Patent Medicine Entrepreneurs: Friend or "Faux"?

Before modern pharmaceuticals and medical practice came to be widely accepted, people had essentially three choices to try to cure what ailed them, none of which was perfect. The first choice was to be treated by a doctor, if one was available, affordable, and trustworthy. The second option was to try a home remedy, found in cookbooks or periodicals or passed down through a family member. The third choice was patent medicines. Readily available and relatively inexpensive—though often suspect and sometimes downright dangerous—patent medicines were a popular option for treatment throughout the 1800s.

The popularity of patent medicines encouraged entrepreneurs to manufacture their own remedies and enter the flourishing patent medicine industry. Some of these entrepreneurs were licensed doctors who decided to become businessmen instead of practitioners. Others were businessmen with a flair for marketing who saw an opportunity to use their skills to peddle an acquired formula or small medicine business they purchased. Unfortunately, some entrepreneurial manufacturers were complete con artists concocting their own remedies that either did absolutely nothing or were quite dangerous to whomever consumed them. Through this blog post, we'll explore the stories behind various entrepreneurial patent medicine manufacturers.

Trade Card for Brown’s Iron Bitters, Brown Chemical Co., 1890-1900. Patent medicines were often advertised as “cure-alls” with packaging and advertisements listing illnesses and complaints that the product was intended to “cure.” This trade card for Brown’s Iron Bitters claims that it cured “indigestion, dyspepsia, intermittent fevers, want of appetite, loss of strength, lack of energy, malaria and malaria fevers,” and other things. / THF277429

The term “patent medicine” is misleading as the medicine advertised was very rarely patented. It originally referred to medicine in which the ingredients were “granted protection for exclusivity,” meaning that the same composition could not be sold by another manufacturer. While it was relatively simple to obtain a patent for medicine, most manufacturers didn’t apply for one because it meant that they would have to divulge the remedy’s ingredients. More often than not, these medicines contained dangerous substances like morphine, cocaine, and high levels of alcohol.

Trade Card for Burdock Blood Bitters, Foster, Milburn & Co., circa 1885. A study conducted by the American Medical Association in 1917 found that Burdock Blood Bitters, a popular patent medicine, contained 25.2% alcohol by volume. This medicine, and others like it, would most likely dull any pain (thanks to the alcohol) but its contents also increased the likelihood of developing dependency or addiction in adults, and could be fatal to children. / THF215182

Having originated in England in the 17th century, patent medicines made their way to America in the 18th century and were a major industry by the 1850s. The last half of the 1800s is considered the “golden age” of American patent medicine, with hundreds of products flooding the market. A number of factors led to this boom in the industry. For one, advances in industrial and manufacturing technology made the process of producing bottles, containers, labels, and the medicine itself more efficient. As the century progressed, advanced transportation methods opened new markets across the continent. Additionally, the introduction of color printing created an advertising frenzy with thousands of newspaper, magazine, trade card, and poster advertisements. And finally, there were essentially no regulations imposed on the drug trade at this time, meaning that individuals could put whatever they wanted into a remedy and advertise it however they pleased. All of this culminated to ensure that the patent medicine trade was highly lucrative, encouraging enterprising individuals to launch their own brand of medicines regardless of medical knowledge or background.

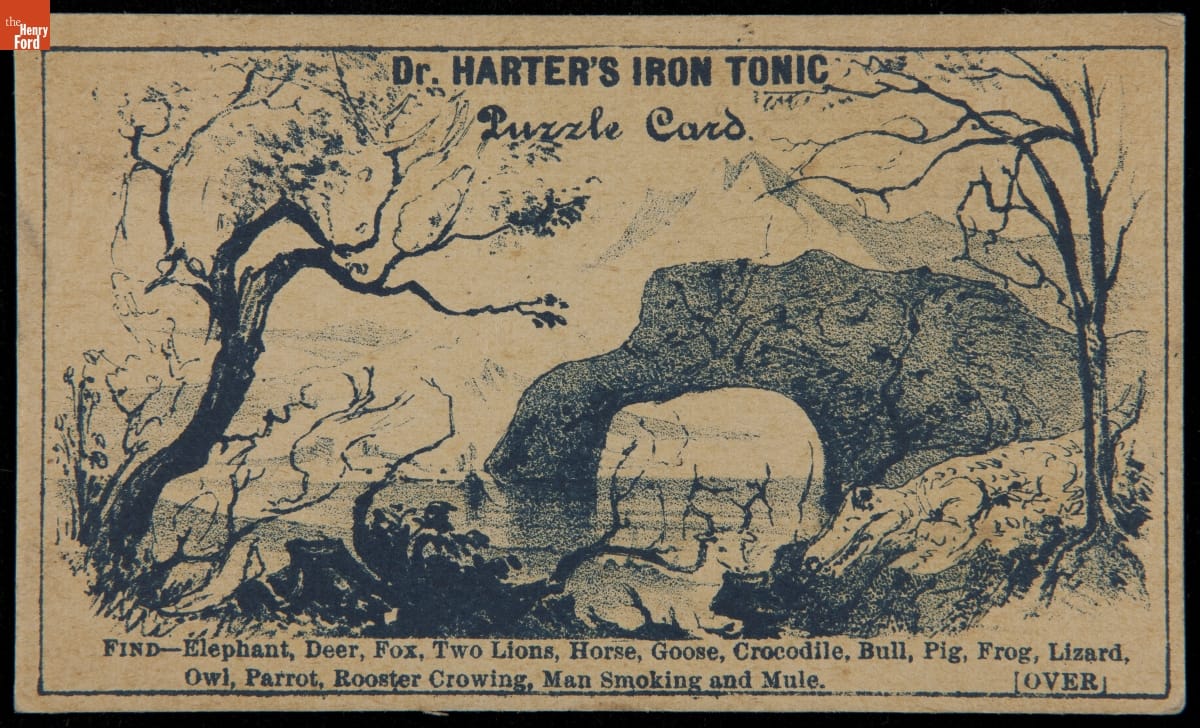

Trade Card for Dr. Harter’s Iron Tonic, 1875-1890. Trade cards were the most popular method for advertising patent medicines. This puzzle card for Dr. Harter’s Iron Tonic featured hidden figures within a drawing for customers to find. / THF214474

While there were hundreds of patent medicines created during this time, the most successful were the ones that were heavily advertised. Consumers encountered many advertisements and brand recognition became extremely important with so many patent medicines on the market. Trade cards of the era inform us who the major players were in the patent medicine industry. They also allow us to examine the advertising tactics used by patent medicine manufacturers to entice potential customers.

Foster, Milburn & Co.

Trade Card for Burdock Blood Bitters, Foster, Milburn, & Co., circa 1885. / THF215179

Orrin Foster and Thomas Milburn were patent medicine manufacturers and distributors. They organized their first business in the 1870s in Toronto before opening a distribution office in Buffalo, New York. The company’s best-known product was Dr. Thomas’ Eclectric Oil, which the pair had purchased from Dr. Samuel N. Thomas in 1876 and marketed heavily to the general public. The back of this trade card for Burdock Blood Bitters—another well-known product by the company—features a popular strategy for advertising patent medicines: testimonials. Testimonials provided prospective buyers with “first-hand experiences” of those who had tried the product. With praises sung by doctors, reverends, and members of the general public, testimonials instilled confidence in the products, persuading consumers to buy. Whether the testimonials were truthful or fabricated is up for debate.

Humphreys’ Homeopathic Medicine Company

Trade Card for Humphreys’ Witch Hazel Oil, Humphrey’s Med. Co., 1870-1900. / THF299894

Humphreys’ Homeopathic Medicine Company is an example of a patent medicine company that actually had a proprietor in the medical field. The company was founded by Frederick K. Humphreys in 1853. He graduated in 1850 from the Pennsylvania Homeopathic Medical College with a Doctor of Homeopathic Medicine degree and established a successful medical practice. Homeopathy is an alternative medical practice based in the belief that the same substances that cause disease in healthy people can be used to treat those who are sick with similar symptoms. According to the Federation of Historical Bottle Collectors, Humphreys helped “form the New York State Homeopathic Medical Society and became an important member of the American Homeopathic Institute.” In 1854, Humphreys began manufacturing and selling homeopathic remedies. Witch Hazel Oil—for curing itching, pain from cuts and burns, chapped hands and feet, bug bites, sunburns, etc.—became one of Humphreys' most popular products over time.

Lydia E. Pinkham’s Medicine Company

Trade Card for Lydia E. Pinkham’s Vegetable Compound, 1880-1890. / THF298977

Lydia E. Pinkham was one of the most prominent names in the sector of the patent medicine industry that catered to “female complaints.” Before entering the business, Pinkham was a teacher and mother. It is said that she was known among her neighbors for mixing her own herbal remedies, keeping a personal notebook she called “Medical Directions for Ailments.” Pinkham’s Vegetable Compound is believed to have been a secret formula given to Lydia’s husband as payment for money owed to him. The couple began producing the compound in 1875, thus entering the patent medicine business. Their sons, Will and Dan, were tasked with marketing the product. In 1879, Dan came up with the idea of using Lydia’s portrait in advertisements—the first woman’s likeness to be used in advertising. Attaching her likeness and signature to advertising was a huge hit, providing women with a friendly and “knowing” face, which instilled confidence in the product.

Carter Medicine Company

Trade Card for Carter’s Little Liver Pills, Carter Medicine Company, 1880-1890. Trade cards were generally printed as small rectangles but unique shapes, like the painter’s palette shape of this card, were also created and were a beneficial advertising tool. / THF297541

The Carter Medicine Company provides another example of a patent medicine manufacturer with a background in the medical field. Pharmacist Dr. John Samuel Carter began selling “Carter’s Little Liver Pills” out of his pharmacy in Pennsylvania for those with “digestive distress.” The product gained popularity throughout the 1850s and in 1880, Carter formed a partnership with New York businessman Brent Good to establish Carter Medicine Company. By World War I, "Carter's Little Liver Pills" had become such a staple in American households that the company remained in business despite a global economic downturn.

C.I. Hood & Co.

Trade Card for C.I. Hood & Co. with Hood’s Photos of the World, “Notre Dame Cathedral, Paris,” 1890-1910. Trade Cards from Hood’s Photos of the World series gave customers views of faraway places, providing a window to the broader world. / THF297455

C.I. Hood & Co. was one of the most recognized names in the patent medicine industry. In 1875, Charles Ira Hood opened his drug store, C.I Hood & Company, in Lowell, Massachusetts. Within a few years, Hood’s was one of the largest patent medicine producers in the United States. The thing that set Hood’s company apart was its state-of-the-art factory, which included its own advertising department. Hood’s factory produced all sorts of ephemera, including calendars, trade cards, and even cookbooks, which helped make it one of the most successful patent medicine manufacturers.

Dr. Seth Arnold’s Medical Corporation

Trade Card for Dr. Seth Arnold Medical Corporation, 1880-1890 / THF214532, THF214533

Seth Arnold worked in a series of industries before entering the patent medicine business in the late 1840s. Following a venture in hotel management, Arnold took several years off due to his health, beginning in 1835. He was said to have used this time to create a remedy for his illness, a medicine that came to be called “Dr. Arnold’s Balsam.” In the New England Union Directory of 1849, Arnold was cited as an “eclectic physician and patent medicine manufacturer” in Smithfield, Rhode Island, where he was also a physician for cholera. In addition to his balsam, two additional products were created—“Cough Killer” and “Bilious Pills”—to be sold by his company, known as Dr. Seth Arnold’s Medical Corporation. Dr. Seth Arnold’s Cough Killer was believed to be his most popular product, but the others were successful as well. If the testimonial on the back of the trade card above is to be believed, customers as far away as Nebraska used Dr. Seth Arnold’s Bilious Pills.

Sterling Remedy Company

Trade Card for “No-To-Bac” Tobacco Habit Cure, Sterling Products Co., circa 1894. / THF298541

Sterling Remedy Company provides an example of a businessman entering the patent medicine industry without any medical knowledge or background. H.L. Kramer was a self-made businessman who established a publishing and advertising company in Lafayette, Indiana, and held interest or managerial positions in the Humane Remedy Company and the Universal Remedy Company (both manufacturers of patent medicines). One of Kramer’s advertising clients was John W. Heath, a local Indiana banker who owned Sterling Remedy Company. Heath also consulted with Kramer on a project to develop a local health spring into a medicinal spa. Following Heath’s death in 1890, Kramer bought out his widow’s interest in the Sterling Remedy Company and the medical springs. By the mid-1890s, Kramer had launched the springs as a “fashionable Midwestern health resort” known as “Mudlavia” because of its specialty mud bath cures. Under Kramer’s leadership (and with thousands of dollars spent on advertising yearly), Sterling Remedy Company gained popularity. Universal Remedy Company’s “No-To-Bac,” a popular tobacco habit cure, was merged with Sterling Remedy Company’s product line. A common side effect of No-To-Bac was constipation, so the company produced Cascarets to help with this inconvenience. Cascarets became the company's most popular product. Despite success, Kramer sold the company in 1909.

Dr. J.C. Ayer & Co.

Trade Card for Ayer’s Hair Vigor, circa 1885. Ayer’s Hair Vigor became a popular hair restorative following its introduction in the 1860s. Examples of packaging for this patent medicine are on display at the J.R. Jones General Store in Greenfield Village. / THF297658

James C. Ayer was one of the most recognized names in the patent medicine industry. This is largely due to the fact that Ayer was an advertising genius, producing thousands of advertisements in the form of trade cards, almanacs, posters, and newspaper and magazine ads. Young Ayer apprenticed for several years at Jacob Robbins’ Apothecary Shop in Ledyard, Connecticut, and studied under Dr. Samuel Dana. Within a few years, Ayer purchased the apothecary shop and began manufacturing his own medicines, including Cherry Pectoral. His medicine was so popular that he was forced to find a larger manufacturing facility, moving operations to Lowell, Massachusetts. In 1855, Ayer entered into a partnership with his brother to form J.C. Ayer & Company, manufacturing patent medicines. Additional remedies created by Ayer since introducing Cherry Pectoral included Cathartic Pills in 1853, Sarsaparilla and Ague Cure in 1858, and restorative Hair Vigor in 1867. In 1860, the Philadelphia Medical University awarded Ayer with an honorary medical degree, leading to the addition of “Dr.” to the company’s name.

“Ayer’s American Almanac, 1907” / THF285177

While trade cards were certainly one of the most effective advertising methods for patent medicines, major manufacturers printed their own almanacs as well. Dozens of almanacs littered the counters of local general stores and urban pharmacies. In an average year, J.C. Ayer & Co. produced roughly 16 million almanacs. In 1889, Ayer’s distributed 25 million almanacs in 21 languages.

Federal Regulation

While the masses were content to self-prescribe patent medicines for themselves, there were some who questioned the effectiveness of the products and the legitimacy of their proprietors. As previously mentioned, relatively few restrictions were placed on the drug trade at this time and manufacturers were not inclined to provide a list of ingredients for their products. Some reputable doctors took it upon themselves to conduct studies to see what some of the most popular patent medicines were made of, and the results were often startling.

Many medicines were found to contain dangerous levels of alcohol. For instance, one study found that Lydia E. Pinkham's Vegetable Compound contained roughly 20% alcohol. Other remedies were found to contain morphine (like Dr. Seth Arnold's Cough Killer) and cocaine. With reports such as these making the general public aware of dangerous substances in some of their favorite medicines, and growing concern against the manufactured food industry regarding sanitation practices and food additives, the Pure Food and Drug Act was passed in 1906, placing federal regulations on these trades. For patent medicines, the passage of the act called for manufacturers to list any harmful ingredients on their containers and prohibited any false or misleading advertising.

Page from “Ayer’s American Almanac, 1907” noting that its products do not contain alcohol. / THF285178

Following the passage of the Pure Food and Drug Act, there was a significant decrease in the number of patent medicines on the market, but there were some companies that were able to remain in business. One of the most successful was Carter Medicine Company. It sustained its legitimacy even with the passage of the Act, and throughout the 20th century, the company diversified its products, leading to research in anti-perspirants and deodorant. The company is still in business today as Carter-Wallace, with well-known products such as Arrid, an antiperspirant and deodorant, and Nair, a hair remover for women.

Two other manufacturers previously mentioned—the Lydia Pinkham Company and Humphreys' Homeopathic Medicine Company (now Humphreys' Pharmacal, Inc.)—also remain in business today with their products available for purchase online.

Samantha Johnson is Project Curator for the William Davidson Foundation Initiative for Entrepreneurship at The Henry Ford. Special thanks to Donna Braden, Senior Curator and Curator of Public Life at The Henry Ford, for sharing her knowledge and resources on the patent medicine industry and for reviewing this content.

19th century, patent medicines, healthcare, entrepreneurship, by Samantha Johnson, advertising

Recreating the Wright Brothers’ Christmas Tree

Christmas tree in the Wright Home during Holiday Nights in Greenfield Village. (Photo courtesy Jim Johnson)

During Holiday Nights in Greenfield Village, we really enjoy showing how Americans would have celebrated Christmas in the 19th century. In almost all the houses, we use historical primary sources to try to glean out descriptions of what people may have done—but we have almost no concrete visual evidence. However, one huge exception is the Wright Home, the family home of Wilbur and Orville Wright.

We know from various sources that in 1900 there was a big homecoming in Dayton, Ohio. Reuchlin Wright, one of Wilbur and Orville’s older brothers, was returning home from living apart for a very long time, slightly estranged. In celebration, the family decided to put up their first Christmas tree. Wilbur and Orville, who were amateur photographers but probably as good as any professional of the time, documented some of that process.

Within the last decade, we have been able to access a very high-resolution image of the Wright family Christmas tree image from the Library of Congress, and the details just leapt out at us. This photograph, which we know was taken in 1900, documents exactly how the Wright Brothers designed and put up their Christmas tree. We examined all the minutiae in the photo and have attempted to recreate this tree as exactly as possible.

Wright Home Parlor Decorated for Christmas, Original Site, Dayton, Ohio, circa 1900 / THF119489

The toys, the various ornaments—it's all in line with what's typical in the time period. So if you look at the tree in the Wright Home, you’ll see it lit with candles—this is not an electrified house yet in 1900. There's a variety of ornaments designed to hold candies and similar things. It has strung popcorn, which would have been homemade, but it also has store-bought German tinsel garland, glass ornaments (either from Poland or Germany), and all kinds of additional decorations that may have been saved from year to year. There's a homemade star on top that has tinsel tails coming off it.

For many years, we just had a low-resolution, fuzzy photograph of the tree, and we reproduced things as faithfully as we could—for example, what appeared to be a paper scrap-art angel. The first glimpse of the high-resolution photograph absolutely flabbergasted us, because front-and-center on the tree is a little scrap-art of a screaming, crying baby. It must have been some sort of inside joke within the family. We were able to reproduce it exactly as it would have looked on the tree.

The screaming baby scrap-art on the Wright Home Christmas tree, both in the original photo and during Holiday Nights in Greenfield Village.

In keeping with tradition, the tree is also covered with gifts for different members of the family. It seems that the adult gifts were hung unwrapped on the tree, whereas many of the children's things were either wrapped or just placed under the tree, based on the photograph. For example, on the tree, we see a pair of what are known as Scotch gloves—you would have found examples of these in Sears catalogues of the early 1900s. There's also a fur scarf, toy trumpets, and even a change purse, all hung on the tree.

Scotch gloves hanging on the Wright Home Christmas tree, both in the original photo and during Holiday Nights in Greenfield Village.

Beneath the tree, the arrangement of toys and gifts is quite fun. There’s a pair of roller skates, a little toy train, tea sets, furniture sets, and all kinds of different things geared specifically toward all the Wright nieces and nephews who would have come to visit on that Christmas morning.

There's also a wonderful set of photographs associated with the tree after Christmas. For example, there’s one of Bertha Wright, one of Reuchlin’s middle daughters, in the next room over, sitting playing with her toys. She's clearly been interrupted in her play, and you can see that in the expression on her face: “Okay, let's get this over with.”

Bertha Wright, Age Five, Niece of the Wright Brothers, Daughter of Reuchlin Wright, circa 1900 / THF243319

There are also photos outside the house, featuring the sleigh (which is prominent under the tree in the high-res photograph, stacked with books). Behind them in all these photographs is a little fir tree—the tree that was inside the house for Christmas has now been placed out there and propped up in the corner, probably for the winter season.

Milton, Leontine, and Ivonette Wright at Wright Home, Dayton, Ohio, circa 1900 / THF243321

During Holiday Nights in Greenfield Village, we have a wonderful large high-resolution blow-up of the tree photograph set up in the Wright Home for our guests to compare-and-contrast with the recreated tree in the corner. Be sure to stop by the Wright Home to see it on your next Holiday Nights visit!

The original historic photo of the Wright family Christmas tree, displayed in the Wright Home during Holiday Nights in Greenfield Village. (Photo courtesy Brian James Egen)

This post was adapted from the transcript of a video featuring Jim Johnson, Director of Greenfield Village, by Ellice Engdahl, Digital Collections & Content Manager at The Henry Ford.

Michigan, Dearborn, Ohio, 20th century, 1900s, Wright Brothers, research, photographs, home life, holidays, Holiday Nights, Greenfield Village buildings, Greenfield Village, events, Christmas, by Jim Johnson, by Ellice Engdahl

"Sampling" the Past: Fabrics from America's Textile Mills

In 2017, The Henry Ford acquired a significant collection of materials from the American Textile History Museum (ATHM) when financial challenges forced that organization to close its doors. Founded in 1960, ATHM was located in Lowell, Massachusetts, a city key to the story of the Industrial Revolution and to the American textile industry. For decades, ATHM gathered and interpreted a superb collection of textile machinery and tools, clothing and textiles, and an extensive collection of archival materials. The Henry Ford was among the many museums, libraries, and other organizations to which ATHM's collections were transferred.

The Henry Ford acquired textile machinery, clothing, and textiles, as well as archival material that includes approximately 3,000 cubic feet of printed materials and fabric samples from various textile manufacturers, dating from the early 1800s into the mid-to-late 1900s. As part of the William Davidson Foundation Initiative for Entrepreneurship, The Henry Ford has digitized many sample books, as well as product literature, from the archival material within the ATHM collection.

So, what is a sample book? Textile manufacturing companies – commonly referred to as mills or print works – kept a record of fabrics produced by the company within a given year or season. These records typically consist of a fabric sample attached to a blank page in a bound book, and are often accompanied by information including pattern name, inventory number, dyestuffs, and in a few cases, the retail company for which the fabric was made.

The pages of these books offer a rich look at the broad range of fabrics produced by an increasingly mechanized textile industry, allowing researchers to see the evolution in textile design, materials, and manufacturing techniques. They also allow a glimpse into the various methods of recordkeeping among the many companies represented in the collection. Finally, the books—and the fabric samples within them—provide us with a broad view into the rich color palate of American textiles of the 1800s and 1900s. This is especially helpful for exploring clothing and textiles in the era before widespread color photography, where our understanding of the period is dulled by black-and-white depictions. The sample books are strikingly beautiful, offering an intriguing glimpse of the evolution of styles and patterns over time.

In addition to the sample books, we had the opportunity to digitize several examples of product literature from the 1900s, including catalogs and brochures. The product literature was used for marketing and sales, rather than as a record of production. These materials offer insight into the fabric and designs available for clothing or domestic use during the 1900s.

Have I piqued your interest? Below are a few favorite items I’ve come across in this collection.

Sample Books

Cocheco Manufacturing Company (Dover, New Hampshire & Lawrence, Massachusetts)

Fabric Samples from the Notebook of Washington Anderton, Color Mixer for Cocheco Print Works, 1876-1877 / THF670738, THF670787, THF670757

Fabric Samples from the Notebook of Washington Anderton, Color Mixer for Cocheco Print Works, November to December 1877 / THF670668, THF670707, THF670697

Sample Book, January 9, 1880 to April 22, 1880 / THF600226

Hamilton Manufacturing Company (Lowell, Massachusetts)

Sample Book, April 9, 1900 to May 27, 1901 / THF600027, THF600141, THF600167

Lancaster Mills (Clinton, Massachusetts)

Sample Book, "36 Inch Klinton Fancies," Fall 1927 / THF299907, THF299924

Sample Book, "Glenkirk," Spring 1928 / THF299970, THF299971

Product Literature

Hellwig Silk Dyeing Company (Philadelphia, Pennsylvania)

Sample Book, "Indanthrene Colors," 1900-1920 / THF299990

Montgomery Ward & Co. (Chicago, Illinois)

Suit Catalog, "Made to Measure All Wool Suits," 1932 / THF600534

I.V. Sedler Company, Inc. (Cincinnati, Ohio)

Catalog, "The Nation's Stylists Present Sedler Frocks," 1934 / THF600502

Carlton Mills, Inc. (New York, New York)

Sales Catalog for Men's Fashion, 1940-1950 / THF670587

Harford Frocks, Inc. (Cincinnati, Ohio)

"Frocks by Harford Frocks, Inc.," 1949 / THF600604

Sears, Roebuck and Company (Chicago, Illinois)

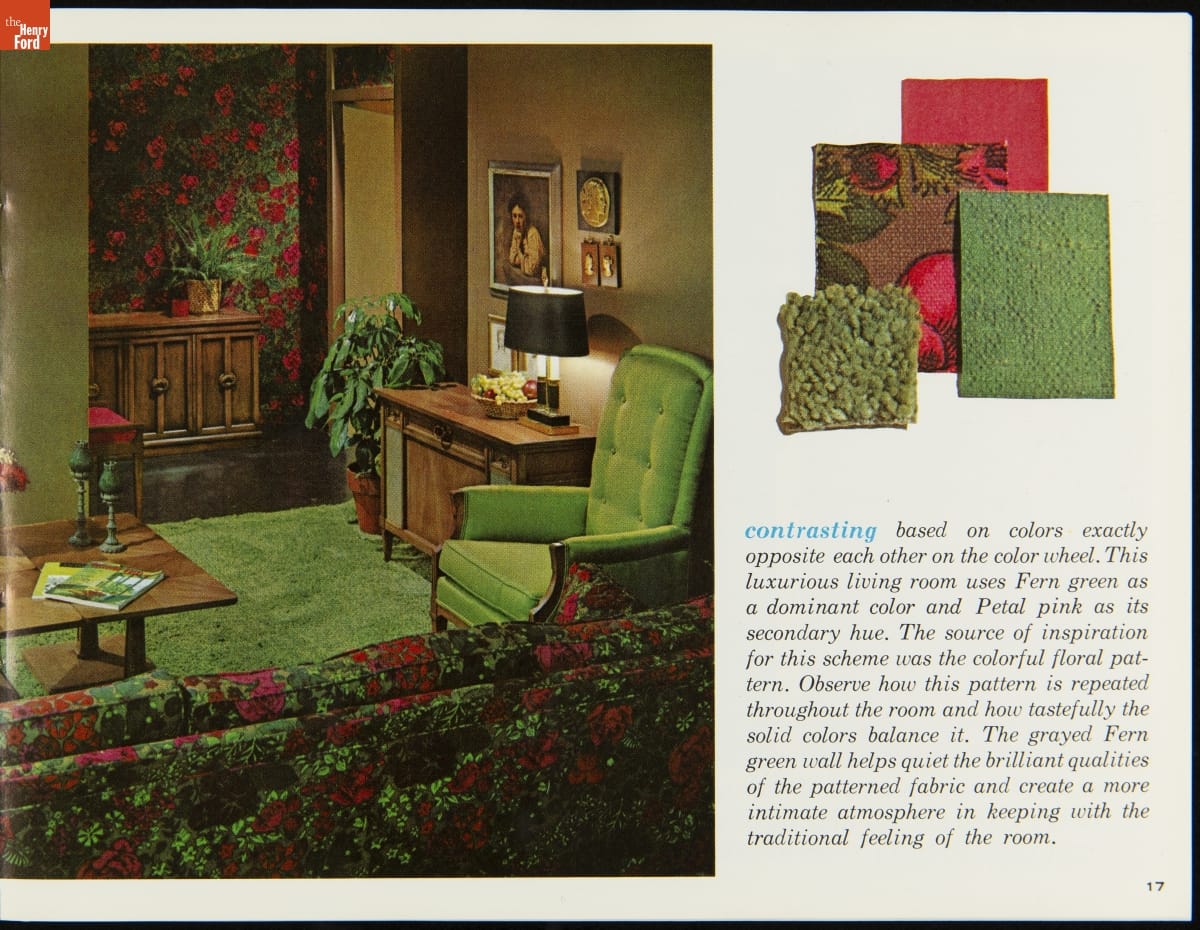

"Sears Decorating Made Easy," 1964 / THF600561

Samantha Johnson is Project Curator for the William Davidson Foundation Initiative for Entrepreneurship at The Henry Ford. Special thanks to Jeanine Head Miller, Curator of Domestic Life at The Henry Ford for sharing her expertise of the textile industry and for reviewing this content.

20th century, 19th century, manufacturing, furnishings, fashion, entrepreneurship, by Samantha Johnson

What Type of Super Hero Are You?

Superman lunchbox, 1954, THF145091

Comic book super heroes can now be found pretty much everywhere: movies, TV shows, handheld games, action figures, and other merchandise. For those of you unfamiliar with the universes and the multiverses, it’s easy to get confused about the plethora of super heroes that are out there today. But if you’re trying to make sense of it all, here’s the single most important thing you need to know. Is it a DC or a Marvel super hero?

To help you understand the differences between these two comic book companies’ approaches, here’s a little personality test. (If the embedded quiz below doesn't work for you, you can also access it here.)

Tour Our Entrepreneurship Sagan

The Henry Ford has long explored creative ways to share our world-renowned collections and provide our guests and visitors with exciting new ways to interact with them. Earlier this year, we launched a new virtual experience that we created in partnership with Saganworks, a technology startup from Ann Arbor, Michigan.

What we created is a Sagan: a virtual room capable of storing content in a variety of file formats, and experienced like a virtual gallery. The Henry Ford curated this Sagan to highlight some of the work the museum has done under the auspices of the William Davidson Foundation Initiative for Entrepreneurship, which focuses on providing resources and encouragement for the entrepreneurs of today and tomorrow. Our Sagan highlights entrepreneurial stories and collections, displaying a sampling of objects we’ve digitized and content we’ve created, all in one place.

As a startup, Saganworks is continuously adapting and evolving its product, and we are happy to announce that we now have the ability to embed our Sagan right here within our blog for you to interact with. (Though please note that this is best experienced on desktop—to experience the Sagan on your phone, you’ll be prompted to download the Saganworks app.)

Continue Reading

Saganworks, entrepreneurship, by Samantha Johnson, technology

The Click Heard around the World

The auditorium at the 1968 Fall Joint Computer Conference before guests arrive. / THF610598

The setting is sparse. The downward sweep of theatre curtains, a man seated stage left, backed by a hinged office cubicle wall. Technology in this image is scarce, and yet it defines the moment. A video camera is perched on top of the wall, its electronic eye turned downwards to surveil a man named Douglas Engelbart, seated in a modified Herman Miller Eames Shell Chair below. A large projection screen shows a molded tray table holding a keyboard at its center, a chunky-looking computer mouse made of wood on the right side, and a “chording keyboard” on the left. Today, we take the computer mouse for granted, but in this moment, it was a prototype for the future.

The empty auditorium chairs in this image will soon be filled with attendees of a computer conference. It is easy to imagine the collective groan of theater seating as this soon-to-arrive audience leans a little closer, to understand a little better. With the click of a shutter from the back of the room, this moment was collapsed down into the camera lens of a young Herman Miller designer named Jack Kelley. He knew this moment was worth documenting because if the computer mouse under Douglas Engelbart’s right hand onstage was soon going to create “the click that was heard around the world,” this scene was the rehearsal for that moment.

Entrance to the 1968 Fall Joint Computer Conference, San Francisco Civic Auditorium. / THF610636

“The Mother of All Demos”

On December 9, 1968, Douglas Engelbart of the Stanford Research Institute (SRI) hosted a session at the Joint Computer Conference at the Civic Center Auditorium in San Francisco. The system presented—known as the oNLine System (or NLS)—was focused on user-friendly interaction and digital collaboration.

Douglas Engelbart demonstrates the oNLine System. / THF146594

In a span of 90 minutes, Engelbart (wearing a headset like the radar technician he once was) used the first mouse to sweep through a demonstration that became the blueprint for modern computing. For the first time, computing processes we take for granted today were presented as an integrated system: easy navigation using a mouse, “WYSIWYG” word processing, resizable windows, linkable hypertext, graphics, collaborative software, videoconferencing, and presentation software similar to PowerPoint. Over time, the event gained the honorific “The Mother of all Demos.” When Engelbart was finished with his demonstration, everyone in the audience gave him a standing ovation.

Fixing the Human-Hardware Gap

In 1957, Engelbart established the Augmentation Research Center (ARC) at SRI to study the relationship between humans and machines. It was here, in 1963, that work on the first computer mouse began. The mouse was conceptualized by Engelbart and realized from an engineering standpoint by Bill English. All the while, work on NLS was percolating in the background.

Douglas Engelbart kicks back with the NLS at the Stanford Research Institute (SRI). / THF610612

While Engelbart was gearing up to present the NLS, Herman Miller Research Corporation’s (HRMC’s) president and lead designer Robert Propst was updating the “Action Office” furniture system. Designed to optimize human performance and workplace collaboration, Action Office caught Engelbart’s attention. He was excited by its flexibility and decided to consult with Herman Miller to provide the ideal environment for people using the NLS. Propst sent a young HMRC designer named Jack Kelley to California so he could study the needs of the SRI group in person.

Jack Kelley and Douglas Engelbart testing Herman Miller’s custom Action Office setup at Stanford Research Institute. / THF610616

After observing and responding to the needs of the team, Kelley recommended a range of customized Action Office items, which appeared onstage with Engelbart at the Joint Computer Conference. One of the items that Kelley designed was the console chair from which Engelbart gave his lecture. He ingeniously paired an off-the-shelf Shell Chair designed by Charles and Ray Eames with a molded tray attachment to support the mouse and keyboard. This one-of-a-kind chair featured prominently in The Mother of All Demos.

An unobstructed view of Jack Kelley’s customization of an Eames Shell Chair with removable, swinging tray for the NLS. The chording keyboard is visible at left, and the prototype mouse is at right. / THF610615

During the consultation, Kelley also noticed that Engelbart’s mouse prototype had difficulty tracking on hard surfaces. He created a “friendly” surface solution by simply lining the right side of the console tray with a piece of Naugahyde. If Engelbart was seen to be controlling the world’s first mouse onstage in 1968, Kelley contributed one very hidden “first” in story of computing history too: the world’s first mousepad. Sadly, the one-of-a-kind chair disappeared over time, but luckily, we have many images documenting its design within The Henry Ford’s archival collections.

A closer view of the world’s first mousepad – the beige square of Naugahyde inset into the NLS tray at bottom right. / THF610645

The computer scientist Mark Weiser said, “the most profound technologies are the ones that disappear. They weave themselves into the fabric of everyday life until they are indistinguishable from it.” If this is true, the impact of Engelbart’s 1968 demonstration—supported by Kelley’s console chair and mousepad—are hidden pieces of the computing history. So as design shaped the computer, the computer also shaped design.

Kristen Gallerneaux is Curator of Communications & Information Technology at The Henry Ford.

California, 20th century, 1960s, technology, Herman Miller, design, computers, by Kristen Gallerneaux

Anniversary of the Thirteenth Amendment

Joint Resolution of the United States Congress, Proposing the 13th Amendment to abolish slavery, February 1, 1865 / THF118475

December 6, 2020, marks the 155th anniversary of the ratification of the Thirteenth Amendment, which legally abolished slavery.

The Emancipation Proclamation, first made public by President Abraham Lincoln in September 1862, laid the foundation for this amendment. With this presidential proclamation and executive order, President Lincoln hoped to counteract severe Union losses during the Civil War by calling on all Confederate states to rejoin the Union within 100 days (by January 1863) or the proclamation would declare enslaved people “thenceforward, and forever free.” On January 1, 1863, President Lincoln proceeded to sign this document, announcing freedom to all enslaved people in the Confederacy. It helped enlist needed support for the war from abolitionists and pro-union and anti-war supporters. But it was not a legal document, and Lincoln knew it.

President Lincoln and his allies in Congress soon began working to enact a constitutional amendment that would legally abolish slavery. Various versions were brought before Congress until, on April 8, 1864, the strongly pro-Union Senate approved this version of the Thirteenth Amendment as we know it today:

Section 1. Neither slavery nor involuntary servitude, except as a punishment for crime whereof the party shall have been duly convicted, shall exist within the United States, or any place subject to their jurisdiction.

Section 2. Congress shall have power to enforce this article by appropriate legislation.

However, this amendment failed to pass in the House of Representatives, whose members were more split on their views. The amendment stalled until November of that year, when, upon his own reelection and with like-minded Republican gains in the House, President Lincoln urged members of the Congress to reconsider the measure and give it their utmost urgency. He enlisted members of his Cabinet and selected allies in the House to help him sway enough House member votes for the amendment to pass.

On January 31, 1865, it barely squeaked by with the requisite two-thirds majority. Upon learning of the final vote, pro-Union and anti-war members of the House erupted in shouts and cheers, while outside spectators who had filled the Capitol’s galleries (both Black and white) wept tears of joy.

On February 1, 1865, members of Congress signed this Joint Resolution of the Thirteenth Amendment, indicating that it had passed by both the Senate and the House of Representatives but had yet to receive state ratification. Although not legally required to do so, President Lincoln signed it as well. Immediately, Lincoln’s foes in both Congress and the press criticized him for wielding unseemly presidential power. But Lincoln was undeterred. Celebrating that evening, Lincoln happily announced, “This amendment is a King’s cure for all evils. It winds the whole thing up.”

It did help wind up the war. Its primary motive was, in fact, to preserve the Union by destroying the cornerstone of the Southern Confederacy. Sadly, on April 15, just as the war was winding down, President Lincoln was assassinated. Afraid that slavery might be re-established by individual states, Radical Republicans in Congress determinedly pushed the Thirteenth Amendment forward for state ratification. It was finally ratified by the requisite three-quarters of states on December 6, 1865—the date we are now commemorating.

Unfortunately, the Thirteenth Amendment was not a “cure for all evils.” Some Southern states were already instituting black codes, denying African Americans basic rights. The Thirteenth Amendment was followed by a Fourteenth and a Fifteenth—legally guaranteeing African Americans the basic rights of citizenship and the ability to vote. But these were just legal documents. Enforcing them was another matter, one fraught with violence and discrimination. African Americans would face an ongoing struggle for freedom and justice.

This is one of a limited number of original manuscript copies known to survive of the February 1, 1865, Joint Resolution of the US Congress, proposing the Thirteenth Amendment to abolish slavery. Lincoln’s signature was added by another hand.

Donna R. Braden is Senior Curator and Curator of Public Life at The Henry Ford.

presidents, 1860s, 19th century, Civil War, Civil Rights, by Donna R. Braden, African American history, Abraham Lincoln

Anniversary of Rosa Parks’ Arrest: December 1, 1955

Montgomery city bus in which Rosa Parks refused to move to the back, now in Henry Ford Museum of American Innovation. / THF14922

This year marks the 65th anniversary of Rosa Parks’ arrest for refusing to stand up and move to the back of this city bus from Montgomery, Alabama (above). In our previous blog posts, we have focused primarily upon the story of Rosa Parks herself—her background, character, motivation, and legacy.

In 1992, Rosa Parks visited Greenfield Village with a group of students during a "Freedom Tour" sponsored by the Raymond and Rosa Parks Foundation. After she spoke to students, she posed here in the Mattox House, the 1930s Georgia home of an African American family. / THF123775

We now take the opportunity to acknowledge the important contributions of numerous other individuals to this legacy.

Our first acknowledgment goes to those who helped lay the foundations for Rosa Parks’ act: the many black Montgomerians who put up with mistreatment and humiliation on segregated buses for years, and even decades, so that when the right time came they were ready to take collective action; to early community activists in Montgomery like Raymond Parks (Rosa’s husband), Mary Fair Burks, Rev. Vernon Johns, Rufus Lewis, Johnnie Carr, and J. E. Pierce; and to Claudette Colvin and Mary Louise Smith, who made the conscious decision to refuse to stand up and move to the back of the buses on which they rode just months before Rosa Parks.

Token used on Montgomery bus lines, about 1955 / THF8293

Second, we recognize the important work of community organizations that worked toward effecting change at the time—the Women’s Political Council, the Montgomery Improvement Association, and the Montgomery chapter of the NAACP (for which Rosa Parks had worked); to black community leaders who shaped these organizations and mobilized the black community to take action as a response to Rosa Parks’ arrest—including Jo Ann Robinson, E.D. Nixon, Rev. Ralph Abernathy, and Rev. Martin Luther King, Jr.; and to young black lawyer and activist Fred Gray for defending both Claudette Colvin and Rosa Parks as well as for bringing other notable civil rights cases to court.

Liberation Magazine from April 1956, featuring the Montgomery bus boycott on its cover. / THF139343

Finally, we acknowledge Montgomery’s black community for courageously defying the city’s segregated bus practices by boycotting Montgomery buses after Rosa Parks’ act. For 381 days, this community surmounted obstacle after obstacle created by those attempting to obstruct and put an end to this boycott. Their courage and determination set an example for others, both then and now.

The story of the Montgomery bus boycott and how it unfolded will appear in future blog posts.

For more background on the story of Rosa Parks, see:

- “What If…I Don’t Move to the Back of the Bus?”

- “Segregated Travel and the Uncommon Courage of Rosa Parks”

- “60th Anniversary of Rosa Parks’ Courageous Act”

To better understand the important role of the individuals and community organizations mentioned above, check out:

- Rosa Parks: My Story, by Rosa Parks and Jim Haskins (1999)

- The Rebellious Life of Mrs. Rosa Parks, by Jeanne Theoharis (2015)

- Rosa Parks: A Life, by Douglas Brinkley (2005)

Donna R. Braden is Senior Curator and Curator of Public Life at The Henry Ford.

Alabama, 20th century, women's history, Rosa Parks bus, Rosa Parks, Civil Rights, by Donna R. Braden, African American history

A Puzzle Block Surprise

In 2017, I had the opportunity to work with our curator of domestic life, Jeanine Head Miller, on a new Expert Set featuring alphabet blocks and spelling toys from our collections. We chose one example based on a nearly 20-year-old photograph from our collections database. It was dated between 1860 and 1880 and appeared to be a set of wooden alphabet blocks with images printed on the reverse that could be assembled to complete two puzzles. Notes in the database and an image on the box lid alluded to more, so we decided to re-photograph the blocks before adding them to our Digital Collections.

Image taken in 2000; touched up in 2017 by Jim Orr, image services specialist / THF133429

While conducting research for the Expert Set, I visited our photographic studio to see the blocks in person. They were in good condition, and I was able to carefully – with gloves and on a clean surface – assemble each of eight possible solutions, revealing not only the alphabet and two 12-block puzzles visible in our existing photograph (“The Farm” and “Anna’s Delight”), but two other pastoral scenes of the same size (“Grandfather’s Visit” and “My Country Residence”), two full-size, 24-block historical images (“William Penn’s Treaty with the Indians” and “Mount Vernon – Washington’s Residence”), and a map of the United States. The borders and place names on the map gave us hope that we might be able to narrow the date range for these blocks, but some text on the Mount Vernon puzzle gave us an even better clue – the lithographer’s name!

Reference image showing lithographer information [REG2017_1103]

A quick Internet search (an invaluable tool for modern museum research) revealed that Thomas S. Wagner worked as the sole proprietor of his Philadelphia lithography firm for a short time, between a dissolved partnership with fellow lithographer James McGuigan in 1858 and Wagner’s death in 1863. (Interestingly, according to the Library Company of Philadelphia, Wagner was “one of the few publishers of wooden lithographic puzzles” at that time.) Not only were we able to considerably narrow our date range from 1860–1880 to 1858–1863, we could now add creator information to our records!

We decided to have our photographer, Rudy Ruzicska, and digital imaging specialist, Jillian Ferraiuolo, create just a few official images of the picture puzzle – enough to document the box and individual blocks and to give online viewers a sense of the possible solutions. But I also captured reference photographs of each of the 8 completed puzzles for our collections database. These wouldn’t typically be available to the public, but to celebrate our recent digital collections milestone – 100,000 artifacts! – I’ve shared a few of them below.

Thanks for reading!

Continue Reading

Pennsylvania, 19th century, toys and games, photography, digitization, by Saige Jedele, #digitization100K, #Behind The Scenes @ The Henry Ford

Ford Motor Company Part Drawing Collection, 1903-1957

By the early 1950s, Ford Motor Company’s engineers had made over one million technical drawings of the parts used to make Ford cars and trucks. In 1949 alone, they used 13 million square feet of blueprint paper!

Ford Motor Company engineers at work, circa 1952. / THF125069

The drawings were being stashed away wherever room could be found. Since many of the drawings were for parts that were still in production, there was concern that the company’s operations would come to a halt if drawings were lost to a fire, a flood, or worse. Plans were made to microfilm the drawings so they could be stored more securely.

Paragraph from a 1951 brochure detailing the microfilming project. Cold War tensions were running high. / detail from THF135511

Eleven fireproof storage safes, holding one million microfilmed drawings, 1951. / THF123713

To save space, most of the original paper blueprints were destroyed after the drawings were copied onto microfilm. But a few can still be found in our Miscellaneous Ford Motor Company Blueprint and Drawings Collection.

Blueprint showing part TT-7851-R for a Ford Model TT Truck. / THF138486

70 mm microfilm copy of the same drawing. / THF406917

The Ford Motor Company Part Drawing Collection consists of over one million Ford engineering drawings from 1903–1957, on 70 mm microfilm. Each piece of film measures approximately 2.625 x 3.5 inches, and is in a manila envelope that shows the part number and the drawing’s latest revision date.

Envelope for drawing TT-7851-R, dated August 25, 1926. / THF406916

As of this writing, about 3,000 Ford part drawings can be seen on our Digital Collections website. Only 997,000 to go!

So, why don’t we “just” digitize them all?

The first challenge is the size of the film. Most high-speed scanners on the market now are not equipped to hold 70 mm film. And because each frame of film was cut from its roll and placed in a separate envelope, the film cannot simply be run through a machine.

We image the film using an Epson Perfection V850 Scanner with built-in Transparency Unit (a light inside the lid that allows it to scan film). Each piece of film measures just under 3 x 4 inches, so a scanning resolution of 1200 dpi (3600 x 4800 pixels) will usually suffice … but we go higher if a drawing looks like it will be difficult to read.

Larger blueprints, like this one for a V-8 Cylinder Block, were microfilmed in segments. / THF401366

After the film has been scanned, the images are straightened and cropped, and adjustments may be made to the brightness and contrast. If the film is a negative, we also create an additional, positive version of the digital image.

This version of the digital image can be printed without using as much toner. / THF406918

However, the bigger challenge is the data entry. Even the best digital image is useless if nobody can find it. To that end, it is necessary to transcribe the part number, the date of the drawing, and the title of the drawing from each piece of film. And many of the drawings include more than one part number!

If parts are symmetrical opposites, there is only one drawing for the pair. / detail from THF400831

The revision history appears in the upper right corner of each drawing. This drawing is dated December 3, 1930 … but earlier versions may also exist. / detail from THF400831

If you are interested in researching the Ford Motor Company Part Drawings Collection, our Popular Research Topics page includes an FAQ and information about how to get started. Inquiries can be sent to research.center@thehenryford.org.

| The Henry Ford is facing unprecedented financial challenges due to the impact of our 16-week closure and reduced operations. We need your help in securing our future. Love the Henry Ford? Please support all that we treasure—including our digitization program. Longtime supporters of The Henry Ford will match your donation dollar for dollar, so your contribution will have double the impact. |

20th century, Ford Motor Company, drawings, digitization, cars, by Jim Orr, archives, #digitization100K, #Behind The Scenes @ The Henry Ford