Posts Tagged farming equipment

1938 Massey-Harris Model 20 Self-Propelled Combine in Henry Ford Museum of American Innovation. / THF110572

Combines loom large on the floor of Henry Ford Museum of American Innovation, but they loom even larger on the physical and historical landscape of America’s agricultural heartland. Standing high on the horizon, combines both symbolize and represent the reality of the mechanization of modern agriculture. The 1938 Massey-Harris Model 20 self-propelled combine, a designated landmark of American agricultural engineering, was the first commercially successful self-propelled combine to make its way through an American harvest.

1930s, 20th century, Henry Ford Museum, food, farms and farming, farming equipment, by Jim McCabe, agriculture

A Horse-Drawn Recycler: The Manure Spreader

International Harvester Manure Spreader, circa 1905 / THF89810

The act of farming draws nutrients from the soil. If the nutrients are not returned, the soil will become depleted and lose productivity. One of the best ways to restore the soil is to recycle what was removed from it by spreading manure. Manure spreaders made this dirty job not-so-dirty.

Caring for the Land: Forgotten—Then Rediscovered

To Europeans living in the American colonies, the availability of land in North America seemed limitless. Farmers paid little attention to caring for the soil, quickly abandoning the fertilizing activities they had practiced in Europe. These farmers felt it more cost effective to simply move on to new land when the soil lost productivity, rather than put in the effort to restore its fertility.

By the 1800s, this strategy had begun to run its course. As land went fallow—first in the east, and later in the Midwest and plains—American farmers had to rediscover the soil stewardship practices they had lost generations earlier. Since much of the grain grown on a farm is fed to livestock, farmers began to gather up barnyard manure from cows, horses, pigs, and other animals and spread it on their fields to restore the soil’s fertility.

This short-handled manure fork (dated 1875-1890) could be used in a stall, wagon, or other confined area. / THF173108

The Dirtiest of the Dirty Jobs

Spreading manure is one of the most unpleasant and labor-intensive jobs on a farm. It requires a lot of effort and a strong constitution to scoop up raw manure and straw bedding from the barnyard and stalls into a wagon, and then fork it out evenly over many acres of fields. David C. Voorhees, a farmer in Somerset, New Jersey, wrote in his diary of spreading 215 loads of manure in September 1875 following the harvest. Spreading manure needs to be done properly to be effective. Too much manure in one spot can “burn” the soil, so clumps need to be broken up before they are tossed on the field.

If ever there was a farm task that was ripe for mechanization, it was spreading manure. Throughout the 1800s, dozens upon dozens of patents were issued for manure spreaders. By the 1870s, the design of manure spreaders had been sufficiently refined, and the manufacturing process had developed enough to make manure spreaders both effective and affordable.

This pamphlet for a Kemp & Burpee Manufacturing Co. manure spreader described its operation and included many testimonials. The company was absorbed by International Harvester in 1906. / THF125272

How to Make the Manure Fly

The more successful manure spreaders had two key design features: a continuously moving apron, or floor, which automatically moved manure toward the back of the wagon to be spread; and a beater at the back of the spreader to pulverize manure and spread it evenly across the field. With a good manure spreader, one person could do the work of five or more—and those other people were surely happy to do some other job.

The beater on this circa 1905 manure spreader broke the manure up into small pieces and spread it evenly on the field. / THF89816

A Remarkable Survivor

If spreading manure was hard on farmers, it was even harder on farm equipment, since manure rapidly corrodes and rots manure spreader parts. Consequently, early manure spreaders rarely survived to be passed on to the next generation, much less make it into a museum.

The Henry Ford’s circa 1905 International Harvester manure spreader is one of these very rare survivors. It is all the more extraordinary because it retains its original paint and parts. It is an excellent example of the prevailing manure spreader design of the early 1900s.

A Sustainability Hero

In many ways, farm practices can work against nature. The manure spreader is a great example of a tool that helped farmers reestablish the natural cycle by recycling the bounty of the soil back into the soil. The manure spreader does the dirtiest job on the farm—but it is a key part of making farming a sustainable undertaking.

Jim McCabe is former Collections Manager/Acting Curator of Agriculture and the Environment at The Henry Ford.

Additional Readings:

- 1975 Sperry-New Holland Combine

- Horse Power

- Getting Seeds in the Ground: Urgent Business

- Mechanizing the Tomato Harvest

Henry Ford Museum, horse drawn transport, environmentalism, farms and farming, farming equipment, agriculture, by Jim McCabe

Horse Power

Detail, 1882 advertisement showing a three-horse tread power in use. / THF277170

How much horsepower really comes from a horse? While the answer to this may seem obvious, it is complicated. The most complete answers start out with "it depends."

Much of farming is strenuous, tedious, repetitive work. For American farmers, chronic labor shortages made the effort of farm work even more taxing, so they looked for ways to get farm work done with less manpower. Horses and oxen were the main source of power, used for centuries for plowing. Improved farm machinery throughout the 1800s added the power of horses to other activities such as planting, cultivating, and, eventually, mowing and harvesting. Farmers understood the effort required for these tasks in terms of the number of horses needed to pull the equipment, such as one horse for a cultivator, and three or more for a harvester or large plow. Applying the power of horses to farm work helped to steadily increase the productivity of American farms throughout the 1800s.

This 1854 engraving depicted the centuries-old practice of plowing with horses. Throughout the 1800s, farmers increasingly used horses or oxen for other work as well, including planting, cultivating, mowing, and harvesting. / THF118302

Yet horsepower as a measure of power pre-dates the mechanization of the farm. It was developed by James Watt in the 1780s as a way to measure the output of a steam engine. Horsepower was based on his observations of how much work a horse could do in a normal ten-hour day, pulling the sweep arms of the horse-powered pumps that were used to remove water from mines. This worked out to 33,000 foot-pounds per minute, or the effort required to raise 33,000 pounds of water by one foot in one minute.

An 1886 trade catalog depicted Russell & Co.’s “New Massillon” grain thresher powered by both a steam traction engine and a horse-driven sweep power. / THF627487, THF627489

As farmers mechanized barn or farmyard work like threshing, winnowing, corn shelling, and corn grinding, they began to use stationary power sources—either treadmills and sweeps powered by horses, or steam engines. Here, the agricultural idea of horsepower and the industrial idea of horsepower bumped heads. For example, the portable steam engine pictured just below is rated at ten horsepower. It could be used to run the same piece of farm equipment as the two-horse tread power depicted below the steam engine, which used, well, two horses. Some farmers came to use a rule of thumb for farm equipment, calculating that one horse was worth about three horsepower in an engine. Why is this?

This ten-horsepower steam engine (top) could power the same piece of farm equipment as a two-horse tread power (bottom). / THF92184, THF32303

Engine horsepower ratings (and there are many varieties of these) are typically overestimated because they are often calculations of the power delivered to the machine—not how much actually reaches its "business end." For example, they do not account for power losses that occur between the piston and whatever the piston is driving—which can be more like 70% to 90% of the rated horsepower. In addition, those measures are made at the ideal engine speed.

On the other hand, numerous studies have shown that peak horsepower for a horse (sustainable for a few seconds) is as high as 12-15 horsepower. This is based on calculated estimates, as well as observed estimates (recorded in a 1925 study of the Iowa State Fair's horse pull). Over the course of a ten-hour workday, however, the average output of a horse is closer to one horsepower—which coincides with James Watt's original way of describing horsepower.

So how much horsepower comes from a horse? As we see, it depends. If we measure it in an optimal way, as we do with engines, it is as high as 15 horsepower. If we measure it as James Watt did—over the course of a long 10-hour day, horses walking in a circle—it gets down to about one horsepower. Nineteenth-century farmers quickly learned that if they were buying an engine for a task horses had previously performed, they needed an engine rated for three horsepower for every horse they had used for the task.

This post by Jim McCabe, former Collections Manager and Curator at The Henry Ford, originally ran as part of our Pic of the Month series in May 2007. It was updated for the blog by Saige Jedele, Associate Curator, Digital Content.

Additional Readings:

- Microscope Used by George Washington Carver, circa 1900

- Bringing in the Beans: Harvesting a New Commodity

- As Ye Sow So Shall Ye Reap: The Bickford & Huffman Grain Drill

- Oliver Chilled Cast Iron Plow, circa 189

engines, by Saige Jedele, by Jim McCabe, power, agriculture, farms and farming, farming equipment, farm animals

Soybean Harvesting / Photo courtesy of the United Soybean Board

Soybean Harvesting / Photo courtesy of the United Soybean Board

Farmers have only a narrow window of opportunity to harvest their crops. For Michigan soybean growers, that window generally runs from the end of September through November, but is impacted yearly by weather events. By that point in the season, the plant is fully mature and has lost most of its leaves, and only the stalk and pods (with three to four beans per pod) stand in the field (R8 Growth Stage). The seeds are brown and hard at this point, and bean moisture content is 13-15%.

A Close-Up of the Modern Soybean Harvesting Process / Photo courtesy of the United Soybean Board

Harvesting soybeans—to cut the stalk, separate the bean from the pod, clean the bean, and store it until moved from harvester to wagon or truck—requires a multifunctional machine. Soybean growers benefitted from around a century of experimentation with specialized harvest machines when it came time for them to look for the best machine for the job. Farmers need machines that work, and different machines to harvest different crops. The Henry Ford has some of the earliest of these mechanical innovations, each suited to a specific crop—the Ambler mowing machine for hay, models of the Hussey and McCormick reapers for grains, and the Manny combined mower and reaper (one machine adaptable for both crops).

These early-19th-century innovations represented solutions to the problem of how to reduce human labor costs. Farm families often could not meet labor demand during harvest seasons. Too little labor meant lost crops, and lost crops made it difficult for farmers to feed their livestock (hay) or earn income from market crops (grain). Hiring labor was expensive, and even more expensive during peak demand at harvest time.

A century passed between the 1830s, when mechanical reapers and mowing machines first became viable, and the 1930s, when the first Allis-Chalmers All-Crop Harvester entered Michigan soybean fields.

Man Driving an Allis-Chalmers Tractor Pulling an Allis-Chalmers All-Crop Harvester at Michigan and Southfield Roads, Dearborn, Michigan, October 1936 / THF286727

The Crop

Michigan growers raised different types of beans during the early 20th century. Some raised bush beans (Phaseolus vulgaris), green beans that they harvested by hand when the pod reached the R5 growth stage and seeds had just begun to develop. Wholesale dealers distributed this perishable commodity to grocery stores while processors turned the bush beans into canned green beans. Others raised large fields of beans on contract with the H.J. Heinz Co. After the beans were fully matured and dry, growers harvested the crop by hand, then hauled the crop to a threshing machine that separated the beans from the pods and stems. Employees at Heinz processing plants continued the handwork, sorting beans from debris. Product advertising emphasized this attention to detail that yielded a quality food product.

A different type of bean—the “soy bean” (or soybean, Glycine max)—became increasingly apparent in southeast Michigan during the 1930s. Interest in this new cash crop grew apace with Henry Ford’s investment in soybean research. Scientists at work in the chemical laboratory that Ford built in Greenfield Village confirmed that soybeans had potential as a domestic source for various industrial products. Industrial demand in the region caused growers to seek a harvester suitable to the task.

Soybean Pods Ready for Harvesting / Photo courtesy of the United Soybean Board

Some farmers raised seed crops to meet growing demand for the new cash crop. This specialized cultivation required careful harvesting, as described in “Soy Bean Seed Production in Michigan” (1936). Others raised crops to meet the growing demand for the new industrial raw material. The Ford Village Industries complex in Saline, Michigan, opened in 1938. A press release issued by Ford Motor Company in July 1938 indicated that 700 farmers planted 22,588 acres of soybeans processed at the Saline facility. Ford processing capacity increased as the soybean processing plant at the Rouge Plant began operations around 1942.

Ready for the Harvest: The Allis-Chambers All-Crop

Farmers needed mechanical harvesters to ensure that they delivered a prime crop to Ford Motor Company. Henry Ford thus took an interest in this technology. Allis-Chalmers released its All-Crop 60 harvester in 1935, designed to operate off a tractor big enough to pull a double-bottom plow and powered by the tractor’s power take-off. The “60” represented the width in inches of the swath cut by the harvester. Ford tested the capability of the Allis-Chalmers All-Crop Harvester on a Ford Farms soybean crop in October 1936. By that time, Allis-Chalmers had sold 8,200 of the machines.

The engineer who took a leading role in the machine’s development was Charles J. Scranton, Jr. He began his career as a draftsman at Avery Company, a Peoria, Illinois, company noted for steam traction engines, threshers, and other farm equipment that went bankrupt in 1923. Scranton, as an assignee to a successor company, the Avery Power Machinery Co., secured several patents for improvements to threshers during the late 1920s.

Scranton joined Allis-Chalmers by working at the LaPorte, Indiana, location by 1934. Over 30 years, he secured around 40 patents, all focused on harvesting machinery. The All-Crop marked a crowning achievement because it suited the needs of farmers operating on a smaller scale and growing different cash crops, including soybeans, clover, milo, and other grains.

Ford featured the Allis-Chalmers All-Crop Harvester in early promotional photographs of the Ford tractor with the “Ferguson System,” the Ford-Ferguson 9N, released in 1939. This marked a ringing endorsement from the industrialist who launched soybeans as a cash crop in Michigan.

A Ford-Ferguson Model 9N Tractor Pulling an Allis-Chalmers “All-Crop” Harvester, Macon, Michigan, November 1939 / THF701486

Rear view of the Allis-Chalmers “All-Crop” Harvester, pulled by a Ford-Ferguson Model 9N Tractor, Macon, Michigan, November 1939 / THF701489

More Crop in the Hopper

As soybean acreage increased across the Midwest after World War II, farm implement companies continued to innovate. The Allis-Chalmers All-Crop was well suited to smaller scale farmers growing a variety of crops, but the scale of production increased dramatically during the 1950s as farmers in the midwestern Corn Belt shifted toward monoculture, e.g., corn, a crop heavily dependent on nitrogen, and soybeans, a legume that helps retain nitrogen in the soil. Farmers saw this combination as a strategy to help reduce input costs for synthetic and nitrogen-rich fertilizers.

Illinois-based agricultural implement manufacturer Deere & Company gained an advantage in 1954 when the company introduced an attachment that farmers could install on their combine harvesters to harvest corn. They could harvest their bean crop by switching out that attachment with a four- or five-bat (or horizontal bar) reel mechanism that drew the bean crop into the cutting head. Interchangeable front-end attachments became an industry standard.

The New Holland TR70 Axial Flow Combine, 1975, with Corn Attachment, on Exhibit in Henry Ford Museum of American Innovation / THF57471

The New Holland TR70 Axial Flow combine in Henry Ford Museum of American Innovation is installed with the corn harvester attachment. Farmers could harvest four rows of corn in one pass through the field with this head. To harvest soybeans, they installed a different attachment to the front end, a “pickup reel,” as illustrated below in a New Holland TR70 product catalog. The promotional literature urged farmers to purchase a floating “cutterbar” and a “robot header height control” to harvest most efficiently.

Sperry Rand Corporation - Sperry New Holland Division Catalog, "TR70 Twin Rotor Combine," 1977, Page 10 Detail / THF298867

Soybean acreage increased rapidly from the late 1970s into the 1980s. This sustained research in and development of combines suitable to cutting, threshing, and cleaning soybean crops (along with corn and other smaller grains).

Ford New Holland Agricultural Equipment, 1985, Detail / THF277396

For additional information:

“Charles Scranton Dies; Was Engineer,” Indianapolis Star, 27 July 1980, pg. 14, sec. 3.

Swinford, Norm. Allis-Chalmers Farm Equipment, 1914-1985. American Society of Agricultural Engineers, 1994.

U.S. Patent and Trademark Office records include more than 40 patents secured by Scranton during his work with Allis-Chalmers and at least three from his years with Avery Company.

Debra A. Reid is Curator of Agriculture and the Environment at The Henry Ford. This blog post was produced as part of our partnership with the Michigan Soybean Committee to deepen understanding of the important soybean crop and to provide the public with the chance to learn more about agriculture and the innovations that have helped farmers feed the world. You can learn more about the partnership, soybeans, and soybean ties to The Henry Ford in our kickoff post here.

Additional Readings:

- Agriculture and the Environment

- Getting Seeds in the Ground: Urgent Business

- A Horse-Drawn Recycler: The Manure Spreader

- Fordson Tractor, 1917-1918, Used by Luther Burbank

Henry Ford Museum, Michigan, by Debra A. Reid, farms and farming, farming equipment, agriculture, soybeans

Versatile #276 Tractor Pulling a Deere Low-Till Planter, 1989 / THF277397

Versatile #276 Tractor Pulling a Deere Low-Till Planter, 1989 / THF277397

Henry Ford Museum of American Innovation includes an exhibition called Agriculture and the Environment. The first section, Preparing the Soil, includes artifacts used by farmers to prepare the seed bed and plant crops. These artifacts all reflect practices common during the mid-19th to early-20th centuries, with the exception of two items: one, a Caterpillar continuous track tractor designed for use in orchards, and the John Deere 7000 No-Till Planter, also known as the MaxEmerge 7000 conservation planter. This post puts the Deere MaxEmerge planter into perspective and explains its utility as a no-till planter, both historically and today.

Tillage

A quick overview of tillage—that is, how farmers prepare land for growing crops—helps lay the groundwork (as it were). For thousands of years, farmers turned the topsoil over with a plow pulled by a draft animal—a single steer or team of oxen, draft horses, or mules. Henry Ford’s experiments with his “automotive plow” and subsequent introduction of the affordable Fordson tractor led to the replacement of draft animals on most farms after World War II, but the plow endured. Plowing broke up the roots of whatever vegetation was established before or between plantings. This was the first step in preparing a seed bed.

Man Using a 1939-1946 John Deere Model "B" Series Tractor / THF286596

The next step involved working the plowed ground to break up clods and create a more even surface. This required use of harrows or discs of various designs, as you can see here. Hitching technology installed on the Ford-Ferguson 9N tractor starting in 1939 and adopted by tractor manufacturers helped keep this disc tracking in line with the tractor. Farmers with large acreages under tillage favored row-crop tractors like the John Deere Model “B” in the photo below, where a farmer is discing a plowed field. The narrow wheel-spacing at the front end ran between rows of crops. After plowing and discing, some farmers harrowed fields to put the finishing touches on the seedbed.

Man Using a 1947-1952 John Deere Model "B" Series Tractor / THF286606

You can explore more than 40 tillage implements in The Henry Ford collection here. This is just the tip of the iceberg of mechanical innovations designed to ease the physically demanding process of field preparation. These tools helped farmers practice integrated pest management, too, because careful field preparation pulverized the organic material that insects like boll weevil in cotton or corn borer larvae lived in during the winter months. These pests could destroy crops in a pre-insecticide agricultural system.

Tillage, however, exposed topsoil to the elements. The more acreage farmers tilled, the more topsoil they lost due to erosion. In addition, severe droughts parched soil, destroying all organic matter. This exacerbated erosion as more and more topsoil blew away or washed away with heavy rains.

Planting and Cultivating

Different crops cover the ground in different ways. Farmers raising small grains drilled seed into prepared seed beds. The grain, planted at times of the year when other plant growth slowed, needed little to no cultivation. You can see grain drills and learn more about them here, including photographs of the Bickford & Huffman grain drill in use at Firestone Farm in Greenfield Village.

Prior to the adoption of in-season herbicides, most crops required cultivation after planting to disturb the roots of plants that threatened to choke out the cash crop. Farmers used different cultivators depending on the crops they grew, but cultivators further disturbed the soil and could hasten moisture evaporation.

Cultivating a Field of Cotton, Around 1911 / THF624655

The photograph below shows a row-crop tractor with an under-mounted cultivator at work in a soybean field. The single-front tire running down the middle of two rows ensured that the cultivators tracked between rows, to better remove weeds in between the cash crop.

Man Using a 1935-1938 John Deere Model "B" Series Tractor / THF286604

The Development of No-Till

You may have already grasped the connection between tillage and the no-till planter. Intensive cultivation of cropland contributed to topsoil erosion. The loss of the fertile topsoil reduced yields, and extreme weather worsened the loss. This led many to call for radical changes in tillage methods.

Agricultural scientists and engineers with the U.S. Department of Agriculture and state-based land-grant colleges addressed the challenge quickly. The University of Illinois established the Dixon Springs Agricultural Center in southern Illinois in 1934 to research soil erosion and low-till options. Purdue University in Indiana began the first experiments planting row crops in uncultivated soil in 1944. Russell R. Poyner, the agricultural engineer who worked on this project, went to work at International Harvester Company in 1945. By 1947, he submitted a patent for a mulch-tiller-planter designed for erosion control and conservation of moisture. He coined the new tillage approach “stubble mulch” farming, and as assignor to International Harvester, received U.S. Patent No. 2,577,363 in 1951. International Harvester produced the two-row McCormick M-21 till planter with fertilizer application only briefly and stopped altogether in 1955 due to sluggish sales.

Another early no-till proponent, agronomist George McKibben, worked at Dixon Springs. He and Donnie Morris, the machinery engineer at Dixon Springs, tested a zero-till planter by 1966. Morris describes the challenges he solved—specifically, how to get the seed in the ground. The research team used his “sod and stubble” planter starting in 1969, but an appeal to Deere and Company (the company that makes John Deere brand items) fell on deaf ears.

Allis-Chalmers released the two-row No-Til planting system in 1966, recognized as the first commercially available (and successful) no-till planter. The planter had a fluted coulter (vertical cutting blade) that sliced crop residue and prepared the seed bed just ahead of the fertilizer tank and planter unit.

The John Deere 7000 No-Till Planter: Agricultural Superstar

John Deere 7000 No-Till Planter, 1978 / THF151661

Peter Cousins, then Curator of Agriculture at The Henry Ford, acquired the John Deere 7000 No-Till Planter because, as he wrote in a memo to The Henry Ford’s collections committee on August 23, 1994, he considered it one of a few “superstars” of modern agricultural technology. In that same memo, he explained that of the three companies that introduced no-till planters, only Deere and Company survived. Allis-Chalmers left the farm implement business in 1985. International Harvester also ended its agricultural lines and broke up in 1985. Thus, he believed that only Deere and Company could locate, restore, and donate a first model no-till planter.

What qualifies as a “superstar?” Peter does not go into detail, but he names one other artifact in his memo—the FMC tomato harvester (1969). These two artifacts share at least three key elements that Peter considered as he strengthened The Henry Ford’s collection of 20th-century agricultural technology. First, the implement represents exchange between adopters, engineers, and others, a process described as the social construction of technology. Second, the implement transforms agricultural production. Third, the consequences of the transformation reverberate beyond farm fields.

A Modern John Deere No-Till Planter Sowing Soybeans / Photo courtesy of the United Soybean Board

The collaborative research undertaken by teams of experts at agricultural experiment stations across the country satisfy the first of these three “superstar” criteria. The experiments station staff worked with farmers to determine their needs and respond to them. The planter donated by Deere and Company to The Henry Ford, for example, had been used by Arthur Kruse on his Calmar, Iowa, farm between 1979 and 1994. It included “a wheel module planter with dry fertilizer option, insecticide box, unit mounted coulters, and cast closing wheels.” That insecticide box is telling—the stubble-mulch farming system came with another set of challenges. The stubble served as a vector for pests, namely the European corn borer in corn. A no-till planter that applied insecticide as well as dry fertilizer appealed to farmers even more.

Soybean Seedlings Emerging Among the Residue of the Previous Year’s Crop / Photo courtesy of the United Soybean Board

No-till planter technology changed the system of agriculture. The title of a July 16, 1994, New York Times article that Peter attached to the collections committee memo says it all: “New Way of Tilling Speeds the Plow’s Demise.” Today, no-till or conservation tillage helps farmers reduce erosion and retain soil moisture. Yet, input costs remain high as they apply herbicide to deaden growth before no-till planting, and then apply fertilizer and insecticides while planting.

On the other hand, Michigan State University researchers claim that “no-till farming practices have very positive economic and environmental benefits over decades.” Farm fields can benefit from the environmental benefits of topsoil retention enriched with hygroscopic (tending to absorb moisture from the air) organic matter. They can also realize higher yields over the long run.

Farmers, Please Share Your Stories

The Henry Ford would love to hear from Michigan farmers about your reasons for adopting no-till farming practices, either wholly or selectively, and what you believe the benefits are. You can e-mail us your feedback at MichiganSoybeanFarmers@thehenryford.org.

Debra A. Reid is Curator of Agriculture and the Environment at The Henry Ford. This blog post was produced as part of our partnership with the Michigan Soybean Committee to deepen understanding of the important soybean crop and to provide the public with the chance to learn more about agriculture and the innovations that have helped farmers feed the world. You can learn more about the partnership, soybeans, and soybean ties to The Henry Ford in our kickoff post here.

Additional Readings:

- Massey-Harris Model 20 Self-Propelled Combine, 1938

- Horse Power

- Steam-Powered Agriculture

- Fordson Tractor, 1917-1918, Used by Luther Burbank

environmentalism, Henry Ford Museum, farms and farming, farming equipment, agriculture, by Debra A. Reid

A Bickford & Huffman grain drill, circa 1890, used at Firestone Farm in Greenfield Village. / THF110028

"In the Farmers' Favorite Plain Drill we offer the best machine for the purpose that has ever been produced, and believe we can prove it to be better made, of better material, better finished, better balance, and capable of sowing a greater range of work easier and better under all circumstances than any other." –Bickford & Huffman Co. Catalogue, 1896

Lyman Bickford and Henry Huffman founded what became the Bickford & Huffman Co. in 1842. By the 1870s, their small company in Macedon, New York, sold one of nation's most effective mechanical planters. The mechanization that took place on American farms with machinery such as horse-drawn grain drills, reapers, and threshing machines allowed American farmers to increase their field size and efficiently harvest small grain crops such as wheat, oats, and barley. If properly planted, these crops grow densely, and farmers did not need to remove weeds. But if the seeds were dropped inconsistently, then weeds would take up space in the field and reduce the harvest. Truly how well you sowed your crop determined the quantity you would reap. To comply with their customers’ beliefs, and to confirm their machines’ superiority, the Bickford & Huffman Co. emblazoned their grain drills with the phrase "As Ye Sow So Shall Ye Reap," along with the name "The Farmers' Favorite."

"As Ye Sow So Shall Ye Reap” printed on our Bickford & Huffman grain drill. / THF189173

From the 1840s into the 1880s, the Midwest served as America's breadbasket. Ohio farmers ranked top in the nation in wheat production in 1840 with 16.5 million bushels—almost one billion pounds of wheat. Farmers such as Benjamin Firestone in Columbia County, Ohio, planted winter wheat in the fall as a cash crop, and oats in the spring to use as horse feed. In 1880, Firestone planted eight acres of wheat and ten acres of oats. Like all farmers, his expectations were heightened as he planted his crops and hoped for a bountiful harvest. Like many farmers, he probably abided by the rule "As Ye Sow, So Shall Ye Reap." By the late 1800s, wheat production shifted to Kansas, Nebraska, and the Dakotas.

You can see a Bickford & Huffman grain drill in use during the spring in Greenfield Village as the hands at Firestone Farm prepare and plant the fields. The drill drops seeds just a few inches apart, and the wheat or oats will sprout and spread, forming a lush field of grain. By the middle of June to early July, the grain will be ready to harvest, after which it will be stored until we thresh it in the fall. This drill, though more than 100 years old, continues to sow the hopes of our farmers and demonstrate innovation in American agriculture.

Firestone barn cat Ellen keeps an eye on our Bickford & Huffman grain drill when not in use. / Photo by Jillian Ferraiuolo

Today, farmers still plant using grain drills. Tractor-drawn machines pull grain drills that are as wide as 30 feet. Farmers still rely on a good stand of grain to help control weeds, but also spray herbicide to kill unwanted plants in the field. Some people worry that the use of these chemicals threatens our environment. Others argue that when used in moderation these chemicals are safe. Though we are reaping bountiful harvests, our farming practices may result in unintended problems—we may not know all that we are harvesting.

Leo E. Landis is the former Curator of Agriculture & Rural Life at The Henry Ford. This post was adapted from the April 2001 entry in our former Pic of the Month series.

Additional Readings:

- Agriculture and the Environment

- FMC Tomato Harvester, 1969

- Steam-Powered Agriculture

- Contradictory Impacts: Mechanizing California’s Tomato Harvest

farming equipment, Greenfield Village, farms and farming, environmentalism, by Leo Landis, agriculture

FMC Cascade Tomato Harvester in Use, circa 1985 / THF146505

FMC Cascade Tomato Harvester in Use, circa 1985 / THF146505

The adoption of mechanical tomato harvesters in the 1960s both industrialized tomato production and ushered in a countermovement of small growers and local food advocates. How could one machine prompt such contradictory but real changes in agriculture? The full story spans decades and reveals complex relationships of supply and demand—for both agricultural products and the people who grow and harvest them.

Shortage and Struggle

California’s labor shortage threatened the supply of processing tomatoes for ketchup, sauces, tomato juice, canned tomatoes, and other products. Can label, "Del Monte Brand Spanish Style Tomato Sauce," circa 1930. / THF294183, detail

To meet rising demand for processing tomatoes (to be made into ketchups, sauces, tomato juice, canned tomatoes, and other products) in the early 20th century, growers needed laborers to pick them. Those laborers, in turn, needed living wages. Tensions between growers and laborers came to a head during the New Deal era of the 1930s, when government policies promised minimum wages, maximum hours, and workers’ compensation. Yet, lobbyists working for growers and agricultural processers convinced policy makers to exempt agricultural workers from these protections.

Laborers voted with their feet, seeking employment beyond farm fields. This caused a critical labor shortage that became even more acute during World War II for growers raising tomatoes and other crops in California and beyond. To meet demand, the United States and Mexican governments negotiated the Mexican Farm Labor Agreement. This guest labor program brought millions of farmworkers, known as braceros, from Mexico to work in the United States for short periods of time between 1942 and 1964.

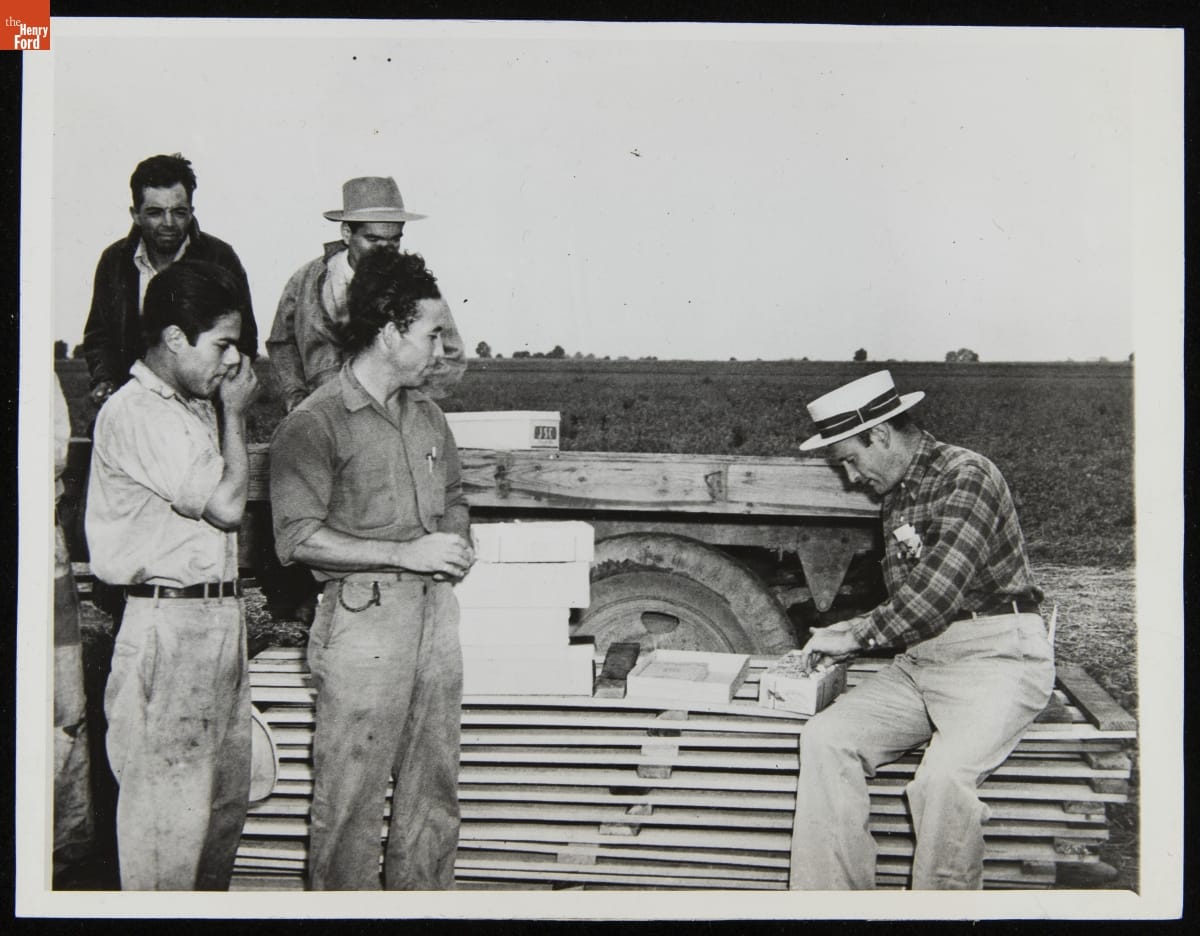

This photograph illustrated a news report on braceros resuming the tomato harvest near Danville, Illinois, in August 1945. / THF147934

A chain of events during the 1960s called attention to the plight of agricultural laborers. Edward R. Murrow’s television documentary Harvest of Shame (1960) highlighted the precarious existence of migrant laborers who worked picking perishable fruits and vegetables in the Midwest and along the East Coast. The Bracero Program expired in 1964, reducing the number of available laborers and increasing growers’ dependence on the existing labor pool. Congress passed the Civil Rights Act of 1964, which, along with other anti-poverty and housing legislation, made it clear that migratory and seasonal laborers had the right to humane treatment.

On the West Coast, Filipino laborers organized as part of the Agricultural Workers Organizing Committee. Seeking better wages and a more favorable rate of payment, they launched a grape strike that expanded into Delano, California, in 1965. The National Farm Workers Association, consisting mostly of Mexican migratory workers, joined the cause. This coordinated effort resulted in a new organization, the United Farm Workers (UFW), with Cesar Chavez as president.

The organizing efforts of groups like the United Farm Workers to secure better wages and living conditions for agricultural laborers in California gained national attention in the 1960s. United Farm Workers flag, circa 1970. / THF94392

The UFW devised innovative solutions to increase pressure on growers, and—especially due to the efforts of co-founder Dolores Huerta—built the Delano grape strike into a national boycott. This focused attention on basic needs for migratory and seasonal laborers. In addition to ensuring some protections for individuals, the coordinated effort secured the right for migratory and seasonal laborers as a class to collectively bargain.

Engineering a Solution to Labor Shortages

Tomato growers, keen on getting their crop planted, cultivated, and harvested at the optimum times, were interested in mechanical solutions that could address labor shortages. Mechanizing the harvest of this perishable commodity, however, proved to be a time-consuming challenge.

Scientists at the University of California, Davis (UC Davis), sought a labor shortage solution through mechanical and biological engineering. Research and development begun in the 1940s finally resulted in the successful design of both a mechanical tomato harvester (created in partnership with Blackwelder Manufacturing Company) and a tomato that could withstand mechanical harvesting (the VF145).

Top: UC Davis vegetable crops researcher Gordie “Jack” Hanna developed the machine-harvestable VF145 tomato. Bottom: An early mechanical tomato harvester underway. Images from the 1968 USDA Yearbook, Science for Better Living. / THF621133 and THF621134

By 1961, Blackwelder had released a commercial harvester and recommended the VF145 tomato for optimum mechanical harvesting. FMC Corporation released a competing harvester by 1966. Manufacturers touted the labor-saving value of mechanical harvesters at a time when the supply of laborers was too small to meet demand, and the adoption of this new technology was swift. In 1961, 25 mechanical harvesters picked about one-half of one percent of California’s tomato crop. Between 1965 and 1966, the number of harvesters doubled from 250 to 512 and the percentage of mechanically harvested tomatoes in California rocketed from 20 percent to 70 percent. By 1970, the transition was complete, with 99.9 percent of California’s tomato crop harvested mechanically. (For more, see Mark Kramer’s essay, "The Ruination of the Tomato," in the January 1980 issue of The Atlantic.)

Contradictory Impact

Some might claim mechanical harvesters helped save California’s processed tomato industry—by 1980, California growers produced 85 percent of that crop. But a closer look reveals a more complicated cause-and-effect. While growers could theoretically save their crop by replacing some labor with machines, many small-scale growers could not save their businesses from large-scale competition. By 1971, the number of tomato farmers had dropped by 82 percent. (This consolidation was mirrored elsewhere in the industry, as just four companies—Del Monte, Heinz, Campbell, and Libby’s—processed 72 percent of tomatoes by 1980.)

Tomato harvester advertisements promised farmers could save their businesses by replacing scarce laborers with machines, but many small-scale growers could not save themselves from large-scale competitors. Advertisement for FMC Corporation Tomato Harvester, circa 1966. / THF610767

A group of growers sued UC Davis, challenging the school for investing so much to develop the tomato harvester without spending comparable resources to address the needs of small farmers. In response, UC Davis opened its Small Farm Center, an advocacy center for alternative farmers, in 1979. These events coincided with wider efforts to hold the United States Department of Agriculture accountable for unequal distribution of support, resulting in increased attention at the national level to economically disadvantaged and ethnically diverse farmers. Around this same time, food activist Alice Waters raised awareness through her advocacy of locally sourced foods. Her restaurant, Chez Panisse, founded in Berkeley, California, in 1971, became an anchor for the burgeoning Slow Food movement.

So, while mechanical tomato harvesters—like the one on exhibit in Henry Ford Museum of American Innovation—represent large-scale scientific and industrial advances, they also offer insight into this country’s complex labor history and help tell stories about small-scale farmers and their connections to communities, customers, and all of us who eat.

Debra A. Reid is Curator of Agriculture & the Environment at The Henry Ford. Adapted by Saige Jedele, Associate Curator, Digital Content, at The Henry Ford.

Additional Readings:

- Agriculture and the Environment

- Bringing in the Beans: Harvesting a New Commodity

- Women in Agricultural Work and Research

- As Ye Sow So Shall Ye Reap: The Bickford & Huffman Grain Drill

farming equipment, research, labor relations, Hispanic and Latino history, food, farms and farming, by Saige Jedele, by Debra A. Reid, agriculture

Mechanizing the Tomato Harvest

Machine-harvesting new tomato varieties, as depicted in the 1968 USDA Yearbook, Science for Better Living. / detail, THF621132

For millennia, people have domesticated plants and animals to ensure survival—this process is agriculture. And while most of us neither grow crops nor raise livestock, agriculture affects all our lives, every day: through the clothes we wear, the food we eat, and the fuel we use to move from place to place.

But agriculture is also the changing story of how this work is done. At every step, people have created new technology and tools to challenge nature’s limitations and to reduce the physical labor required to plant, cultivate, and harvest.

People produced much of what they ate until processed foods became big business in the United States during the late 1800s. As market demand increased, and commercial growing and canning grew, it prompted changes in farming. Take the tomato. Canning required ample quantity to guarantee supply, and vast fields of perishable crops required rapid harvest to ensure delivery of the best crop to processors.

Workers harvest tomatoes by hand at a Heinz farm in 1908. / THF252058

But mechanizing the tomato harvest required changing the crop—the tomato itself—so it could tolerate mechanical harvesting. During the 1940s and 1950s, crop scientists cross-pollinated tomatoes to create uniform sizes and shapes that matured at the same time, and with skins thick enough to withstand mechanical picking.

Agricultural engineers developed harvesting machines that combined levers and gears to dislodge tomatoes from the stalk and stem. But humans remained part of the harvesting process. At least eight laborers rode along on the machines and removed debris from the picked fruit.

In 1969, the first successful mechanical harvester picked tomatoes destined for processing as sauce, juice, and stewed tomatoes.

The 1968 United States Department of Agriculture Yearbook, Science for Better Living, depicted new machine-harvestable tomato varieties that “all ripen near same time, come from vine easily, and are firm fruited.” The oblong shape reduced rolling and bruising. / THF621135

Today, all processed tomatoes—the canned products you find on grocery store shelves—make their way from field to table via the levers, gears, and conveyor belts of a mechanical harvester. But you can still buy a hand-picked tomato at your local farmers’ market—or grow your own.

The process of growing food still involves planting and nurturing a seed. But exploring agriculture in all its complexity helps us recognize the many effects of human interference in these natural processes—an ever-changing story that affects all our daily lives.

Adapted by Saige Jedele, Associate Curator, Digital Content, from a film in Henry Ford Museum of American Innovation’s Agriculture and the Environment exhibit. The team that wrote and refined the film script included Debra Reid, Curator of Agriculture & the Environment; Ryan Jelso, Associate Curator, Digital Content; Ellice Engdahl, Manager, Digital Collections & Content; and Aimee Burpee, Associate Registrar—Special Projects.

Additional Readings:

- Agriculture and the Environment

- Horse Power

- #InnovationNation: Agriculture & Environment

- Biomimicry: Making Mother Nature Our Muse

Henry Ford Museum, farming equipment, food, farms and farming, by Saige Jedele, agriculture

Horse-Drawn Vehicles in the Country

Farm wagon with horse and driver, 1911–1915. / THF200478

During the Carriage Era, while large American cities were crowded with horses, rural areas had fewer animals—but horses were just as important. In the country, horses were much less likely to be used for hauling people and more likely to pull farm equipment, such as plows and reapers, or to haul wagons loaded with hay, grain, cotton, or freight.

In large parts of the South, mules (the offspring of male donkeys and female horses) were preferred over horses. Mules are sterile and so cannot reproduce on their own, but live longer than horses. Southerners believed that mules withstood heat better than horses, though they are smaller and weaker than the large draft-horse breeds. Unlike horses, mules will refuse to be overworked. Their famous “stubbornness” is in reality a self-preservation method—when tired, they simply stop and will not resume their labor until their energy is restored.

Uses for Horse-Drawn Vehicles in the Country

At the beginning of the 19th century, rural horses were primarily employed in tilling the soil, pulling plows, harrows, and cultivators. But later in the century, inventive minds rolled out a steady stream of new farm equipment—reapers, rakes, binders, mowers, seed drills, and manure spreaders. Implements that could be pulled with one or two horses gave way to four-horse plows, eight-horse disc harrows, and giant combines pulled by 25 mules. In addition, every farmer needed one or more wagons for hauling crops to market or supplies from town.

For much of the 19th century, most farmers could not afford vehicles whose only purpose was hauling people. The family could always ride in a wagon. But by mid-century, light people-hauling buggies were cheap enough for some to afford. Mechanization caused their price to fall steadily, so that by the end of the century, one could mail-order a buggy from Sears or Montgomery Ward for $25. Well before Henry Ford’s Model T automobile, cheap carriages whetted people’s appetites for inexpensive personal transportation that did not depend on public conveyances running on fixed routes and fixed schedules.

Milton Bryant with his nephew, Edsel Ford, in a typical farm buggy, 1894. / THF204970

A good deal of commercial transportation also moved through the countryside. Stagecoaches carried passengers between towns and cities. Freight wagons hauled goods from depots to towns not served by railroads. Commodities like kerosene were distributed by wagon.

Horse-Drawn Country Vehicle Highlights from The Henry Ford’s Collection

Fish Brothers Farm Wagon, 1895-1902

THF80599

This is a typical, all-purpose farm wagon with a basic square-box body and a seat mounted on leaf springs. Wagons like these were usually drawn by two horses, and thousands were made by many companies across the country. Franz Eilerman of Shelby County, Ohio, bought this particular wagon, which is on exhibit in Agriculture and the Environment in Henry Ford Museum of American Innovation, in 1902 for his son, Henry.

Hay Wagon, circa 1890

THF80616

This wagon, used in Montgomery County, Pennsylvania, near Philadelphia, is an example of a special purpose wagon. It has flared sides to increase its load-carrying capacity and includes tall end racks, called “hay ladders,” to assist in tying down large loads of hay. In a horse-powered world, hay was an essential crop. While much hay was used on farms, huge quantities were also transported to cities on wagons like this and sold at central hay markets.

Buckboard Used by the Dr. George E. Woodbury Family, circa 1885

THF87328

The buckboard is an American innovation. It is essentially a pair of axles connected by springy floorboards mounting a seat. The floorboards provide a springing action in place of a heavier, more complex spring system. Buckboards were developed in the first third of the 19th century and could carry both people and goods. This rather elaborate buckboard with a pair of seats was used by a Massachusetts physician, Dr. George E. Woodbury, and was drawn by two horses.

Mail Wagon Used for Rural Delivery in Missouri, circa 1902

THF75675a

One of the major innovations that helped break down rural isolation was Rural Free Delivery (RFD), instituted by the Post Office Department in 1896. Prior to 1896, farmers had to pick up their mail at the post office. Rural mail carriers were required to provide their own vehicles, and many chose light mail wagons like this one. Its wood and canvas construction keeps its weight down, and it features pigeonholes for sorting mail. It is even outfitted with a coal-burning stove to keep the mail carrier warm in winter. This wagon was used by August Edinger to deliver mail in Kimmswick, Missouri, from 1902 to 1925. In 1925, he bought a Model T Ford and retired his horse-drawn wagon.

Oil Tank Wagon for Standard Oil Company, circa 1892

THF80588

Standard Oil of Indiana used wagons like this one to distribute kerosene and lubricating oils throughout the Midwest. By 1902, some 6,000 such wagons plied the rural roads. This two-horse wagon served the region of Michigan between Chicago and Detroit.

Pleasure Wagon, circa 1820

THF75657

The pleasure wagon is an American innovation developed in the early 19th century. The idea was to create a light wagon suitable for carrying both people and goods. The seat is mounted on long pieces of wood that serve as springs; the seat can be removed to increase the carrying capacity. The wagon is suspended on leather thoroughbraces and is highly decorated with paint. It was drawn by a single horse.

Skeleton Break, circa 1900

THF148858

Horses had to be trained to pull vehicles and farm implements. A whole class of vehicles called breaks was created for this purpose. Individual farmers would likely not have breaks, but breeders would have them so they could break their animals to the harness before selling them.

This vehicle takes its name from its purpose—to break, train, and exercise pairs and teams of carriage horses. Heavily built, to give animals the feel of a heavy carriage, it can also stand the abuse that unruly horses might give it. An unbroken horse was usually matched with a steady, reliable horse during training.

Julian Stage Line Stage Wagon, circa 1900

THF75679

Lighter and less expensive than the more famous Concord coach, stage wagons served much the same purpose. They carried passengers and mail over designated rural routes on a regular schedule. This one ran between Julian, a California mining town, and Foster Station, where passengers caught a train for the 25-mile trip to San Diego. This wagon was pulled by two, possibly four, horses.

Two-Horse Treadmill-Type Horse Power, circa 1900

THF32303

Not all horse power was used to pull vehicles. With the aid of treadmills, sweeps, and whims, horses could become portable motors for powering sugar cane mills, threshers, corn shellers, small grain elevators and so forth. This two-horse model of treadmill, on exhibit in the Soybean Lab Agricultural Gallery in Greenfield Village, is typical: The horses walked on an endless belt, turning wheels that could power machines.

Runabout, 1876

THF87349

An example of the light, relatively cheap passenger vehicles that appeared in the last quarter of the 19th century, this runabout features James B. Brewster’s patented sidebar suspension and extremely light, steam-bent hickory wheels. It exemplifies the light construction that came to characterize American carriages, weighing just 96 pounds. It was pulled by a single horse.

Bob Casey is former Curator of Transportation at The Henry Ford. This post is adapted from an educational document from The Henry Ford titled “Transportation: Past, Present, and Future—From the Curators.”

Additional Readings:

- Agriculture and the Environment

- A Horse-Drawn Recycler: The Manure Spreader

- Fordson Tractor, 1917-1918, Used by Luther Burbank

- Hidden Histories of the Cotton Gin

farming equipment, horse drawn transport, farms and farming, farm animals, by Bob Casey

Harvesting Wheat at Firestone Farm

Harvesting wheat at Firestone Farm / Photo by Lee Cagle.

Every year, the staff of Firestone Farm go into the fields to harvest wheat. Our living history program at Firestone Farm is set in 1885, and because the area of east central Ohio where the farm originates was not an intense grain-raising area, the latest and greatest harvesting technology was generally not in use. As a result, we use a somewhat older technology—a “self-rake reaper.” Our machine was produced by the Johnston Harvester Company out of Batavia, New York, and was built likely in the mid-1880s.

The machine combines a mowing machine (which cuts down the wheat, gathering it on a large wooden bed) with a raking mechanism (which can be adjusted to sweep the accumulated grain stalks off the bed of the machine into measured piles). It has a wonderful robotic action as it makes it way around the field. The machine is pulled by two large horses and the entire mechanism is powered by them.

Firestone Farm’s Johnston Harvester Co. Self-Rake Reaper, 1878-1900 / THF74908

The loose piles of wheat then need to be gathered up and tied into bundles. In turn, these bundles are stood up on end with other bundles to create a shock or stook. This allows the grain to finish drying before it is stored or stacked for threshing later in the season. (Threshing is the process of separating the grain from the stems, or straw, and the chaff, or the covering of the individual wheat berries.) This is all done by hand—and it takes many hands. Both men and women would have worked together in the field, but before the age of machines (pre-1840s), men typically did the blade work (using sickles, scythes, and grain cradles) and women did the bundling and shocking.

In 1885, each part of the grain harvest was a separate process, using a different machine. Machines that both cut and tied/bundled the grain began to see more common use at the end of the 1880s. These were called binders, and first used wire, then twine, to do this. Eventually, all the harvest processes, including threshing, were “combined” into one step with the advent of the combine. Early versions were horse drawn, but by the 1930s, self-propelled versions began to be used. The final transition took place after World War II as the horse finally was replaced by the tractor on the American farm.

You can get a quick overview of the many steps in wheat production at Firestone Farm in the video below.

Continue Reading

farming equipment, horse drawn transport, Greenfield Village buildings, Greenfield Village, farms and farming, events, by Jim Johnson, agriculture