Posts Tagged the henry ford's innovation nation

Ideas in Action

This feature originally ran in the June-December 2016 edition of The Henry Ford Magazine.

TV, The Henry Ford's Innovation Nation, technology, flying, inventors, The Henry Ford Magazine

Innovation Nation: The Wild Web We Can Wear

Forgo the needle and thread — all you need to make clothes from scratch is a computer and an idea.

In fashion, “printed” usually refers to patterned fabric. But when it comes to one company, it actually describes the way clothing is made.

Bay Area-based startup Electroloom is using 3-D printing to create seamless garments that are soft as butter. Its innovative electrospinning process ultimately makes it possible for anyone with some CAD ability to design and produce fabric items on demand. Dubbed field-guided fabrication, it entails making a mold, placing it in the Electroloom machine and watching as 3-D printer nozzles layer microscopic fibers up around it. Still in its infancy, the technology has so far been used to make simple garments such as beanies, tank tops and skirts.

After the Electroloom appeared on The Henry Ford's Innovation Nation earlier this year, The Henry Ford Magazine caught up with co-founder and CEO Aaron Rowley to talk more about the technology and the possibilities yet to unfold.

THF Magazine: How did the idea for Electroloom come about?

Rowley: I’ve been working in the technology industry, as have my co-founders, and we saw an obvious lacking in terms of 3-D-printing capability — it couldn’t make soft goods and material things like clothing, towels, shoes — anything that’s soft and flexible. We wanted to expand 3-D printing to produce those items. We knew that it would be extremely valuable, so we set out on this hypothetical task. We just started prototyping and designing, and that’s where the original genesis came from.

THF Magazine: How has your company evolved?

Rowley: When we first started working, we were in a garage and in our apartments working on the kitchen floor. Then, we began to work out of a technology shop and maker’s space, a community of people that supports a facility that has equipment, classes and training. We also participated in accelerated programs, which catapulted us to the next level. While the origins of this project were truly conceptual, when we were successfully getting fabrics and soft material, that’s what propelled us into building these larger, more robust machines.

THF Magazine: How does the Electroloom work?

Rowley: The simplest way to describe it is that we convert liquids into textiles. Basically, we use electricity to pull on the liquid, and the liquid, as it’s being pulled on, then hardens into a fiber and as you pull that across a gap — let’s say inside of a machine — that liquid converts into a fiber as it dries. The final product is completely seamless.

THF Magazine: So what does the fabric feel like?

Rowley: The fibers that we work with are actually single fibers, really tiny micro- or even nanoscale fibers. They’re very, very small, which makes the material very soft. The fabric has been described as a hybrid between cotton and suede. The texture on the surface is soft like suede, but it’s got the look and dimensions of cotton and polyester with comparable thickness.

THF Magazine: What’s next for the Electroloom?

Rowley: We are in the middle of fundraising right now. We also received a grant from the National Science Foundation specifically for projects pursuing advanced technology and nanotechnology. We are exploring some private investments, too. The goal is to expand the team to refine the technology and, later this year or early next year, have an actual set of machines “out in the wild” as well as our own clothing brand.

THF Magazine: How do you see this technology being applied?

Rowley: We’ve been approached by several clothing brands interested in working with the technology and product design teams who want to work with this method. A few stores are even interested in having the tools in-store to engage with customers. We’re flushing this out to determine what’s most doable in the near future. We’ll be settling on something soon and making some cool announcements.

THF Magazine: Do you really see people using Electroloom to make clothing in their own homes?

Rowley: I try to discern between near-term realistic stuff and what’s our bigger vision. Having people make things in their homes is far off, but the goal is to, over the years, refine this technology so if somebody did want to have this in their home to print fibrous products — from kitchen towels to socks and underwear — to supplement actually going out and purchasing these items in stores, we would love for that to happen and for people to be able to add customization, colors and shapes.

Did You Know?

It takes between eight and 14 hours to encapsulate a mold with printed fibers in the Electroloom.

How it Works

See the full episode of The Henry Ford's Innovation Nation here.

manufacturing, technology, making, fashion, The Henry Ford's Innovation Nation, The Henry Ford Magazine

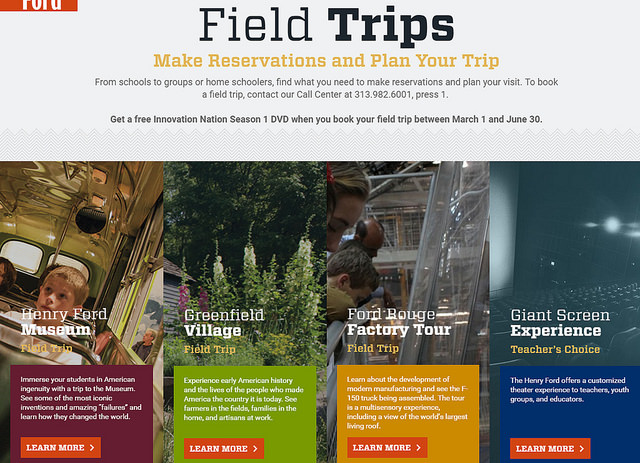

The Key to Successful Field Trips at The Henry Ford

The education department at The Henry Ford has the pleasure of working with teachers who do an excellent job of planning their field trips. They each bring their schools and classrooms here for a multitude of reasons but they all agree that preparing their students is the key to a successful field trip. The more preparation that students receive increases their comfort and excitement, leading to a more powerful learning experience. This “prep work” includes both the logistics of the visit and linking what they do and see at The Henry Ford to what they are learning in the classroom.

This spring, we are making two major investments to help teachers better prepare their students prior to visiting us:

The Henry Ford has a newly designed website to help teachers easily find the many options for customizing a field trip to meet specific curriculum and scheduling needs. Each venue has its own page with logistical assistance for your trip and our most popular curriculum-aligned activities to use before, during and/or after your visit. If you don’t find the perfect resource there, additional activities can be found in our Resource Bank.

Each teacher who books a field trip now through June 30, 2016 will receive a season one DVD of The Henry Ford’s Innovation Nation. In this Emmy-award winning TV series, host Mo Rocca meets up with our curators to learn the significance of our most famous artifacts and experiences – and lets viewers in on some hidden gems. Then, co-hosts visit with today’s innovators, linking the past with the present and future. Some of these innovators are even the same age as our field trip visitors! The clips can tie classroom curriculum to the artifacts and experiences at The Henry Ford. For example, a high school U.S. History class visiting Henry Ford Museum should watch our segment on the Rosa Parks Bus. An elementary class studying inventors should check out the Wright Brothers and Thomas Edison segments before coming to Greenfield Village.

The clips can tie classroom curriculum to the artifacts and experiences at The Henry Ford. For example, a high school U.S. History class visiting Henry Ford Museum should watch our segment on the Rosa Parks Bus. An elementary class studying inventors should check out the Wright Brothers and Thomas Edison segments before coming to Greenfield Village.

If you are interested in your own copy of The Henry Ford’s Innovation Nation Season 1 DVD, it is available in our gift shops and online. You can also access individual clips of both season 1 and season 2 on The Henry Ford’s YouTube channel.

Check your local listings to see when The Henry Ford’s Innovation Nationis airing on CBS in your area.

We believe that equipping teachers with new features on our revamped website and episodes from the TV show will help to better prepare students for a visit to The Henry Ford so that they can be inspired by the stories of American ingenuity, resourcefulness and innovation. After all…THEY are the ones who will produce future innovations to help shape a better future.

Catherine Tuczek is Curator of School and Public Learning and Phil Grumm is Curator of Digital Learning at The Henry Ford. Want to be the first to know about our latest resources and special offers? Then sign up for our OnLearning newsletter.

TV, The Henry Ford's Innovation Nation, educational resources, education, field trips, by Phil Grumm, by Catherine Tuczek

Just Added to Our Digital Collections: Loranger Gristmill

Season two of The Henry Ford’s Innovation Nation is well under way, and we’re doing research within our collections and digitizing material related to some of the upcoming storylines. One we worked on this week involves the Loranger Gristmill and American inventor Oliver Evans. The Gristmill was built in 1832 in Monroe, Michigan, and ground wheat and corn for local farmers into the 20th century; it was moved to Greenfield Village in 1928. The conveyor system that moved grain around inside the building was developed by Evans in the 1700s—but this was not his only creation. In the early 1800s, he developed a dredging machine called the “Oructor Amphibolis,” shown here in an image from our collections, that was powered by a steam engine he also invented. Visit our collections website to browse more artifacts related to Evans and to Loranger Gristmill—and keep an eye out to see the gristmill in action on The Henry Ford's Innovation Nation.

Ellice Engdahl is Digital Collections & Content Manager at The Henry Ford.

Michigan, digital collections, The Henry Ford's Innovation Nation, Greenfield Village buildings, Greenfield Village, by Ellice Engdahl

On the Set with Tesla: Handling an Inventor

In a typical day at The Henry Ford I find myself answering patron questions or assisting with research. Then, there’s the not-so-typical day when I’m coordinating and work on the Special Access team.

July 13, 2015, was one of those not-so-typical days. I found myself face to face with someone people may call one of the most fascinating inventors in history, Nikola Tesla. You might be asking, how does one find herself in this position? Well, let me show you.

July 13, 2015, was one of those not-so-typical days. I found myself face to face with someone people may call one of the most fascinating inventors in history, Nikola Tesla. You might be asking, how does one find herself in this position? Well, let me show you.

The Special Access Program is designed to allow for closer examination of artifacts in storage, access to artifacts beyond visitor barriers, or filming behind the scenes at The Henry Ford. It allows patrons (film crews, enthusiasts, model makers, etc.) access to our collections that can’t be accommodated in the usual ways such as viewing exhibits and items on display, searching collections online, or viewing material in the public reading room.

In fact, the artifacts from the collection are some of the biggest stars of our television show, The Henry Ford’s Innovation Nation, so the Special Access team is very busy during filming. The first episode of season 2 – filmed in part on this day in July – features the work of Nikola Tesla. I brought several objects to “center stage” for the shoot, including the death mask of Nikola Tesla, shown above. I worked with our Exhibits team to move the electroplated copper mask and its beautifully designed pedestal (which together weigh more than 50 pounds!) from a case in the Made in America exhibition to a sturdy table. It joined several objects that I had moved temporarily from collections storage to the museum for filming: Continue Reading

collections care, #Behind The Scenes @ The Henry Ford, by Stephanie Lucas, The Henry Ford's Innovation Nation, inventors

We do a lot of preparatory research in our collections for each episode of our television series, The Henry Ford’s Innovation Nation. Sometimes, we find things that we weren’t expecting. That happened recently, when in investigating material related to food wagons, our registrar Lisa Korzetz recalled an image in our collection of a chuck wagon. Accompanying the chuck wagon photo, we found about a dozen more photographs of the American West in the 19th century, many in the Wyoming Territory, taken by the Dalgliesh Photo Studio and given to The Henry Ford in 1930 by George Dalgliesh, one of the photographers. The photos are an amazing record of everyday cowboy and ranch life in the West, so we’ve digitized all of them, including this image of the romantically named “Robbers Roost Road Ranch.” View all these newly digitized Western images by visiting our collections website.

Ellice Engdahl is Digital Collections & Content Manager at The Henry Ford.

Wyoming, 19th century, The Henry Ford's Innovation Nation, photographs, digital collections, by Ellice Engdahl

What's on this weekend's episode of The Henry Ford's Innovation Nation? Take a look!

Lish Dorset is Social Media Manager at The Henry Ford.

Model Ts, technology, roads and road trips, by Lish Dorset, The Henry Ford's Innovation Nation

The Henry Ford's Innovation Nation: Apple 1

On this weekend's episode of The Henry Ford's Innovation Nation you'll learn about our 1976 Apple 1 computer. Want to learn more about the history of personal computers? Take a look below.

Read

The Rise and Fall of the Osborne Computer Corporation

Lish Dorset is Social Media Manager at The Henry Ford.

by Lish Dorset, technology, computers, The Henry Ford's Innovation Nation

What's new on The Henry Ford's Innovation Nation this weekend? Host Mo Rocca shows us the hardware store robot; the incredible patent models from Thomas Edison that show us the beginning of our electronic world; how the USG Corp. is leading the way with grooming the next generation of engineers and mathematicians; the Israeli inventors of a printer that fits in your pocket. Learn more here and see a sneak peek below.

Lish Dorset is Social Media Manager at The Henry Ford.

printing, technology, by Lish Dorset, Thomas Edison, The Henry Ford's Innovation Nation

On this week's episode of "The Henry Ford's Innovation Nation" you'll learn more about our collection of trains found inside Henry Ford Museum. Want to learn more? Take a look.

Look

Locomotives of Greenfield Village

Expert set: Some of the locomotives of Greenfield Village—working artifacts

Lish Dorset is Social Media Manager at The Henry Ford.

Henry Ford Museum, railroads, by Lish Dorset, The Henry Ford's Innovation Nation