Posts Tagged making

Peggy Hoyt: "Milliner and Dressmaker to the American Aristocracy"

Our latest installation of What We Wore, featuring designer Peggy Hoyt. / THF189263

Our latest installation of What We Wore, featuring designer Peggy Hoyt. / THF189263

Our current What We Wore exhibit in Henry Ford Museum of American Innovation features garments and hats designed by Peggy Hoyt.

Advertisement for Peggy Hoyt, Inc., 1923. / THF624600

Peggy Hoyt, from “The Right Angle,” The Christy Walsh Syndicate, 1922. Gift of Colleen Cruise Reynolds. / THF626352, detail

Peggy Hoyt began her career making hats as a milliner’s apprentice and went on to become a highly successful fashion designer whose creations would rival those of Paris.

The Early Years

Peggy Hoyt was born Mary Alice Stephens in Saginaw, Michigan, in 1886, to Charles J. Stephens, a partner in a wholesale lumber business, and Carrie Stiff Stephens.

As a child, Mary Alice liked to draw and paint. She had a keen interest in clothes, often designing and making clothing for her large family of paper dolls. When her father’s illness resulted in his inability to resume his business activities, the family’s fortunes declined. A Civil War veteran, Charles Stephens was by 1905 living in the National Home for Disabled Soldiers in Hampton, Virginia, where he died in 1915.

Carrie Stephens moved with her daughter to New York City about 1900. Here, she felt she would have a better chance to get work that offered more than a bare living, as well as provide educational advantages for her daughter, Mary Alice. Though finding work turned out to be harder than anticipated, Carrie Stephens eventually found a job as a comparison shopper for a large department store. In the years following, Carrie Stephens worked her way up to a position as one of the highest salaried European buyers for the department store B. Altman.

In 1905, 18-year-old Mary Alice Stephens married Frank Hoyt in Monterey, Massachusetts—though the couple separated after only 18 months of marriage and Mary Alice then returned to New York City. Life on a 500-acre farm in the Berkshires didn’t suit Mary Alice—she missed the excitement of urban life. She and Frank Hoyt finally divorced in 1911; she kept her married name.

Becoming Peggy Hoyt

In her late teens, Hoyt worked as an apprentice in a Fifth Avenue millinery (hat) shop. By 1910, with a talent for design, a flair for business, and $300 borrowed from her mother, Hoyt established her own millinery shop in tiny quarters on upper Fifth Avenue, a shopping destination lined with luxurious stores. A year later, the business was successful enough to warrant an upgrade. She rented a larger room in the same building and hired an assistant. By 1915, Peggy Hoyt, Inc. was born.

In February 1918, Hoyt married Aubrey Eads—an officer in the American Naval Aviation Detachment who had recently returned after 14 months in France during World War I. Eads became her business partner.

A Leading American Designer

In the late 1910s, Hoyt moved her growing business into the elegant Phillip Rhinelander mansion at 16 East 55th Street in Manhattan, where she added women’s clothing to her offerings. The mansion, located in Manhattan’s Upper East Side shopping area, provided over 27,000 square feet of space with a stately white marble hall and a magnificent stairway. Hoyt transformed the mansion into one of the most exquisite fashion centers in America. The first floor became a reception room, salon, and fitting rooms. The second floor was devoted entirely to millinery. The top floors held workrooms and a lunchroom for employees.

Peggy Hoyt leased the Phillip Rhinelander mansion on at 16 East 55th Street, transforming it into a stunning setting for her increasingly successful salon. Gift of Colleen Cruise Reynolds. / THF120772, THF120770

A few years after she moved to the Rhinelander mansion, Peggy Hoyt ventured into theatrical costume design for a brief time. Her elegant costumes for Henry W. Savage’s revival of The Merry Widow in September 1921 were a huge success. The following year, she created costumes for the Savage musical The Clinging Vine.

Program for The Merry Widow. The operetta ran for 56 performances in fall of 1921 at the Knickerbocker Theatre in New York. Note the credits for Peggy Hoyt at the top of page 33 (you can click through to our Digital Collections to zoom in). / THF624648, THF624630, THF624638

Hoyt quickly became one of the foremost American designers of gowns and millinery. Her designs were creative and unique, employing her signature pastels, rhinestone ornaments, and handkerchief hems. Hoyt designed each of the hundreds of gowns and hats in her shop, taking great pride in her work. For nearly twenty years, Hoyt dressed a small, but exclusive, clientele in every large American city.

Advertisement: "Peggy Hoyt: New York's Smartest Millinery and Dressmaking Establishment," April 1925. / THF624602

Peggy Hoyt discussed the type of garment, color, style, and fabric with her client, and then sketched the designs. Hoyt oversaw the next steps in the workroom, where staff cut and sewed the garment. Clients had their very own dress form, an adjustable mannequin on which Hoyt’s designs came to life. At the client’s next appointment, the garment was taken to the front of the salon for the final fitting.

A Peggy Hoyt Client: Elizabeth Parke Firestone

Elizabeth Parke Firestone, about 1927. Gift of Mrs. Harvey Firestone, Jr. / THF119839

Receipt for Mrs. H.S. Firestone, Jr. from Peggy Hoyt, Inc., 1934. Gift of Martha F. Ford. / THF626330

Elizabeth Parke Firestone of Akron, Ohio—wife of tire magnate Harvey S. Firestone, Jr.—was among the wealthy women who frequented Peggy Hoyt’s salon. Mrs. Firestone traveled to New York, where Hoyt would confer with her client and then create the beautiful garments and hats for Mrs. Firestone shown here.

Evening dress designed by Peggy Hoyt, 1928. Gift of Mrs. Harvey Firestone, Jr. / THF6688

Evening dress designed by Peggy Hoyt, 1928-1929. Gift of Mrs. Harvey Firestone, Jr. / THF6720

Chemise dress designed by Peggy Hoyt, 1929. Gift of Mrs. Harvey Firestone, Jr. / THF6710

Evening dress designed by Peggy Hoyt, 1931. Gift of Mrs. Harvey Firestone, Jr. / THF6731

Cloche designed by Peggy Hoyt, 1920-1935. Gift of Martha Firestone Ford and Anne Firestone Ball. / THF17330

Cloche designed by Peggy Hoyt, 1925-1936. Gift of Mrs. Harvey Firestone, Jr. / THF30500

Picture hat designed by Peggy Hoyt, 1925-1935. Gift of Mrs. Harvey Firestone, Jr. / THF6754

Picture hat designed by Peggy Hoyt, 1926-1936. Gift of Mrs. Harvey Firestone, Jr. / THF6747

An Unhappy Ending

Peggy Hoyt, Inc., box lid, 1925-1935. Gift of Colleen Cruise Reynolds. / THF188547

At its height, Peggy Hoyt, Inc., earned over $1 million annually and had hundreds of employees. Yet Peggy Hoyt, Inc.—and Peggy herself—would not survive the depression of the 1930s as the faltering economy brought down the thriving business.

Peggy Hoyt died by suicide on October 26, 1937 (though her family maintained that her death resulted from pneumonia). Hoyt, who had an intense dislike of personal publicity, had asked her mother and husband to honor her wishes for privacy upon her death. At the request of Hoyt’s employees, her husband did consent to a small service at the Little Church Around the Corner (the Church of the Transfiguration) before Hoyt’s body was brought to Detroit and laid to rest in Elmwood Cemetery.

Peggy Hoyt, Inc., briefly continued after Hoyt’s passing, with her mother and husband maintaining the salon until its bankruptcy and liquidation in 1939–1940.

Jeanine Head Miller is Curator of Domestic Life at The Henry Ford. Many thanks to Stacy McNally, Local History & Genealogy Librarian at the Public Libraries of Saginaw, and Gil Gallagher, curatorial volunteer at The Henry Ford, for their meticulous research assistance on Peggy Hoyt. Many thanks also to Sophia Kloc, Office Administrator for Historical Resources at The Henry Ford, for editorial preparation assistance with this post.

Firestone family, New York, 20th century, 19th century, women's history, What We Wore, Michigan, making, Henry Ford Museum, hats, fashion, Elizabeth Parke Firestone, design, by Jeanine Head Miller

When thinking about the celebrated figures in decorative arts history, one first thinks of individuals like Thomas Chippendale, Duncan Phyfe, and Gustav Stickley in furniture, Paul Revere and Tiffany and Company in silver, and Josiah Wedgwood in ceramics. All these prominent figures have something in common—they all are men. There are few celebrated female leaders in the decorative arts. This may be due to the scholarly focus on great men, to the detriment of women, until recent years.

Cover of Tried by Fire by Susan Frackelton, 1886. / THF627718

One of the most important and underrecognized women in decorative arts history was Susan Frackelton (1848–1932). She was a founder of the field of women’s china painting in the 1870s and 1880s. She was also a catalyst in transforming that pastime into a profession with the evolution of china painting into art pottery in the 1890s. Unlike her more famous peers, Susan Frackelton earned her living and supported her family on the proceeds of her publishing, teaching, and collaborations with like-minded artists.

Susan Frackelton faced many challenges in her personal and professional life. In many ways, she was a trailblazer for the modern, independent woman. Only in recent years have her contributions been recognized. Like other major figures in the decorative arts, including Thomas Chippendale, she is best remembered for a publication, her 1886 Tried by Fire. In the introduction, she states, “If the rough road that I have traveled to success can be made smoother for those who follow, or may hereafter pass me in the race, my little book will have achieved the end which is desired.”

Why Was China Painting a Means for Women’s Liberation?

Many factors fueled the growth of amateur china painting in late-19th-century America. As America became wealthier after the Civil War, women of the middle and upper middle classes gained more leisure time for personal pursuits. China painting became a socially acceptable pastime for women because it allowed them to create decorative objects for the home. Further, the influence of the English Aesthetic movement and later the Arts and Crafts movement advocated that the creation of art should be reflected in the home. By the 1870s and 1880s, wealthy women were freer to leave the confines of the home through organizations that they set up to create and exhibit their work.

What Is China Painting?

Pitcher, 1890–1910, decorated by an amateur china painter. / THF176880

This pitcher is a good example of the work of an amateur china painter. The artist would take a “blank”—a piece of fired, undecorated, white porcelain, in this case a pitcher made by the English firm Haviland—and paint over the glaze. These blanks could be purchased in multiples at specialty stores. One of the most prominent of these was the Detroit-based L.B. King China Store. It was founded in 1849 and closed during the Great Depression, about 1932. According to a 1913 advertisement, the retailer sold hotel china, fine china dinnerware, cut glass, table glassware, lamps, shades, art pottery, china blanks, and artists materials. Elbert Hubbard, founder and proprietor of the Roycrofters, a reformist community of craft workers and artists that formed part of the Arts and Crafts movement, wrote enthusiastically about the products of the L.B King China Store: “The store is not only a store—it is an exposition, a school if you please, where the finest displays of hand and brain in the way of ceramics are shown.” A woman seeking to learn about china painting could literally walk into the L.B. King Store and walk out with paints, blanks, and a manual like Frackelton’s Tried by Fire and start painting her own china.

The pitcher above is part of a large group of serving pieces in our collection. Also in our collections is a full set of china decorated by a young woman and her friends who learned china painting at what is now Michigan State University. They decorated the dinnerware service in preparation for the young woman’s wedding in 1911. According to family history, the young woman purchased the blanks at the L.B. King Store.

How Did China Painting Evolve in the Late 19th Century?

During the 1870s, Cincinnati was the center of American china painting. The movement was led by two wealthy women, Maria Longworth Nichols (1849–1932), who later founded the Rookwood Pottery, and her rival, Mary Louise McLaughlin (1847–1939). Both studied with European male ceramic artists who had made their way to Cincinnati. Both evolved from amateur status into extraordinary artists, who moved from painting over the glaze to learning how to throw and fire their own vessels, create designs, and formulate glazes for their vessels. This all occurred during the late 1870s, following a display of ceramic art at the Women’s Pavilion of the 1876 Centennial Exhibition in Philadelphia. Both sought to outdo each other in the formulations of glazes. It is generally believed McLaughlin was the first to learn the technique of underglaze decoration, although Nichols later claimed that she was the first to do so. Nichols’ most important achievement was in creating the Rookwood Pottery in Cincinnati in 1880. It was essentially the first commercial art pottery company in America, and it led the way in the development of new techniques that were widely imitated by other firms. Rookwood and its competitors began to hire women to decorate ceramics, opening a new livelihood for women less well off than Nichols and McLaughlin.

Vase, 1902, decorated by Grace Young, Rookwood Pottery Company, Cincinnati, Ohio. / THF176709

Vase, 1917, decorated by Lenore Asbury at the Rookwood Pottery Company in Cincinnati, Ohio. / THF176918

Tile, 1910–1920, made by the Rookwood Pottery Company in Cincinnati, Ohio. / THF176941

Essentially, through the pastime of china painting, a new industry, art pottery, came into being by 1900. Under the influence of popular magazines like the Ladies’ Home Journal and House Beautiful, Americans eagerly acquired art pottery. In fact, tastemakers like the young architect Frank Lloyd Wright filled his houses with art pottery. He considered it very much part of his total aesthetic. Through the first three decades of the 20th century, art pottery was considered a must in any well-furnished American home. It only fell out of fashion in the 1930s, when the Great Depression drastically altered lifestyles.

How Does Susan Frackelton’s Story Fit into All of This?

Susan Stuart Goodrich Frackelton was a contemporary of both Maria Longworth Nichols and Mary Louise McLaughlin, born in 1848 like Maria Longworth Nichols, and just a year older than Mary Louise McLaughlin. Unlike either of these women, she came from a modest background. Her father was a brick maker in Milwaukee, and she was raised in a middle-class environment. Susan began her artistic career studying painting with the pioneer Wisconsin artist Henry Vianden. In 1869, she married Richard Frackelton and eventually raised three sons and a daughter.

Richard’s business was importing English ceramics and glass and was relatively successful. Within a few years, however, the business began a sharp decline and Susan stepped in to help. She later said that she learned about American taste in ceramics and business while working with her husband. Concurrently, she began to experiment with china painting, applying her experience in painting with Henry Vianden. She was essentially self-taught, unlike her contemporaries in Cincinnati. Through publications, she was aware of what was going on in the field. She was also aware of the innovations of Mary Louise McLaughlin in glazes, and by the late 1870s was experimenting in underglaze painting herself.

Frackelton’s contributions to china painting began in 1877, when she opened Frackelton’s Decorating Works in Milwaukee. She trained young women in the art of china painting. By 1882 she opened a related business called Mrs. Frackelton’s Keramic Studio for Under and Overglaze, where she sold her own work, wares made by her students, commercial china, and glassware, as well as painting supplies. Like Detroit’s L.B. King store, she created a one-stop shop for young women interested in exploring china painting and, later, art pottery.

Title page, Tried by Fire, 1886. / THF627720

Frackelton made a national name for herself in 1886 with the publication of Tried by Fire. It differed from other manuals for china painters in that it was written by a teacher for beginning students. Frackelton’s conversational style and advice on not expecting too much too soon appealed to readers and the book became a best seller, reprinted in two revised editions in 1892 and 1895. As a teacher, Frackelton had no equal in the world of art pottery. She advocated that both wealthy and poor women could enjoy the art of china painting: “Beauty is the birthright of the poor as well as the rich, and he lives best who most enjoys it.”

Color plate from Tried by Fire, 1886. / THF627772

Color plate from Tried by Fire, 1886. / THF627773

Color plate from Tried by Fire, 1886. / THF627775

Color plate from Tried by Fire, 1886. / THF627774

Pitcher, 1890–1910, decorated by an amateur china painter. Note that the botanical decoration on this pitcher is similar to the Tried by Fire color plates. / THF176879

Another major innovation was the development of a patented gas-fired kiln, first offered in the advertising section of Tried by Fire. By 1888 she was granted a second patent for a new and improved version.

Advertising section of Tried by Fire showing Frackelton’s portable gas kiln. / THF627793

By 1890 Frackelton was a well-known figure and was noted for displaying her work in international exhibits. In 1893 she won eight awards for her work in a competition held at Chicago’s World’s Columbian Exposition. Additionally, she became renowned for her work in a variety of ceramic media, especially for her blue and white salt-glazed stoneware. She also worked to create new and easier-to-use paints for decoration. She went so far as to organize the National League of Mineral Painters in 1892, an organization “aimed to foster a national school of ceramic art and provide a link between china painters throughout the country.”

By the late 1890s, Frackelton’s reputation was secure, as were her finances. In 1897 she divorced Richard Frackelton and moved to Chicago and spent much of her time lecturing and promoting ceramic art. She collaborated with several ceramic artists, including the now famous George Ohr, a unique artist who called himself “the mad potter of Biloxi.” Together, they created several highly unusual pieces, now in the collections of the Wisconsin Historical Society.

In her later years, Frackelton moved away from working in ceramics, preferring to return to painting and working as an illuminator of manuscripts. However, Frackelton’s promotion of the ceramic arts made her one of the most admired female artists in America in the first decade of the 20th century. Susan Frackelton was a remarkable figure in American ceramics, justifiably earning her status as one of the prominent figures in the decorative arts and certainly in broadening the role of women in American society.

Charles Sable is Curator of Decorative Arts at The Henry Ford. Many thanks to Sophia Kloc for editorial preparation assistance with this post.

Illinois, Wisconsin, 20th century, 19th century, women's history, teachers and teaching, making, furnishings, entrepreneurship, education, decorative arts, ceramics, by Charles Sable, books, art

Suits for the Stars: Spacesuits of Yesterday, Today, and Tomorrow

Cocooned within 21 layers of synthetics, neoprene rubber, and metalized polyester films, Apollo 11 astronaut Buzz Aldrin was well protected from the airless moon’s extremes of heat and cold, deadly solar ultraviolet radiation, and even the off chance of a hurtling micrometeorite. / Photo by Neil Armstrong/NASA

Cocooned within 21 layers of synthetics, neoprene rubber, and metalized polyester films, Apollo 11 astronaut Buzz Aldrin was well protected from the airless moon’s extremes of heat and cold, deadly solar ultraviolet radiation, and even the off chance of a hurtling micrometeorite. / Photo by Neil Armstrong/NASA

It’s possibly the most recognizable image in all of human history: Buzz Aldrin on the surface of the moon, his left arm drifting up as if checking the time during a stroll through the park.

The photo sticks in the imagination more than any image of sleek rockets on the launchpad or metallic modules landing on an inhospitable world. Perhaps it’s the casual, individual bravado oozing off Aldrin’s puffed-up frame that truly captures the essence of humans pushing past the ultimate boundary: space.

And yet the spacesuit is rarely the star of the human spaceflight epic. Which is a shame, since this was the most intimate component of the engineering endeavor that landed man on the moon 50 years ago—intimate also because the surprising winner of NASA’s spacesuit contract was a spinoff of Playtex, the underwear manufacturer which still makes items from bras to feminine products to this day.

Playtex made everyday women’s girdles like those shown in this ad before making an unlikely jump to producing clothing for space travel to the moon in the 1960s. / Photo courtesy of Wikimedia Commons

“The suits that other companies provided were stiff, they were bulky, they couldn’t fit the narrow confines of the mission parameters,” said Nicholas de Monchaux, professor of architecture at University of California Berkeley’s College of Environmental Design and writer of a deeply researched book called Spacesuit: Fashioning Apollo.

At the core is the idea of the “human factor,” often overlooked by engineers in their quest to reach the lunar surface. The Saturn V rocket and the lunar module were exquisitely engineered, with sharp, clean lines governed by the unchanging forces of physics: thrust, gravity, air resistance. But the same equations are blurred when dealing with the human form. “The human body doesn’t operate from first principles,” said de Monchaux.

In the race to win the initial suit contract, companies such as David Clark Company, which made the Mercury mission spacesuits, and Hamilton Standard, a division of conglomerate United Aircraft, produced concepts informed by their decades-long experience with high-altitude pressure suits. These options proved much more difficult to maneuver than the suit produced by ILC Dover, the Playtex spinoff whose patented “convolutes” included rubber identical to that filling Playtex’s girdle molds, as well as nylon tricot and webbing taken from the supplies feeding its brassiere assembly lines.

The Apollo spacesuit designed by ILC Dover and worn on the moon had 21 layers, 20 of which were created with synthetics made by chemical giant DuPont. Familiar household names like nylon, Lycra, and Teflon were found in various layers, a fact DuPont proudly advertised at the time.

In 1966, events came to a head when a new ILC spacesuit had to compete once more against prototypes from Hamilton Standard and David Clark. Test subjects using the competing suits had trouble moving around, operating switches, and fitting in and out of the mock landing module. Imagine if Aldrin and Neil Armstrong had touched down successfully on the moon only to not fit through the hatch to step on the surface!

Though each competing suit was custom fitted, only the 21-layer ILC Dover soft suit was sewn by hand by a hotshot crew of the best seamstresses taken from Playtex’s sewing floor—eschewing paint-by-numbers engineering in favor of highly personalized, artisanal craftsmanship. Each spacesuit created by the ILC Dover team bore a laminated photograph of the astronaut it belonged to in order to create a connection to the person whom they were literally keeping alive with their craftsmanship.

Arlene Thalene of ILC Dover inspects a spacesuit’s mylar insulation layers. / Photo courtesy of ILC Dover, LP

Their knowledge, gained by fashioning bras and girdles for women’s activewear, proved indispensable to creating a superior product. The material itself was co-opted: “The rubber that made the suit was literally from the same tank that was, originally at least, supplying the girdle-making that had made Playtex’s fortune,” said de Monchaux.

ILC Dover employee Velma Breeding installs a bladder into a boot. / Photo courtesy of ILC Dover, LP

The ILC Dover suit bested the others in official NASA tests, but the systems-engineering bureaucracy of the Apollo program was still skeptical of an untested spinoff holding such a critical contract. When again faced with competition for the last phase of Apollo’s missions (numbers 14-17), the ILC Dover team even resorted to filming a test subject playing football in a pressurized suit for several hours. “And, as became clear on watching the films, the suited subject’s attempts were at the very least equivalent to those of an engineer in shirtsleeves and slacks who joined him on the field,” wrote de Monchaux. “ILC Dover, née Playtex, had won the Apollo game.”

A composite of the final drawings from ILC Dover depicts (from right to left) an Apollo 11 spacesuit’s pressure garment assembly, a suit with its Thermal Micrometeoroid Garment (TMG) attached, and an astronaut wearing a suit with TMG outer cover, gloves, and helmet. Once securely attached to the spacesuit’s inner pressure garment, the multilayered TMG protected astronauts against micrometeoroid impacts, solar and galactic radiation, thermal conduction, and abrasion, and also provided fire protection. / Drawings courtesy of ILC Dover, LP

Dressed for Health

More than 50 years after the Apollo 11 astronauts donned their spacesuits on the moon, I’m sitting in an office at hygiene and health giant Essity’s facility in North Carolina trying to pull on what looks like your average thick knee-high black socks. Kevin Tucker, the global technical innovations manager for a division of Essity, chuckles while I struggle with the fabric as it tightens like a vice. Tucker is in charge of the company’s work with NASA to develop a compression suit for astronauts returning from space. He points out as he puts the socks away that future NASA astronauts will wear something with twice the compression power.

Essity’s bread and butter is making compression garments for people with venous and lymphatic diseases. That’s when the body has issues with pumping fluids against the pull of gravity, causing symptoms from lack of feeling in extremities to loss of consciousness. It’s something we have all experienced to some degree, said Tucker. “If you’re sick in bed with the flu and you’re lying down for a long period of time and you have to go run to the bathroom, the first step you usually take you end up on your nose.”

Astronauts also have trouble with fluid control. When they first get up into space and gravity is no longer a factor, fluids are pumped more into their torso and head. That’s why new arrivals to the International Space Station have puffy faces. After a while, the body adjusts and pumps less to accommodate the lack of gravity. But the problem rears its head again upon re-entry and the rapid reintroduction to gravity. At that point, the body’s fluid pumping is weakened, and astronauts often have to be carried out of the capsule. “This sudden rush of fluid away from the head and heart down into the legs can affect your consciousness,” said Tucker. That’s something his team is trying to change.

To help NASA, Essity is applying its expertise in designing compressive socks, sleeves, and girdles to create a compression suit future astronauts would wear on re-entry to prevent or avoid the sudden redistribution of fluids to the lower extremities upon return to Earth’s gravity. When Tucker lays out the current design on a table, it’s a crisscross of tight black fabric and a few zippers, woven in a way reminiscent of those fancy yoga pants that have sheer patterns.

Health giant Essity is currently working with NASA to create a compression suit that astronauts will wear upon re-entry to Earth. The garments, shown separately here for illustrative purposes, will prevent or avoid the sudden redistribution of fluids to the lower extremities upon return to Earth’s gravity. / Photo courtesy of Essity

It’s slated to be the first layer of gear NASA astronauts will put on as they prepare to splash down—so getting stuck as you pull on the suit is simply not an option. Another “soft” consideration is that the astronauts will have to wear these for hours in a seated, upside-down position, and tests of earlier designs irritated subjects’ bent knees. The newest version of the compression suit comes slightly pre-bent at the joint, making it more comfortable.

The Human Factor and What’s Next

The human body was not meant for space travel, and the soft problems it presents require innovative solutions with intimate knowledge of the human body. Some of those challenges (and ways suits can help) are listed below.

Vacuum: Exposed to the vacuum of space, a body’s fluids would start boiling away as the body puffs up. A spacesuit protects you—but, be warned, it will puff up, too.

Temperature: Outside the International Space Station, the temperature swings wildly from 250 to -250 degrees Fahrenheit. But with no atmosphere to transfer heat or cold, a well-insulated spacesuit keeps you comfy.

Radiation: Above the protection of the Earth’s atmosphere and magnetic field, cosmic radiation is the most consistent health concern. A spacesuit provides very limited protection—as does the space station.

Lack of Gravity: Low or no gravity makes muscles atrophy, bones lose density, and fluids redistribute. NASA is working on it.

Unfortunately, the human body is not always something the engineering culture of rocket scientists takes into account. “We’re still thinking about the engineering and the propulsion systems and the vehicle, but we’re not thinking enough about the pink, squishy things that are in the middle of that vehicle,” said Diana Dayal, who did a year-long apprenticeship at the National Space Biomedical Research Institute (NSBRI). Funded by NASA’s Human Research Program, NSBRI, which closed in 2017, was NASA’s lead partner in space biomedical research and provided hands-on lab opportunities for young scientists, engineers, and physicians such as Dayal to access careers in human spaceflight.

On future, longer space missions, the human factor will be amplified. New challenges will arise from the long stint in low gravity. “The deconditioning of your bones and muscles is going to be an unavoidable problem on a three-year Mars mission,” said Dayal. “How are you supposed to send people to Mars and expect them to set up a habitat?”

Astronaut Neil Armstrong—shown here aboard the Apollo 11 Lunar Module Eagle, the first crewed vehicle to land on the moon—later quipped that his spacesuit was one of the most widely photographed spacecrafts in history. Decades later, he sent a note to the team that designed the spacesuit, complementing it and calling it “tough, reliable and almost cuddly.” You can see the “cuddly” spacesuit worn by Armstrong, held by the Smithsonian National Air and Space Museum, on their collections website. / Photo by NASA / Edwin E. Aldrin Jr.

One of the solutions being explored is enhancing the spacesuit with an exoskeleton—essentially empowering the humans by linking them to a stronger robotic carapace. This is a good idea, but the prototype Dayal saw at NASA’s Johnson Space Center was so large and cumbersome, it was hard to imagine it on an average person.

“It’s so cool that you basically have all this circuitry that simulates nerves, but at the same time, who did you build this for? Who’s going to wear it?” They were questions posed by Dayal’s group, she said, pointing out that current designs lack sufficient modularity to adjust to different body types.

While the lessons learned in developing the soft Apollo spacesuit decades earlier may have to be revisited as we look to longer missions, it’s also an opportunity to push the boundaries of design. “All of your constraints are out the window; everything is a variable,” said Dayal. “If anything, designing for space should help us better design for Earth.”

Fedor Kossakovski is a freelance science writer and producer. This post was adapted from an article in the June–December 2019 issue of The Henry Ford Magazine.

The Henry Ford Magazine, making, women's history, engineering, design, fashion, by Fedor Kossakovski, space

Cast in Plaster: Isaac Hathaway and Sculpture as Black Biography

Black sculptor Isaac Scott Hathaway (1872–1967) took issue with inadequate recognition of Black achievement. He dedicated his career to creating and marketing affordable plaster busts and other commemorative sculpture, literally putting Black activists, educators, ministers, and dozens of other individuals on a pedestal. These stood in stark contrast to lawn jockeys and other statuary that emphasized caricatures and stereotypes.

Plaster Plaque of George Washington Carver (1864?–1943) Cast by Isaac Scott Hathaway, 1945. / THF152082

Hathaway remembered visiting a Midwestern museum when he was nine years old (around 1881), with his father, Robert Elijah Hathaway (1842–1923). The young Hathaway wondered why museums did not include statues of Black people. His father explained that white people modeled their own, and that if Black Americans wanted to see sculptures of Black Americans, “we will have to grow our own sculptors.”

This museum visit changed Hathaway’s life, as he recalled in a 1939 Federal Writers’ Project interview and in a 1958 article in the Negro History Bulletin. He studied art during the era of the New Negro, a movement of the 1890s to 1910s that emphasized African and Black American contributions to the arts, literature, and culture. He taught school, created sculpture, and distributed his plaster casts through the Afro Art Company, which he launched after he moved to Washington, D.C., in 1907.

Hathaway moved when opportunities to further ceramics education arose. He relocated to Pine Bluff, Arkansas, by 1915 to launch ceramics education at the Branch Normal College (now the University of Arkansas at Pine Bluff). He moved his company, renamed the Isaac Hathaway Art Company, to Pine Bluff at the same time. In 1937, he joined the faculty at Tuskegee Institute (now Tuskegee University) in Alabama, to introduce a ceramics curriculum there. In 1947, he moved to Montgomery, Alabama, to direct ceramics instruction at Alabama State College (now Alabama State University).

Plaster Cast of George Washington Carver's Hand, 1943. / THF34092

The Henry Ford has two of Hathaway’s plaster casts. Hathaway gave them to Henry Ford in December 1945, explaining that he wanted Ford to have the small plaque (shown at the beginning of this post) and “a cast … made from the hand of the late Dr. George Washington Carver” (shown above). The plaque was one of three types of casts of Carver that Hathaway made. The others included a small bust (around one foot tall) and a heroic bust, visible in this photograph of the artist at work (courtesy of the Tuskegee University Archives).

Carver’s hands attracted a lot of attention, long and strong and well-worn after years of physical labor. Based on Hathaway’s description, it appears that he made the cast of Carver’s hand after Carver died on January 5, 1943. Hathaway instructed students in techniques he used. Photographs show him instructing students in creating molds of their hands at Alabama Polytechnic University (now Auburn University) around 1947.

Hathaway’s reputation earned him a commission in 1946 to design the Booker T. Washington Memorial Half Dollar. This was the first coin designed by a Black American for the U.S. Mint, and the first coin minted that featured a Black American. You can read more about this in “Coining Liberty: The Challenge of Commemorating Black History.”

Hathaway’s plaster casts remind us of the importance of acknowledging Black accomplishments. Others followed his examples.

Benjamin Akines (c1904–?), a bricklayer and brick mason living in Jackson, Mississippi, knew of Henry Ford’s interest in and respect for Carver’s work. Akines gave Ford a bust of the Black scientist in 1941, four years before Hathaway sent his two casts to Ford.

Bust of George Washington Carver, circa 1941. / THF170783

Akines sent the plaster bust and a letter directly to Henry Ford: “Enclosed you will find a token (in the form of a bust) of one of whom I am told you esteem very highly … I trust this will mean a moment of happiness to you.” Akines claimed that he “was divinely inspired to model,” though he worked as a bricklayer. The back of the bust represents the work of a bricklayer, sculpted with a cut stone foundation with a laid brick pier. This brickwork was his signature, as Akines included bricks in other creative works. On November 10, 1931, he received a patent for an ornamental clock case in the form of a brick façade and sides (Patent Des. 85,507).

Bust of George Washington Carver, circa 1941, Cast by Benjamin Akines. / THF170784

Eager to share his efforts, Akines communicated his news to the Chicago Defender, the Black newspaper in the then second-largest U.S. city, Chicago, Illinois. It reported that “Akines, a bricklayer who indulges in sculpturing as a hobby,” gave Ford a plaster cast of Carver, and that Ford’s secretary and Carver himself acknowledged his generosity (“Bricklayer-Sculpturor [sic] is Lauded for Bust of Carver,” July 12, 1941).

It is difficult to know whether others who cast busts of Carver influenced Akines’ approach. For example, German-born Steffen Thomas (1906–1990) sculpted a clay model of Carver during a 1936 visit to Tuskegee. This was the model from which he cast the sculpture recognizing Carver’s 40 years of service to Tuskegee. The gift received media coverage at the time Carver received it in 1937 and appeared prominently during the dedication of the Carver Museum in 1941, given its location on a plinth outside the museum.

George Washington Carver and Austin W. Curtis, Jr., at Tuskegee Institute with Sculpture by Steffen Thomas, circa 1938. / THF213732

These last two examples indicate more recent commemorations of Black historical figures. One represents a respectful but commercial venture, and the other an exceptional recognition.

Commemorative Bust of Rosa Parks (1913–2005), designed by Sarah’s Attic, Inc., 1995. / THF98391

A popular Michigan-based figurine manufacturer, Sarah’s Attic., Inc., released a limited-edition bust of rights activist Rosa Parks in 1995. Cast of synthetic resin and hand-painted, it was one of four “Faces of Courage” in the Black Heritage Collection. The others featured abolitionist Harriet Tubman, a Buffalo Soldier, and a Tuskegee Airman. The Rosa Parks bust was one of 9,898 made and distributed through a commercial contract, with Sarah’s Attic holding the copyright and Rosa Parks holding the license.

Commemorative Bust of Detroit Lions Tight End Charlie Sanders (1946–2015), 2007. / THF165543

This cast metal bust of the Detroit Lions’ legendary tight end Charlie Sanders exists because of his election to the Pro Football Hall of Fame. The Hall commissioned Tuck Langland, an artist and retired university educator, to cast Sanders. Langland first created a bust out of clay based on photographs and a visit with Sanders. That clay statue became the model for the cast bronze bust displayed in the Hall of Fame Gallery in Canton, Ohio, and the copy presented to Sanders (and later donated to The Henry Ford).

So many variables exist in the business of commemoration.

When Isaac Scott Hathaway created respectful sculptures of Black Americans, he challenged white exceptionalism. Who decided who received recognition? Hathaway. What criteria informed his decisions? He selected subjects he respected, but as an educator, he selected people with lessons to teach, and as a businessman, he selected subjects that would sell. Disagreements over selections can derail seemingly straightforward acknowledgment.

What form should the recognition take? Hathaway mass-produced inexpensive plaster casts. Others create one-of-a-kind sculpture or mass-produce limited-edition items. Other recognition in the form of a historical marker or a street sign can draw attention to places of significance and the people who lived there.

Recognition of Black accomplishments remains important—in fact, critical—to understanding the human experience.

Sources

Gates, Henry Louis, Jr. “The New Negro and the Black Image: From Booker T. Washington to Alain Locke.” Freedom’s Story, TeacherServe©. National Humanities Center.

“The Hathaway Family: A Journey from Slavery to Civil Rights,” a paper compiled by scholars Yvonne Giles, Reinette Jones, Henri Linton, Brian McDade, Quantia "Key" M. Fletcher, and Mark Wilson, based in materials at these institutions: Alabama State University, Montgomery, Alabama; Auburn University, Auburn, Alabama; the Isaac Scott Hathaway Museum, Lexington, Kentucky; the Mosaic Templars Cultural Center, Little Rock, Arkansas; Tuskegee University Archives, Tuskegee, Alabama; the University Museum and Cultural Center, University of Arkansas Pine Bluff, Pine Bluff, Arkansas. (n.d.).

“Isaac Scott Hathaway,” a product of the Appalachian Teaching Project, Auburn University, and the Tuskegee Human and Civil Rights Multicultural Center (2012).

"Isaac Scott Hathaway: Artist and Teacher," Negro History Bulletin, vol. 21, no. 4 (January 1958), pp. 74, 78-81.

Perry, Rhussus L. Federal Writers’ Project Interview of Isaac Hathaway. February 2, 1939. Folder 60, Coll. 03709, Federal Writers' Project papers, Southern Historical Collection, The Wilson Library, University of North Carolina at Chapel Hill.

Register, Heather. “Isaac Scott Hathaway (1872-1967).” Encyclopedia of Arkansas.

Zinkula, Jacob. “South Bend Artist Busts His Way into Football Hall of Fame.” South Bend Tribune. 13 July 2015.

Debra A. Reid is Curator of Agriculture and the Environment at The Henry Ford, and sends appreciation to Saige Jedele and Sophia Kloc for comments that strengthened this post.

teachers and teaching, education, making, George Washington Carver, Rosa Parks, by Debra A. Reid, art, African American history

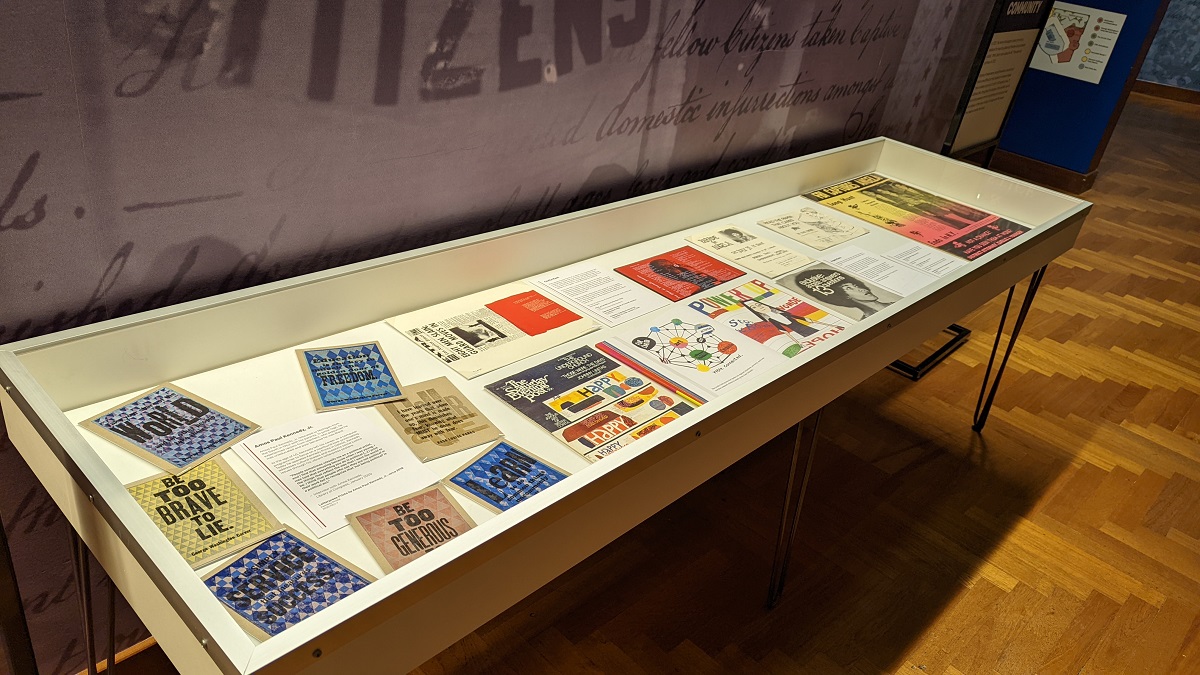

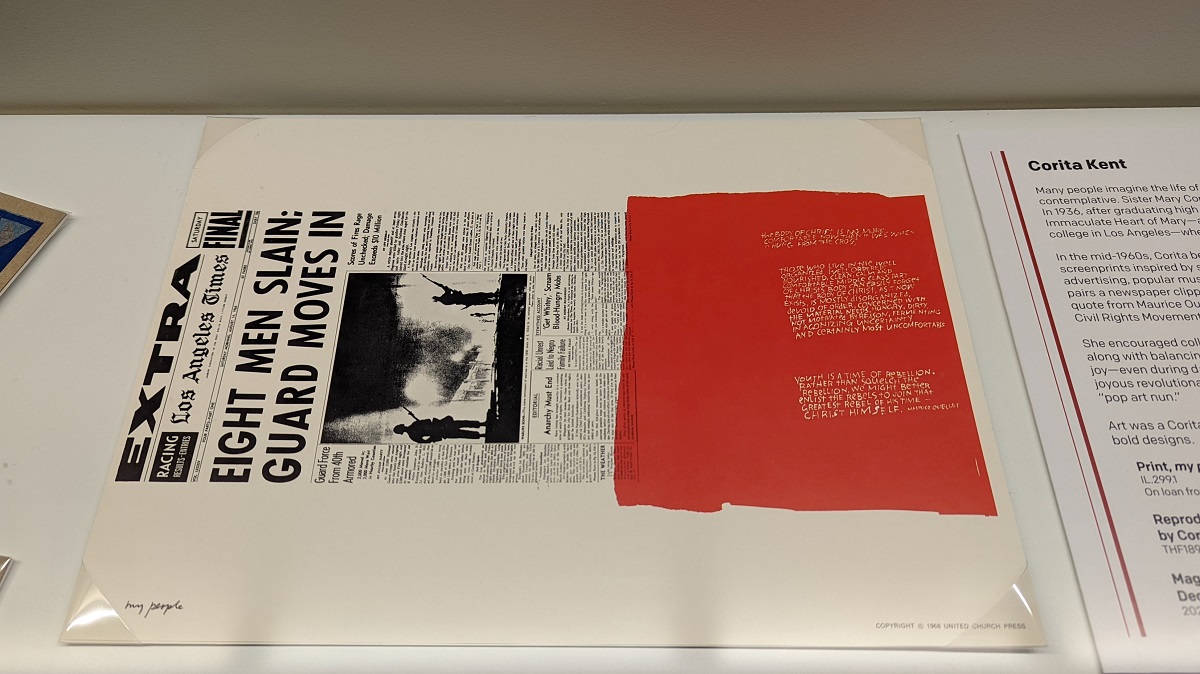

Quiet & Loud Protest

Photo by Curatorial Staff of The Henry Ford

When you think of the word “protest,” what does it mean to you?

- Marching at a rally with a sign?

- Participating in a “walk out” at school?

- Boycotting companies?

- Wearing a shirt or hat with a message?

- Correcting people on their biases?

- Donating money to organizations?

- Civil disobedience?

A new temporary exhibit now on view in Henry Ford Museum of American Innovation, Quiet & Loud Protest, explores this question by demonstrating the ways that protest can be both loud and quiet. Throughout history, people have found different ways to advocate for change, whether marching in the streets or finding quieter ways to be an ally. Both are valuable in drawing attention to injustices. The exhibit draws together a small selection of recent acquisitions that showcase how artist-activists have used graphics to demand change and organize communities. The content of the exhibition is replicated in this post (with slightly expanded descriptions) for those unable to see it in person.

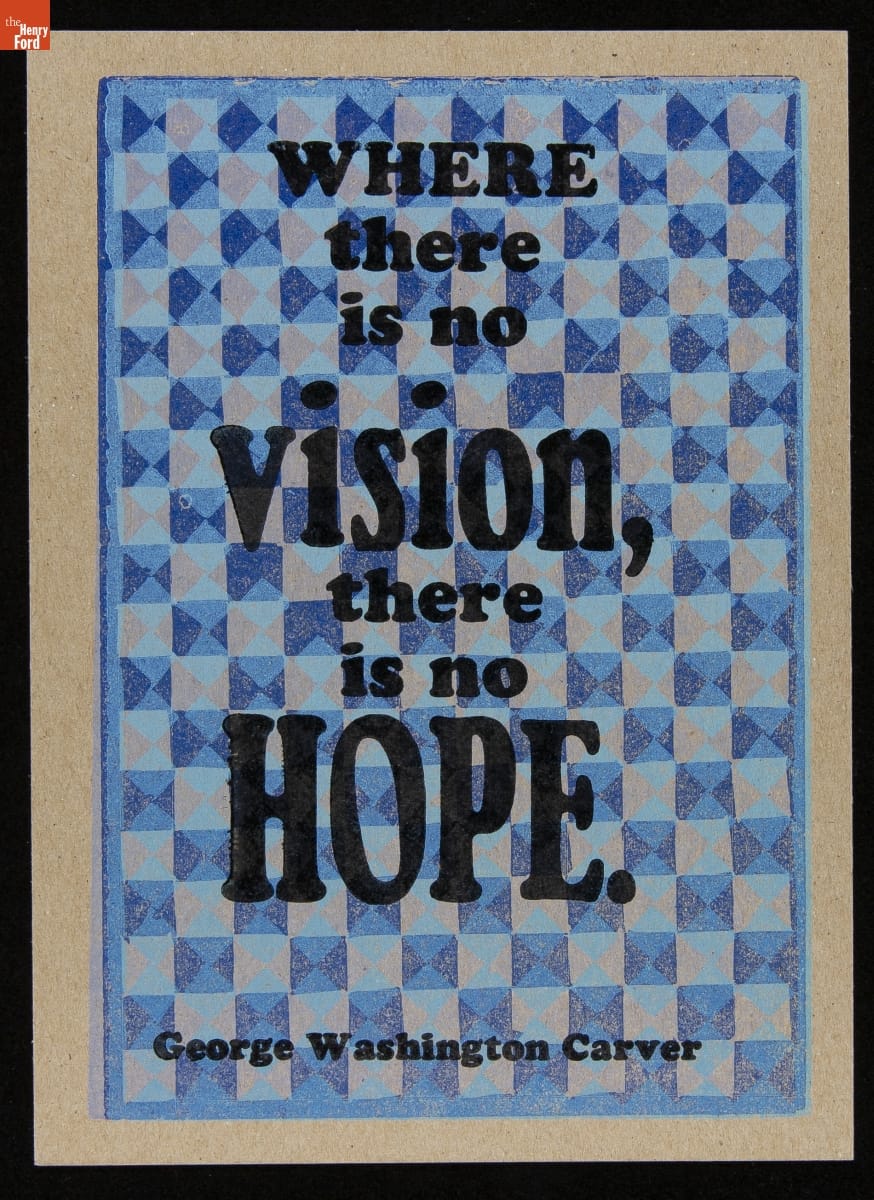

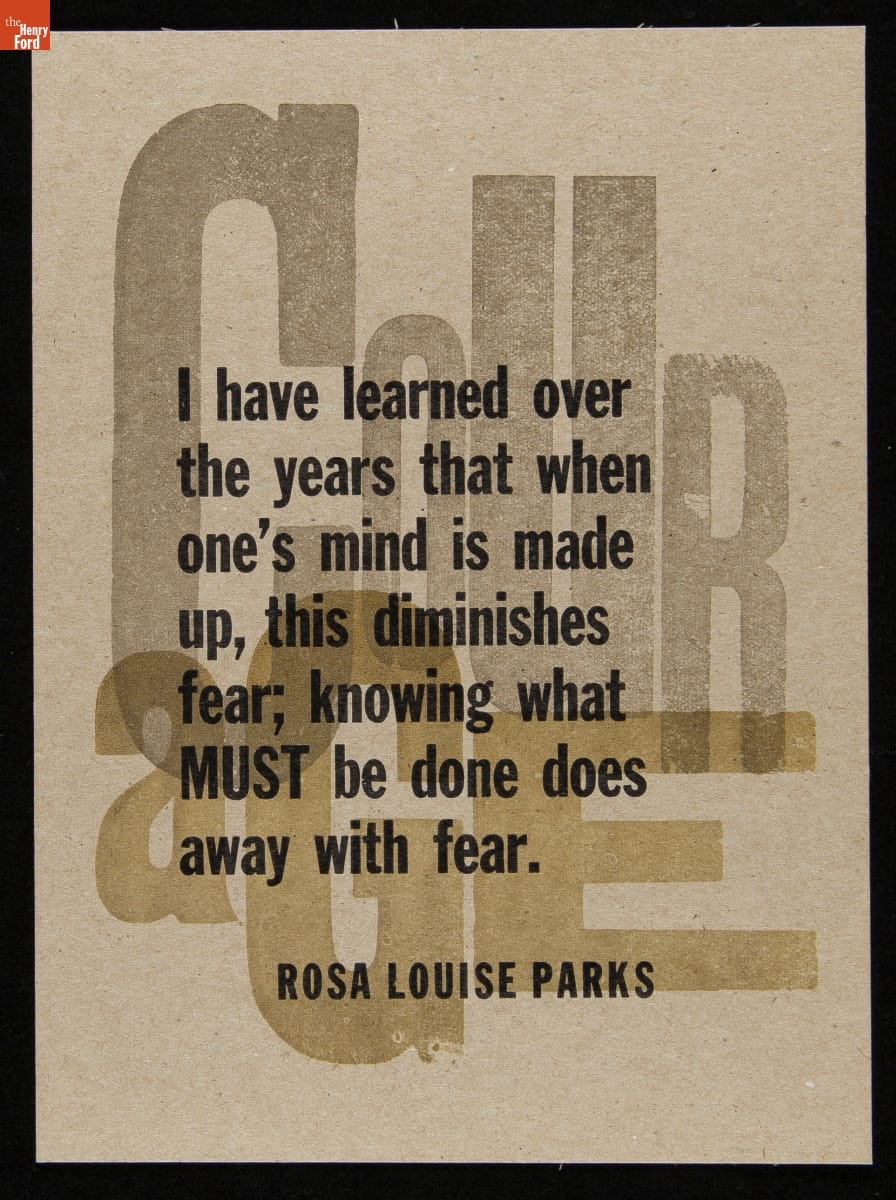

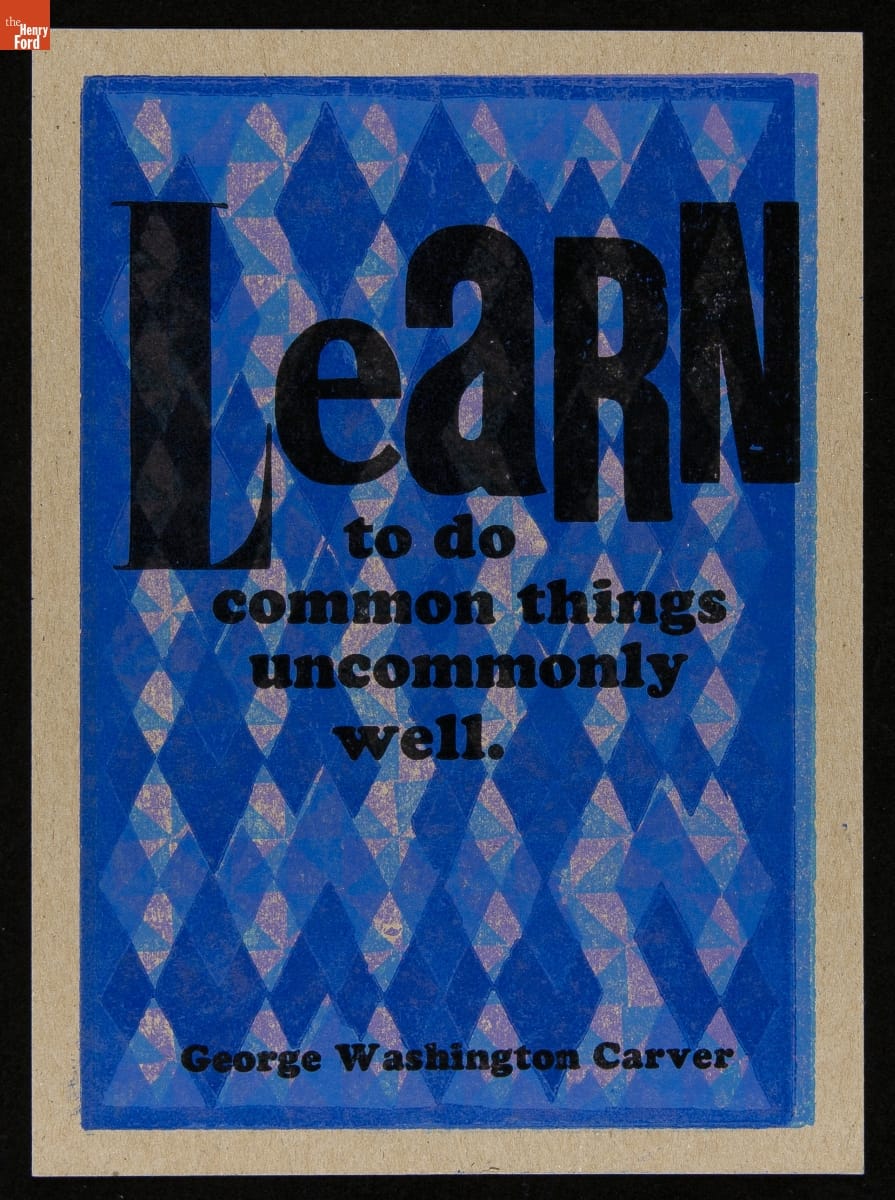

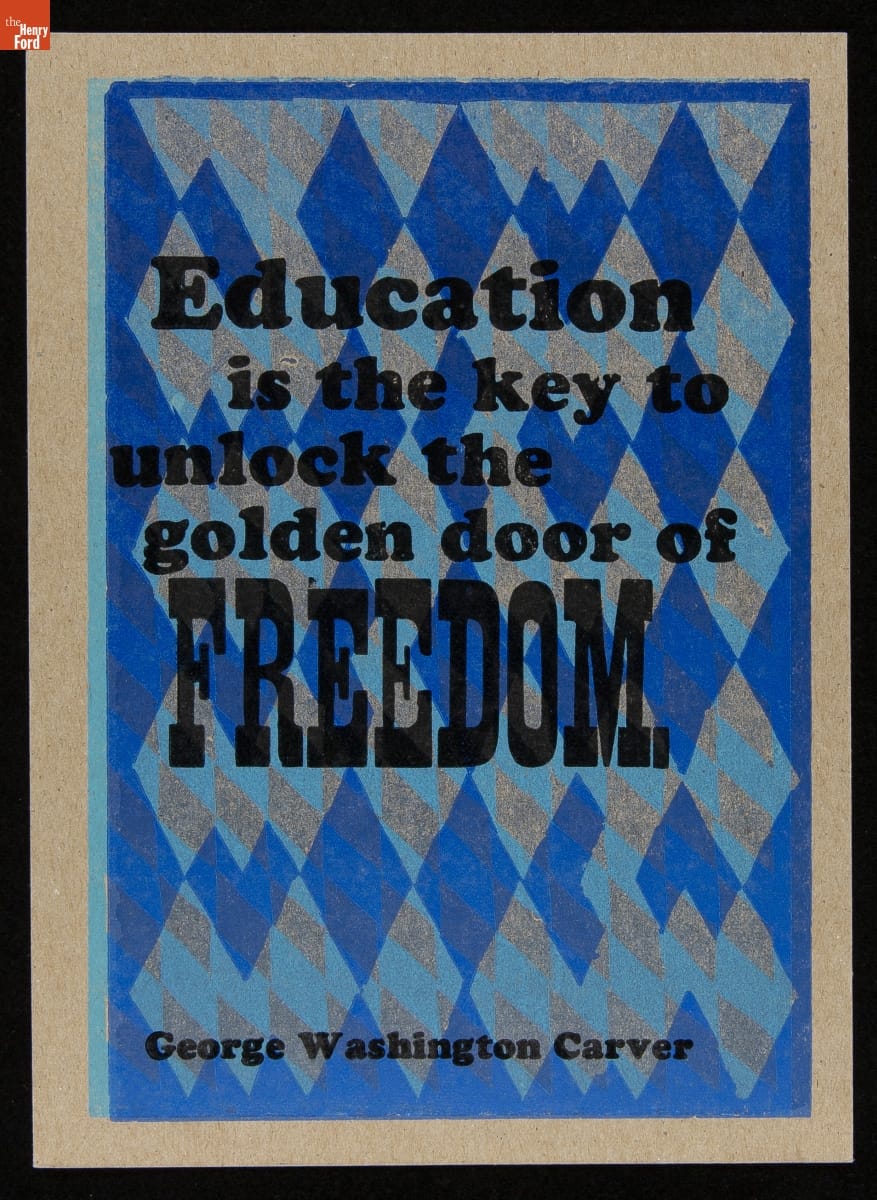

Amos Paul Kennedy, Jr.

Amos Paul Kennedy Jr. has generously donated several prints to the collections of The Henry Ford. These examples feature quotes attributed to George Washington Carver and Rosa Parks—two advocates for change who are prominent in our collections. / THF626953 (top), THF626939 (bottom)

These letterpress prints are by Amos Paul Kennedy, Jr., who relocated to Michigan from the South in 1963 with his parents. In junior high, he experienced racism from teachers who presumed he was uneducated and poor because he was Black.

At the age of 40, Kennedy visited Colonial Williamsburg while on vacation with his family and was so enamored with the letterpress and bookbinding demonstrations being given by historical reenactors that he went home and began to take classes at a community print shop. His love for the medium grew to the point where he made the decision to leave his career as a corporate computer programmer at AT&T so that he could focus on printmaking full time.

Letterpress prints by Amos Paul Kennedy, Jr./ THF626947 (top), THF626949 (bottom)

He went on to earn an MFA in Fine Arts and taught in university art programs. When Kennedy left academia, he adopted the historical role of an iterant printer, travelling through the American South to different print shops, learning about print media and developing his style over the course of many years. Kennedy sometimes describes himself as a “humble Negro printer” and wears bib overalls with a pink dress shirt. By doing this, Kennedy confronts people with their biases, causing them to question race, language use, and class. In 2013, Kennedy moved to Detroit, where he operates Kennedy Prints today.

Letterpress prints by Amos Paul Kennedy, Jr. / THF626943 (top), THF626941 (bottom)

Kennedy is known for his prolific output of vibrant letterpress prints that address cultural biases and social justice issues. Many of his prints feature quotes by Black civil rights activists and abolitionists, scientists and innovators, and literary figures, as well as traditional African proverbs. In an interview with the Library of Congress in January 2020, Kennedy said:

“People sometimes classify me as a political artist, and I find that amusing because when I was young, I was told that everything you do is political […] I print the things that reflect the way that I want the world to be. I think that people who say they are not political in their work fail to recognize that ‘not being political’ is a political act.”

Kennedy refuses to call himself an artist and sells his work at affordable prices to make it more accessible. Thanks to the power of the multiple, Kennedy can use printmaking to spread messages of hope widely—to reflect exactly the type of world that he wants to live in.

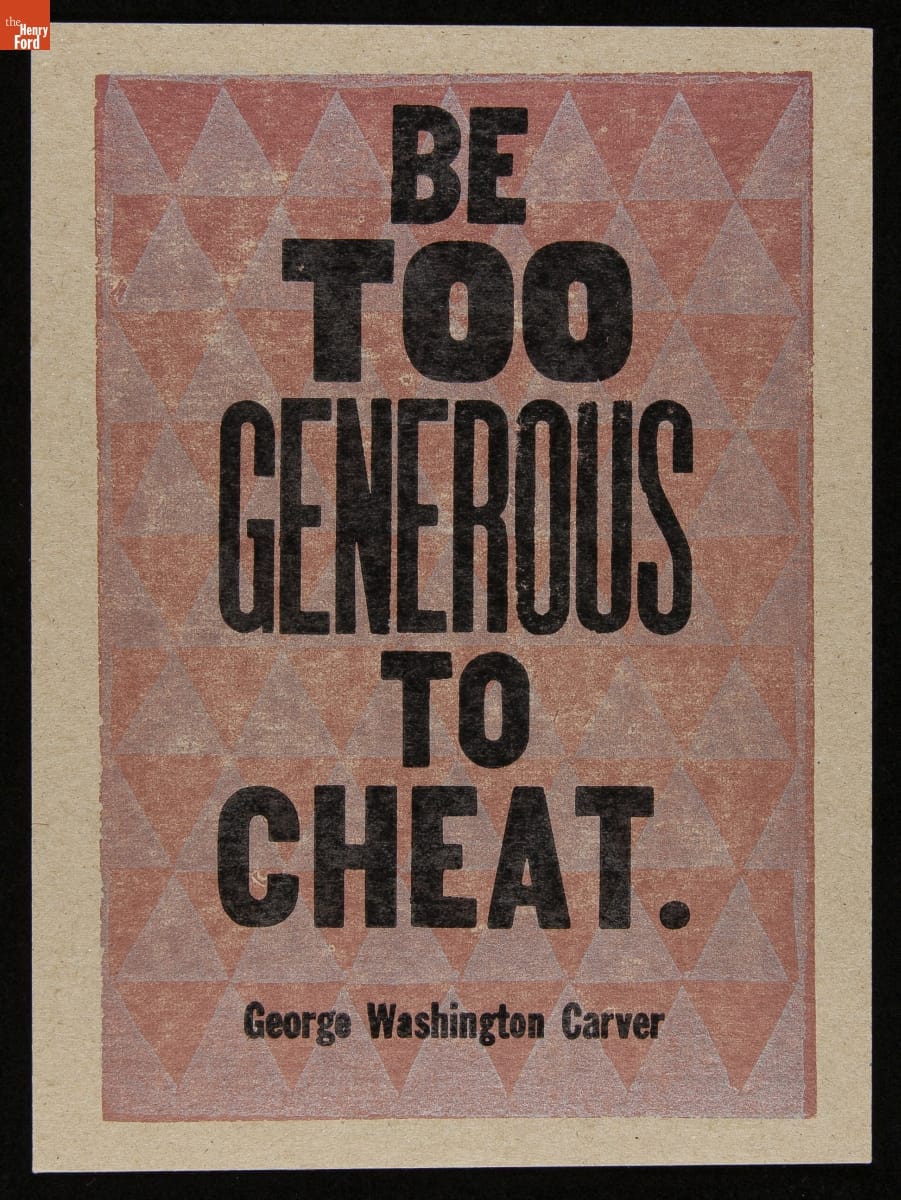

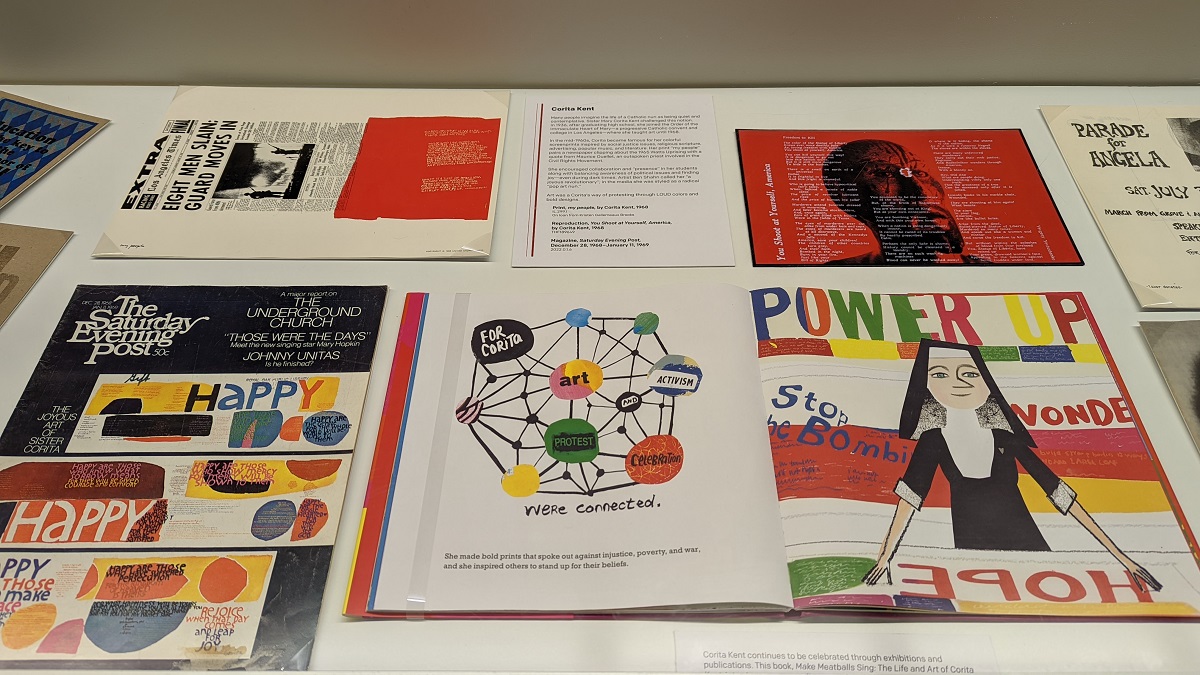

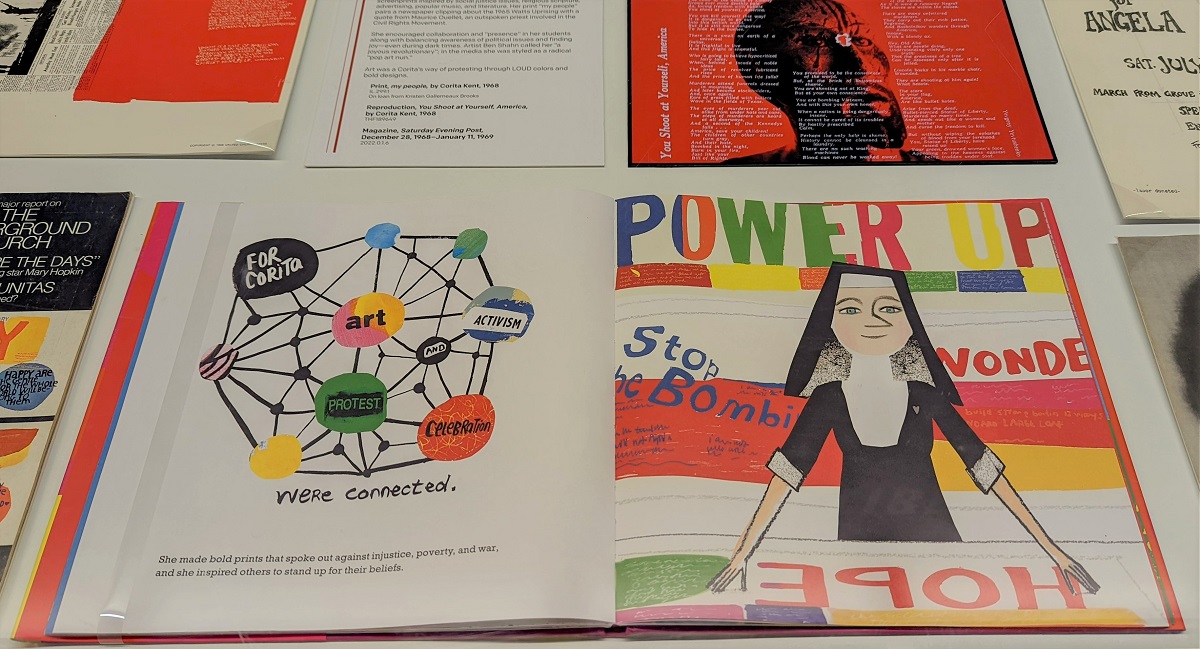

Corita Kent

Photo by Kristen Gallerneaux

Many people imagine the life of a Catholic nun as quiet and contemplative. Sister Mary Corita Kent challenged this notion. In 1936, after graduating high school, she joined the Order of the Immaculate Heart of Mary—a progressive Catholic convent and college in Los Angeles—where she taught art until 1968.

In the mid-1960s, Corita became famous for her colorful screenprints inspired by social justice issues, religious scripture, advertising, popular music, and literature. Her most celebrated prints are text-heavy and vibrant, layering blocks of bright color and DayGlo ink with high-key photographic imagery and words that twist around the page.

Detail of Quiet & Loud Protest exhibit with Corita Kent’s “my people” print. / Photo by Kristen Gallerneaux

Her print “my people” pairs a newspaper clipping about the 1965 Watts Uprising with a quote from Maurice Ouellet, an outspoken priest involved in the Civil Rights Movement in Selma, Alabama. Part of the quote Corita included reads: “Youth is a time of rebellion. Rather than squelch the rebellion, we might better enlist the rebels to join that greatest rebel of his time—Christ himself.” And in an oral history, Corita herself said: “I feel that the time for physically tearing things down is over. It’s over because as we stand and listen, we can hear it crumbling from within.”

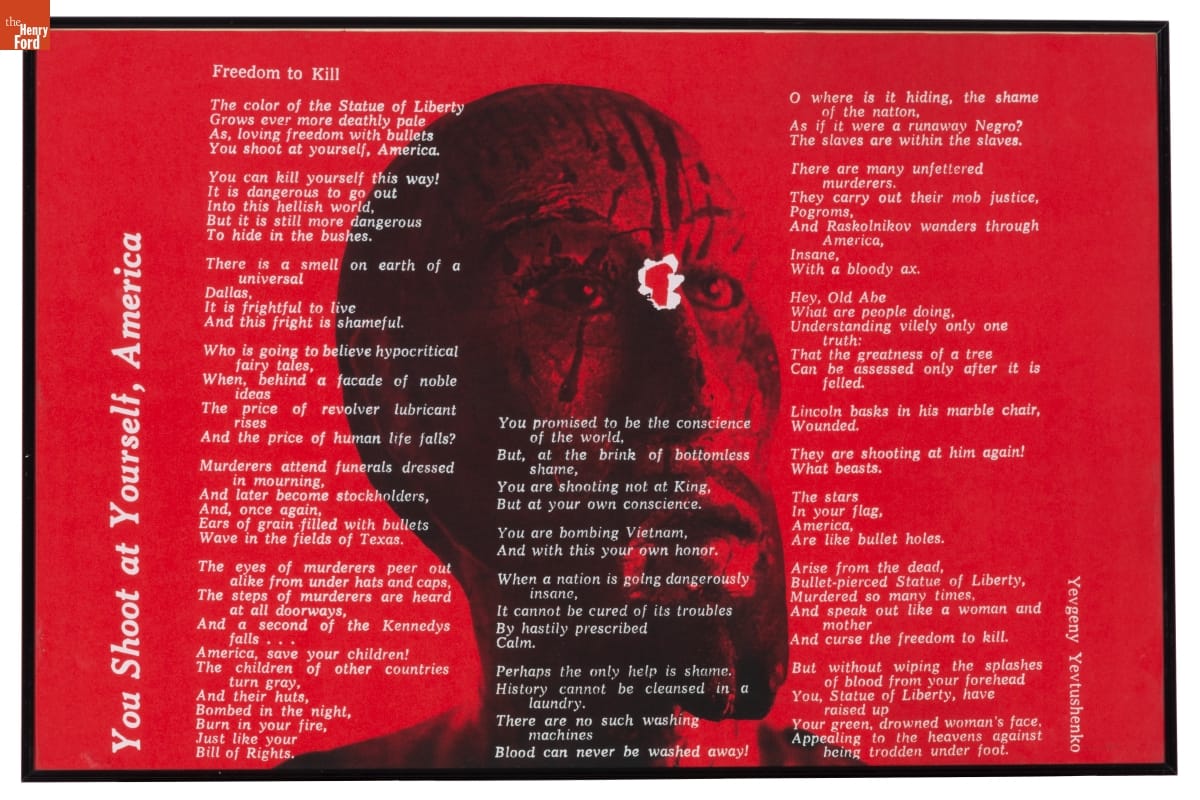

Corita Kent’s print “You Shoot at Yourself, America” was created in response to the 1968 assassination of Robert F. Kennedy. It features a poem by Yevgeny Aleksandrovich. / THF189649

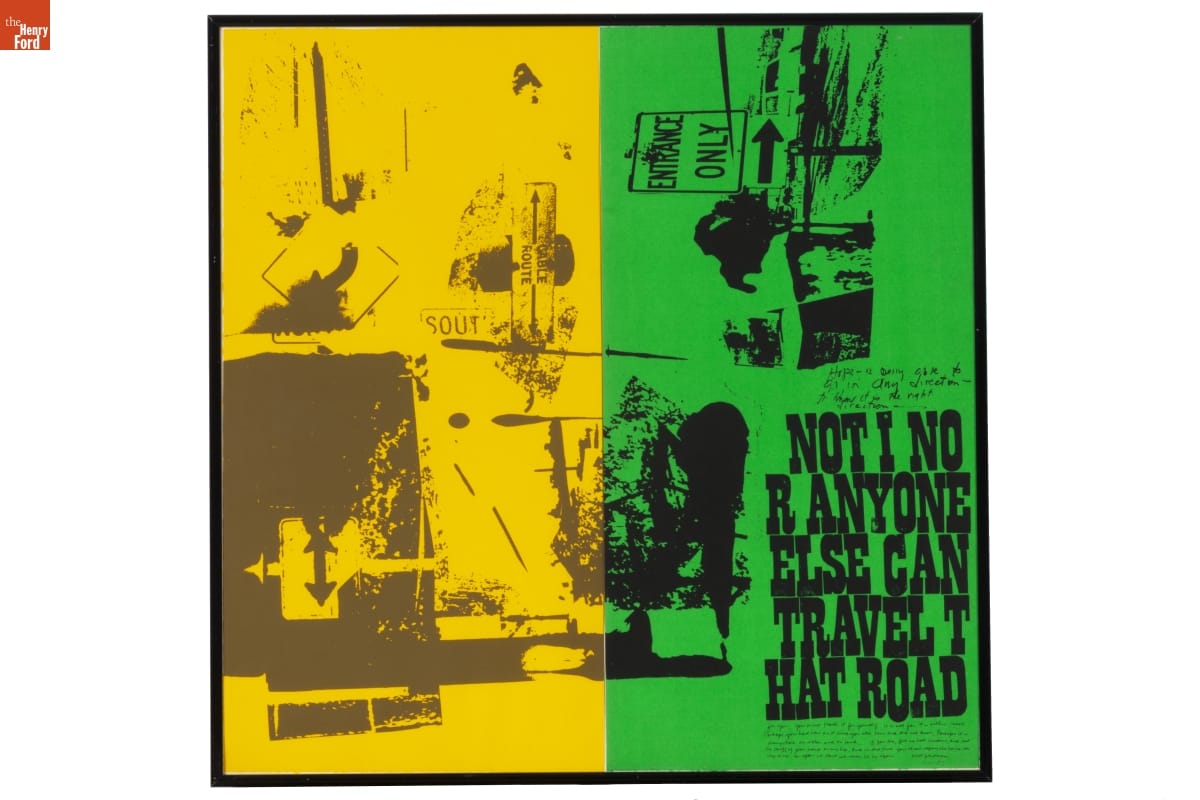

Corita Kent’s print “Road Signs (Part 1 & 2)” features text excerpted from Walt Whitman’s Leaves of Grass. / THF189650

Corita encouraged collaboration and “presence” among her students and encouraged them to balance awareness of political issues with finding joyful moments—even during dark times. Many important designers and creative thinkers visited her classroom, including Buckminster Fuller and Charles and Ray Eames. Artist Ben Shahn once called her “a joyous revolutionary” and in the media she was styled as a radical “pop art nun.”

Art was a Corita’s way of protesting through LOUD colors and bold designs.

During the height of Corita’s fame, the Catholic Church was reassessing many of its traditions, striving for unity and modernization under Vatican II. And yet not everyone agreed. In 1967, the Los Angeles archdiocese and Archbishop James McIntyre claimed the Immaculate Heart Community’s (IHC’s) approach to education was “communist” and referred to Corita’s work as being “blasphemous.” When the IHC sisters were ordered to end the liberating “renewal innovations” they had come to enjoy—or be asked to leave their teaching posts—many asked to be released from their vows and left in protest.

Corita’s decision to leave the order came a little sooner. In 1968, exhausted from an intense schedule and censorship from the church, Corita took a sabbatical. At the end of her time away, she left the Order and moved to Boston. There, she continued to receive commissions and to create art such as painting the Boston Gas Company’s tanks and designing the iconic “Love” postage stamp.

Corita Kent continues to be celebrated through exhibitions and publications. This book, Make Meatballs Sing: The Life and Art of Corita Kent, introduces young audiences to her story. / Photo by Kristen Gallerneaux

Angela Davis

Angela Davis is an activist, educator, and scholar who was a member of the Communist Party USA and the Black Panther Party. In 1970, Davis was placed on the FBI’s “Most Wanted” list. Guns registered to her name were used in a fatal attempt to free the Soledad Brothers during a courtroom trial. Davis was not present at the event. She fled police, fearing unfair treatment. After her capture, she spent 18 months in prison until being cleared of charges.

For some people, Davis is a controversial figure who believed in non-peaceful protest. To others, she is an inspiration as an outspoken supporter of women’s and civil rights, prison reform, and socialism. In recent years, she came out as lesbian and advocates for LGBTQ+ rights as well as those of Palestinian people.

The following artifacts relate to the impact of Angela Davis’s activism, past and present..jpg?sfvrsn=cc0a3601_2)

Vermont S. Galloway—a WWII veteran—made this “FBI Captures Angela” screenprint at Westside Press to advocate for Davis’s freedom. Galloway was fatally shot by the Los Angeles Police Department in 1972. / THF277084

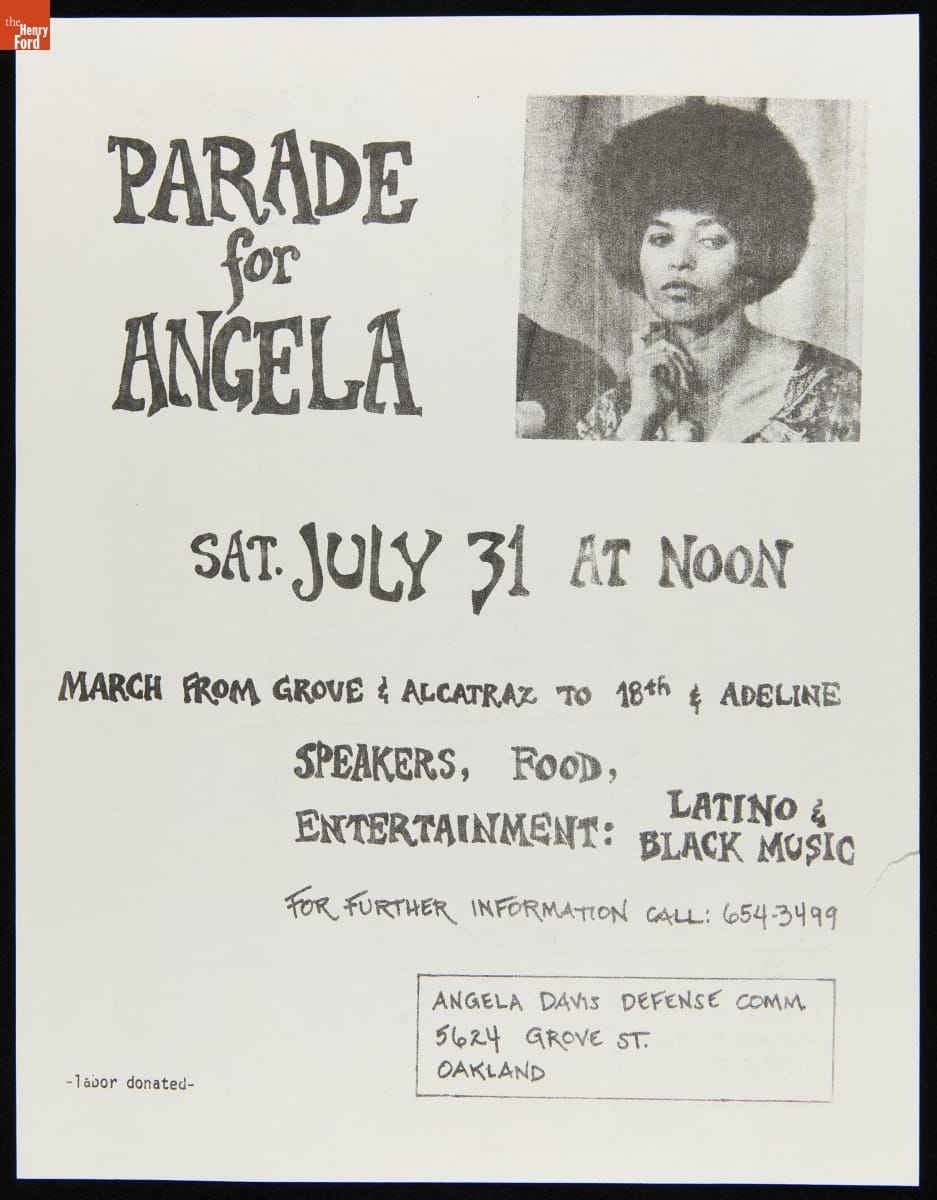

A parade flier documents the international “Free Angela” movement. The reverse side shows the planned route through Oakland, California. / THF627614

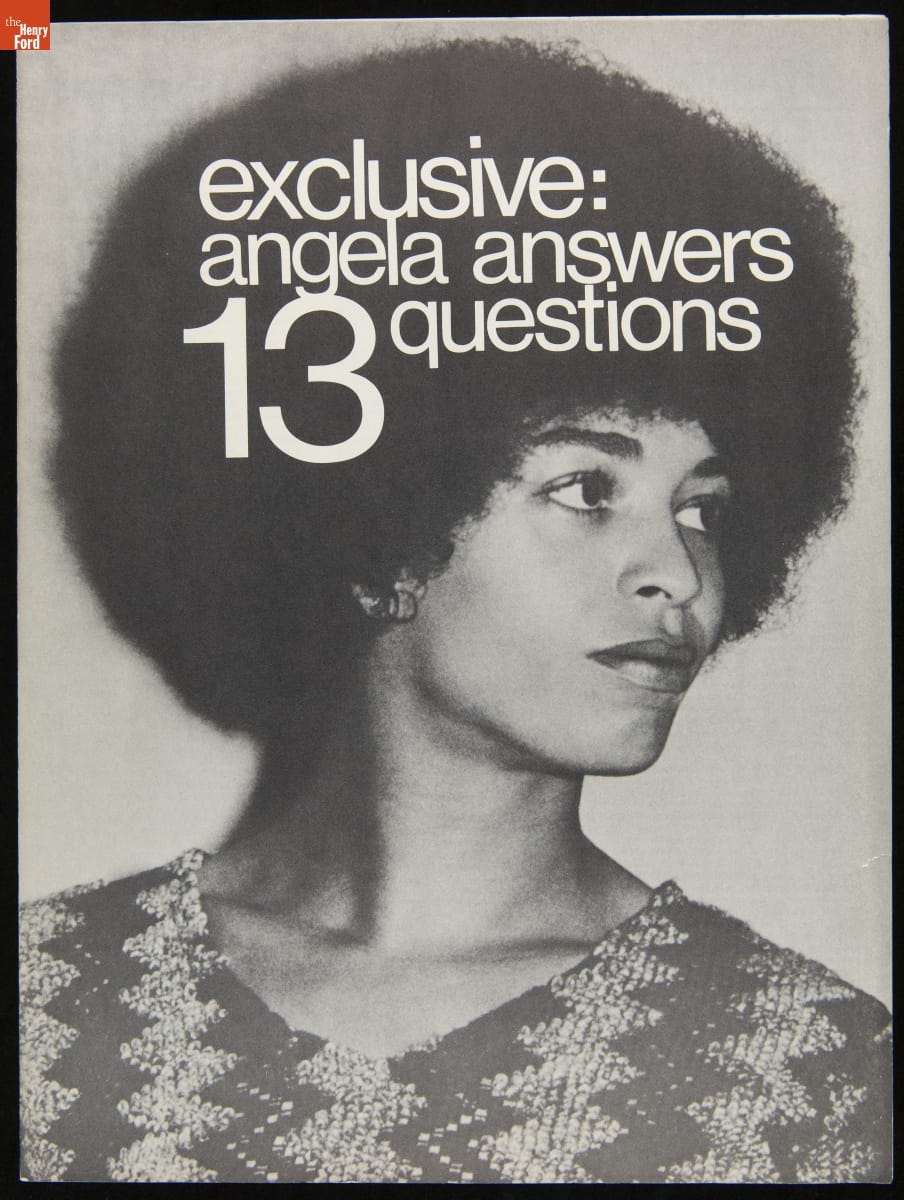

“13 Questions…” was the first interview with Davis while she was incarcerated. Her discussion with Joe Walker covers topics such as the surveillance of Black people, legal corruption, solidarity, and dismal prison conditions. / THF627594

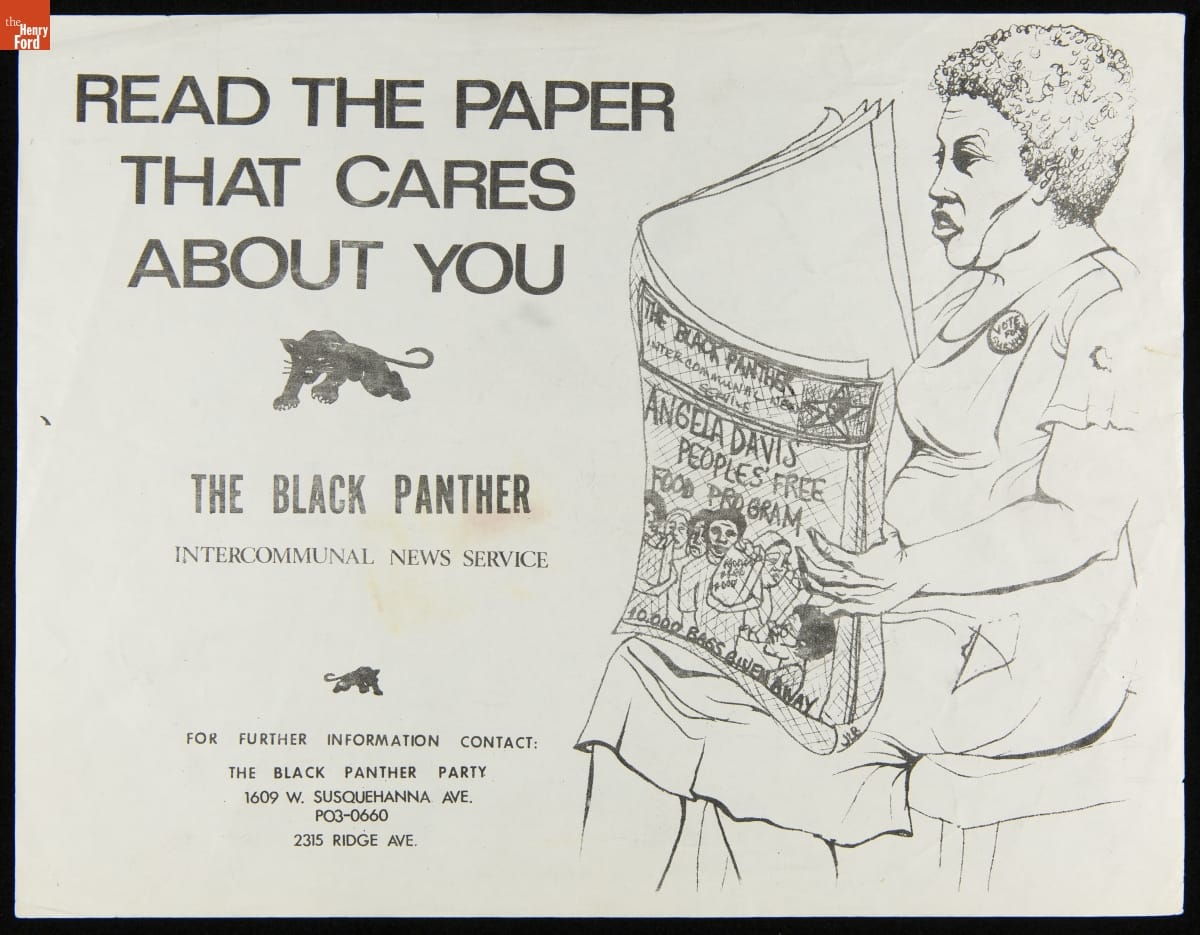

An illustration by Akinsanya Cambon advertises the Black Panther Party’s newspaper and the “Free Breakfast for Children Program,” using Davis’s name. / THF627598.jpg?sfvrsn=c40a3601_2)

Davis appears in a poster by Tongva artist Mer Young for the Amplifier Foundation. This poster shows the continued impact of Davis’s legacy and was created to encourage Black and Indigenous voting in the 2020 election. / THF626361

Listening to Our Community

In 2021, The Henry Ford began to seek community feedback for ways to update and improve our permanent exhibit With Liberty and Justice for All. This work is continuing in 2022.

Stories of movements, social innovators, and political history are difficult to fully capture in museum labels. There is always too much to tell in 100 words or less. To address this, throughout the display of this exhibit, we will be inviting several community partners to contribute their own labels, in their own voices, to foreground the issues they believe matter the most.

By the Curatorial Staff of The Henry Ford. Quiet & Loud Protest is on view in Henry Ford Museum of American Innovation until March 31, 2022.

Civil Rights, art, making, women's history, African American history, Henry Ford Museum, printing

"The Busy World" Automaton

“The Busy World” automaton, 1830–1850. / THF187282

“The Busy World” automaton, 1830–1850. / THF187282

I was about nine years old when I first saw it. My family and I were visiting Henry Ford Museum when I spotted “The Busy World”—an intriguingly detailed and well-populated automaton displayed along the museum’s Street of Shops displays. I was entranced. “The Busy World” would remain among my most vivid memories of this visit. Little did I know that many years later I would be involved in further research on this fascinating, whimsical object.

An automaton is a non-electric moving machine that performs a predetermined set of operations. With approximately 300 moving figures, “The Busy World” automaton is a kind of mechanized diorama with six individual platforms powered by gears, belts, and pulleys. When the automaton is cranked, the figures go into motion.

1869 Beers Atlas map of Delaware County, New York. / Image courtesy of the Delaware County Historical Association

Delaware County in upstate New York—where “The Busy World” was likely built and spent much of its working life—was a place of farms and small villages during the 19th century. The wagon's lively, hand-cranked animations would have had tremendous popular appeal for adults and children alike at country fairs and small exhibitions.

“The Busy World” features six different animated scenes. Click on the links under the scenes below to see those images in our Digital Collections, where you can zoom in on the details.

Left section of “The Busy World.” / THF187276, detail

At the upper left, figures perform activities of everyday life, including rocking a baby, getting warm by the stove, chopping food, spinning thread, churning butter, and sharpening a tool.

In the scene at lower left, people attend a ballroom dance while musicians play. At the left of the dance scene are caricatured figures of African Americans. This “Busy World” scene reflects not only the activities of the time period but also the racism of the era.

Center section of “The Busy World.” / THF187277, detail

The scene at upper center shows men making rakes and grain cradles in a factory. Delaware County had at least one rake factory. During the early 19th century, New York was the grain belt of the United States. Wooden rakes were essential tools on farms.

Biblical scene from “The Busy World.” / THF125152

At lower center, a small revolving “stage” features eight Biblical stories.

Right section of “The Busy World.” / THF187278, detail

At upper right, soldiers in uniform promenade with ladies.

The scene at lower right features a regiment of soldiers parading in formation to the “sounds” of a military band.

“The Busy World” Comes to The Henry Ford

“The Busy World” came to The Henry Ford in 1963. The museum purchased the automaton from Janos and Mary Williams of Stone Henge Antiques in Sidney, New York. Where was it before that? Well, we know part of the story.

The Williamses had acquired “The Busy World” from a man named David Smith. About 1944, David Smith (1923–2002) saw an ad in a Walton, New York, newspaper offering “The Busy World” for sale: “Will sell cheap, if sold this week, ONE busy world.” Twenty-one-year-old Smith, who lived in nearby Delhi, New York, couldn’t resist. He drove the 17 miles to Walton to take a look. Amazed and delighted with what he saw, Smith purchased the automaton with his own savings, over the objections of his family. For the first seven years that he owned it, Smith stored “The Busy World” in his family’s barn in Delhi. David Smith got it to run, at least sporadically.

It wasn’t until September 1951 that “The Busy World” once again had a public showing. David Smith’s mother had offered the family barn to the Delaware County Horticultural Society as a place to hold their annual Harvest Show. “The Busy World” delighted local people who came to see the choice vegetables, flower arrangements, and potted plants on display there. Some of those attending recalled 30 or so years before when the automaton had appeared at county fairs in the area.

Next stop for “The Busy World”? David Smith opened an antique store in his hometown of Delhi, where he displayed the automaton. The name of the shop? Busy World Antiques.

David Hoy Takes “The Busy World” on the Road

“The Busy World” platforms exhibited in an unidentified location, probably in the early 20th century. An advertising banner hangs above—one that may date from the late 1860s or 1870s. / THF125153

David Smith had purchased “The Busy World” from Elizabeth Hoy Thomas (1874–1949). She was the daughter of David Hoy (1848–1934), the man who exhibited “The Busy World” at local fairs and carnivals at the turn of the 20th century. According to David Smith, Elizabeth Hoy Thomas told him that “The Busy World” took 17 years to build and was constructed by two men—one carved the figures and the other assembled the machinery.

David Hoy’s 1934 obituary recalled Hoy’s yearly exhibitions of the “World at Work” or “Busy World” automaton at local fairs. Hoy is said to have charged five or ten cents to see “The Busy World” in motion. David Hoy exhibited “The Busy World” regularly until the mid-1910s, and then for one last time at the Walton Armory in late 1933. After his death the following year, the automaton remained in a shed at Hoy’s daughter’s home in Walton. She placed the newspaper ad offering it for sale about ten years later—the ad seen by young David Smith.

These tickets were found in the wagon. They appear to date between 1890 and 1910 and may have been used as “The Busy World” made the rounds of country fairs and carnivals in the latter portion of its career. In Latin, androides means “resembling a man,” and was used during the 19th century to describe an automaton resembling a human being in form and movement. / THF187284

Looking for Answers

We had many unanswered questions about “The Busy World.”

Curatorial research volunteer Gil Gallagher worked many months to dig up some answers, trolling census records and countless newspapers online. Ray LaFever, archivist at the Delaware County Historical Association, lent his research skills and familiarity with Delaware County history to the quest. Here’s what their research turned up.

When they sold it, antique dealers Janos and Mary Williams mistakenly told The Henry Ford that “The Busy World” had been built by David Hoy. And that he “began it in 1830 and took 17 years to make it.” As we found, not quite so—at least the part about David Hoy. Our research showed that Hoy didn’t build it. He acquired the automaton sometime later.

The general dates given for the construction of “The Busy World” appear to be correct. The figures and objects shown in the scenes reflect the era of the 1830s—including the women’s fashions, the Franklin heating stove (upper left section), and the serpent, a musical instrument (lower right section).

Therefore, David Hoy couldn’t have made it. Hoy was born in Bovina in Delaware County—but not until 1848. His family moved to Iowa when he was ten. By the mid-1870s, Hoy returned to Delaware County, where he married and had three children. During the following decades, he would make his living as a farmer, carpenter, stone mason, and teamster. Hoy must have acquired “The Busy World” sometime after he returned to Delaware County as an adult. (A 1905 newspaper article noted that the automaton was “now run by a Walton man, David Hoy,” so someone else probably toured it before Hoy.) The wagon that now carries “The Busy World” was a later addition—one likely added by Hoy, who mounted the automaton figures and machinery in the wagon to make it easier to transport. (One newspaper article mentions that the automaton platforms were originally displayed in a tent.)

So, we found some answers—yet questions remain.

Was the automaton originally called “The Busy World”? It seems that it may have acquired that title in the late-19th or early-20th century, since it is not mentioned on the banner or tickets.

And, despite all our efforts, the identities of the original makers of “The Busy World”—whoever these talented individuals were—remain a mystery for now.

Jeanine Head Miller is Curator of Domestic Life at The Henry Ford. Many thanks to Sophia Kloc, Office Administrator for Historical Resources at The Henry Ford, for editorial preparation assistance with this post.

20th century, New York, 19th century, research, popular culture, making, by Jeanine Head Miller, #Behind The Scenes @ The Henry Ford

Touch-Free Mathematica

The Mathematica exhibit in Henry Ford Museum of American Innovation. / Photo by KMS Photography

When Henry Ford Museum of American Innovation reopened in July 2020 after months of shutdown because of COVID-19 restrictions, museumgoers were excited to be back on the floor. Many of them were super excited to get back to one of their favorite exhibitions, Mathematica—a favorite because it’s so hands-on.

And therein lay the problem, said Jake Hildebrandt, historic operating machinery specialist at The Henry Ford. As COVID-19 spread, the hands-on interactivity of Mathematica caused it to remain closed. Mixing a little bit of ingenuity, technology, and lots of problem-solving skills, Hildebrandt, along with master craftsman Brian McLean, ensured the exhibition could remain interactive yet hands-free and open to the public.

Mathematica’s Moebius Band was modified by staff from The Henry Ford to start via a hand wave. / Photo by Jillian Ferraiuolo

The push-start buttons on the Moebius Band and Celestial Mechanics installations, for example, are now initiated with a wave of the hand—no touch necessary. And the 27-button panel of the Multiplication Machine has been covered with Plexiglas for safety and new software installed so random math problems run on the cube throughout the day for visitor education and enjoyment.

A newly-added note under the Plexiglas installed on the Multiplication Machine in Mathematica reads “This machine has been temporarily modified for a touch-free experience / It now multiplies random numbers on its own.” The styling of the note is intended to match the original design of Charles and Ray Eames. / Photo by Jillian Ferraiuolo

“Projects like these, DIY challenges that have high criteria, limited time and budget, are my favorite kinds of projects,” said Hildebrandt. All the alterations to Mathematica are easily reversible, he added, and when you head to the museum to see them, you’ll notice the respectful attention given to the exhibition’s classic Eames styling.

This post was adapted from an article first published in the January–May 2021 issue of The Henry Ford Magazine.

#Behind The Scenes @ The Henry Ford, The Henry Ford Magazine, making, Henry Ford Museum, healthcare, design, COVID 19 impact, collections care

New Acquisition: The Lillian F. Schwartz Collection

Lillian Schwartz working with a joystick interface at Bell Laboratories. Photo by Gerard Holzmann. / THF149836

In early 2021, The Henry Ford secured a very exciting donation: the Lillian F. Schwartz & Laurens R. Schwartz Collection. This material—which came to us through the generosity of the Schwartz family—spans from early childhood to late career and includes thousands of objects that document Lillian Schwartz’s expansive and inquisitive mindset: films and videos, two-dimensional artwork and sculptures, personal papers, computer hardware, and film editing equipment.

The late 1960s in California were a heady time in computing history. Massively influential technologies that are now part of our everyday lives were being invented or improved upon: home computers, the graphical user interface, the computer mouse, and ARPAnet. Meanwhile, on the opposite side of the country in New Jersey, the artist Lillian Schwartz was about to walk through the doors of revered technology incubator Bell Telephone Laboratories. Schwartz had recently met Bell Labs perceptual researcher Leon Harmon at the opening for the Museum of Modern Art’s group exhibition “The Machine at the End of the Mechanical Age.” Harmon and Schwartz each had work in the exhibit, and the pair struck up a conversation that led to an invitation for Lillian to visit the Labs.

A poster for the Museum of Modern Art exhibit that led to Schwartz and Leon Harmon’s friendship (top) and a portrait of Harmon painted by Schwartz (bottom). / THF188555, THF188581

This fateful meeting led to Schwartz’s decades-long tenure as a “resident visitor” at Bell Labs, where she was exposed to powerful equipment like the IBM 7090 mainframe computer and Stromberg Carlson SC-4020 microfilm plotter. Allowing artists access to this high-end research and development facility upended conventions, creating an environment that was fruitful for cross-disciplinary collaboration between the sciences, humanities, and arts. From 1968 until the early 2000s, Schwartz paid regular visits to the Labs, where she developed groundbreaking computer films and videos, and an impressive array of multimedia artworks.

Continue Reading

women's history, making, technology, computers, The Henry Ford Magazine, by Kristen Gallerneaux, art

Two Makers from Greenfield Village’s Liberty Craftworks Community

In Greenfield Village’s Liberty Craftworks district, skilled artisans practice authentic period crafts and trades with techniques that are, in some cases, centuries old. Here, we ask two of our talented Liberty Craftworks staff, both of whom have worked at The Henry Ford for more than a decade, why they like to make things with their hands.

Joshua Wojick: Crafts and Trades Program Manager, The Henry Ford

Mediums: Glassblowing, Mixed-Media Sculpture

Years at The Henry Ford: 16

A student at the College for Creative Studies in Detroit in the 1990s, Joshua was interested in industrial design, thinking about going into the automotive industry. Then he decided to take a glassblowing class. “I was hooked instantly,” he said. “It spawned my love of craft, of materiality and the honesty of material, of making.”

He changed majors and has never looked back.

Photo courtesy of Joshua Wojick.

At The Henry Ford, he appreciates the boutique expression of production afforded by the Liberty Craftworks community. “It’s a tough world getting into strict production craftmaking. It takes specific focus to make the same things over and over again. When you get to see it in a smaller setting—where artists are working, controlling, understanding the material moment by moment—it draws you in. That is what’s unique to The Henry Ford.”

He is also grateful for the guests he can interact with in Greenfield Village during daily demonstrations. “I have always looked at this interaction as the driving force of the Craftworks community. As artists, we have the opportunity to meet unique people and hear their life journeys, which can help you think differently throughout the day.”

Photo courtesy of Joshua Wojick.

Joshua never stops making things, creating award-winning art inside as well as outside of The Henry Ford. See more of his work at joshuawojick.com.

Melinda Mercer: Pottery Shop Lead, The Henry Ford

Mediums: Wood-Fired Porcelain, Salt-Glazed Stoneware, Patchwork Quilting

art, making, Greenfield Village, by Jennifer LaForce, #Behind The Scenes @ The Henry Ford

Years at The Henry Ford: 17

Melinda has loved pottery for decades, first enthralled by its artistry as she watched her high school art teacher throw clay on his potter’s wheel and next while earning her fine arts degree. Then, as an intern at The Henry Ford a few years later, she had the privilege of tutelage under Bryan VanBenschoten, a lead potter in the Pottery Shop for nearly 40 years.

Photo courtesy of Melinda Mercer.

One of her favorite things in the world is wood-firing in the shop’s wood kiln. She calls it a labor of love, a rewarding team effort that the potters do only once or twice a year. “It takes us months to prepare,” she said. “And once we start putting wood in the kiln, we have to stay with the kiln for 30 hours, loading more wood every couple minutes. There’s no electricity, no technology. Just us, the wood, and the fire.”

Melinda loves the individuality the wood-firing process affords her. “We really get to stretch artistically,” she said. More importantly, she can share the experience with guests at The Henry Ford. “The wood-firing is a magical event—when visitors see the flames shooting from the top of the kiln, their reactions are quite remarkable.”

Continue Reading

Creatives of Clay and Wood

Michele Michael, who discovered ceramics in 2010, likes to create utilitarian objects for the tabletop, loving the feel and meditative properties of the clay in her hands. She is always experimenting with new techniques and processes to make her housewares, like painting freehand with indigo and cobalt underglazes. / Photo by Michele Michael

Michele Michael and Patrick Moore understand the importance of ordinary days and have a renewed appreciation for the concept of time.

Today, Michael creates ceramics that reflect the natural beauty, quiet, and peacefulness that surround her in midcoast Maine. Mostly she creates utilitarian objects for the tabletop. She builds, fires, and glazes her wares—typically porcelain, sometimes stoneware—on the first floor of, or in season outside on the porch of, a light-drenched, barn-style studio that she shares with her husband, Moore, a woodworker.

Michael came to ceramics serendipitously back in 2010. At the time, she and Moore were leading a higher-octane lifestyle in New York City, where they owned a successful prop house together. Michael curated a large collection of tabletop items that she would rent out for photo shoots for magazines, cookbooks, and advertising. Moore built surfaces and other props for their business and also sets for film and music videos, often out of wood he salvaged from dumpsters at construction sites around the city.

On one fateful spring day, Michael ventured into a ceramics studio in their Brooklyn neighborhood (to see if they had any plates or bowls she might want to buy for her inventory), then on a whim signed up for a class that started that very week. It was kismet. Michael loved everything about her experience: the feel of the clay in her hands, the meditative process of forming it into her desired shapes, the warm and supportive community of fellow makers.

“In my career as a magazine editor, then photo stylist and business owner, I was constantly multitasking,” Michael said. “Right away, it felt so good to do something where I was fully in the moment, plus it was just nice to be using my hands to make something again.”

Here, Michele Michael created texture by rolling out the clay between two pieces of handwoven linen. / Photo by Michele Michael

Within just three years, Michael and Moore had sold their apartment and moved full-time to what had until then been a summer home in the small town of Dresden, Maine. By consigning their prop collection to another company similar to theirs, they could keep some of that income stream flowing while changing their way of life dramatically. They would build a studio where Michael could devote herself to her ceramics practice and Moore could do his woodworking.

Today, they are able to live a life they fantasized about away from the city: in sync with not only the natural world that nourishes them but also the creative curiosity that drives them. Michael creates her wares—mostly platters and vases—and then photographs and posts them to their retail website, called Elephant Ceramics, in batches several times a year. Moore’s one-of-a-kind cutting boards, which he makes out of birch, maple, black walnut, cherry, oak, and hickory he sources from a nearby mill, are also for sale on the site. Inventory sells out fast but isn’t replenished until months later, when they feel ready to create a new body of work.

Patrick Moore seeks out wood with unusual grain with which to make his cutting boards. As he cuts, planes, sands, and finishes each piece, his aim is to showcase and maximize the wood’s natural beauty. / Photo by Michele Michael

“We are constantly in a process of learning and trying new things,” said Michael. “I can’t imagine a life without making things. I think it’s in my DNA.”

In between these bursts of making, the two are able to slow down and enjoy ordinary pleasures: walks, birdwatching, gardening, cooking nourishing meals, kayaking on the river that borders their property—and following those ever-important whims. Moore might transform random lobster rope that washes up on the beaches into boat fenders and other nautical knots, weave sticks and saplings collected while pruning in the yard into vessels to be used as planters or compost bins, or teach himself to knit, inspired by a collection of old needles he picked up at a yard sale. Michael sometimes sets off on trips to faraway places and takes workshops—block printing in India, ceramics and cooking in Japan, and weaving in Mexico so far—or she might stay home and hook a chair cushion using yarn from her stash and strips of wool cut from old clothing.

As Michael shared, “Often my inspiration comes from an idea of something I’d like to have but cannot find. I think making things yourself helps you see the value in items that are handmade. You realize how much goes into something that is carefully thought-out and crafted. It also teaches you patience."

With our hands, we take agency over our lives. We connect with others, past and present, near and far, with a similar passion. We feel a sense of belonging, not only to one another but to the planet.

Melanie Falick is an independent writer, editor, and creative director. This post was adapted from “Keeping in Touch,” an article in the June–December 2021 issue of The Henry Ford Magazine.

Additional Readings:

- Women Design: Peggy Ann Mack

- Marshmallow Love Seat, 1956-1965

- Table, Used as a Writing Desk by Mark Twain, 1830-1860

- Sidney Houghton: The Fair Lane Rail Car and the Engineering Laboratory Offices

decorative arts, 21st century, 2020s, 2010s, The Henry Ford Magazine, making, home life, furnishings, ceramics, by Melanie Falick