Posts Tagged engineering

Leo Goossen

Supercharger Assembly Drawing of Offenhauser Engine by Leo Goossen, April 21, 1934 / THF175170

Leo Goossen was an automotive draftsman, engineer, and one of the most influential engine designers in American auto racing. In a presentation from our monthly History Outside the Box series on Instagram earlier this year, Processing Archivist Janice Unger recognized Goossen’s 130th birthday with a quick biography and look at some of Goossen’s work from our collections. If you missed it on Insta, you can watch below.

California, 20th century, racing, race cars, Michigan, History Outside the Box, engines, engineering, drawings, cars, by Janice Unger, by Ellice Engdahl, archives

Barney Korn: Tether Car Craftsman

Barney Korn’s work is featured in The Henry Ford’s exhibit Driven to Win: Racing in America. / Photo by Matt Anderson

In the 1930s and 1940s, race fans who didn’t have the budget or the bravery for full-size auto racing could find big thrills in small scale through the world of tether cars. These gas-powered model cars were raced by adults in organized competition. The models either raced against the clock, running in circles while tethered to a pole, or they raced against each other on a scaled-down board track fitted with guide rails.

The fastest tether cars topped 100 miles per hour—real miles, not scale miles—which explains another name given to them: spindizzies. (Imagine watching a little car zooming around a pole and the name makes perfect sense.) Though they look like toys, these models could be expensive. By the time you bought the car, the engine, the tools, and the accessories, you could be looking at more than $100—at a time when you could by a Ford DeLuxe Convertible for well under $1,000. At the hobby’s peak, some 25 major manufacturers and hundreds of individual builders produced tether cars. But few makers matched the skill and craftsmanship of Barney Korn.

Barney Korn’s skill was apparent from his high school days, as when he built this working engine in shop class. / THF160779

Bernard Barney Korn was born in Los Angles on April 24, 1903. He showed his modeling talents at an early age, building an elaborate water-cooled model engine as a project for his high school shop class. After high school, Korn honed his skills in part by working as a machinist for aviation innovator Howard Hughes, whom he joined in 1924.

One of Barney Korn’s “Indianapolis” models, with the hood removed to expose the single-cylinder gas engine. / THF157084

As tether cars became more popular, Barney Korn joined the booming business and formed B.B. Korn Specialty Manufacturing Company in 1939. His first production model, the “Meteor,” was also his rarest. Only 18 examples are known to have been made. The following year, Korn began production of his best-known and, many would say, best-looking model: the “Indianapolis.” Based on real Indianapolis 500 race cars of the time, Korn’s “Indianapolis” was handsome and well proportioned. It was a big model, with an overall length over 20 inches. Many were also exceptionally detailed. The “Liberty Special” car even had a working compass in its dashboard! But the “Indianapolis” was rare too. It’s believed that Korn produced fewer than 70 examples in total. Most featured rear-wheel drive trains and aluminum bodies, though a few had lightweight magnesium bodies. When materials were restricted during World War II, Korn mixed and matched aluminum and magnesium components as needed.

Korn’s working dynamometer measured engine performance in his model cars. / THF159749

Barney Korn used precision tools, molds, and patterns to build his model cars. In a particularly impressive feat, Korn even built a working dynamometer to test his cars’ performance. Like full-size dynamometers, Korn’s version was basically a treadmill for engines. It allowed a model car’s drive wheels to spin while the car itself remained stationary. Korn’s dyno measured the power and torque of the .60-cubic inch engine as it delivered power to the wheels. The little dynamometer was even adjustable to accommodate both front and rear-wheel drive models.

This unfinished Korn “Indianapolis 29” kit would have appealed to the budget-conscious tether car buyer. / THF162913

The B.B. Korn Manufacturing Company provided a few options for budget-conscious buyers. Instead of a standard “Indianapolis” model, they could purchase one of Korn’s “Indianapolis 29” cars. Everything about the “29” series was smaller—from the .29-cubic inch engines (source of the name), to the dimensions, to the all-important price tags. Those wanting to save even more could opt for an unassembled “Indianapolis 29” kit rather than a fully assembled car. With the kit, it was up to the buyer to finish rough edges on the balsa wood body, and to source an engine separately.

Barney Korn’s tether cars were beautifully made and carefully detailed, but that quality came at a price—in dollars and in performance. Korn’s models were too expensive for amateur hobbyists and too slow for serious racers. Poor sales made the B.B. Korn Manufacturing Company unsustainable, and it closed just a few years after it opened.

Barney Korn went on to a career in modelmaking for special effects work in films. His detailed miniatures can be seen in movies like To Please a Lady, a 1950 racing melodrama staring Clark Gable and Barbara Stanwyck, and Moby Dick, the 1956 adaptation of Herman Melville’s novel directed by John Huston. In the early 1980s, Korn even built a few improved versions of his original tether car designs.

Barney Korn died in Los Angeles on October 23, 1996, but his craftsmanship survives. Replicas of Korn’s models are readily available today, and originals are highly prized by collectors. It’s a proud legacy for a talented artist who some regard as the Leonardo da Vinci of the tether car hobby.

Explore Further

“Barney Korn: Tether Car Craftsman” expert set

“Tether Cars: Big Thrills in Small Scale” expert set

Driven to Win: Racing in America exhibit information

Artifacts related to tether cars in our Digital Collections

Matt Anderson is Curator of Transportation at The Henry Ford.

Additional Readings:

- 2016 Le Mans Class-winning Ford GT Race Car, On Loan from Ford Motor Company

- 1901 Ford "Sweepstakes" Race Car

- 1902 Ford "999" Race Car, Built by Henry Ford

- 1906 Locomobile "Old 16" Race Car

engineering, engines, making, Henry Ford Museum, Driven to Win, toys and games, by Matt Anderson, cars, racing

Accidental Toy Inventions

Accidents happen—and not all have a bad outcome. Sometimes they launch loads of fun, like these classic toys that delight us as kids.

Slinky

Advertisement for Slinky, "Insist on Slinky Toys," 1957 / THF109573

Slinky, 1970-1980 / THF309090

In 1942, marine engineer Richard James of Philadelphia was working on a sensitive marine meter designed to monitor horsepower on naval battleships. His quest? To develop an inner spring that would assure that the device—even if rocked at sea—would give an accurate reading. As James worked, he accidentally knocked one of the rejected prototypes off his desk. The spring hit the ground—then kept spiraling, coil by coil, over the office floor!

This unexpected response intrigued James, who immediately realized that it would make a great toy. For several years he tested various metals, thicknesses, and proportions to come up with the perfect design. His wife, Betty, came up with the perfect name—Slinky. Then James began to sell his Slinkys in local stores. But people weren’t buying.

Clearly customers needed to be shown what a Slinky could do. Richard and Betty James, determined to find success, convinced the Gimbels department store to let them do an in-store demonstration. James had arranged with a local machine ship to manufacture 400 Slinkys—98 coils of high-grade, blue-black Swedish steel piled 2 ½ inches high. Armed with a small set of stairs, the Jameses set out for Gimbels with their Slinkys. As the department store’s curious customers looked on, the Slinky gracefully moved down the stairs. Within minutes, the entire stock of 400 had sold.

Slinkys look simple—but they are actually quite intricate. The original dark steel was later replaced with a silver-colored steel. And, while Slinkys now come in colored plastic, the classic Slinky has remained virtually unchanged.

There’s something rather lifelike about a Slinky, whether walking down some stairs or a sloped board, or shuffling back and forth between one’s hands. And the sound of a Slinky in motion—quite melodious. I have fond childhood memories of a Slinky gliding coil over coil down our stairs—each move punctuated by that distinctive Slinky “snap”—as my siblings and I looked on mesmerized by its flowing passage. How did it know how to do that?

Silly Putty

Silly Putty, circa 1962 / THF135811

During World War II, the Japanese invasion of the Far East cut off the United States’ rubber supply—rubber badly needed for the mass production of tires and boots. The War Production Board asked General Electric to develop an inexpensive rubber substitute. Chemical engineer James Wright set to work at the company’s New Haven, Connecticut, lab, experimenting with boric acid and silicone oil. Unexpectedly, the two substances gelled. The result was a gooey compound that bounced when tossed on the floor—even higher than rubber did. It stretched farther and retained its properties over a wide temperature range. And oddly enough, it had the ability to lift text or images off the pages of newspapers and comic books. Quite amazing stuff. But the United States War Production Board rejected it as a rubber substitute. And—despite investigation into other possibilities—one seemingly without a practical use.

Silly Putty became a curiosity that made the rounds of New Haven cocktail parties, where it found itself an amusing “guest.” Ruth Fallgatter, who owned a toy store, and Peter Hodgson, her advertising consultant, took notice. Soon, the putty appeared in the store’s holiday catalog as a novelty gift for adults called Bouncing Putty. There was no image, only a description of the product. You guessed it. Bouncing Putty was a huge hit among Fallgatter’s customers.

Fallgatter lost interest in continuing to market the product, but Hodgson persevered. He purchased a large batch of the putty from General Electric, hired Yale students to separate it into one-ounce portions, then packaged it in multicolored plastic eggs. Since “bouncing” didn’t cover everything this remarkable putty could do, Hodgson called it Silly Putty.

Silly Putty’s reception at the 1950 New York Toy Fair didn’t go too well. Hodgson managed to get only a few accounts. One of these was Doubleday bookshops—and that proved to be enough. Silly Putty soon got its “big break” when a staff writer for The New Yorker discovered it when he stopped in the chain’s Manhattan store, then mentioned Silly Putty in the magazine’s popular “Talk of the Town” column. A few days later, Hodgson had orders for over 250,000 items. Since then, the contents of hundreds of millions of Silly Putty eggs have been bounced and stretched by kids and adults alike.

Oh—that thing about Silly Putty not having a practical purpose? Apparently, it does for some. People have used it to clean typewriter keys or level the legs of wobbly tables. Silly Putty even orbited the moon in 1968 with the Apollo 8 astronauts, helping to keep their tools fastened down in the weightless environment.

Like other kids, I would grab Silly Putty and the Sunday comics, then lift an image from the page. At first, I pulled carefully to distort the image in interesting ways. By the end of pulling, the image was so distorted that it was no longer recognizable—then every trace magically disappeared as I kneaded the putty. (I hear this no longer works, since the printing process for color comics has changed.) But perhaps my favorite Silly Putty-related activity was bouncing it—Silly Putty had an energetic, almost otherworldly bounce. And I can’t recall childhood memories of Silly Putty without thinking of the time my sister took it to bed with her. For years afterwards, a perfectly oval Silly Putty stain graced the sheets.

Colorforms

Colorforms Set, Popeye the Weatherman, 1959 / THF135813, THF135805

You’ve heard of starving artist stories. Well, this is one.

In 1951, Harry and Patricia Kislevitz were experimenting with various materials and mediums—preferably of the least expensive sort. A friend who owned a handbag business gave them a large roll of flexible vinyl that he didn’t want. The Kislevitzes discovered that it stuck really well to the semi-gloss paint on their bathroom walls—then proceeded to cut out basic shapes and arrange them artistically. When guests visited, they found vinyl and scissors lying on the bathroom counter, beckoning them to join in. A good time was had by all as everyone added to or rearranged the giant collage!

The Kislevitzes decided to market their idea. They created vinyl pieces in standard geometric shapes and primary colors. Then they packaged them with a sheet of black laminated paperboard. Colorforms caught on! And they soon came in new sets—pieced, die-cut, and screened to look like characters or everyday objects.

A kid could design dinosaurs, dress ballet dancers, or send vinyl superheroes on adventures. Scenes from favorite movies or TV shows like Mary Poppins or Sesame Street were within two-dimensional reach. The possibilities were rich—and less messy, done without scissors, paste, or paint.

My favorite Colorforms in young childhood? A set where you dressed a character for the weather—similar to the Popeye version above.

Play-Doh

Set of Play-Doh, circa 1979 / THF190091

When a New Jersey nursery schoolteacher happened to mention that the modeling clay used by her students was too firm for their small fingers, her brother-in-law took note. Joe McVicker, who was working for his father’s Cincinnati soap and cleaning products company, thought he might have an answer. In the mid-1950s, McVicker formulated a putty-like non-toxic substance and sold it as a wallpaper cleaner. Not only could it be easily shaped, but this compound also stayed soft indefinitely if stored in a tightly sealed container.

McVicker double-checked to assure that it was safe, then mailed some off to his sister-in-law’s school. Kids loved the putty—and so did the teachers. He knew he was on to something.

McVicker contacted the Cincinnati Board of Education, who bought the product for all the kindergartens and elementary schools in the district. Next, the putty made its debut at an educational convention, where it was noticed by the wife of a buyer for the Woodward & Lothrop department store in Washington, DC. After a successful in-store demo there, major retailers like Macy’s and Marshall Field placed their own orders.

By 1956, this wallpaper-cleaner-turned-kid’s-toy became known as Play-Doh. And the company? The family business transformed from Kutol Chemicals—not very kid-friendly—to Rainbow Crafts.

Play-Doh was originally offered only in white. By its second year on the market, it came in an even softer consistency and three colors: red, yellow, and blue—developed by company chemist Dr. Tien Liu. In the early 1980s, pink, purple, green, and orange made playtime with Play-Doh even more colorful. Day-glo and glitter versions would later follow.

What’s Play-Doh modeling compound made of? Apparently, that formula is a closely guarded secret.

I grew up in the red-yellow-blue era. I loved the way mixing these not-quite-primary colors could create other beautiful Play-Doh hues. The only downside? Once mixed and kneaded, you couldn’t return them back into their primary basics.

Super Soaker

Super Soaker 50 Water Gun, 1991-1992 / THF185767

Engineers, businesspeople, artists—and NASA scientists. Accidental toy inventions have landed in toy boxes through these “out of the box” thinkers.

NASA rocket scientist? Yes, that would be Lonnie Johnson and his Super Soaker water gun.

Johnson was passionate about inventing not only at his day job as an engineer working with hundreds of colleagues, but also working on his own inventions in his spare time. In 1982, Johnson was in his home workshop developing an environmentally friendly cooling system. To test his idea of using circulating water and air pressure instead of the chemical Freon, Johnson connected a high-pressure nozzle to his bathroom faucet, aimed the nozzle, turned it on, and then blasted a powerful stream of water into the bathtub. He quickly recognized its potential as a toy—a pressurized water gun that didn’t require batteries and was safe enough for kids to play with!

Johnson quickly produced a prototype using Plexiglas, PVC pipe, a two-liter soda bottle, and other materials. Over the next few years, he continued to make improvements. In 1989, Johnson licensed his design for the Super Soaker to Larami. The company launched the toy in 1990.

Kids loved it! Within two years, the Super Soaker generated over $200 million in sales, becoming the top-selling toy in the United States. Improved versions of the Super Soaker debuted have debuted since then—delighting millions of kids and adults, too.

Johnson didn’t just take his royalty money and retire. It was a means to achieving his real goal—establishing his own research company, Johnson Research & Development Co., where Johnson develops innovative technology.

You can see more artifacts related to Slinky, Colorforms, Play-Doh, and Super Soaker, as well as hundreds of other toys, in our Digital Collections.

Jeanine Head Miller is Curator of Domestic Life at The Henry Ford.

engineering, making, inventors, popular culture, by Jeanine Head Miller, toys and games

Ford’s Game-Changing V-8 Engine

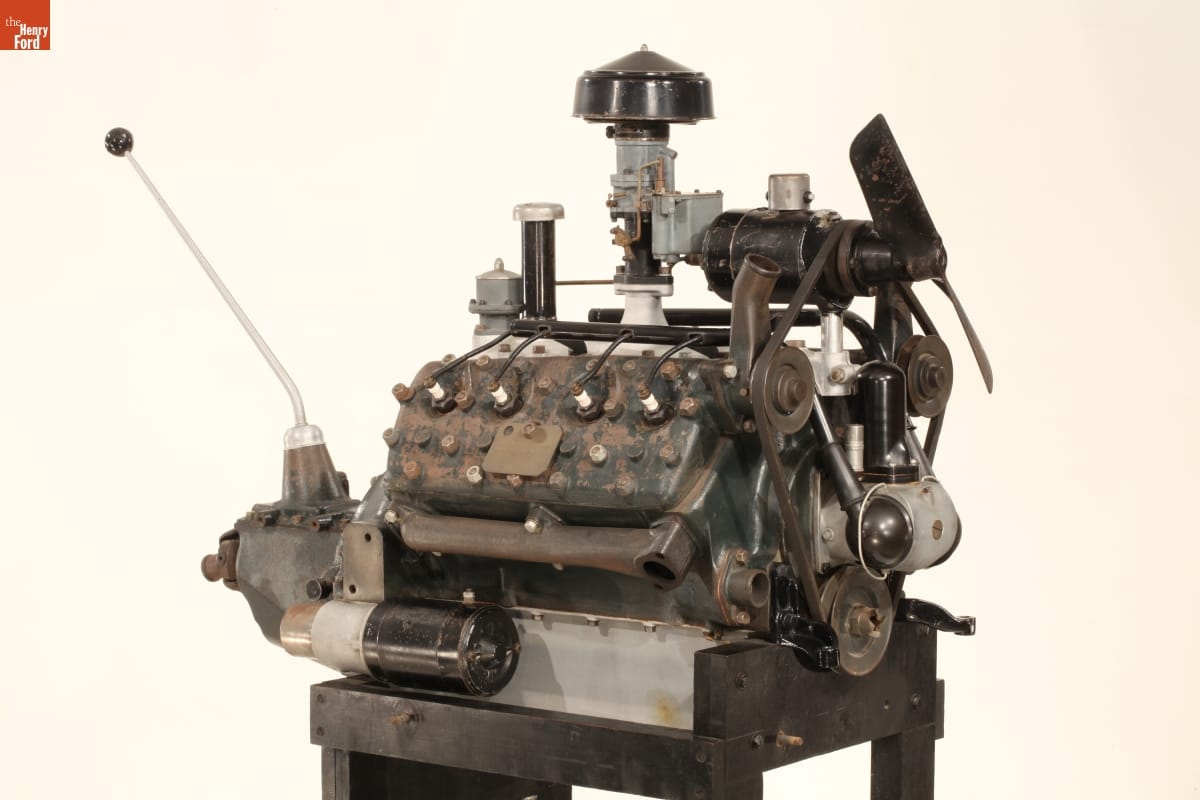

1932 Ford V-8 Engine, No. 1. / THF101039

It’s been said that when the Ford flathead V-8 went into production in 1932, Ford Motor Company revolutionized the automobile industry—again. And the engine put the hot rod movement into high gear.

What made this engine revolutionary? It was the first V-8 light enough and cheap enough to go into a mass-produced vehicle. The block was cast in one piece, and the design was conducive to backyard mechanics’ and gearheads’ modifications.

This 1932 brochure illustrates the difference between the Ford V-8, with the cylinders and crankcase cast as a single block of iron, and a traditional V-8, built by bolting separate cylinders onto the crankcase. / THF125666

With so much at stake, you would think Henry Ford would set up his engineers tasked with the engine’s design in the most state-of-the-art facility he had at his disposal.

Not so. Instead, Ford sent a handpicked crew to Greenfield Village to gather in Thomas Edison’s Fort Myers Laboratory, which had been moved from Fort Myers, Florida, to Dearborn not long before.

Henry Ford and Thomas Edison with Fort Myers Laboratory at its original site, Fort Myers, Florida, circa 1925. / adapted from THF115782

“Henry Ford likely used the building because it provided his engineers with privacy and freedom from distraction,” said Matt Anderson, Curator of Transportation at The Henry Ford. “I imagine he also thought the team might be inspired by the surroundings.”

Ford’s plan worked. In just two years, Ford’s engineering crew left the lab in Greenfield Village with a final design.

Continue Reading

Greenfield Village history, Greenfield Village buildings, Greenfield Village, Ford Rouge Factory Complex, Henry Ford, Ford Motor Company, manufacturing, design, engineering, engines, race cars, cars, racing, The Henry Ford Magazine

Suits for the Stars: Spacesuits of Yesterday, Today, and Tomorrow

Cocooned within 21 layers of synthetics, neoprene rubber, and metalized polyester films, Apollo 11 astronaut Buzz Aldrin was well protected from the airless moon’s extremes of heat and cold, deadly solar ultraviolet radiation, and even the off chance of a hurtling micrometeorite. / Photo by Neil Armstrong/NASA

Cocooned within 21 layers of synthetics, neoprene rubber, and metalized polyester films, Apollo 11 astronaut Buzz Aldrin was well protected from the airless moon’s extremes of heat and cold, deadly solar ultraviolet radiation, and even the off chance of a hurtling micrometeorite. / Photo by Neil Armstrong/NASA

It’s possibly the most recognizable image in all of human history: Buzz Aldrin on the surface of the moon, his left arm drifting up as if checking the time during a stroll through the park.

The photo sticks in the imagination more than any image of sleek rockets on the launchpad or metallic modules landing on an inhospitable world. Perhaps it’s the casual, individual bravado oozing off Aldrin’s puffed-up frame that truly captures the essence of humans pushing past the ultimate boundary: space.

And yet the spacesuit is rarely the star of the human spaceflight epic. Which is a shame, since this was the most intimate component of the engineering endeavor that landed man on the moon 50 years ago—intimate also because the surprising winner of NASA’s spacesuit contract was a spinoff of Playtex, the underwear manufacturer which still makes items from bras to feminine products to this day.

Playtex made everyday women’s girdles like those shown in this ad before making an unlikely jump to producing clothing for space travel to the moon in the 1960s. / Photo courtesy of Wikimedia Commons

“The suits that other companies provided were stiff, they were bulky, they couldn’t fit the narrow confines of the mission parameters,” said Nicholas de Monchaux, professor of architecture at University of California Berkeley’s College of Environmental Design and writer of a deeply researched book called Spacesuit: Fashioning Apollo.

At the core is the idea of the “human factor,” often overlooked by engineers in their quest to reach the lunar surface. The Saturn V rocket and the lunar module were exquisitely engineered, with sharp, clean lines governed by the unchanging forces of physics: thrust, gravity, air resistance. But the same equations are blurred when dealing with the human form. “The human body doesn’t operate from first principles,” said de Monchaux.

In the race to win the initial suit contract, companies such as David Clark Company, which made the Mercury mission spacesuits, and Hamilton Standard, a division of conglomerate United Aircraft, produced concepts informed by their decades-long experience with high-altitude pressure suits. These options proved much more difficult to maneuver than the suit produced by ILC Dover, the Playtex spinoff whose patented “convolutes” included rubber identical to that filling Playtex’s girdle molds, as well as nylon tricot and webbing taken from the supplies feeding its brassiere assembly lines.

The Apollo spacesuit designed by ILC Dover and worn on the moon had 21 layers, 20 of which were created with synthetics made by chemical giant DuPont. Familiar household names like nylon, Lycra, and Teflon were found in various layers, a fact DuPont proudly advertised at the time.

In 1966, events came to a head when a new ILC spacesuit had to compete once more against prototypes from Hamilton Standard and David Clark. Test subjects using the competing suits had trouble moving around, operating switches, and fitting in and out of the mock landing module. Imagine if Aldrin and Neil Armstrong had touched down successfully on the moon only to not fit through the hatch to step on the surface!

Though each competing suit was custom fitted, only the 21-layer ILC Dover soft suit was sewn by hand by a hotshot crew of the best seamstresses taken from Playtex’s sewing floor—eschewing paint-by-numbers engineering in favor of highly personalized, artisanal craftsmanship. Each spacesuit created by the ILC Dover team bore a laminated photograph of the astronaut it belonged to in order to create a connection to the person whom they were literally keeping alive with their craftsmanship.

Arlene Thalene of ILC Dover inspects a spacesuit’s mylar insulation layers. / Photo courtesy of ILC Dover, LP

Their knowledge, gained by fashioning bras and girdles for women’s activewear, proved indispensable to creating a superior product. The material itself was co-opted: “The rubber that made the suit was literally from the same tank that was, originally at least, supplying the girdle-making that had made Playtex’s fortune,” said de Monchaux.

ILC Dover employee Velma Breeding installs a bladder into a boot. / Photo courtesy of ILC Dover, LP

The ILC Dover suit bested the others in official NASA tests, but the systems-engineering bureaucracy of the Apollo program was still skeptical of an untested spinoff holding such a critical contract. When again faced with competition for the last phase of Apollo’s missions (numbers 14-17), the ILC Dover team even resorted to filming a test subject playing football in a pressurized suit for several hours. “And, as became clear on watching the films, the suited subject’s attempts were at the very least equivalent to those of an engineer in shirtsleeves and slacks who joined him on the field,” wrote de Monchaux. “ILC Dover, née Playtex, had won the Apollo game.”

A composite of the final drawings from ILC Dover depicts (from right to left) an Apollo 11 spacesuit’s pressure garment assembly, a suit with its Thermal Micrometeoroid Garment (TMG) attached, and an astronaut wearing a suit with TMG outer cover, gloves, and helmet. Once securely attached to the spacesuit’s inner pressure garment, the multilayered TMG protected astronauts against micrometeoroid impacts, solar and galactic radiation, thermal conduction, and abrasion, and also provided fire protection. / Drawings courtesy of ILC Dover, LP

Dressed for Health

More than 50 years after the Apollo 11 astronauts donned their spacesuits on the moon, I’m sitting in an office at hygiene and health giant Essity’s facility in North Carolina trying to pull on what looks like your average thick knee-high black socks. Kevin Tucker, the global technical innovations manager for a division of Essity, chuckles while I struggle with the fabric as it tightens like a vice. Tucker is in charge of the company’s work with NASA to develop a compression suit for astronauts returning from space. He points out as he puts the socks away that future NASA astronauts will wear something with twice the compression power.

Essity’s bread and butter is making compression garments for people with venous and lymphatic diseases. That’s when the body has issues with pumping fluids against the pull of gravity, causing symptoms from lack of feeling in extremities to loss of consciousness. It’s something we have all experienced to some degree, said Tucker. “If you’re sick in bed with the flu and you’re lying down for a long period of time and you have to go run to the bathroom, the first step you usually take you end up on your nose.”

Astronauts also have trouble with fluid control. When they first get up into space and gravity is no longer a factor, fluids are pumped more into their torso and head. That’s why new arrivals to the International Space Station have puffy faces. After a while, the body adjusts and pumps less to accommodate the lack of gravity. But the problem rears its head again upon re-entry and the rapid reintroduction to gravity. At that point, the body’s fluid pumping is weakened, and astronauts often have to be carried out of the capsule. “This sudden rush of fluid away from the head and heart down into the legs can affect your consciousness,” said Tucker. That’s something his team is trying to change.

To help NASA, Essity is applying its expertise in designing compressive socks, sleeves, and girdles to create a compression suit future astronauts would wear on re-entry to prevent or avoid the sudden redistribution of fluids to the lower extremities upon return to Earth’s gravity. When Tucker lays out the current design on a table, it’s a crisscross of tight black fabric and a few zippers, woven in a way reminiscent of those fancy yoga pants that have sheer patterns.

Health giant Essity is currently working with NASA to create a compression suit that astronauts will wear upon re-entry to Earth. The garments, shown separately here for illustrative purposes, will prevent or avoid the sudden redistribution of fluids to the lower extremities upon return to Earth’s gravity. / Photo courtesy of Essity

It’s slated to be the first layer of gear NASA astronauts will put on as they prepare to splash down—so getting stuck as you pull on the suit is simply not an option. Another “soft” consideration is that the astronauts will have to wear these for hours in a seated, upside-down position, and tests of earlier designs irritated subjects’ bent knees. The newest version of the compression suit comes slightly pre-bent at the joint, making it more comfortable.

The Human Factor and What’s Next

The human body was not meant for space travel, and the soft problems it presents require innovative solutions with intimate knowledge of the human body. Some of those challenges (and ways suits can help) are listed below.

Vacuum: Exposed to the vacuum of space, a body’s fluids would start boiling away as the body puffs up. A spacesuit protects you—but, be warned, it will puff up, too.

Temperature: Outside the International Space Station, the temperature swings wildly from 250 to -250 degrees Fahrenheit. But with no atmosphere to transfer heat or cold, a well-insulated spacesuit keeps you comfy.

Radiation: Above the protection of the Earth’s atmosphere and magnetic field, cosmic radiation is the most consistent health concern. A spacesuit provides very limited protection—as does the space station.

Lack of Gravity: Low or no gravity makes muscles atrophy, bones lose density, and fluids redistribute. NASA is working on it.

Unfortunately, the human body is not always something the engineering culture of rocket scientists takes into account. “We’re still thinking about the engineering and the propulsion systems and the vehicle, but we’re not thinking enough about the pink, squishy things that are in the middle of that vehicle,” said Diana Dayal, who did a year-long apprenticeship at the National Space Biomedical Research Institute (NSBRI). Funded by NASA’s Human Research Program, NSBRI, which closed in 2017, was NASA’s lead partner in space biomedical research and provided hands-on lab opportunities for young scientists, engineers, and physicians such as Dayal to access careers in human spaceflight.

On future, longer space missions, the human factor will be amplified. New challenges will arise from the long stint in low gravity. “The deconditioning of your bones and muscles is going to be an unavoidable problem on a three-year Mars mission,” said Dayal. “How are you supposed to send people to Mars and expect them to set up a habitat?”

Astronaut Neil Armstrong—shown here aboard the Apollo 11 Lunar Module Eagle, the first crewed vehicle to land on the moon—later quipped that his spacesuit was one of the most widely photographed spacecrafts in history. Decades later, he sent a note to the team that designed the spacesuit, complementing it and calling it “tough, reliable and almost cuddly.” You can see the “cuddly” spacesuit worn by Armstrong, held by the Smithsonian National Air and Space Museum, on their collections website. / Photo by NASA / Edwin E. Aldrin Jr.

One of the solutions being explored is enhancing the spacesuit with an exoskeleton—essentially empowering the humans by linking them to a stronger robotic carapace. This is a good idea, but the prototype Dayal saw at NASA’s Johnson Space Center was so large and cumbersome, it was hard to imagine it on an average person.

“It’s so cool that you basically have all this circuitry that simulates nerves, but at the same time, who did you build this for? Who’s going to wear it?” They were questions posed by Dayal’s group, she said, pointing out that current designs lack sufficient modularity to adjust to different body types.

While the lessons learned in developing the soft Apollo spacesuit decades earlier may have to be revisited as we look to longer missions, it’s also an opportunity to push the boundaries of design. “All of your constraints are out the window; everything is a variable,” said Dayal. “If anything, designing for space should help us better design for Earth.”

Fedor Kossakovski is a freelance science writer and producer. This post was adapted from an article in the June–December 2019 issue of The Henry Ford Magazine.

The Henry Ford Magazine, making, women's history, engineering, design, fashion, by Fedor Kossakovski, space

1920 Dayton-Wright RB-1 Airplane

The Dayton-Wright RB-1 is a dramatic presence in Heroes of the Sky. / THF39666

“Racing breeds innovation.” It’s a time-tested saying that we often associate with auto racing, where things like rear-view mirrors and disc brakes proved themselves on the track before making their way into production cars. But that line holds just as true for early airplane racing. The proof is in competition craft like the 1920 Dayton-Wright RB-1.

Above all else, the RB-1 was built for speed. Designers Howard M. Rinehart (the “R” in “RB-1”) and Milton C. Baumann (the “B”) designed the airplane specifically to compete in the 1920 Gordon Bennett Air Race in France. First staged in 1909, the Bennett race was the premier venue for showcasing the latest in aircraft design and aviation technology. The competitions were held annually through 1913, but World War I forced a pause. The 1920 Bennett race, held in Orléans and Étampes, France, marked the first (and, as it turned out, last) running after the wartime hiatus.

Rods and linkages moved flaps that changed the shape of the RB-1’s wing. / THF1463

Rinehart and Baumann gave the RB-1 several features—taken for granted today—that were absolutely cutting edge for the time. To start, it was a monoplane (single wing) design in an age when double wing biplanes dominated. The RB-1’s wing was cantilevered, meaning that it was entirely self-supporting via an internal framework. The wing didn’t require struts or cables to hold it in place. Both the wing and fuselage (the body of the plane) were made from laminated balsa wood covered with plywood and varnished linen. The designers equipped the RB-1’s wing with flaps on the front leading and rear trailing edges. Moving the flaps changed the wing’s camber—the shape of its curve. The flaps hung down during takeoffs and landings to produce maximum lift at low speeds, and they turned up flush with the wing during flight to reduce drag at high speeds.

Notice how the RB-1’s wing flaps and wheels move together. / THF169298, THF169299, THF169300

Rinehart and Baumann realized that the wheels and struts used in an airplane’s landing gear produced significant wind resistance. They solved that problem with a pair of retractable wheels that could be pulled up into the fuselage when the plane was in flight. The RB-1 is believed to have been the first land-based airplane to use retractable landing gear. (Some earlier floatplanes—airplanes equipped with pontoons for water-based operation—had auxiliary retractable wheels.) The RB-1’s wing flaps and wheels were interlocked. When the pilot turned a hand crank on the control panel, the flaps and wheels moved simultaneously—wheels and flaps up after takeoff, or wheels and flaps down for landing.

The pilot’s view—or lack thereof—from the RB-1’s cockpit. / THF15954

Rinehart and Baumann also gave the RB-1 an enclosed cockpit. This further reduced drag, but at a significant cost. The design left the pilot with absolutely no forward vision, and with only limited lateral vision through a set of portholes on either side of the fuselage. The pilot had to fly in a zigzag pattern to see what was ahead.

The RB-1’s specifications were as impressive for 1920 as its appearance. The plane was equipped with an inline six-cylinder, water-cooled engine capable of 250 horsepower. Top speed recorded in competition was 165 miles per hour, but observers at the time thought the RB-1 was capable of 190 or even 200 miles per hour. The airplane measured 22 feet, 6 inches long, with a wingspan of 23 feet, 3 inches. The plane measured 6 feet, 2 inches high at its tallest point. Range was estimated at 275 miles—though that would’ve been cut considerably when flying at top speed.

The Dayton-Wright Company of Dayton, Ohio, built the RB-1. Dayton-Wright had been founded by a group of Dayton-area investors in 1917. Orville Wright served as a consultant to the firm, and he lent it the use of his name, but beyond that Dayton-Wright had no connection to the Wright brothers or their earlier Wright Company. (Wilbur Wright died of typhoid fever in 1912, and Orville Wright largely retired from business a few years later.) General Motors purchased the Dayton-Wright Company in 1919.

Howard Rinehart demonstrates the strength of the RB-1’s cantilevered wing. / THF270970

The work of piloting the RB-1 in the Gordon Bennett Air Race fell to Howard Rinehart. He had learned to fly in 1914 and, by the time the RB-1 project came together, Rinehart’s resume included stints as an exhibition flyer, a flight instructor, and a test pilot. Rinehart was a capable and experienced pilot well suited for the demanding Bennett competition, and the RB-1 was as fine an airplane as one could wish in 1920. When Rinehart took off on race day, September 28, 1920, he was America’s best chance to take the Bennett Trophy back from French pilot Maurice Prevost, who’d won the 1913 contest. But, in the words of poet Robert Burns, “the best-laid schemes of mice and men go oft awry.”

Soon after Rinehart left the ground, the RB-1’s variable wing camber system gave him trouble. He could not get the wing flaps moved into racing position. And because the flaps were interconnected with the wheels, he couldn’t get the landing gear pulled completely into the fuselage either. To make things worse, Rinehart started having problems with the control rod. One of its connecting cables broke, and he found himself unable to turn the plane to the left. After about 20 minutes of struggle, Rinehart brought the RB-1 in for a landing. He touched down safely, but his chance for a victory was gone. Newspapers reported that “there were tears in the pilot’s eyes as he stepped from his machine.”

The Dayton-Wright RB-1, photographed in August 1920. / THF270958

In the RB-1’s defense, mechanical problems were common in racing airplanes of that era. For that matter, technical gremlins continue to haunt racing vehicles of all types to this day—it’s just the nature of the game. The RB-1 never raced again. But in the years to come, its innovative features became commonplace.

Following the disappointment in France, Milton Baumann presented the RB-1 to the University of Michigan, his alma mater. It’s possible that engineering students used the aircraft for hands-on experiments. The university gifted the airplane to The Henry Ford in 1940. Knowing that the RB-1 had been modified several times leading up to the Bennett race, and that students may have made further alterations, museum staff members were eager to return the airplane to its race-day configuration. They turned to Charles Kettering, then the general manager of General Motors’ Research Laboratories Division in Detroit, for advice. Gearheads know Kettering for automotive innovations like the electric starter and leaded gasoline. But he was also one of the Dayton-Wright Company’s founders in 1917, and he was involved in the RB-1 project in 1920.

Today visitors will find the Dayton-Wright RB-1 on display in Heroes of the Sky, where it anchors our collection of early record-breaking aircraft. It may not have won any prizes in 1920, but the RB-1 continues to win admiration from those who see it.

Matt Anderson is Curator of Transportation at The Henry Ford.

Additional Readings:

- 1917 Curtiss JN-4 “Canuck” Biplane

- Neil Armstrong: Reluctant Hero

- The 1929 Women’s “Powder Puff” Air Derby

- Getting into the Air: Alexander Graham Bell’s Aerial Experiment Association

aviators, racing, Heroes of the Sky, Henry Ford Museum, flying, engineering, design, by Matt Anderson, airplanes

Collecting Mobility: Insights from General Motors

Our new limited-engagement exhibit, Collecting Mobility: New Objects, New Stories, opening to the public October 23, 2021, takes you behind the scenes at The Henry Ford to show you how we continue to grow our vast collection of more than 26 million artifacts. One key question the exhibit asks is why we collect the items we collect. To get more insight on the artifacts on exhibit and future trends that may impact our collecting, we reached out to several of our partners. In this post from that series, our friends at General Motors (GM), donors of the General Motors first-generation self-driving test vehicle in the exhibit and contributors to our Driven to Win: Racing in America exhibit, tackle questions about autonomous vehicles (AVs), electric vehicles (EVs), and racing.

Our latest permanent exhibit, Driven to Win: Racing in America, is presented by General Motors. How has GM’s racing program evolved over time?

GM’s Chevrolet and Cadillac brands have both had long, storied histories in motorsports. Racing is a fundamental part of what we do—from transferring technology learned on the track to help us build better vehicles to connecting with consumers through something they love.

Racing driver Louis Chevrolet co-founded GM’s Chevrolet brand with William C. Durant in 1911. / THF277330

Chevrolet has been successful in professional motorsports in the United States and around the globe, capturing many manufacturer, driver, and team championships in NASCAR, IndyCar, IMSA, and the NHRA. From stock cars to advanced prototypes, Cadillac Racing has a rich history—more than half a century—of racing around the world and around the clock on some of the world’s notably challenging circuits.

Off the track, our racing programs have evolved with the help of our GM facilities. In 2016, General Motors opened the doors to the all-new GM Powertrain Performance and Racing Center—a state-of-the-art facility designed to enhance the development processes for the company’s diverse racing engine programs.

In 2021, General Motors broke ground on the new Charlotte Technical Center, a 130,000-square-foot facility that will expand GM’s performance and racing capabilities. The facility is a $45 million investment for GM and it will be a strong hub for the racing and production engineering teams to collaborate, share resources, and learn together, delivering better results more quickly, both on the racetrack and in our production vehicles.

The Chevrolet Corvette has a long, proud history in professional and amateur sports car racing. This pair of Corvettes is seen at a Sports Car Club of America race in Maryland in 1959. / THF135778

Engineering has become incredibly advanced over time, and leveraging tools between racing and production has become extremely important. We use tools like computational fluid dynamic models, which uses applied mathematics, physics, and computational software to visualize how a gas or liquid flows. These CFD models help us predict things like powertrain performance and aerodynamics.

Also, our Driver-in-the-Loop simulator allows us to test vehicles on courses virtually. It is the combination of two technologies: a real-time computer (with vehicle hardware) and a driving simulator. The driving simulator allows our development engineers to drive and test the real-time computer simulation and added hardware system on a virtual track, just like they would a physical prototype. The simulator was used extensively during the development of the mid-engine Corvette C8.R race car.

The 2001 C5-R Corvette is currently on loan from General Motors and can be seen by guests inside Driven to Win: Racing in America. Why was this vehicle selected to go on display inside Henry Ford Museum of American Innovation?

The Corvette C5-R made its debut in 1999 at the Rolex 24 at Daytona and was a fixture of global GT racing for the next five years. From 1999–2004, Corvette Racing and the C5-R set the standard for racing success with 31 victories in the American Le Mans Series, along with an overall victory at the Rolex 24 in 2001.

During six years of competition, Corvette Racing—the first factory-backed Corvette team in the car’s history—led the C5.R to an overall victory at the Daytona 24-hour race and three 1-2 finishes in the GTS class at the 24 Hours of Le Mans. During the 2004 season, Corvette Racing won every race the team entered and captured every pole position in the American Le Mans Series.

2001 C5-R Corvette, on loan from General Motors Heritage Center and currently on exhibit in Driven to Win: Racing in America in Henry Ford Museum of American Innovation. / THF185966

This specific car raced 17 times from August 2000 through June 2002 with 10 wins. It brought home the first win for the factory Corvette Racing program—Texas 2000 in the ALMS’ GTS class. Then it went on to become 2001 overall winner at Rolex 24, which was quite an accomplishment for a GT car. The car went on to win its class at Le Mans 24 in both 2001 and 2002. The modern era of Corvette’s factory racing program continues today, after over 20 years and 4 generations (C5/C6/C7/C8).

The success of this C5-R essentially started it all and we are proud to have it on display.

General Motors' donation of the 2016 GM First-Generation Self-Driving Test Vehicle was our first self-driving car acquisition. Why was it important to have this car join more than 300 others—including GM landmarks like the 1927 LaSalle and the 1997 EV1 Electric—in the collections of The Henry Ford?

This vehicle represents a huge step forward on the journey to fully autonomous driving. With Cruise, our majority-owned subsidiary, we’re determined to commercialize safe, autonomous, and electric vehicles on our way to a driverless future—one with zero crashes.

General Motors tested a series of autonomous vehicles in San Francisco, California, and Scottsdale, Arizona, in 2016. These cars used a combination of cameras, radar and lidar sensors, cellular and GPS antennas, and powerful computers to drive themselves on public streets in both cities. GM donated this one, now on exhibit in Driving America in Henry Ford Museum of American Innovation, to The Henry Ford in 2018. / THF173551

Cruise was the first AV company permitted to give rides to the public in its current driverless vehicles in the San Francisco area. Expansion of our real-world test fleet will help ensure that our self-driving vehicles meet the same strict standards for safety and quality that we build into all of our vehicles.

GM became the first company to assemble self-driving test vehicles in a mass-production facility when its next generation of self-driving Chevrolet Bolt EV test vehicles began rolling off of the line at Orion Township, Michigan, in January 2017.

The self-driving Chevrolet Bolt EVs feature an array of equipment, including LIDAR, cameras, sensors, and other hardware designed to accelerate development of a safe and reliable fully autonomous vehicle.

Reshaping cities and the lives of those who live in them has tremendous societal implications. Since we believe that all AVs will be EVs, these efforts will clearly advance our vision of zero crashes, zero emissions, and zero congestion, and help us build a more sustainable and accessible world.

This vehicle was really the first of its kind and its display is a sneak peek at the future of autonomy.

By 2025, General Motors plans to offer more than 30 electric vehicles globally. What does an all-electric future look like for Generation E?

For electric vehicles to make an impact, we need consumers to embrace them in mass numbers. So earlier this year, General Motors introduced the world to EVerybody In.

This is our brand commitment toward advancing a world with zero crashes, zero emissions, and zero congestion. EVerybody In is more than a brand campaign, it's a global call to action for everybody to join us on the road to an all-electric future.

GM introduced the EV1 in 1997. It was among the most sophisticated electric cars built during the 20th century. / THF91060

GM wants to put everyone in an EV. Thanks to Ultium, our EV architecture, GM is able to reimagine the vehicles it produces today as electric vehicles with equivalent power, excellent range, and a manufacturing cost different that is expected to diminish as EV production increases.

Not only will our EVs be fun to drive and cost less to own, they will also provide an outstanding customer experience. This is how we will encourage and inspire mass consumer adoption of EVs. GM has the technology, talent, scale, and manufacturing expertise to do it.

The all-electric future we are creating goes beyond our vehicles, it is inspiring us to do even more to help mitigate the effects of climate change. We plan to source 100 percent renewable energy to power our U.S. sites by 2025, and to become carbon neutral in our global vehicles and operations by 2040.

General Motors wants to impact society in a positive way and these are some of the steps we are taking to make it happen.

General Motors is committed to electrification—what types of current EV projects from the company might we expect to see in the museums of tomorrow?

With more than 30 EVs being introduced by 2025, we have a lot of exciting vehicles coming. From sedans, to trucks, to full-size SUVs, we will have a wide range of offerings in terms of size and design.

We are entering an inflection point in the transportation industry, a transformation the industry has not seen in decades—the mass adoption of electric vehicles. The first of any of these entries will be a sight to see in the museums of tomorrow for generations to come.

Lish Dorset is Marketing Manager, Non-Admission Products, at The Henry Ford. Todd Christensen is Strategy and Operations Manager, Chevrolet Motorsports Marketing & Activation, and Gina Peera is Corporate Strategy and Executive Communications at General Motors. General Motors is a global automotive manufacturer, driving the world forward with the goal to deliver world-class customer experiences at every touchpoint and doing so on a foundation of trust and transparency. See Collecting Mobility for yourself in Henry Ford Museum of American Innovation from October 23, 2021, through January 2, 2022.

Additional Readings:

- Driven to Win: Sports Car Performance Center

- A Lesson in Safety: Salt Walther’s Race Car

- I Would Drive 500 Miles: Scottish Drivers at the Indy 500

- 2001 Chevrolet Corvette C5-R. On Loan from General Motors Heritage Center.

engineering, manufacturing, Henry Ford Museum, Driving America, Chevrolet, alternative fuel vehicles, technology, autonomous technology, Driven to Win, race cars, racing, cars, by Gina Peera, by Todd Christensen, by Lish Dorset

Remembering Mose Nowland (1934-2021)

Mose Nowland, with wife Marcia and daughter Suzanne, at The Henry Ford in June 2021.

The Henry Ford lost a dear friend and a treasured colleague on August 13, 2021, with the passing of Mose Nowland. When he joined our Conservation Department as a volunteer in 2012, Mose had just concluded a magnificent 57-year career with Ford Motor Company—most of it in the company’s racing program—and he was eager for something to keep himself occupied in retirement. We soon discovered that “retire” was just about the only thing that Mose didn’t know how to do.

To fans of Ford Performance, Mose was a legendary figure. He joined the Blue Oval in 1955 and, after a brief pause for military service, he spent most of the next six decades building racing engines. Mose led work on the double overhead cam V-8 that powered Jim Clark to his Indianapolis 500 win with the 1965 Lotus-Ford. Mose was on the team behind the big 427 V-8 that gave Ford its historic wins over Ferrari at Le Mans—first with the GT40 Mark II in 1966 and then again with the Mark IV in 1967. And Mose was there in the 1980s when Ford returned to NASCAR and earned checkered flags and championships with top drivers like Davey Allison and Bill Elliott.

Mose with one of his creations during Ford’s Total Performance heyday.

Following his retirement, Mose transitioned gracefully into the role of elder statesman, becoming one of the last remaining participants from Ford’s glory years in the “Total Performance” 1960s. Museums and private collectors sought him out with questions on engines and cars from that era, and he was always happy to share advice and insight. Mose’s expertise was exceeded only by his modesty. He never claimed any personal credit for Ford’s racing triumphs—he was just proud to have been part of a team that made motorsport history. Mose was able to see that history reach a wider audience with the success of the recent movie Ford v Ferrari.

Michigan, Dearborn, The Henry Ford staff, 21st century, 20th century, racing, race cars, philanthropy, Old Car Festival, Model Ts, Mark IV, making, in memoriam, Henry Ford Museum, Greenfield Village, Ford workers, Ford Motor Company, engines, engineering, collections care, cars, by Matt Anderson, #Behind The Scenes @ The Henry Ford

Steam Locomotive "Sam Hill," 1858 / THF91565

The “Sam Hill,” on exhibit in Henry Ford Museum of American Innovation, is, in many people’s eyes, an example of the quintessential American locomotive. No argument here—in fact, for this writer it is certainly, along with the Mississippi riverboat, one of the utterly and absolutely quintessential American mechanisms.

Why?

Well, first, it captures a fundamental sense of youthful abandon hardwired into the American character. Locomotives like this were in their day the fastest and most glamorous ways to travel on Earth. The nature of their flamboyance captures a characteristically American engagement with technology’s possibilities—a machine as a canvas for the celebration of ambition, achievement, and a brighter, faster future. The liberal application of gold pinstriping and polished brass—even in some instances the incorporation of landscape scenes and further personalization with antlers and weathervane-like figures—all capture a uniquely American manner of celebrating and owning what was in fact a highly advanced technology.

And second, from a mechanical standpoint, the Sam Hill represents a supremely innovative technology. Its combination of flexibility, light weight, and high power output were the result of a distinctly American set of circumstances. The twisting, grade-heavy nature of our railroads—a situation that arose from the clash between low-investment/fast-return attitudes and American topography and distances—ensured that imported British locomotive technology would end up being transmuted into something entirely new. Locomotives such as the Sam Hill are the direct result of that process.

The “Sam Hill” poses with a New York Central diesel locomotive, nearly a century its junior, in Greenfield Village in May 1953. / THF133489

The development of these locomotives did not come about through what we would now consider “rational” research methods; instead, they grew out of hands-on, seat-of-the-pants engineering knowledge. This homespun advanced engineering and humanized high tech is characteristic of, and crucial to, the American industrial experience.

Learn more about the history and innovative engineering of the “Sam Hill” here.

This post is adapted from an educational document from The Henry Ford titled “Transportation: Past, Present, and Future—From the Curators.”

travel, technology, railroads, Henry Ford Museum, engineering

Henry Ford: Case Study of an Innovator

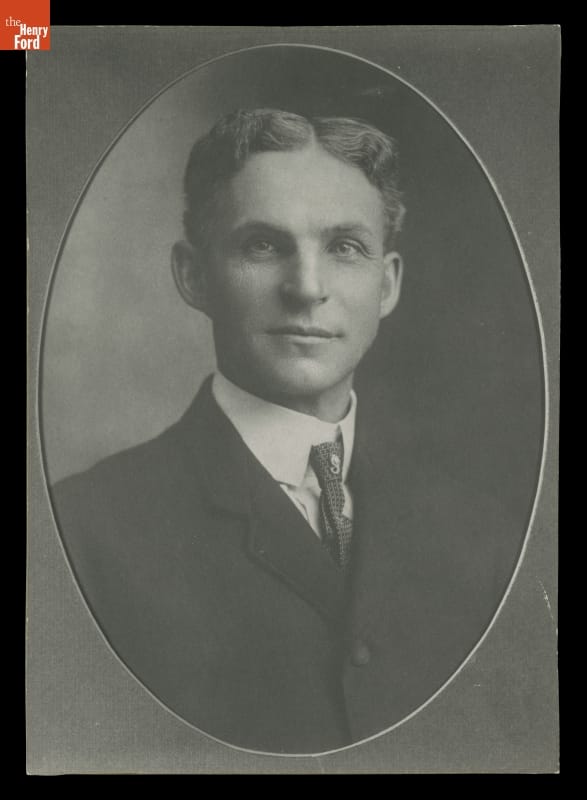

Henry Ford’s first official Ford Motor Company portrait, 1904. / THF97952

Henry Ford did not invent the automobile. But more than any other single individual, he was responsible for transforming the automobile from an invention of unknown utility into an innovation that profoundly shaped the 20th century and continues to affect the 21st. His work at Ford Motor Company revolutionized the automotive industry, setting new standards for production and accessibility.

Innovators change things. They take new ideas—sometimes their own, sometimes other people’s—and develop and promote those ideas until they become an accepted part of daily life. Innovation requires self-confidence, a taste for taking risks, leadership ability, and a vision of what the future should be. Henry Ford had all these characteristics, but it took him many years to develop all of them fully.

Portrait of the Innovator as a Young Man

Ford’s beginnings were perfectly ordinary. He was born on his father’s farm in what is now Dearborn, Michigan, on July 30, 1863. At this time, most Americans were born on farms, and most looked forward to being farmers themselves. Early on, Ford demonstrated some of the characteristics that would make him successful. In his family, he became infamous for taking apart his siblings’ toys as well as his own. He organized other boys to build rudimentary waterwheels and steam engines. He learned about full-size steam engines by becoming acquainted with the engines’ operators and pestering them with questions. He taught himself to fix watches and used the watches themselves as textbooks to learn the basics of machine design. Thus, at an early age, Ford demonstrated curiosity, self-confidence, mechanical ability, the capacity for leadership, and a preference for learning by trial and error. These characteristics would become the foundation of his whole career.

Artist Irving Bacon depicted Henry Ford in his first workshop, along with friends, in this 1938 painting. / THF152920

Ford could simply have followed in his father’s footsteps and become a farmer. But young Henry was fascinated by machines and was willing to take risks to pursue that fascination. In 1879, he left the farm to become an apprentice at a machine shop in Detroit. Over the next few years, he held jobs at several places, sometimes moving when he thought he could learn more somewhere else. He returned home in 1882 but did little farming. Instead, he operated and serviced portable steam engines used by farmers, occasionally worked in factories in Detroit, and cut and sold timber from 40 acres of his father’s land.

By now, Ford was demonstrating another characteristic—a preference for working on his own rather than for somebody else. In 1888, Ford married Clara Bryant, and in 1891 they moved to Detroit. Ford had taken a job as night engineer for the Edison Electric Illuminating Company—another risk on his part, because he did not know a great deal about electricity at this point. He took the job in part as an opportunity to learn.

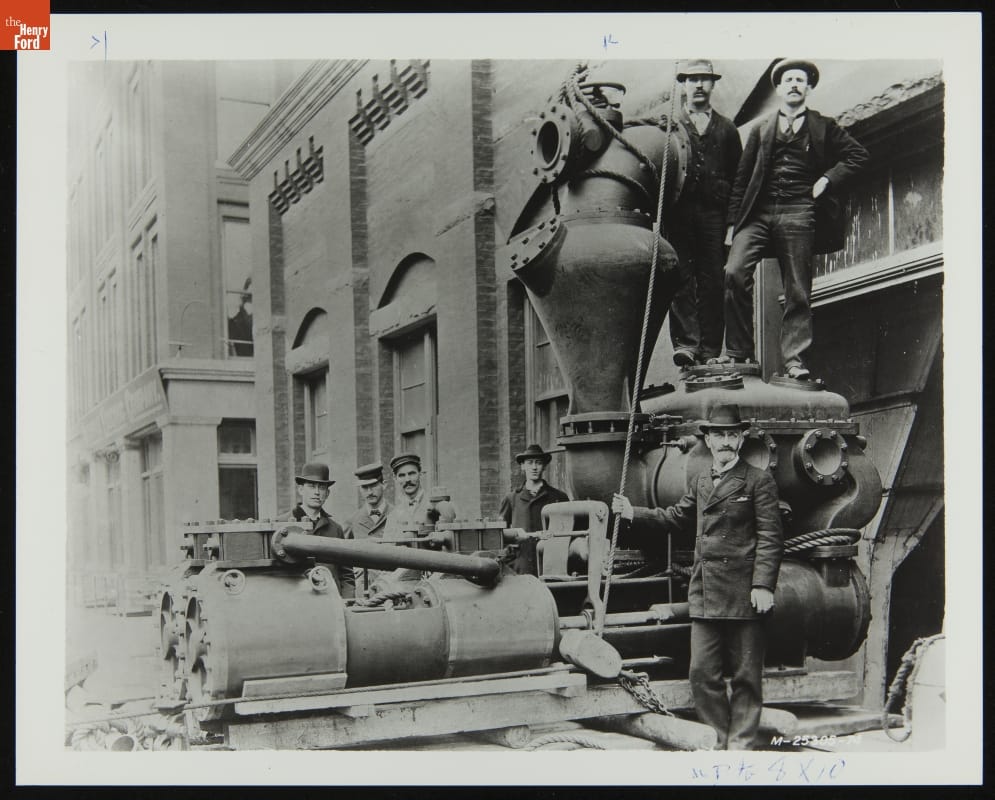

Henry Ford (third from left, in white coat) with other employees at Edison Illuminating Company Plant, November 1895. / THF244633

Early Automotive Experiments: Failure and Then Success

Henry was a skilled student, and by 1896 had risen to chief engineer of the Illuminating Company. But he had other interests. He became one of the scores of other people working in barns and small shops trying to make horseless carriages. Ford read about these other efforts in magazines, copying some of the ideas and adding some of his own, and convinced a small group of friends and colleagues to help him. This resulted in his first primitive automobile, the Quadricycle, completed in 1896. A second, more sophisticated car followed in 1898. These early experiments laid the groundwork for his future endeavors in the automotive industry.

Henry Ford’s 1896 Quadricycle Runabout, the first car he built. / THF90760

Ford now demonstrated one of his most important characteristics—the ability to articulate a vision and convince other people to sign on and help him achieve that vision. He convinced a group of businessmen to back him in the biggest risk of his life—starting a company to make horseless carriages. But Ford knew nothing about running a business, and learning by doing often involves failure. The new company failed, as did a second. His first venture, the Detroit Automobile Company, failed due to the poor quality of its vehicles. Ford tried again, this time with the Henry Ford Company. But disputes over the new company’s direction soon caused Ford and his investors to part ways.

To revive his fortunes, Ford took bigger risks, building and even driving a pair of racing cars. The success of these cars attracted additional financial backers, and on June 16, 1903, just before his 40th birthday, Henry incorporated his third automobile venture, the Ford Motor Company.

The early history of Ford Motor Company illustrates another of Henry Ford’s most valuable traits—his ability to identify and attract outstanding talent. He hired a core of young, highly competent people who would stay with him for years and make Ford Motor Company into one of the world’s great industrial enterprises. He hired a core of young, highly competent people who would stay with him for years, reshaping America’s automotive industry while building Ford Motor Company into one of the world’s great industrial enterprises.

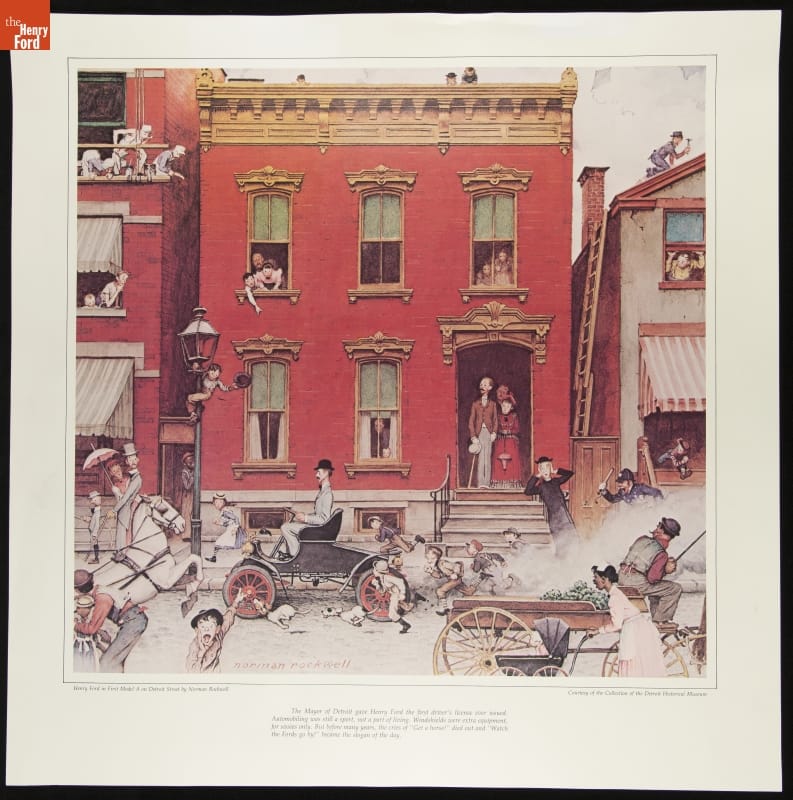

Print of Norman Rockwell's painting, "Henry Ford in First Model A on Detroit Street." / THF288551

The new company’s first car was called the Model A, and a variety of improved models followed. In 1906, Ford’s 4-cylinder, $600 Model N became the best-selling car in the country. But by this time, Ford had a vision of an even better, cheaper “motorcar for the great multitude.” Working with a small group of employees, he came up with the Model T, introduced on October 1, 1908. The Model T was a game-changer, designed to be simple, reliable, and ultimately affordable for the average American.

The Automobile: A Solution in Search of a Problem

As hard as it is for us to believe, in 1908 there was still much debate about exactly what automobiles were good for. We may see them as a necessary part of daily life, but the situation in 1908 was very different. Americans had arranged their world to accommodate the limits of the transportation devices available to them. People in cities got where they wanted to go by using electric street cars, horse-drawn cabs, bicycles, and shoe leather because all the places they wanted to go were located within reach of those transportation modes.

This Boston street scene, circa 1908, shows pedestrians and horse-drawn carriages on the road—but no cars. / THF203438

Most of the commercial traffic in cities still moved in horse-drawn vehicles. Rural Americans simply accepted the limited travel radius of horse- or mule-drawn vehicles. For long distances, Americans used our extensive, well-developed railroad network. People did not need automobiles to conduct their daily activities. Rather, the people who bought cars used them as a new means of recreation. They drove them on joyrides into the countryside. The recreational aspect of these early cars was so important that people of the time divided motor vehicles into two large categories: commercial vehicles, like trucks and taxicabs, and pleasure vehicles, like private automobiles. The term “passenger cars” was still years away. The automobile was an amazing invention, but it was essentially an expensive toy, a plaything for the rich. It was not yet a true innovation.

Henry Ford had a wider vision for the automobile. He summed it up in a statement that appeared in 1913 in the company magazine, Ford Times:

“I will build a motor car for the great multitude. It will be large enough for the family but small enough for the individual to run and care for. It will be constructed of the best materials, by the best men to be hired, after the simplest designs that modern engineering can devise. But it will be so low in price that no man making a good salary will be unable to own one—and enjoy with his family the blessings of hours of pleasure in God’s great open spaces.”

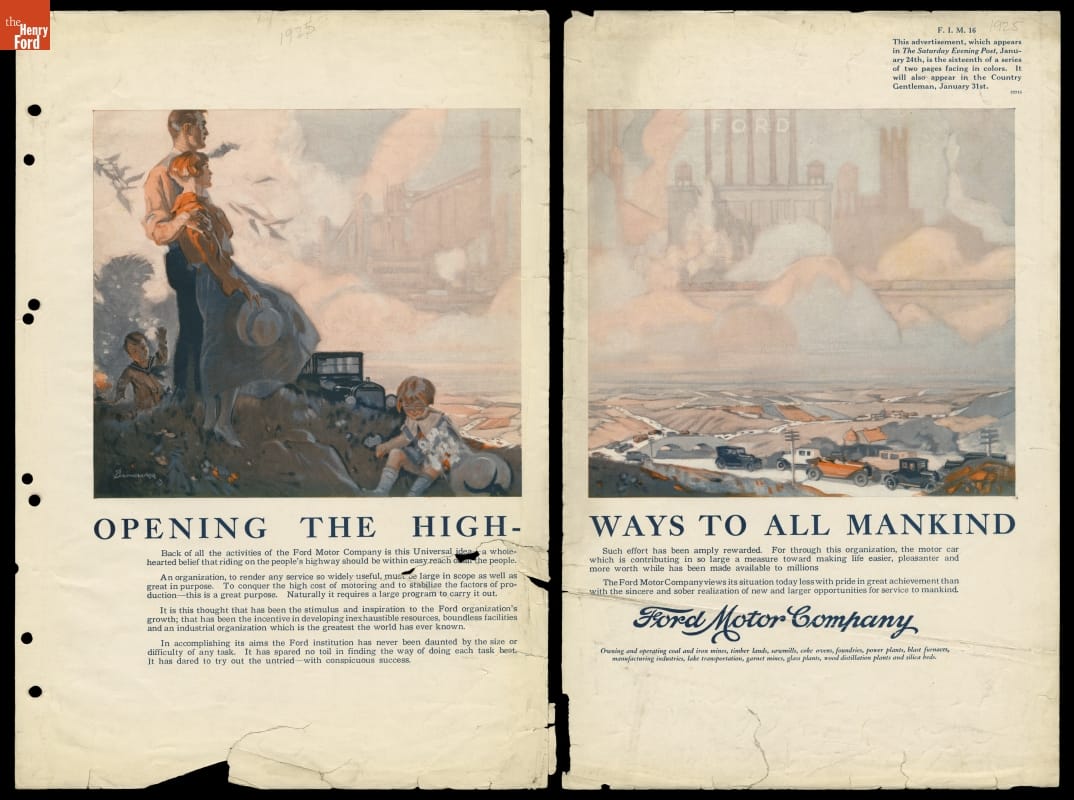

This 1924 Ford ad, part of a series, echoes the vision expressed 11 years earlier by Henry Ford: “Back of all of the activities of the Ford Motor Company is this Universal idea—a wholehearted belief that riding on the people’s highway should be in easy reach of all the people.” / THF95501

It was this vision that moved Henry Ford from inventor and businessman to innovator. To achieve his vision, Ford drew on all the qualities he had been developing since childhood: curiosity, self-confidence, mechanical ability, leadership, a preference for learning by trial and error, a willingness to take risks, and an ability to identify and attract talented people.

One Innovation Leads to Another

Ford himself guided a design team that created a car that pushed technical boundaries. The Model T’s one-piece engine block and removable cylinder head were unusual in 1908 but would eventually become standard on all cars. The Ford’s flexible suspension system was specifically designed to handle the dreadful roads that were then typical in the United States. The designers utilized vanadium alloy steel that was stronger for its weight than standard carbon steel. The Model T was lighter than its competitors, allowing its 20-horsepower engine to give it performance equal to that of more expensive cars. The Model T forever changed the automotive industry and American culture. Its impact can still be felt today.

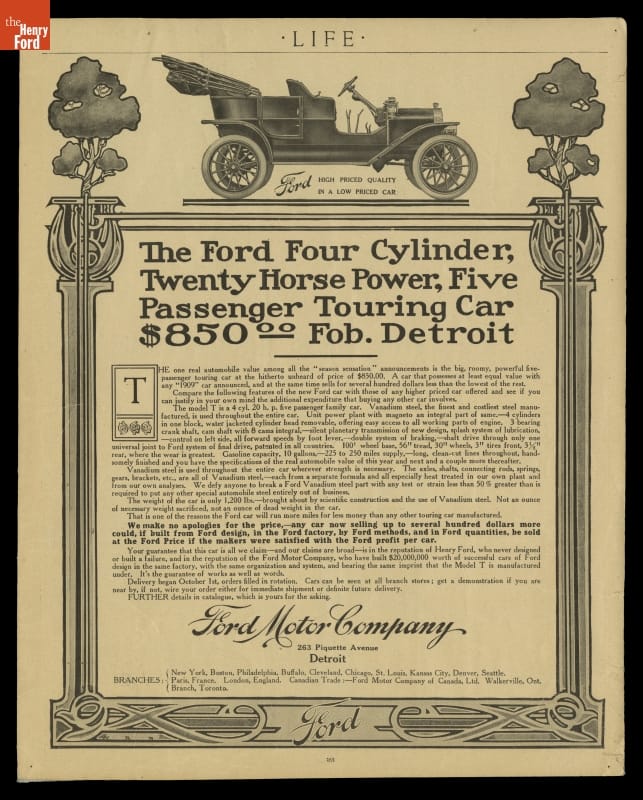

1908 advertisement for the 1909 Ford Model T. In advertisements, Ford Motor Company emphasized key technological features and the low prices of their Model Ts. Ford's usage of vanadium steel enabled the company to make a lighter, sturdier, and more reliable vehicle than other early competitors. / THF122987

The new Ford car proved to be so popular that Henry could easily sell all he could make, but he wanted to be able to make all he could sell. So Ford and his engineers began a relentless drive both to raise the rate at which Model Ts could be produced and to lower the cost of production.

In 1910, the company moved into a huge new factory in Highland Park, a city just north of Detroit. Borrowing ideas from watchmakers, clockmakers, gunmakers, sewing machine makers, and meat processors, Ford Motor Company had, by 1913, developed a moving assembly line for automobiles. But Ford did not limit himself to technical improvements.

When his workforce objected to the relentless, repetitive work that the line entailed, Ford responded with perhaps his boldest idea ever—he doubled wages to $5 per day. With that one move, he stabilized his workforce and gave it the ability to buy the very cars it made. He hired a brilliant accountant named Norval Hawkins as his sales manager. Hawkins created a sales organization and advertising campaign that fueled potential customers’ appetites for Fords. Model T sales rose steadily while the selling price dropped. By 1921, half the cars in America were Model Ts, and a new one could be had for as little as $415.

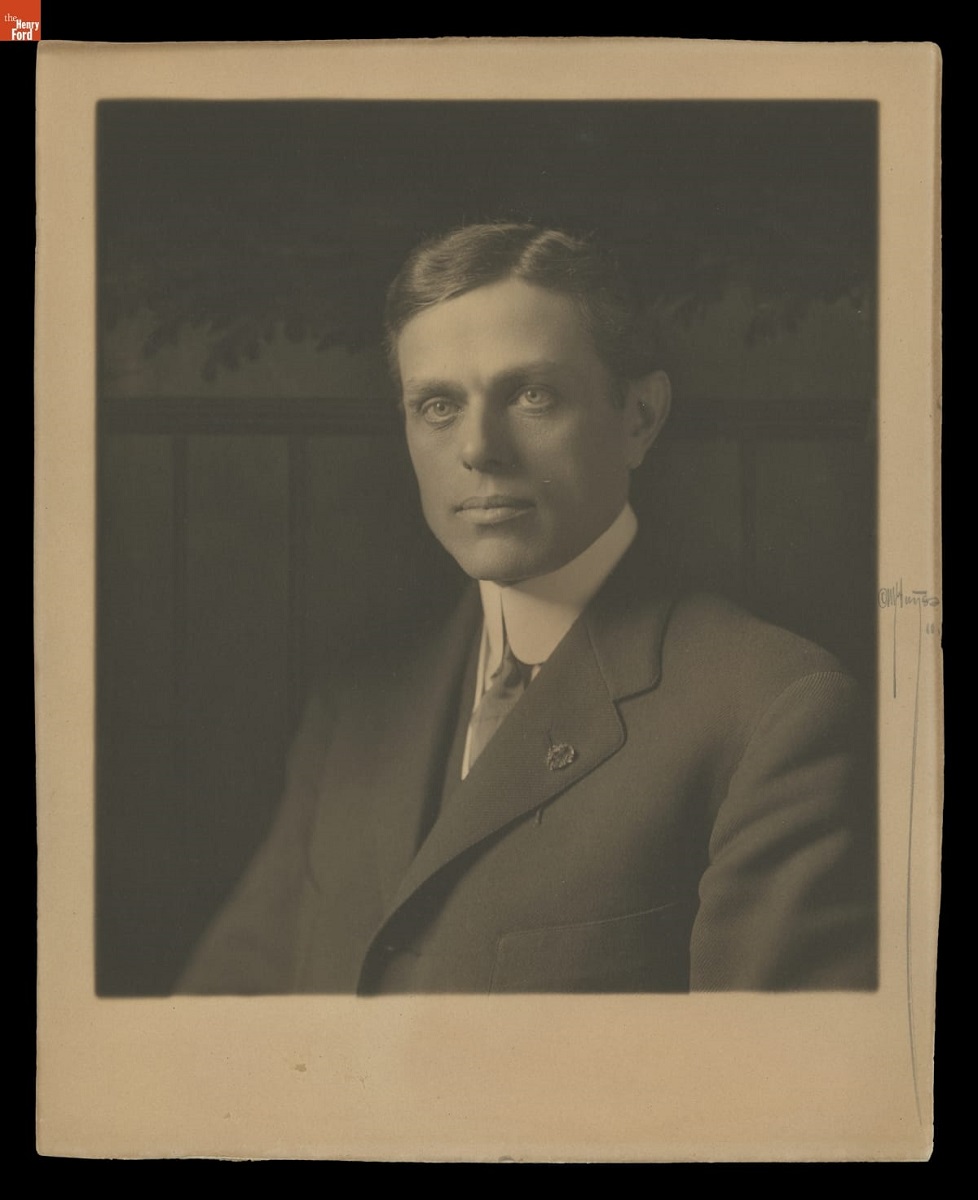

Norval Hawkins headed the sales department at Ford Motor Company for 12 years, introducing innovative advertising techniques and increasing Ford’s annual sales from 14,877 vehicles in 1907 to 946,155 in 1919. / THF145969

Through these efforts, Ford turned the automobile from an invention bought by the rich into a true innovation available to a wide audience. By the 1920s, largely as a result of the Model T’s success, the term “pleasure car” was fading away, replaced by “passenger car.” Ford’s moving assembly line and $5 day ushered in a new era of mass production and affordability. American society itself was transformed as motorists were free to travel where they wanted, when they wanted.

The assembly line techniques pioneered at Highland Park spread throughout the auto industry and into other manufacturing industries as well. The high-wage, low-skill jobs pioneered at Highland Park also spread throughout the manufacturing sector. Advertising themes pioneered by Ford Motor Company are still being used today. Ford’s curiosity, leadership, mechanical ability, willingness to take risks, ability to attract talented people, and vision produced innovations in transportation, manufacturing, labor relations, and advertising. His legacy is preserved at places like Greenfield Village, showcasing his impact on American life and the evolution of the automotive industry.

What We Have Here Is a Failure to Innovate

Henry Ford was slow to admit that customers no longer wanted the Model T. However, in 1927, he finally acknowledged that shift, and Henry Ford and his son, Edsel Ford, drove this last Model T—number 15,000,000—off the assembly line at Highland Park. / THF135450

Henry Ford’s great success did not necessarily bring with it great wisdom. In fact, his very success may have blinded him as he looked to the future. The Model T was so successful that he saw no need to significantly change or improve it. He did authorize many detail changes that resulted in lower cost or improved reliability, but there was never any fundamental change to the design he had laid down in 1907.

He was slow to adopt innovations that came from other carmakers, like electric starters, hydraulic brakes, windshield wipers, and more luxurious interiors. He seemed not to realize that the consumer appetites he had encouraged and fulfilled would continue to grow. He seemed not to want to acknowledge that once he started his company down the road of innovation, it would have to keep innovating or else fall behind companies that did innovate. He ignored the growing popularity of slightly more expensive but more stylish and comfortable cars, like the Chevrolet, and would not listen to Ford executives who believed it was time for a new model.

But Model T sales were beginning to slip by 1923, and by the late 1920s, even Henry Ford could no longer ignore the declining sales figures. In 1927, he reluctantly shut down the Model T assembly lines and began the design of an all-new car. It appeared in December 1927 and was such a departure from the old Ford that the company went back to the beginning of the alphabet for a name—it was called the Model A.

Edsel and Henry Ford introduce the new Model A at the Ford Industrial Exposition in New York in January 1928. Edsel had worked to convince his father to replace the outmoded Model T with something new. / THF91597

One area where Ford did keep innovating was in actual car production. In 1917, he began construction of a vast new plant on the banks of the Rouge River southwest of Detroit. This plant would give Ford Motor Company complete control over nearly all aspects of the production process. Raw materials from Ford mines would arrive on Ford boats, and would be converted into iron and steel, which were transformed into engines, transmissions, frames, and bodies. Glass and tires would be made onsite as well, and all of this would be assembled into completed cars. Assembly of the new Model A was transferred to the Rouge. Eventually the plant would employ 100,000 people and generate many innovations in auto manufacturing. The River Rouge complex became a symbol of Ford's ambition and scale, a testament to his vision for vertically integrated production.

But improvements in manufacturing were not enough to make up for the fact that Henry Ford was no longer a leader in automotive design. The Model A was competitive for only four years before needing to be replaced by a newer model. In 1932, at age 69, Ford introduced his last great automotive innovation, the lightweight, inexpensive V-8 engine. It represented a real technological and marketing breakthrough, but in other areas Fords continued to lag behind their competitors. The Ford factory continued to evolve, but the company faced new challenges in keeping up with changing consumer preferences and technological advancements in the automotive industry.

The V-8 engine was Henry Ford’s last great automotive innovation. This is the first V-8 engine produced, which is on exhibit in Henry Ford Museum of American Innovation. / THF101039

By 1936, the company that once sold half of the cars made in America had fallen to third place behind both General Motors and the upstart Chrysler Corporation. By the time Henry Ford died in 1947, his great company was in serious trouble, and a new generation of innovators, led by his grandson Henry Ford II, would work long and hard to restore it to its former glory. Henry’s story is a textbook example of the power of innovation—and the power of its absence. His contributions to the automotive industry and American society are undeniable, but his later resistance to change serves as a cautionary tale.

Bob Casey is former Curator of Transportation at The Henry Ford. This post is adapted from an educational document from The Henry Ford titled “Henry Ford and Innovation: From the Curators.”

Detroit, Michigan, Dearborn, 20th century, 19th century, quadricycle, Model Ts, manufacturing, Henry Ford, Ford Rouge Factory Complex, Ford Motor Company, entrepreneurship, engines, engineering, cars, by Bob Casey, advertising