Posts Tagged by debra a. reid

Acquiring an Agras MG-1 Drone

"Agras MG-1" Drone, with remote control, battery, and battery charger, 2016. Gift of Northwestern Michigan College / THF199347

Curators at The Henry Ford document milestones in their given areas of responsibility. For agriculture and environment collections, one significant recent development involves uses of uncrewed aerial technology — popularly known as drones — to apply growth enhancers (fertilizers) and plant protectors (herbicides and pesticides) to specific locations in fields, vineyards, and orchards. Curator Debra Reid began conversations with the Michigan Soybean Committee in 2023 to secure a drone for our collections to document this aspect of precision agriculture.

Drones flew on military missions, predominately, until the early 2000s. One example includes the 1918 Kettering Bug, described as the world's first "self-flying aerial torpedo.” As a Smithsonian Magazine article explained, “the simple, cheaply made 12-foot-long wooden biplane with a wingspan of nearly 15 feet” included “a 180-pound bomb. It was powered by a four-cylinder, 40-horsepower engine manufactured by Ford.” These precision-based technologies aimed to put fewer pilots at risk.

Employees of the Dayton-Wright Airplane Company Working on the Kettering Bug, 1918 / THF270430

Other drones in The Henry Ford’s collections address robotics in aerial photography and stunts.

3DRobotics Solo Drone, 2015-2016. Gift of Industrial Designers Society of America / THF193809

3D Robotics (3DR) released its Solo drone in 2015 to great fanfare. NBC News claimed the Solo, when paired with a GoPro HERO camera, could take Hollywood-quality shots. 3DR, the largest North American manufacturer of drones for consumers at the time, believed that the quadcopter with its open-source operating software would dominate the aerial photography market. It may have done so, but competition from the China-based Dajiang Innovation Technology Company (DJI) challenged 3DR and outmaneuvered the Berkeley, California, company. In response, 3DR abandoned the drone manufacturing business and DJI came to dominate the hobby market for uncrewed aerial vehicles (UAVs).

Front view of the "Agras MG-1" Drone with propellers folded to show the radar module, spray tank, spray nozzles, and landing gear, 2016. Gift of Northwestern Michigan College / THF199333

DJI manufactured the Agras MG-1 specifically for the growing market in precision agriculture and advertised the octocopter as “designed for variable rate application of liquid pesticides, fertilizers, and herbicides, bringing new levels of efficiency and manageability to agriculture." Farmers found the investment paid off in numerous ways. They reduced input costs by reducing the quantity of synthetic chemicals applied. Additional environmental benefits included reduced run-off that negatively affects water quality and reduced greenhouse gas emissions because farmers used less fossil fuel during application. Reducing vehicular traffic also improved field health by reducing soil compaction which supported regenerative agriculture goals.

The rapid expansion of hobby and commercial drone markets prompted licensing regulation. The Federal Aviation Administration (FAA) required commercial drone operator licensing in 2016, but some schools had anticipated the need. Northwestern Michigan College first offered a course in Uncrewed Aerial Systems operation at the Yuba Airport in Grand Traverse County, Michigan, in 2010, becoming one of the first schools in the United States to do so. In 2013, NMC launched an Associate in Applied Science degree with a specialization in UAS. Then, NMC purchased one of the first DJI spray drones used in the United States, according to Tony Sauerbrey, UAS program manager at NMC. The Agras MG-1 facilitated the rapid expansion of commercial drone use in Michigan farm fields.

Instruction in Agras MG-1 operation. Gift of Northwestern Michigan College / THF717085

Learning to operate the Agras MG-1, dispensing water, rather than chemicals. Gift of Northwestern Michigan College / THF717084

The Agras MG-1 in flight over a Michigan vineyard. Gift of Northwestern Michigan College / THF717081

DJI designed the Agras MG-1 to carry 22 pounds of liquid pesticides, herbicides, or fertilizers — an amount that could treat an average of an acre in 10 minutes. Its “intelligent” operating system relied on global positioning systems (GPS) data to fly level to the terrain and to automatically adjust the quantity of spray to the flying speed and thus ensure even distribution. Operators had to understand the inputs as well as ways to override them if the battery ran low, the tank ran dry or changes in the weather made it difficult to operate the drone safely.

Rapid expansion in drone-aided agriculture led to training alliances. NMC partnered in 2017 with Michigan State University's Institute of Agricultural Technology so MSU students could meet drone licensing requirements. NMC also partnered in 2020 with Unmanned Systems Institute which administered additional industry safety certifications. Instructors need up-to-date technology, not dated UAS. Thus, NMC retired its Argas M-1, and we acquired it to document early UAS use in precision agriculture.

Debra Reid is Curator of Agriculture and the Environment at The Henry Ford.

Green Museum Work at The Henry Ford

The Henry Ford identified “Cultivating Environmental Responsibility” as one of its strategic goals in anticipation of its 100th anniversary in 2029. A few staff began assessing factors relevant to this goal in August 2019. The Henry Ford’s Green Team (previously the Environmental Focus Group) emerged out of this work and formally organized in May 2021 with responsibilities to benchmark and manage THF’s energy and water use and to reduce waste by recycling and composting. This work aligns with a call to action put forth in Sarah S. Brophy and Elizabeth Wylie’s The Green Museum: A Primer on Environmental Practice, namely, that going green “is becoming mainstream because of its importance, not its fashion” (pg 2).

You could argue that The Henry Ford has pursued green museum work since its beginning in 1929. Certainly, historical precedence lays a solid foundation for current initiatives. Three examples indicate how preservation, reuse, and local sourcing factored prominently in The Henry Ford’s history.

First, historic preservation is a green action. Committing to preservation and adaptive reuse rather than demolition reduces financial costs and energy expenditures.

Rebuilding the Clinton Inn in Greenfield Village, April 1929 / THF149382

Second, reusing landscape features supports actions that reduce environmental degradation. Namely a pond created by laborers excavating clay for use in Anthony Wagner’s brickyard starting in the 1860s became a rainwater holding tank for the museum. Design masked the multi-part infrastructure that re-purposed runoff from museum roofs for use in landscape irrigation.

Pond adjacent to Henry Ford & Son’s tractor plant, October 22, 1918, and north of The Henry Ford’s staff parking area today, remains central to The Henry Ford’s rainwater management system / THF116967

Museum plans drafted in 1928 incorporated pumphouses in two courtyards that pushed rain runoff through a drainage system and into the pond. Facilities managers take this history of environmental change into account when undertaking pond and pumping infrastructure maintenance.

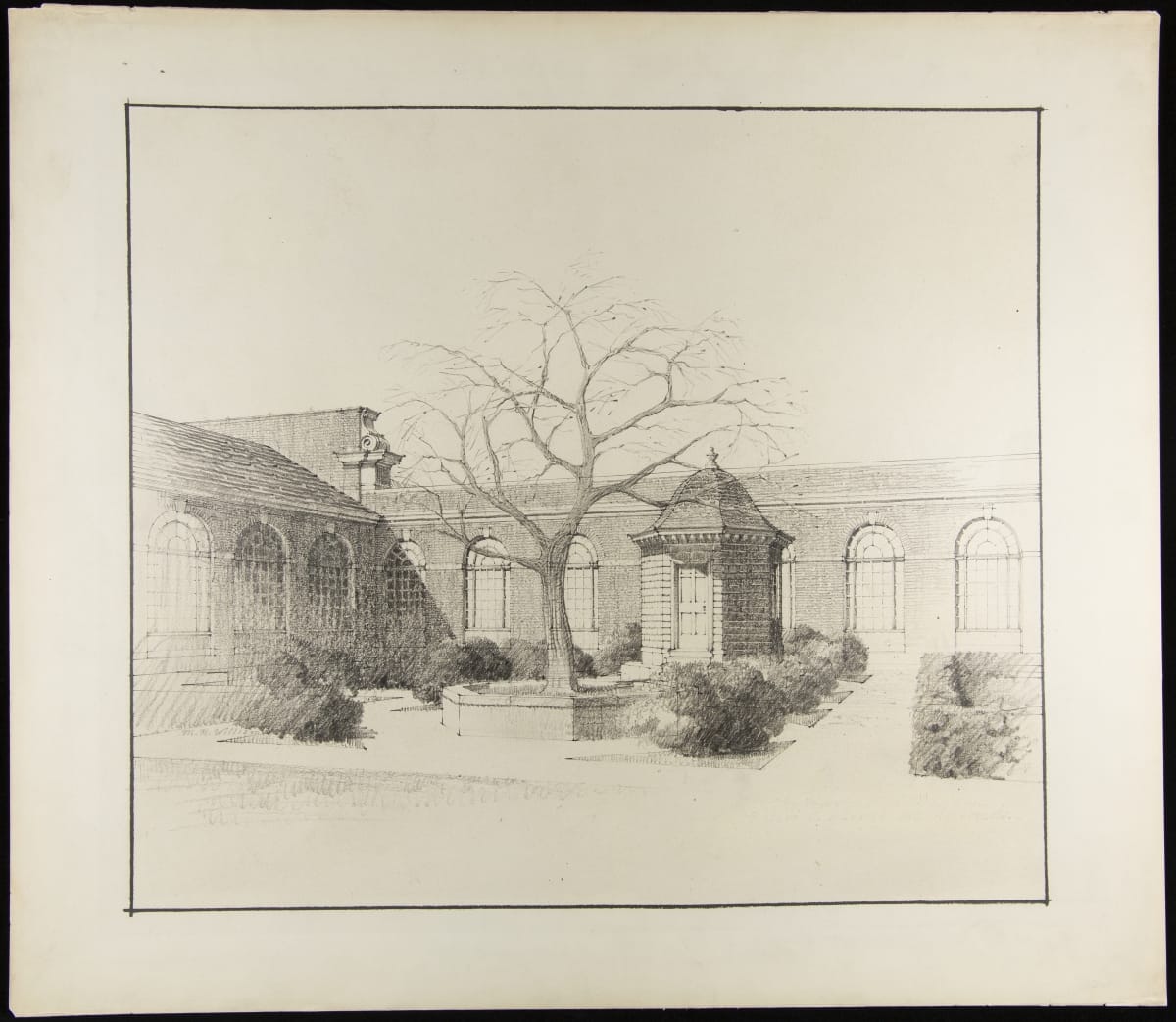

Drawing of the Virginia Court with pumphouse replicating a garden feature from Mount Vernon, 1928 / THF294374

Third, Henry Ford confirmed the importance of locally sourced materials when he constructed the chemical laboratory at the entrance to Greenfield Village. More than a dozen chemists worked in this structure, seeking domestic products for industrial use. By December 1931, soybeans became the focus of their research, and a new agricultural commodity took hold in southwestern Michigan. Ford joined others in Illinois, North Carolina, and beyond, exploring the potential of soybeans to meet local industrial demand for alternative oils for paint and alternative proteins for foods. Today we know that locally sourced products reduce carbon emissions by reducing transportation from the point of production to processing and consumption locations.

Chemical laboratory in Greenfield Village with Lovett Hall, The Edison Institute, visible in the background, 1930. This image predates Henry Ford instructing the chemists to focus on soybeans / THF236433

These historic approaches (among others) laid a firm foundation for Green Team actions over the past five years (2019 to 2024). Staff prioritized benchmarking, recycling, and composting as important steps toward cultivating environmental responsibility. Efforts aligned with national initiatives such as the Culture Over Carbon project, funded by the Institute of Museum and Library Services. More than 130 cultural institutions across the United States, including The Henry Ford, shared energy-use data that identified trends for the field. This supported a larger goal, to establish a cultural institution benchmark for Energy Star ratings.

Green Team members also engaged with Detroit’s 2030 District chapter through which they met with other museum and culture partners within and beyond the area. The national network of 2030 Districts, made up of businesses, cultural institutions, and municipal governments, all in efforts to pursue new models for urban sustainability and economic vitality. Ongoing conversations help put institutional work into context, including a signature accomplishment at The Henry Ford in 2024, namely, the installation and operation of the second biodigester in the Detroit area.

The Henry Ford staff, Amber Stankoff, producer (left) with Brian Egen, executive producer and head of studio productions (center), filming Alec Jerome, senior director of facilities management and security, discussing the biodigester installed at Stand 44, the new restaurant in Greenfield Village, June 26, 2024. Photograph by Debra A. Reid.

These actions are steps on the longer path toward cultivating environmental responsibility. Extending information more broadly to THF staff and guests makes clear how each of us will contribute to realizing this ambitious goal. Doing so will ensure a more stable environment for staff and guests in perpetuity.

Debra A. Reid is curator of agriculture and the environment at The Henry Ford and has been a member of the Green Team since its formation. She serves on the Climate & Sustainability Community of the American Association for State and Local History and is the secretary of the International Council of Museums' international committee, SUSTAIN (Museums and Sustainable Development).

Snowshoes: 2024 IMLS Feature

As we come to the end of our 2022-2024 IMLS (Institute of Museum and Library Services) grant project, the Conservation staff are showcasing standout objects recently treated. During the two-year project we have conserved and relocated 2,106 objects, and created fully digital catalog records for 815 of these. The following blog highlights the snowshoes that made their way through this grant, now made accessible to the public via The Henry Ford’s Digital Collections.

Snowshoes have a long history in North America. Indigenous peoples invented the form using thin strips of collagenous material (sinew or treated hide) and bent wood. The woven strips created a netting used for walking on snow. In fact, using snowshoes helped Indigenous peoples in snowy areas thrive during wintertime. The shoes facilitated trade, hunting, trapping, and self-defense. You can read more about the advantages of Indigenous snowshoe knowledge in Thomas M. Wickman’s book, Snowshoe Country: An Environmental and Cultural History of Winter in the Early American Northeast (2018).

Wickman focuses on the Wabanaki, including Mi’kmaq, Maliseet, Passamaquoddy, and Penobscot peoples, in northern New England. The Wabanaki held advantage in the area during the 1600s, but by the early 1700s, British colonizers co-opted Indigenous tactics, including snowshoes, and launched winter offensives with the goal of eliminating their Indigenous opponents. Snowshoes then became a tool that British colonizers used for daily winter transport.

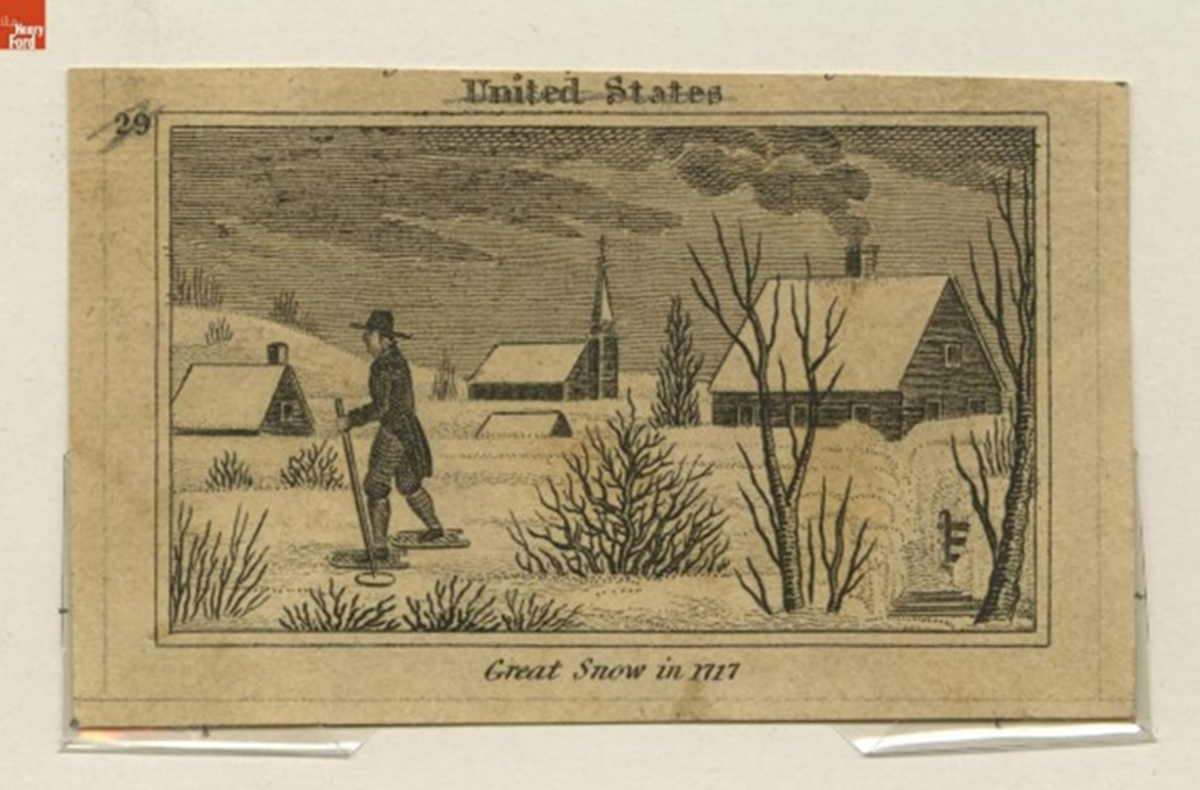

Copperplate engraving made around 1820, "Great Snow in 1717" / THF118620

A description of the “Great Snow Storm” of 1717, included in Historical Scenes in the United States (1827), described the snow as being so deep that “people stepped out of their chamber-windows on snow shoes.” The author, John W. Barber, mentions consequences of the 1717 snow, a “terrible tempest” that trapped New Englanders in upward of 15 feet of snow accumulated over several storms in late February and early March. The rather bucolic illustration does not convey the tragedy of the weather event. The 1891 book Historic Storms of New England does a better job. Author Sidney Perley puts the storm into context in his chapter, “The Winter of 1716-1717,” including the loss of livestock and humans. He also provides detail about those colonists who donned snowshoes, including mail carriers and residents who relied on the shoes to tend to livestock or assist neighbors, and sometimes to visit sweethearts.

Native American Basket Market, Ojibwa Tribe, Mackinac Island, Michigan, September 1904 / THF118996

Indigenous knowledge remained essential to snowshoe construction. A photograph shows Ojibwa people selling baskets, and in the background, a pair of snowshoes leaning against a tree. The snowshoes treated during the IMLS grant project lack the decorative tufts of either dyed moose hair or wool visible on the Ojibwa snowshoes, but the intact webbing, carefully conserved, still indicates the craftsmanship evident in each shoe.

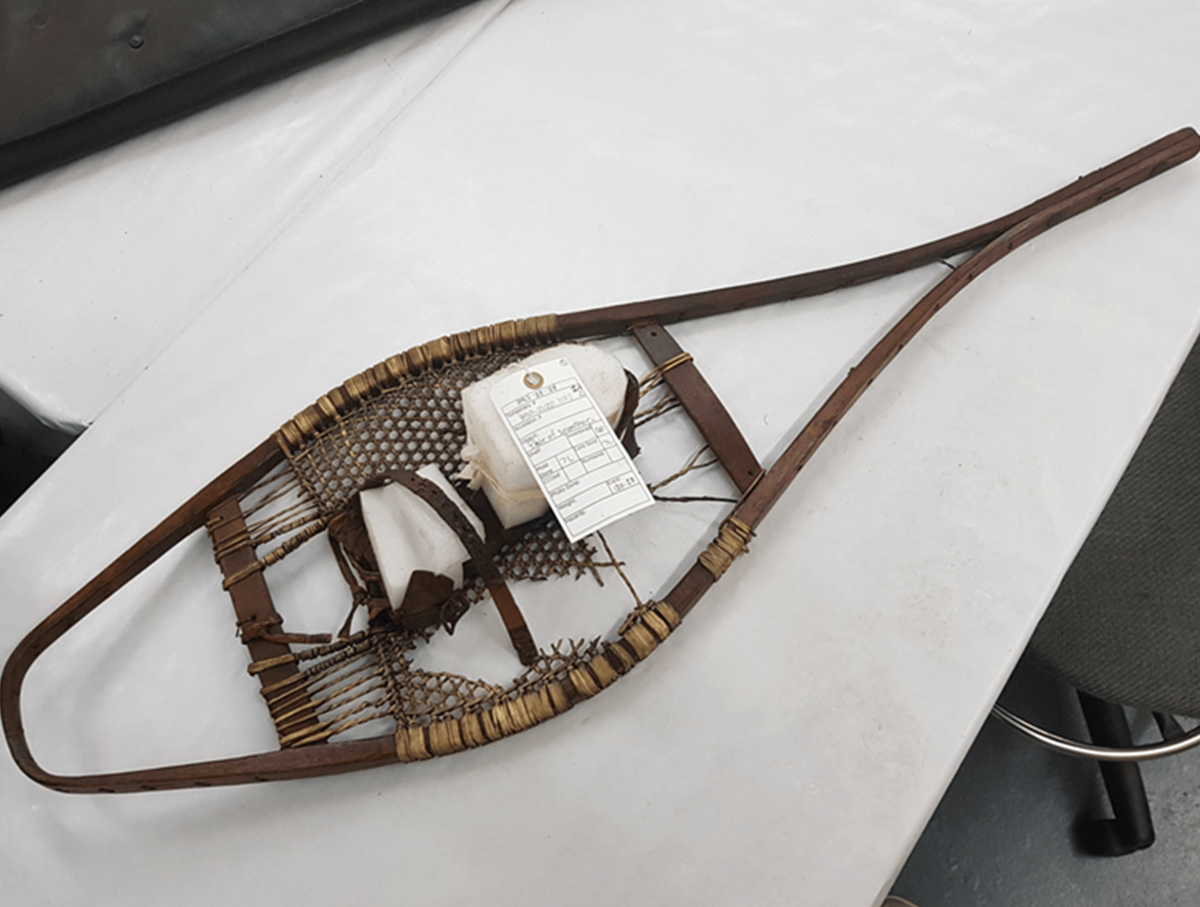

Some of the snowshoes in The Henry Ford’s collections still have their leather ankle loops and toe thongs intact. These details secured the toe to the shoe, leaving the heel free to lift the shoe and step forward with each stride.

The following images show the work of conservation, and the photography that was used to document our process. We are pleased to be able to share these remarkable artifacts via THF’s Digital Collections.

One shoe of a pair of snowshoes needed stabilization before proper handling. A section of the wood frame was missing, leaving sharp pieces of wood sticking out. The dowels keeping the tail together had split, causing more tension on the weakened rawhide webbing. / Images by Jeeeun Sims (Jee Eun Lim)

The tail was stabilized with painted wooden dowels inserted between the gaps that were secured with wood glue. The large loss to the wood frame was filled with a wood putty that was levelled, scored with a dental pick to create the wood grain, and painted to match the rest of the wood. / Images by Jeeeun Sims (Jee Eun Lim)

The rawhide was then cleaned with a mild detergent and distilled water with a stiff brush to remove as much dirt as possible. The rawhide webbing is rather sturdy, even where it had detached from the wooden frame, and was not in need of reattachment at this time. / Images by Jeeeun Sims (Jee Eun Lim)

Another pair of snowshoes in a different shape from the previous pair has leather shoe holders attached to the mesh component made of rawhide. One-fourth of the mesh is missing, while the rest of the mesh was stained by dirt and dust. The overall surface of the leather was fragile, cracked, missing, and broken in some areas. A leather strap to hold the toes was split and separated from the object. / Images by Jeeeun Sims (Jee Eun Lim)

The leather was consolidated with Jade R adhesive and Japanese tissue attached to the reverse side of broken leather areas after cleaning with distilled water. The split leather strap was also reattached in the original position by the same restoration method. The restored areas by Japanese tissue were painted to match the rest of the leather. The rawhide was cleaned with the same method as described with the previous snowshoes. / Images by Jeeeun Sims (Jee Eun Lim)

The leather shoe holder is held in place with a foam support to keep the shape and avoid further physical damage. Oil-based gel stain mixed with nutmeg and antique walnut color was applied on the wood surface of the object to match the rest of the color of the wood. / Images by Jeeeun Sims (Jee Eun Lim)

Thanks to the work of the IMLS team, the care and conservation of these organic artifacts is complete. In the photo studio, the snowshoes presented even more complexities.

They proved to be one of the trickiest (and most delicate) objects photographed throughout the IMLS grant project. Senior photographer and studio manager, Jillian Ferraiuolo, outlines below how the snowshoes needed to be handled carefully to be properly photographed.

Snowshoes set up for photography / Image by Jillian Ferraiuolo

Because they are so large, the snowshoes were photographed on the ground, with white boards placed underneath to protect them from the floor. A white background also makes it easier to clean the background during the editing phase and remove anything that’s not a part of the object.

Object 2022.0.22.646 / THF800530

Object 2022.0.22.645 / THF800534

Object 2022.0.22.644 / THF800535

Photographing the snowshoes was one of the final steps towards getting these important objects added to THF’s Digital Collections webpage. Thanks to IMLS funding, these and more artifacts that tell agricultural and environmental histories have become more accessible.

This blog was written by Jeeeun Sims (Jee Eun Lim), IMLS project conservator; Jillian Ferraiuolo, senior photographer & sudio manager; and Debra A. Reid, curator, agriculture and the environment.

Marlene Gray, senior conservator; Julia Fahling, conservation specialist; Eleanor Glenn, former conservation specialist; Mary Fahey, chief conservator; and volunteers (Eric Bergmann, Maria Gramer, Frances McCans, and Larry McCans) assisted Jee throughout the two-year grant project.

My friend Jennifer introduced me to Marian Morash’s The Victory Garden Cookbook (Alfred A. Knopf, 1982) in 2022. She explained that the cookbook was her mother's go-to wedding present. When Jennifer and her daughter saw a feature article about Mrs. Morash and her husband in Better Homes & Gardens (2017) they wrote her. They thanked her for the inspiration the cookbook provided three generations of cooks in Jennifer's family, and the modest Beard-Award-winning chef, author and TV personality wrote back, amazed that the cookbook could still be found.

Marian’s inspiration came from none other than Julia Child who passed along partially cooked foods from a cooking show that Marian’s husband, Russell Morash, piloted in 1962. The following summarizes the connections that laid the groundwork for the influential Victory Garden Cookbook.

Dust jacket, The Victory Garden Cookbook (1982). / THF708642

Hardcover, The Victory Garden Cookbook (1982). / THF708645

Morash's Background and Inspiration

Morash’s husband, TV producer Russell Morash, first encountered Julia Child, co-author of Mastering the Art of French Cooking (1962), on the WGBH-TV show I’ve Been Reading, in an episode likely broadcast on February 19, 1962. Child captivated WGBH-TV staff and viewers with her cooking demonstration, and the station decided to produce three pilot episodes of The French Chef. These aired in 1962 on July 26 (the omelet), August 2 (coq au vin) and August 23 (the souffle). The new series, The French Chef, debuted February 11, 1963. Marian’s husband, Russell Morash, produced the new series. The half-prepared recipes that Russell salvaged from the show, along with Julia Child’s directions written to Marian so she could complete the cooking, nurtured the nascent chef. In 1975, Marian co-founded Straight Wharf Restaurant in Nantucket, Massachusetts, and ran it as executive chef. Continue ReadingElectric Mower with 74-Inch Cut Comes to The Henry Ford

The Henry Ford has a grounds crew that works year-round to keep the expansive lawns in tip-top condition. Green practices have driven much of the care from the beginning. The millponds in Liberty Craftworks and behind A Taste of History are all part of a natural water filtration system that allows residue to settle out of rainwater runoff before it enters the Rouge River. That’s just one part of water management at The Henry Ford, however, because that water is also reused to irrigate the lawns.

The irrigation system keeps the yards lush. Thus, mowing consumes many an hour in the grounds crew’s schedule. A grant from the Aptiv Foundation Inc. funded purchase of a new Evo electric zero-turn riding mower. The 74-inch width means the grounds crew can cut more grass in a day (and the battery will power up to 8 hours of work on a single charge).

Continue Readinglawn care, nature, Greenfield Village, by Debra A. Reid, #Behind The Scenes @ The Henry Ford

Soybean Harvesting / Photo courtesy of the United Soybean Board

Soybean Harvesting / Photo courtesy of the United Soybean Board

Farmers have only a narrow window of opportunity to harvest their crops. For Michigan soybean growers, that window generally runs from the end of September through November, but is impacted yearly by weather events. By that point in the season, the plant is fully mature and has lost most of its leaves, and only the stalk and pods (with three to four beans per pod) stand in the field (R8 Growth Stage). The seeds are brown and hard at this point, and bean moisture content is 13-15%.

A Close-Up of the Modern Soybean Harvesting Process / Photo courtesy of the United Soybean Board

Harvesting soybeans—to cut the stalk, separate the bean from the pod, clean the bean, and store it until moved from harvester to wagon or truck—requires a multifunctional machine. Soybean growers benefitted from around a century of experimentation with specialized harvest machines when it came time for them to look for the best machine for the job. Farmers need machines that work, and different machines to harvest different crops. The Henry Ford has some of the earliest of these mechanical innovations, each suited to a specific crop—the Ambler mowing machine for hay, models of the Hussey and McCormick reapers for grains, and the Manny combined mower and reaper (one machine adaptable for both crops).

These early-19th-century innovations represented solutions to the problem of how to reduce human labor costs. Farm families often could not meet labor demand during harvest seasons. Too little labor meant lost crops, and lost crops made it difficult for farmers to feed their livestock (hay) or earn income from market crops (grain). Hiring labor was expensive, and even more expensive during peak demand at harvest time.

A century passed between the 1830s, when mechanical reapers and mowing machines first became viable, and the 1930s, when the first Allis-Chalmers All-Crop Harvester entered Michigan soybean fields.

Man Driving an Allis-Chalmers Tractor Pulling an Allis-Chalmers All-Crop Harvester at Michigan and Southfield Roads, Dearborn, Michigan, October 1936 / THF286727

The Crop

Michigan growers raised different types of beans during the early 20th century. Some raised bush beans (Phaseolus vulgaris), green beans that they harvested by hand when the pod reached the R5 growth stage and seeds had just begun to develop. Wholesale dealers distributed this perishable commodity to grocery stores while processors turned the bush beans into canned green beans. Others raised large fields of beans on contract with the H.J. Heinz Co. After the beans were fully matured and dry, growers harvested the crop by hand, then hauled the crop to a threshing machine that separated the beans from the pods and stems. Employees at Heinz processing plants continued the handwork, sorting beans from debris. Product advertising emphasized this attention to detail that yielded a quality food product.

A different type of bean—the “soy bean” (or soybean, Glycine max)—became increasingly apparent in southeast Michigan during the 1930s. Interest in this new cash crop grew apace with Henry Ford’s investment in soybean research. Scientists at work in the chemical laboratory that Ford built in Greenfield Village confirmed that soybeans had potential as a domestic source for various industrial products. Industrial demand in the region caused growers to seek a harvester suitable to the task.

Soybean Pods Ready for Harvesting / Photo courtesy of the United Soybean Board

Some farmers raised seed crops to meet growing demand for the new cash crop. This specialized cultivation required careful harvesting, as described in “Soy Bean Seed Production in Michigan” (1936). Others raised crops to meet the growing demand for the new industrial raw material. The Ford Village Industries complex in Saline, Michigan, opened in 1938. A press release issued by Ford Motor Company in July 1938 indicated that 700 farmers planted 22,588 acres of soybeans processed at the Saline facility. Ford processing capacity increased as the soybean processing plant at the Rouge Plant began operations around 1942.

Ready for the Harvest: The Allis-Chambers All-Crop

Farmers needed mechanical harvesters to ensure that they delivered a prime crop to Ford Motor Company. Henry Ford thus took an interest in this technology. Allis-Chalmers released its All-Crop 60 harvester in 1935, designed to operate off a tractor big enough to pull a double-bottom plow and powered by the tractor’s power take-off. The “60” represented the width in inches of the swath cut by the harvester. Ford tested the capability of the Allis-Chalmers All-Crop Harvester on a Ford Farms soybean crop in October 1936. By that time, Allis-Chalmers had sold 8,200 of the machines.

The engineer who took a leading role in the machine’s development was Charles J. Scranton, Jr. He began his career as a draftsman at Avery Company, a Peoria, Illinois, company noted for steam traction engines, threshers, and other farm equipment that went bankrupt in 1923. Scranton, as an assignee to a successor company, the Avery Power Machinery Co., secured several patents for improvements to threshers during the late 1920s.

Scranton joined Allis-Chalmers by working at the LaPorte, Indiana, location by 1934. Over 30 years, he secured around 40 patents, all focused on harvesting machinery. The All-Crop marked a crowning achievement because it suited the needs of farmers operating on a smaller scale and growing different cash crops, including soybeans, clover, milo, and other grains.

Ford featured the Allis-Chalmers All-Crop Harvester in early promotional photographs of the Ford tractor with the “Ferguson System,” the Ford-Ferguson 9N, released in 1939. This marked a ringing endorsement from the industrialist who launched soybeans as a cash crop in Michigan.

A Ford-Ferguson Model 9N Tractor Pulling an Allis-Chalmers “All-Crop” Harvester, Macon, Michigan, November 1939 / THF701486

Rear view of the Allis-Chalmers “All-Crop” Harvester, pulled by a Ford-Ferguson Model 9N Tractor, Macon, Michigan, November 1939 / THF701489

More Crop in the Hopper

As soybean acreage increased across the Midwest after World War II, farm implement companies continued to innovate. The Allis-Chalmers All-Crop was well suited to smaller scale farmers growing a variety of crops, but the scale of production increased dramatically during the 1950s as farmers in the midwestern Corn Belt shifted toward monoculture, e.g., corn, a crop heavily dependent on nitrogen, and soybeans, a legume that helps retain nitrogen in the soil. Farmers saw this combination as a strategy to help reduce input costs for synthetic and nitrogen-rich fertilizers.

Illinois-based agricultural implement manufacturer Deere & Company gained an advantage in 1954 when the company introduced an attachment that farmers could install on their combine harvesters to harvest corn. They could harvest their bean crop by switching out that attachment with a four- or five-bat (or horizontal bar) reel mechanism that drew the bean crop into the cutting head. Interchangeable front-end attachments became an industry standard.

The New Holland TR70 Axial Flow Combine, 1975, with Corn Attachment, on Exhibit in Henry Ford Museum of American Innovation / THF57471

The New Holland TR70 Axial Flow combine in Henry Ford Museum of American Innovation is installed with the corn harvester attachment. Farmers could harvest four rows of corn in one pass through the field with this head. To harvest soybeans, they installed a different attachment to the front end, a “pickup reel,” as illustrated below in a New Holland TR70 product catalog. The promotional literature urged farmers to purchase a floating “cutterbar” and a “robot header height control” to harvest most efficiently.

Sperry Rand Corporation - Sperry New Holland Division Catalog, "TR70 Twin Rotor Combine," 1977, Page 10 Detail / THF298867

Soybean acreage increased rapidly from the late 1970s into the 1980s. This sustained research in and development of combines suitable to cutting, threshing, and cleaning soybean crops (along with corn and other smaller grains).

Ford New Holland Agricultural Equipment, 1985, Detail / THF277396

For additional information:

“Charles Scranton Dies; Was Engineer,” Indianapolis Star, 27 July 1980, pg. 14, sec. 3.

Swinford, Norm. Allis-Chalmers Farm Equipment, 1914-1985. American Society of Agricultural Engineers, 1994.

U.S. Patent and Trademark Office records include more than 40 patents secured by Scranton during his work with Allis-Chalmers and at least three from his years with Avery Company.

Debra A. Reid is Curator of Agriculture and the Environment at The Henry Ford. This blog post was produced as part of our partnership with the Michigan Soybean Committee to deepen understanding of the important soybean crop and to provide the public with the chance to learn more about agriculture and the innovations that have helped farmers feed the world. You can learn more about the partnership, soybeans, and soybean ties to The Henry Ford in our kickoff post here.

Additional Readings:

- Agriculture and the Environment

- Getting Seeds in the Ground: Urgent Business

- A Horse-Drawn Recycler: The Manure Spreader

- Fordson Tractor, 1917-1918, Used by Luther Burbank

Henry Ford Museum, Michigan, by Debra A. Reid, farms and farming, farming equipment, agriculture, soybeans

Versatile #276 Tractor Pulling a Deere Low-Till Planter, 1989 / THF277397

Versatile #276 Tractor Pulling a Deere Low-Till Planter, 1989 / THF277397

Henry Ford Museum of American Innovation includes an exhibition called Agriculture and the Environment. The first section, Preparing the Soil, includes artifacts used by farmers to prepare the seed bed and plant crops. These artifacts all reflect practices common during the mid-19th to early-20th centuries, with the exception of two items: one, a Caterpillar continuous track tractor designed for use in orchards, and the John Deere 7000 No-Till Planter, also known as the MaxEmerge 7000 conservation planter. This post puts the Deere MaxEmerge planter into perspective and explains its utility as a no-till planter, both historically and today.

Tillage

A quick overview of tillage—that is, how farmers prepare land for growing crops—helps lay the groundwork (as it were). For thousands of years, farmers turned the topsoil over with a plow pulled by a draft animal—a single steer or team of oxen, draft horses, or mules. Henry Ford’s experiments with his “automotive plow” and subsequent introduction of the affordable Fordson tractor led to the replacement of draft animals on most farms after World War II, but the plow endured. Plowing broke up the roots of whatever vegetation was established before or between plantings. This was the first step in preparing a seed bed.

Man Using a 1939-1946 John Deere Model "B" Series Tractor / THF286596

The next step involved working the plowed ground to break up clods and create a more even surface. This required use of harrows or discs of various designs, as you can see here. Hitching technology installed on the Ford-Ferguson 9N tractor starting in 1939 and adopted by tractor manufacturers helped keep this disc tracking in line with the tractor. Farmers with large acreages under tillage favored row-crop tractors like the John Deere Model “B” in the photo below, where a farmer is discing a plowed field. The narrow wheel-spacing at the front end ran between rows of crops. After plowing and discing, some farmers harrowed fields to put the finishing touches on the seedbed.

Man Using a 1947-1952 John Deere Model "B" Series Tractor / THF286606

You can explore more than 40 tillage implements in The Henry Ford collection here. This is just the tip of the iceberg of mechanical innovations designed to ease the physically demanding process of field preparation. These tools helped farmers practice integrated pest management, too, because careful field preparation pulverized the organic material that insects like boll weevil in cotton or corn borer larvae lived in during the winter months. These pests could destroy crops in a pre-insecticide agricultural system.

Tillage, however, exposed topsoil to the elements. The more acreage farmers tilled, the more topsoil they lost due to erosion. In addition, severe droughts parched soil, destroying all organic matter. This exacerbated erosion as more and more topsoil blew away or washed away with heavy rains.

Planting and Cultivating

Different crops cover the ground in different ways. Farmers raising small grains drilled seed into prepared seed beds. The grain, planted at times of the year when other plant growth slowed, needed little to no cultivation. You can see grain drills and learn more about them here, including photographs of the Bickford & Huffman grain drill in use at Firestone Farm in Greenfield Village.

Prior to the adoption of in-season herbicides, most crops required cultivation after planting to disturb the roots of plants that threatened to choke out the cash crop. Farmers used different cultivators depending on the crops they grew, but cultivators further disturbed the soil and could hasten moisture evaporation.

Cultivating a Field of Cotton, Around 1911 / THF624655

The photograph below shows a row-crop tractor with an under-mounted cultivator at work in a soybean field. The single-front tire running down the middle of two rows ensured that the cultivators tracked between rows, to better remove weeds in between the cash crop.

Man Using a 1935-1938 John Deere Model "B" Series Tractor / THF286604

The Development of No-Till

You may have already grasped the connection between tillage and the no-till planter. Intensive cultivation of cropland contributed to topsoil erosion. The loss of the fertile topsoil reduced yields, and extreme weather worsened the loss. This led many to call for radical changes in tillage methods.

Agricultural scientists and engineers with the U.S. Department of Agriculture and state-based land-grant colleges addressed the challenge quickly. The University of Illinois established the Dixon Springs Agricultural Center in southern Illinois in 1934 to research soil erosion and low-till options. Purdue University in Indiana began the first experiments planting row crops in uncultivated soil in 1944. Russell R. Poyner, the agricultural engineer who worked on this project, went to work at International Harvester Company in 1945. By 1947, he submitted a patent for a mulch-tiller-planter designed for erosion control and conservation of moisture. He coined the new tillage approach “stubble mulch” farming, and as assignor to International Harvester, received U.S. Patent No. 2,577,363 in 1951. International Harvester produced the two-row McCormick M-21 till planter with fertilizer application only briefly and stopped altogether in 1955 due to sluggish sales.

Another early no-till proponent, agronomist George McKibben, worked at Dixon Springs. He and Donnie Morris, the machinery engineer at Dixon Springs, tested a zero-till planter by 1966. Morris describes the challenges he solved—specifically, how to get the seed in the ground. The research team used his “sod and stubble” planter starting in 1969, but an appeal to Deere and Company (the company that makes John Deere brand items) fell on deaf ears.

Allis-Chalmers released the two-row No-Til planting system in 1966, recognized as the first commercially available (and successful) no-till planter. The planter had a fluted coulter (vertical cutting blade) that sliced crop residue and prepared the seed bed just ahead of the fertilizer tank and planter unit.

The John Deere 7000 No-Till Planter: Agricultural Superstar

John Deere 7000 No-Till Planter, 1978 / THF151661

Peter Cousins, then Curator of Agriculture at The Henry Ford, acquired the John Deere 7000 No-Till Planter because, as he wrote in a memo to The Henry Ford’s collections committee on August 23, 1994, he considered it one of a few “superstars” of modern agricultural technology. In that same memo, he explained that of the three companies that introduced no-till planters, only Deere and Company survived. Allis-Chalmers left the farm implement business in 1985. International Harvester also ended its agricultural lines and broke up in 1985. Thus, he believed that only Deere and Company could locate, restore, and donate a first model no-till planter.

What qualifies as a “superstar?” Peter does not go into detail, but he names one other artifact in his memo—the FMC tomato harvester (1969). These two artifacts share at least three key elements that Peter considered as he strengthened The Henry Ford’s collection of 20th-century agricultural technology. First, the implement represents exchange between adopters, engineers, and others, a process described as the social construction of technology. Second, the implement transforms agricultural production. Third, the consequences of the transformation reverberate beyond farm fields.

A Modern John Deere No-Till Planter Sowing Soybeans / Photo courtesy of the United Soybean Board

The collaborative research undertaken by teams of experts at agricultural experiment stations across the country satisfy the first of these three “superstar” criteria. The experiments station staff worked with farmers to determine their needs and respond to them. The planter donated by Deere and Company to The Henry Ford, for example, had been used by Arthur Kruse on his Calmar, Iowa, farm between 1979 and 1994. It included “a wheel module planter with dry fertilizer option, insecticide box, unit mounted coulters, and cast closing wheels.” That insecticide box is telling—the stubble-mulch farming system came with another set of challenges. The stubble served as a vector for pests, namely the European corn borer in corn. A no-till planter that applied insecticide as well as dry fertilizer appealed to farmers even more.

Soybean Seedlings Emerging Among the Residue of the Previous Year’s Crop / Photo courtesy of the United Soybean Board

No-till planter technology changed the system of agriculture. The title of a July 16, 1994, New York Times article that Peter attached to the collections committee memo says it all: “New Way of Tilling Speeds the Plow’s Demise.” Today, no-till or conservation tillage helps farmers reduce erosion and retain soil moisture. Yet, input costs remain high as they apply herbicide to deaden growth before no-till planting, and then apply fertilizer and insecticides while planting.

On the other hand, Michigan State University researchers claim that “no-till farming practices have very positive economic and environmental benefits over decades.” Farm fields can benefit from the environmental benefits of topsoil retention enriched with hygroscopic (tending to absorb moisture from the air) organic matter. They can also realize higher yields over the long run.

Farmers, Please Share Your Stories

The Henry Ford would love to hear from Michigan farmers about your reasons for adopting no-till farming practices, either wholly or selectively, and what you believe the benefits are. You can e-mail us your feedback at MichiganSoybeanFarmers@thehenryford.org.

Debra A. Reid is Curator of Agriculture and the Environment at The Henry Ford. This blog post was produced as part of our partnership with the Michigan Soybean Committee to deepen understanding of the important soybean crop and to provide the public with the chance to learn more about agriculture and the innovations that have helped farmers feed the world. You can learn more about the partnership, soybeans, and soybean ties to The Henry Ford in our kickoff post here.

Additional Readings:

- Massey-Harris Model 20 Self-Propelled Combine, 1938

- Horse Power

- Steam-Powered Agriculture

- Fordson Tractor, 1917-1918, Used by Luther Burbank

environmentalism, Henry Ford Museum, farms and farming, farming equipment, agriculture, by Debra A. Reid

Great Lakes Water Quality

"Pulpit Rock on Presque Isle," Lake Superior near Marquette, Michigan, 1898. / THF118818

The border between the United States and Canada runs through four of the five lakes that constitute the world’s largest freshwater system—the Great Lakes. Policy makers on both sides of this fluid border have agreed to protect access and use of these bodies of water and their bays, arms, and inlets for more than 100 years.

View from the Harbor, Petoskey, Michigan, circa 1906. / THF118856

In the Boundary Waters Treaty of May 5, 1909, the United States and Great Britain (speaking for its Dominion of Canada) agreed to ensure free access and shared use of the navigable waterways. This sustained lucrative transportation and trade networks that the locks at Sault Ste. Marie, Michigan, helped facilitate.

Photochrom Print, "The Locks, Sault Ste. Marie, Michigan," 1905. Ships moved between Lake Superior and Lake Huron via these locks. / THF113687

The Boundary Waters Treaty of 1909 also stressed the shared responsibility for protecting water quality. Specifically, the United States and Great Britain “agreed that the … boundary waters … shall not be polluted on either side to the injury of health or property on the other” (Article IV).

Man Drinking from Flowing Well, Wequetonsing, Michigan, circa 1906. / THF119004

Increased populations, however, created problems that the partners had to solve. The treaty called for a six-person International Joint Commission (IJC) to mediate or investigate issues that arose. When cholera outbreaks increased in 1912, the IJC launched a comprehensive study of the boundary waters. Research conducted over five years confirmed that untreated water polluted with raw sewage carried bacteria that caused cholera and typhoid. Findings affirmed transnational responsibility for protecting public health and drew attention to the need for communities to ensure drinking water purity. You can read the final report from 1918 here. And this work continues, as “The Great Lakes Water Quality Centennial Study – Phase 1 Report” (2021) underscores.

Industrial pollution, especially the release of manufacturing waste into boundary waters, further increased the sense of urgency to maintain Great Lakes water quality.

View from Incline Railway, Duluth, Minnesota, circa 1908. / THF119376

Beautiful postcards, like this illustration of the bridge over the Mackinac Straits, could not compete with the evidence of growing Great Lakes degradation.

Postcard, Mackinac Straits Bridge, circa 1957 / THF144098

Growing public concern over industrial pollution found an outlet in Earth Day, April 22, 1970. That same year, the IJC released a report that stressed the “grave deterioration of water quality” in the Great Lakes, drawing on the Boundary Waters Treaty of 1909 as precedent for reaffirming the rights and obligations of both parties to not pollute boundary waters.

On April 15, 1972, representatives from Canada and the United States signed the Agreement on Great Lakes Water Quality. The two countries pledged to restore and enhance water quality in the Great Lakes. This included general objectives to keep the boundary waters free from substances that result from human activity and that might negatively affect aquatic life or waterfowl, be toxic or harmful to humans, or create a nuisance, including concentrations that could encourage aquatic weeds or algae. The agreement also itemized specific water quality objectives and targets around controlling phosphorus and monitoring vessel design, construction, and operation, as well as vessel waste and other forms of shipping pollution. It specified procedures for handling polluted dredged spoil (the waste material produced by dredging) and discharge of pollutants into boundary waters. You can read this 1972 agreement here.

April 15, 2022, marks the 50th anniversary of this transnational agreement to protect the Great Lakes ecosystem. The IJC continues to function as established in the Boundary Waters Treaty of 1909. You can read more about how the IJC links the ongoing transnational work to your life here.

Mission Point and Arnold Dock, Mackinac Island, Michigan, circa 1905. / THF114337

And if you find yourself in the boundary waters, recognize the long-term investment in Great Lakes environmental sustainability that helps protect those waters today.

Debra A. Reid is Curator of Agriculture and the Environment at The Henry Ford.

Reading an Artifact: The Reconstructed Detroit Central Market Vegetable Shed

Panoramic view of the reconstructed vegetable shed from Detroit Central Market on April 10, 2022. The entrance that originally faced south is front and center in this view. / Compiled from two photographs taken by Debra A. Reid

Panoramic view of the reconstructed vegetable shed from Detroit Central Market on April 10, 2022. The entrance that originally faced south is front and center in this view. / Compiled from two photographs taken by Debra A. Reid

The vegetable shed from Detroit Central Market, opening this week in Greenfield Village, provides the perfect opportunity to be a building detective! You can practice your powers of observation as you explore this open-sided structure. In the process, you can become a more informed observer of the built environment around you.

The following highlights should whet your appetite to learn more about this “shed.” Originally, it sheltered vendors who helped feed hungry Detroiters for more than 30 years, from April 1861 to February 1894. Then it spent 110 years on the upper end of Belle Isle sheltering horses, operating as a public riding stable, and as a storage facility for the City of Detroit. The Henry Ford acquired it in 2003, saving it from demolition. Then, between 2003 and 2021, we conducted research and raised funds to reconstruct it in Greenfield Village. Now you can explore the reconstructed Detroit Central Market shed starting its new life in the heart of Greenfield Village.

Is This Building a Reconstruction?

Rudy Christian, a traditional timber-frame expert and principal of Christian & Son, Inc., describes the Detroit Central Market shed as a reconstruction. He bases this on his experiences dismantling the structure in 2003, advocating for use of original materials and prepping the timber-frame elements, and reassembling the roof system during reconstruction in Greenfield Village during 2021.

The Secretary of the U.S. Department of the Interior (DOI) first defined “reconstruction” in 1978 as “the act or process of reproducing by new construction the exact form and detail of a vanished building, structure, or object, or a part thereof, as it appeared at a specific period of time” (Federal Register, Vol. 43, No. 236, December 7, 1978, page 57251). You can read more about the DOI’s standards for the treatment of historic buildings and landscapes here, including more about reconstruction and the other three standards: preservation (when the property retains distinctive materials and thus conveys historic significance without extensive repair or replacement), restoration (removal of features to return a property to an appearance of a particular time in the past), and rehabilitation (retention of a property’s historic character, but modifications may occur given ongoing use).

What Percentage of the Building Is Original?

The Detroit Central Market vegetable shed, while “new construction,” is authentic because of the significant percentage of original material incorporated into the reconstruction. Fifty percent of the columns (16 of 32) are original. The 16 originals are distinctive because of acanthus-leaf details on the bases, a spiral design, and capitals onto which cast S-scroll leaf ornaments are mounted.

Architectural S-scroll leaf ornament from the Detroit Central Market, 1860. / THF177806

These original cast-iron columns, however, are brittle. It is impossible to calculate their tensile strength—that is, the maximum stress that the cast iron can stand when being stretched or pulled before breaking. Modern code requires structural materials to meet tensile-strength specifications. This posed a significant challenge.

How Can We Meet Modern Building Codes with an Historic Structure?

The facilities team at The Henry Ford contracted with O’Neal Construction, Inc., of Ann Arbor, Michigan, on the reconstruction of the Detroit Central Market building. They were involved in all phases of the planning process and oversaw reconstruction from 2021 to its completion. The team considered different options to support the building, but ultimately selected an innovative solution that exceeds code requirements. In effect, the solution involved flipping the structural support upside down.

Alec Jerome, Director of Facilities at The Henry Ford, explaining the invisible framing system that anchors the vegetable shed on August 26, 2021. / Screenshot from THF Conversations: A Market Shed in its 160th Year

Ensuring guest safety required construction of an underground “moment frame” that anchors the structure and prevents it from acting like a huge umbrella on a windy day. The above screenshot shows the system of rebar that runs between the 48-inch-deep footers. The footers extend up to octagonal bases, or piers. These footers also accommodate modern infrastructure—specifically, electrical conduit that runs underground and up into the piers. All 32 columns are attached to the individual piers with anchor bolts, but 16 of the 32 columns are steel and specially designed extensions of the moment frame. As a whole, the moment frame ensures that the structure will remain on the ground and standing in perpetuity.

The entrance that originally faced north on April 10, 2022, now behind Hanks Silk Mill in Greenfield Village. There are original columns at both sides of the side-entrance gable, but rows of specially designed columns, integral to the moment frame, visible to both the left and right of this side-entrance. / Photograph by Debra A. Reid

The 16 new columns are distinctive from the originals in several ways. They are smooth, not spiral. They have fluted gussets (brackets) at the top, instead of capitals. Finally, they are larger in diameter than the originals. These distinctions make clear which columns are original and which are not, to inform guests of the innovation required to ensure their safety.

How Does the New Footprint Compare to the Original?

What was originally the west entrance, now facing State Street in Greenfield Village, on April 10, 2022, with original columns as well as additional columns installed in two rows in front of the structure. This gives guests a better impression of the original building footprint, though an additional eight columns would be required to mimic the full original size of 11 bays and 242 feet in length. / Photograph by Debra A. Reid

The reconstructed vegetable shed is 7/11ths as long as the original. Why 7/11ths? The original structure was three bays wide by eleven bays long. A bay is the space between architectural elements. You can see the eleven bays visible on the south side of the structure in the detail below from a late-1880s photograph—five bays from the east-facing entrance to the south-facing entrance, with that entrance bay being the sixth bay, and then five bays beyond it to the west-facing entrance (less easy to see given the perspective). The Central Market building towers in the distance.

Detail of the vegetable shed from the Detroit Central Market, circa 1888. / THF200604

The reconstructed Detroit Central Market vegetable shed in Greenfield Village includes only seven of the eleven original lengthwise bays—three on each side of the side-entrance bay. Thus, the reconstruction is 7/11ths the length of the original. Jim McCabe, former collections manager and buildings curator at The Henry Ford, deserves credit for this specification, as he spent nearly two decades working on the project between 2003 and 2022.

The reconstruction is true to the width of the original, three bays total—one on each side of the central entrance, which is also a bay. You can see these bays most clearly in this July 6, 2021, photograph below, showing columns in place and the roof structure in process.

Detroit Central Market reconstruction in process on July 6, 2021, showing the three-bay width and the seven-bay length. / Photograph by Debra A. Reid

How Much of the Timber-Frame Roof Is Original?

The timber-framing system is clearly visible inside the structure. Just walk in and look up! Approximately 80% of the original old-growth white pine was reused in the reconstruction. This resulted from careful detective work during the quick dismantling process.

The Henry Ford contracted with Christian & Son, Inc., to number and measure the original structural and decorative woodwork elements, photograph them, and prep the material for storage. Then we contracted with Jeff DuPilka and West Shore Services, Inc., to disassemble the structure. West Shore, Christian & Son, and staff from The Henry Ford accomplished this in 10 to 12 weeks during the summer of 2003.

Woodwork in one of four outside corners, original to the vegetable shed at Detroit Central Market and still intact after it served as the riding stable at Belle Isle, Detroit, Michigan (photographed in 2003). / THF113493

Christian & Son, Inc., documented all original wooden elements, including those in the section of the building that was fire-damaged due to a car wreck (visible in the photograph below). They believed that documenting the whole required documentation of all parts, so they took as much care tagging, measuring, and dismantling this burned section as they did with the other sections. In fact, timbers from the charred section were reused in the reconstruction and are visible on the exterior of the originally east-facing entrance (the entrance now facing the Detroit Toledo & Milwaukee Roundhouse in Greenfield Village).

West Shore Services, Inc., crane in action, removing a piece of the original timber-frame roof system from the former riding stable (and originally the Detroit Central Market vegetable shed) on Belle Isle, Detroit, Michigan, 2003. / THF113575

What Are Some Notable Details?

The reconstruction of the Detroit Central Market vegetable shed in Greenfield Village includes ornamental woodwork throughout. The following rendering by architecture firm Quinn Evans itemizes seven distinctive brackets, each designed for a specific location in the building, and one “drop,” an accessory at all four gable entrances and used with the decorative fascia along the eaves.

Decorative wood details of the Detroit Central Market vegetable shed, prepared by Quinn Evans, Ann Arbor, Michigan, for The Henry Ford. / Courtesy of The Henry Ford’s facilities team

These decorative elements were all hand-carved during the original construction in 1860. Not all of the decorative elements survived the move to Belle Isle. The elaborate crests atop each of the four gable entrances on the Detroit Central Market vegetable shed, for example, were not included when it served as the horse shed on Belle Isle, as the illustration of it in Seventy Glimpses of Detroit indicates. Missing pieces were replicated to complete the structure’s appearance during its heyday as a public market.

Jim Johnson, Director of Greenfield Village & Curator of Historic Structures and Landscapes at The Henry Ford, starting to inventory architectural elements from the Detroit Central Market vegetable shed not used in the reconstruction, February 8, 2022. / Photograph by Debra A. Reid

What Style Is the Building?

Each of the ornamental elements was part of a stylistic whole that the reconstruction faithfully conveys. If it reminds you of a Swiss chalet, you have an astute eye for style. John Schaffer, the architect, trained in Munich, Bavaria, and incorporated Schweizerstil (Swiss-chalet style) details into his plans, drafted in 1860. Thus, this structure likely introduced that aesthetic to Detroiters. His plans included gently sloping gabled roofs with wide eaves, large brackets, and decorative fretwork, all details common to Swiss-style architecture. Additional Swiss features included sawtooth siding, scroll-sawn fascia, and the elliptical design of the siding at each gable-end.

The Detroit Central Market vegetable shed has so much to teach. Learning to read the details of this addition to Greenfield Village is an important first step on the journey. Learn even more by checking out additional blog posts and artifacts related to Detroit Central Market.

Debra A. Reid is Curator of Agriculture and the Environment at The Henry Ford. Comments from Rachel Yerke, Curatorial Assistant at The Henry Ford, improved this post.

Additional Readings:

- Farmers Market

- Bring the Detroit Central Farmers Market to Greenfield Village

- Detroit Central Market Coming to Life

- Greenfield Village Reopens for 2022 Season April 16 with First Permanent Addition in More Than 20 Years

#Behind The Scenes @ The Henry Ford, collections care, making, design, Michigan, Detroit, Detroit Central Market, by Debra A. Reid, Greenfield Village buildings, Greenfield Village

Deepening Our Understanding of Soybeans

Soybean Processing for Fiber and Oil, Ford Exposition, New York World's Fair, 1939 / THF216213

Soybean Processing for Fiber and Oil, Ford Exposition, New York World's Fair, 1939 / THF216213

A New Partnership

Today, on National Agriculture Day, The Henry Ford is pleased to announce a new partnership with the Michigan Soybean Committee to deepen our understanding of this important crop, from field to factory.

The Michigan Soybean Committee works on behalf of Michigan’s 12,000 soybean farmers to drive demand, fund research advancements, share the story of agriculture, and identify ways to help farmers grow soybeans sustainably for generations to come. Michigan Soybean Committee has a renewed focus on consumer outreach and working with partners to provide information to the public about soybeans and agriculture in the state of Michigan. The collections of The Henry Ford help tell the long history of soy, and especially the launch of the legume in Michigan, a project with a long history dating back to Henry Ford himself. Michigan Soybean Committee is excited to work with The Henry Ford to provide the public with the chance to learn more about agriculture and the innovations that have helped farmers feed the world.

Soybeans Planted in 30-inch Rows / Photo courtesy Michigan Soybean Committee

Why Soybeans?

The soybean (soya bean, Glycine max) moved from relatively obscure forage crop in 1920 to center stage on global markets in 2020. Today soybean farmers in 19 states, including Michigan, raise 96% of the more than 4 billion bushels of beans produced in the United States. Each of those soybeans contains oil, protein, and biomass, attributes that processors use to transform the soybean into valuable products.

Mrs. Hardy Checking Soybean Milk in Ford Lab, March 1944 / THF272478

Today we encounter soybeans in almost every aspect of our daily lives, but we may not recognize the legume, even when we use or consume it. Drink soymilk? Use a non-dairy creamer or whipped topping? Eat chocolate? Use soy oil for cooking? Is your candle made of soy? How about the bioplastic coating your take-out food container or disposable coffee cup? Have you ever filled your vehicle with biodiesel? These products, and many more, likely include ingredients derived from soybeans. The Michigan Soybean Committee recommends the United Soybean Board website https://soynewuses.org/ as a good resource to learn even more about all of the products made with soy.

Presto Whip Building, Dearborn, Michigan, 1976 / THF115752

Why Soybean Stories from The Henry Ford?

Our founder, Henry Ford, was intrigued by and invested in research on the humble soybean, both as a food source and for use in industrial products. Our collections contain much information on these topics. You can read more about “Soybeans: Henry Ford’s Miracle Crop,” or explore related artifacts in this Expert Set that illustrates Henry Ford’s soybean research, some of which took place at the Soybean Laboratory (now the Soybean Lab Agricultural Gallery) in Greenfield Village. A clip from the first season of The Henry Ford's Innovation Nation features host Mo Rocca and Matt Anderson, Curator of Transportation at The Henry Ford, in the Soybean Lab discussing “Different Uses of Soybeans.” Content related to that episode includes a soyfoods Expert Set and one of our most popular research inquiries from guests, information about Henry Ford’s soybean plastic car.

Robert Boyer and Henry Ford in a Soybean Field, 1936 / THF98619

Black chemists contributed to this soybean research. Paul Foster focused on food research. “Paul Foster and Food Research in Henry Ford’s Laboratories, 1930-1942” introduces readers to Foster and explores some of the soy recipes that resulted from research he conducted. George Washington Carver and his assistant, Austin Curtis, Jr., chemists working at Tuskegee Institute in Alabama, shared Henry Ford’s enthusiasm for chemurgy (industrial uses for raw materials). Both Carver and Curtis participated in the third Dearborn Conference on Industry in 1937, featuring lectures by chemists working with farm-grown crops and industrial products, and Curtis even worked one summer in Ford’s Greenfield Village Soybean Lab. Ford expanded soy food research in 1942 with dedication of the Carver Nutrition Laboratory on Michigan Avenue in Dearborn, near Greenfield Village.

Ford Motor Company shared its soybean research at World’s Fairs during the 1930s. The Ford Exposition exhibited the William Ford Barn (now in Greenfield Village) transformed into “the industrial farm of the future” at the 1934 World’s Fair in Chicago. Giveaways included a souvenir box containing items from the Earth (including soybeans) used in Ford manufacturing. At the 1936 Texas Centennial Exposition, Ford Motor Company handed out salt-and-pepper shakers converted from gear shift knobs made from soy products. Ford staff demonstrated chemical experiments used to extract oil and transform it into fiber during the 1939–1940 New York World’s Fair.

Soybean Processing for Fiber and Oil, Ford Exposition, New York World's Fair, 1939 / THF216215

Coming Soon

What do we have in store for this partnership?

We’ll kick things off on March 23 on The Henry Ford’s Facebook page, with an interview with Laurie Isley, Michigan farmer and president of Michigan Soybean Committee. You can get a sneak peek of Isley’s work at the websites for U.S. Soy and the Michigan Agriculture Council.

John Deere Tractor and Planter Planting Soybeans / Photo courtesy United Soybean Board

Our plans for 2022 focus on exploring untold stories, adding to existing stories, and engaging the public in the process. We will explore changes in biological and mechanical technologies between 1920 and 2020, and document agricultural research at Ford farms focused on producing soybeans richer in oil content and better suited to industrial uses. We will deepen existing content on the daily operations of soybean research undertaken at the chemical laboratory constructed by Henry Ford in Greenfield Village in 1928 (still standing today), and in the George Washington Carver Nutrition Laboratory launched by Ford in 1942.

Over the growing season, we’ll explore the year-round work it takes to produce soybeans in Michigan, from planting to growing to harvesting, with the farmers who do this work. This will also involve a collaborative contemporary collecting effort to document Michigan soybean farmers today and add those stories to the permanent collections of The Henry Ford.

Case IH Combine Harvesting Soybeans / Photo courtesy Michigan Soybean Committee

The Michigan Soybean Committee will share its popular teacher resources with The Henry Ford’s learning and engagement staff. This will benefit rising fifth graders in The Henry Ford’s 2022 Growers summer camp, presented by the Michigan Soybean Committee, as they explore soya from bean to bioplastic. From June to August, students in the Growers summer camp will interact directly with Michigan Soybean Committee resources and soybeans growing in Greenfield Village for the first time since the 1940s.

Cultivating and Planting Activity at Soybean Laboratory, Greenfield Village, Dearborn, Michigan, 1937–1950 / THF236443

Both The Henry Ford and Michigan Soybean Committee are eager for this 2022 soybean-knowledge growing season, and we look forward to having you along for the journey.

Debra A. Reid is Curator of Agriculture and the Environment at The Henry Ford. Many thanks to the Michigan Soybean Committee for their collaboration on this post.

Ford Motor Company, world's fairs, African American history, Henry Ford, Greenfield Village, Greenfield Village buildings, food, research, soybeans, philanthropy, agriculture, by Debra A. Reid