claire Zimmeth completed the project by mending the sleeves and sewing in the sleeve lining. Since there was damage at the end of the original sleeve length and at the end of the remodeled/current length, it was decided that the entire area should be covered with tulle. Again, the tulle was placed to avoid covering embroidery (see the work-in-progress image below).

Covering the sleeves with tulle (in progress). / Photo by Joan Sheridan

Bringing It All Together

This suit is an excellent example of 18th-century tailoring, style, color, and embroidery talent. It reminds us that court styles didn’t change much over more than a hundred years and didn’t keep up with the current fashions.

Working on this garment was challenging, mainly in that there is always concern about handling fragile, antique textiles. It was a privilege to work on the suit and be able to explore the history of the suit via the wear, stitches, and inner construction. Even though this jacket has no formal provenance, it still has a story to tell. The suit will be on display in the Fashion and Nature exhibit at the Grand Rapids Public Museum from April 23–July 23, 2022.

Photo by Mary Fahey

Joan Sheridan is Volunteer Textile Specialist at The Henry Ford.

18th century, making, fashion, conservation, collections care, by Joan Sheridan, #Behind The Scenes @ The Henry Ford