Posts Tagged ford workers

Remembering Mose Nowland (1934-2021)

Mose Nowland, with wife Marcia and daughter Suzanne, at The Henry Ford in June 2021.

The Henry Ford lost a dear friend and a treasured colleague on August 13, 2021, with the passing of Mose Nowland. When he joined our Conservation Department as a volunteer in 2012, Mose had just concluded a magnificent 57-year career with Ford Motor Company—most of it in the company’s racing program—and he was eager for something to keep himself occupied in retirement. We soon discovered that “retire” was just about the only thing that Mose didn’t know how to do.

To fans of Ford Performance, Mose was a legendary figure. He joined the Blue Oval in 1955 and, after a brief pause for military service, he spent most of the next six decades building racing engines. Mose led work on the double overhead cam V-8 that powered Jim Clark to his Indianapolis 500 win with the 1965 Lotus-Ford. Mose was on the team behind the big 427 V-8 that gave Ford its historic wins over Ferrari at Le Mans—first with the GT40 Mark II in 1966 and then again with the Mark IV in 1967. And Mose was there in the 1980s when Ford returned to NASCAR and earned checkered flags and championships with top drivers like Davey Allison and Bill Elliott.

Mose with one of his creations during Ford’s Total Performance heyday.

Following his retirement, Mose transitioned gracefully into the role of elder statesman, becoming one of the last remaining participants from Ford’s glory years in the “Total Performance” 1960s. Museums and private collectors sought him out with questions on engines and cars from that era, and he was always happy to share advice and insight. Mose’s expertise was exceeded only by his modesty. He never claimed any personal credit for Ford’s racing triumphs—he was just proud to have been part of a team that made motorsport history. Mose was able to see that history reach a wider audience with the success of the recent movie Ford v Ferrari.

Michigan, Dearborn, The Henry Ford staff, 21st century, 20th century, racing, race cars, philanthropy, Old Car Festival, Model Ts, Mark IV, making, in memoriam, Henry Ford Museum, Greenfield Village, Ford workers, Ford Motor Company, engines, engineering, collections care, cars, by Matt Anderson, #Behind The Scenes @ The Henry Ford

"An Honest Effort": Claude Harvard and Ford Motor Company

“Speaking from my own experience, brief as it is, I feel certain that the man or woman who has put his very best into honest effort to gain an education will not find the doors to success barred.”

One of the few, if not the only, Black engineers employed by Henry Ford at the time, Claude had been personally sent to Tuskegee by Ford to showcase an invention of his own creation. Even in the face of societal discrimination, the message of empowerment and perseverance that Claude imparted on that day was one that he carried with him over the course of his own career. For him, there was always a path forward.

Claude Harvard practicing radio communication with other students at Henry Ford Trade School in 1930. / THF272856

Born in 1911, Claude spent the first ten years of his life in Dublin, Georgia, until his family, like other Black families of the time period, made the decision to move north to Detroit in order to escape the poor economic opportunities and harsh Jim Crow laws of the South. From a young age, Claude was intrigued by science and developed a keen interest in a radical new technology—wireless radio. To further this interest, he sold products door-to-door just so he could acquire his own crystal radio set to play around with. It would be Claude’s passion for radio that led him to grander opportunities.

At school in Detroit, Harvard demonstrated an aptitude for the STEM fields and was eventually referred to the Henry Ford Trade School, a place usually reserved for orphaned teen-aged boys to be trained in a variety of skilled, industrial trade work. His enrollment at Henry Ford Trade School depended on his ability to resist the racial taunting of classmates and stay out of fights. Once there, his hands-on classes consisted of machining, metallurgy, drafting, and engine design, among others. In addition to the manual training received, academic classes were also required, and students could participate in clubs.

Claude Harvard with other Radio Club members and their teacher at Henry Ford Trade School in 1930. / THF272854

As president of the Radio Club, Claude Harvard became acquainted with Henry Ford, who shared an interest in radio—as early as 1919, radio was playing a pivotal role in Ford Motor Company’s communications. Although he graduated at the top of his class in 1932, Claude was not given a journeyman’s card like the rest of his classmates. A journeyman’s card would have allowed Claude to be actively employed as a tradesperson. Despite this obstacle, Henry Ford recognized Claude’s talent and he was hired at the trade school. By the 1920s, Ford Motor Company had become the largest employer of African American workers in the country. Although Ford employed large numbers of African Americans, there were limits to how far most could advance. Many African American workers spent their time in lower paying, dirty, dangerous, and unhealthy jobs.

The year 1932 also saw Henry Ford and Ford Motor Company once again revolutionize the auto industry with the introduction of a low-priced V-8 engine. By casting the crankcase and cylinder banks as a single unit, Ford cut manufacturing costs and could offer its V-8 in a car starting under $500, a steal at the time. The affordability of the V-8 meant many customers for Ford, and with that came inevitable complaints—like a noisy rattling that emanated from the engine. To remedy this problem, which was caused by irregular-shaped piston pins, Henry Ford turned to Claude Harvard.

1932 Ford V-8 Engine, No. 1 / THF101039

To solve the issue, Harvard invented a machine that checked the shape of piston pins and sorted them by size with the use of radio waves. More specifically, the machine checked the depth of the cut on each pin, its length, and its surface smoothness. It then sorted the V-8 pins by size at a rate of three per second. Ford implemented the machine on the factory floor and touted it as an example of the company’s commitment to scientific accuracy and uniform quality. Along with featuring Claude’s invention in print and audio-visual ads, Ford also sent Harvard to the 1934 World’s Fair in Chicago and to the Tuskegee Institute in Alabama to showcase the machine.

Piston Pin Inspection Machine at the 1934 World’s Fair in Chicago, Illinois. / THF212795

During his time at Tuskegee, Harvard befriended famed agricultural scientist George Washington Carver, who he eventually introduced to Henry Ford. In 1937, when George Washington Carver visited Henry Ford in Dearborn, he insisted that Claude be there. While Carver and Ford would remain friends the rest of their lives, Claude Harvard left Ford Motor Company in 1938 over a disagreement about divorcing his wife and his pay. Despite Ford patenting over 20 of Harvard’s ideas, Claude’s career would be forced in a new direction and over time, the invention of the piston pin sorting machine would simply be attributed to the Henry Ford Trade School.

Despite these many obstacles, Claude’s work lived on in the students that he taught later in his life, the contributions he made to manufacturing, and a 1990 oral history, where he stood by his sentiments that if one put in a honest effort into learning, there would always be a way forward.

Ryan Jelso is Associate Curator, Digital Content, at The Henry Ford.

Michigan, Detroit, 1930s, 20th century, technology, radio, manufacturing, making, Ford workers, Ford Motor Company, engines, engineering, education, by Ryan Jelso, African American history, #THFCuratorChat

As part of the William Davidson Foundation Initiative for Entrepreneurship, we have had the opportunity to explore a number of fascinating stories of entrepreneurs represented in our collections. Recently, we’ve examined the life and work of aspiring entrepreneur and automobile designer McKinley Thompson, Jr.

While working for Ford Motor Company, Thompson conceived of an idea for an all-terrain vehicle that would do for Third World countries what the Model T did for America. This post highlights Thompson’s life and career as the first African-American automobile designer and sheds light on his little-known project for a vehicle ahead of its time, dubbed the Warrior.

Finding His Passion

On an October afternoon in 1934, 12-year-old McKinley Thompson, Jr., was stopped in his tracks while walking home from school. The reason? He had spotted a brand-new silver DeSoto Airflow, the first silver-colored and streamlined vehicle he had ever seen. In an interview from 2001, Thompson recalled that “the clouds opened up for the sunshine to come through… It lit that car up like a searchlight.” Awestruck by the unique design of the car, it was right then and there that Thompson knew what he wanted to be when he grew up: an automobile designer.

McKinley Thompson, Jr., undated (Photograph Courtesy of McKinley Thompson, Jr.)

In his youth, Thompson showed promise in drawing and was particularly interested in futuristic themes. He participated in commercial art courses throughout high school and, upon graduation in 1940, completed drafting courses where he learned to plan projects and present his ideas through drawings and concept illustrations. With these skills, Thompson acquired his first job as a draftsman with the National Youth Administration. He then worked as an engineering design layout coordinator for the Army Signal Corps until he was drafted to serve in the Army Corps of Engineers during World War II. Following the war, he continued working for the Signal Corps until 1953, when he found an opportunity to pursue his childhood dream of becoming an automobile designer.

Seizing the Opportunity

“Do you want to be an Automotive Designer” contest article from Motor Trend magazine, March 1953 THF299257

In March of 1953, Motor Trend magazine sponsored an Automotive and Industrial Design contest with the goal of discovering talented young adults. The prize? One of five, four-year tuition-free scholarships to the prestigious Art Center School of Design in Los Angeles – one of the most respected schools for industrial design. Contest entry required several drawings and sketches, photographs, or models of cars and other products, along with an essay responding to the prompt, “What I think the trend in automotive design will be in the next ten years.” For McKinley Thompson, this was the chance of a lifetime – and he won.

Motor Trend magazine’s winning contest entries, September 1953 THF299267

McKinley Thompson’s winning entry in the article, “From Dream to Drawing Board to…?” in Motor Trend magazine, September 1953. In his essay, Thompson wrote that cars of the future would sacrifice aerodynamics to accommodate “more functional roominess and reduced size.” THF299268

Thompson’s gas turbine car, which incorporated reinforced plastic (an unusual choice of material at the time), won him the top prize. Thompson became the first African American to attend the Art Center, where he excelled throughout his course of study. After graduation, Thompson was offered a job with Ford Motor Company in the Advanced Styling Studio, finally realizing his childhood dream and breaking a barrier by becoming the first African-American automobile designer.

In the Advanced Styling Studio, designers were given a great deal of creative freedom. This suited Thompson’s interest in futuristic themes, allowing him to contribute sketches for fantastical ideas, such as a flying car and a nuclear-powered multi-trailered truck. He also worked on the Allegro and Gyron concept cars and collaborated on design ideas for the production Mustang and Bronco.

1961 Ford Gyron THF299432

The Warrior

While Thompson’s career at Ford gave him the opportunity to work on a variety of vehicles and concepts that could change the automotive industry, his most innovative idea had the potential to change the world. Thompson envisioned an all-terrain vehicle for Third World countries that would be easy to build and maintain, with low production costs. But his vision extended beyond the vehicle, which he dubbed the Warrior. He anticipated auto plants – located in the developing nations that would use the car – bringing jobs, better roads, and eventual economic independence to the host countries. Much like how the Model T brought America into the modern age and stimulated the economy through accessible and affordable mobility, Thompson believed the Warrior could do the same for Third World nations.

His program was called “Project Vanguard.” The plan was to use Uniroyal plastic components – known as Royalex – because they were lightweight, durable, and relatively cost-efficient. The first phase of the plan involved building a facility where Royalex could be fabricated for use on the Warrior and other assets. The second phase would involve the building of the vehicle division (to encompass the Warrior and other future vehicles), followed by a marine division for constructing boats, and a container division where “habitat modules” would be fabricated for housing. Though Ford Motor Company was supportive when Thompson first brought his idea to the company in 1965, Ford ultimately passed on the project in 1967, believing that the vehicle would not sell in large enough quantities to warrant the investment.

1974 Warrior Concept Car THF92162

Despite this setback, Thompson still believed that his vehicle could succeed. He thought that if he produced a prototype car and could demonstrate the possibilities of this unique application of Royalex, he could garner interest for investment in the program. He gathered several friends to help in financing the Warrior prototype, including Wally Triplett – the first African American to play in the National Football League (for the Detroit Lions). By day, McKinley Thompson drafted concept drawings for Ford, but by night he worked tirelessly to bring his Warrior to life in a rented garage on Detroit’s west side.

McKinley Thompson and Crew Testing the Warrior Concept Car, 1969. Click here to check out other images of the Warrior from a scrapbook compiled by Wally Triplett! THF113754

Once his prototype was complete, Thompson and his partners attempted to market it to other investors and groups. They reached out to the Small Business Administration, which turned them down because the endeavor would take place outside the United States. They tried to gain assistance from the Agency for International Development but received little interest. A group of people at Chrysler, who assisted small businesses in getting started, suggested to Thompson that he first establish a market for Royalex in the United States. Plastic-bodied vehicles were still an unusual concept, and American automakers at the time were only experimenting with the idea on a limited scale. Thompson realized he was caught in a classic catch-22: He needed a Royalex facility to establish a market for plastic-bodied vehicles, but he couldn’t get the facility built without an existing market for plastic-bodied vehicles.

Instability on the African continent derailed opportunities to conduct business with the nations themselves. Thompson even tried to secure a bank loan to build Warrior cars in Detroit, but he was ultimately denied in this attempt as well. (Triplett later recounted that he felt that race played a role.) While every potential investor he approached told him it was a good idea, Thompson simply was unable to secure the funding needed to pursue his idea, eventually causing him to shut down the project in 1979.

Image from a 1965 Royalex sales brochure, showing the possibilities of an amphibious vehicle using Royalex materials. Interestingly, the Warrior was designed to be an all-terrain vehicle – including use for crossing rivers and small inland lakes! Click here to check out the rest of this brochure in which Uniroyal has suggested other uses for Royalex. THF290896

An Inspiring Career

Around the same time that the doors were closing on the Warrior, Thompson developed another way to influence and change people’s lives. He coordinated a traveling exhibit, featuring the work of other African-American automobile designers, to motivate and encourage young people toward careers in design. Thompson traveled across the country, staging his exhibit in schools and shopping centers.

Photograph from the Ford Motor Company publication, “Rouge News,” March 19, 1962 THF299429

McKinley Thompson had an impressive 28-year career with Ford. In 1962 he was awarded Ford’s highest honor for community service, the Citizen of the Year Award. He contributed to a variety of projects (including experimental concept cars), worked in the Thunderbird and Falcon design studios, and eventually oversaw 50 craftspeople and modelers before retiring in 1984.

Despite his career success, Thompson continued to regret that his Warrior vehicle and overall program never materialized – though he was proud of his accomplishment in building the Warrior and proving it’s basic feasibility. The Warrior project was ahead of its time in design and philosophy. The extensive use of plastic, so common today, was revolutionary at the time. Mr. Thompson’s larger economic prophecy was partially fulfilled in 1995 when Ewert Smith’s URI, an all-terrain vehicle designed for African topography, was manufactured in the small town of Witvlei, Namibia. The URI plant became Witvlei’s largest employer, providing economic stability to the area.

Even though the Warrior never made it to market, Thompson kept the car as a leisure vehicle, taking it on family vacations and occasionally using it to run errands – usually attracting a fair amount of attention. Thompson donated his prototype to The Henry Ford in 2001.

McKinley Thompson, Jr., passed away at the age of 83, after battling Parkinson’s disease, in 2006.

Samantha Johnson is Project Curator for the William Davidson Foundation Initiative for Entrepreneurship at The Henry Ford. This post expands upon Bart Bealmear’s “The Warrior,” blog post from February 2014. Special thanks to Matt Anderson, Curator of Transportation, for his help in reviewing the content.

20th century, Michigan, Ford workers, Ford Motor Company, entrepreneurship, Detroit, design, cars, by Samantha Johnson, African American history

Ford’s Mode:Flex Bicycle: Automakers Go Multimodal

While the concept of the e-bike has been around since the 1890s, it was not until the 1990s that battery, motor, and materials technology had advanced to the point where motorized bicycles became practical. While fully motor-driven units do exist, most e-bikes are of the “assist” variety. The rechargeable battery-powered motors on these bikes aren’t intended to replace muscle. Rather, they deliver a boost on steep hills or provide a few moments’ rest for a fatigued pedaler. The motors supplement rather than supplant human effort.

The Henry Ford acquired its first examples of electric-assist bicycle technology in 2017, with two prototype bicycles from Ford Motor Company’s Mode:Flex project. This 2015 initiative came out of the company’s efforts to position itself as a “mobility provider” for a post-car future. With the millennial generation returning to cities and, to some extent, turning away from automobiles in favor of public transit and other alternative forms of transportation, Ford charged teams of designers and engineers to create prototype bicycles specifically tailored for its automobile customers.

One of two Mode:Flex units acquired by The Henry Ford in 2017, this prototype bicycle is fully functional and capable of carrying a rider. Made of mostly steel, it weighs around 80 pounds – considerably heavier than a typical road bike’s 20-30 pounds. Bruce Williams, who led the Mode:Flex project, contended that the weight could be halved by using different materials if the bicycle ever went into production. THF172635

The Mode:Flex team – led by Bruce Williams, a Senior Creative Designer who had previously worked on the redesign of Ford’s F-150 pickup – developed a concept for a jack-of-all-trades bicycle that is easily disassembled for compact storage in any Ford vehicle. The front and rear ends are interchangeable between city, road and mountain bike configurations. (The bike’s seat post, which houses its 200-watt electric motor and rechargeable battery, remains the same in any configuration.)

The Mode:Flex connects to an app that controls the electric-assist motor; operates the LED headlight, taillight and turn signal (inspired directly by the units on the Ford F-150); and provides speedometer and trip odometer functions, navigation assistance, and real-time traffic updates. Running in “No Sweat” mode, the app monitors a user’s heart rate. When the heart rate climbs, the bicycle’s electric motor kicks in with a corresponding level of assistance, allowing novice bikers to ride to work in standard office attire (rather than Lycra or Spandex).

This non-functional mock-up of the Mode:Flex bicycle was largely created from thermoplastic materials rendered on a 3D printer. Built for promotional display purposes only, it lacks a working motor and is unable to support the weight of a rider, but it clearly illustrates the Mode:Flex bike’s foldability. THF172637

While the Mode:Flex could be used as a commuter’s sole mode of transportation, it is particularly geared toward those making multi-modal commutes. Someone might drive in from a distant suburb, park in a satellite lot outside the urban core, and then bike the “last mile” to work, shopping or entertainment. The bicycle’s app is designed to work seamlessly with an owner’s car as well. It can lock and unlock doors, monitor gas mileage or electric vehicle charging, track parking locations and perform other similar functions. The bicycle’s battery can be pulled out for remote charging or connected directly to a Ford vehicle’s electrical outlet.

The Mode:Flex bikes in The Henry Ford’s collection are concept prototypes, and Ford has no immediate plans to put them into production. Nevertheless, they represent concrete efforts by automakers to broaden their product lines and customer bases in response to evolving trends in personal transportation.

Matt Anderson is Curator of Transportation at The Henry Ford.

design, 21st century, 2010s, Ford workers, technology, Ford Motor Company, by Matt Anderson, bicycles

Remembering Lee Iacocca, 1924-2019

Lee Iacocca (right) lights a candle with Henry Ford II (center) and Don Frey to celebrate the Ford Mustang’s first birthday in April 1965. (THF113838)

A Born Salesman

Lee Iacocca, the charismatic corporate executive whose long careers at Ford and Chrysler made him one of the best-known businessmen in America, passed away on July 2 at age 94. With his passing, the automotive industry lost one of its most colorful figures of the last 60 years.

Born and raised in Allentown, Penn., Iacocca earned a degree in industrial engineering from Lehigh University in 1945. Given his location, one might have expected him to take a job in the steel industry. But Iacocca was one of those people with gasoline in the veins. He wanted to build cars – specifically, he wanted to build them for Ford Motor Company. He joined the Blue Oval in 1946 as an engineer. But for a born salesman like Iacocca, it was an awkward fit at best. He asked for a reassignment to sales in Ford’s Philadelphia district, and his career blossomed from there.

Iacocca first attracted attention from senior Ford managers with a novel promotion in the mid-1950s. He dreamed up a “’56 for 56” gimmick in which customers could buy a new 1956 Ford with 20 percent down and monthly payments of $56 thereafter. It was simple, it was catchy, and it was a hit. The promotion earned him a transfer to Ford’s world headquarters in Dearborn.

Total Performance

Lee Iacocca made no small plans. Barely into his 30s when he moved to Dearborn, Iacocca resolved that he’d be a Ford vice president by age 35. Though he climbed up the ranks quickly, he missed his goal – Iacocca wasn’t named Vice President and General Manager of the Ford Division until he’d turned 36. By a twist of fate, Ford President Robert McNamara left to become President Kennedy’s Secretary of Defense soon after Iacocca’s appointment. Iacocca’s influence at Ford Motor Company increased accordingly.

Young, enthusiastic, and a car guy to the core, Iacocca was the polar opposite of McNamara, whose major accomplishments at Ford included turning the sensuous two-seat Thunderbird into a four-seat family sedan. (Though to be fair, McNamara nearly doubled Thunderbird’s sales as a result.) Iacocca wanted his company to think young. He remembered the Ford V-8 of his own youth which, with help from legions of hot rodders, gave Ford a performance image. Chevrolet snatched that image in the mid-1950s with its small-block V-8 and its classic “Tri Five” Chevys of 1955-57.

Iacocca (right) with Jimmy Clark (center), Benson Ford, and the double overhead cam V-8 that Ford developed for the Indianapolis 500. (THF110520)

Among Iacocca’s first moves were to get Ford Motor Company back into racing. He greenlit a striking mid-engine sports car prototype and then – with Henry Ford II, Leo Beebe, Carroll Shelby, Jacque Passino, and others – launched an all-out assault in nearly every form of racing under the banner “Total Performance.” By decade’s end, Ford had racked up victories in NASCAR, on drag strips, at Indianapolis, and at Le Mans. But Iacocca’s tenure at Ford is forever tied to one car.

The Youth Car

Working in secret with a select team, Iacocca pitched the need for a “youth car” targeted at the up-and-coming Baby Boomers. He wanted something with the appeal of a Thunderbird, the look of a Ferrari, and the economy of a Volkswagen – a tall order to be sure. But Ford’s designers and engineers rose to the challenge. In one of the automotive industry’s great triumphs, they put a sporty body on the existing Ford Falcon compact car chassis, produced a seemingly endless menu of options and accessories that encouraged customers to personalize, and dubbed their new creation “Mustang” – a name that evoked freedom, open spaces, and, in the words of one marketing expert, “was American as all hell.”

Ford optimistically hoped to sell 200,000 Mustangs in the first model year. But the car’s splashy launch – at the 1964 New York World’s Fair – and a savvy marketing campaign kicked off a mania rarely seen in automotive showrooms. By the end of the 1965 model year, more than 680,000 buyers had taken a new Mustang home.

Mustang’s success made Iacocca a household name. But his rising star contributed to growing tensions between Iacocca and Henry Ford II, the company’s chairman and ultimate authority. After several difficult years, their strained relationship foundered and, in 1978, led to an acrimonious parting of the ways between Iacocca and Ford Motor Company.

Iacocca found the perfect pitchman for Chrysler – himself. His print and television ads made him one of the best-known business figures in the United States. (THF103024)

A Second Act

No one could have blamed Iacocca if he’d retired then and there. The Mustang alone was enough to secure his legacy. But retirement wasn’t Iacocca’s style. He missed being at the center of the action. When the failing Chrysler Corporation offered him the job of CEO, he couldn’t resist. Iacocca’s second act was even more impressive than his first.

Iacocca took over a company in ruin. Chrysler was losing millions with little hope of recovery. His first and most important act was to secure a loan guarantee from the U.S. Congress. He then set about rebuilding the automaker’s product line. First came the K-Car, a highly-adaptable front-wheel drive platform that Chrysler offered under any number of makes, models and designs. Then came another vehicle that, like the Mustang before it, transformed the industry. The minivan, manifested in the Plymouth Voyager and the Dodge Caravan, was born of an idea Iacocca had toyed with at Ford to no avail. At Chrysler, the innovative minivan became a best-seller that redefined the family car for a generation of Americans. To top off his achievements, Iacocca added an evergreen marque to Chrysler’s lineup when he acquired American Motors and its enduring Jeep brand in 1987.

Eager to restore faith in Chrysler vehicles, Iacocca personally vouched for his products in a series of memorable television and print ads. He ended many of them with a simple, straightforward challenge to his audience: “If you can find a better car, buy it.” The ads were effective, and he enjoyed making them. In truth, he enjoyed the limelight. Through the 1980s, Iacocca added to his celebrity by writing two best-selling books, leading a successful effort to restore the Statue of Liberty, and appearing in a bit part on the popular TV series Miami Vice. For a time, there was even serious talk about Iacocca as a candidate for President of the United States.

Enough for Two Lifetimes

Iacocca retired from Chrysler in 1992. He’d returned the company to profitability, restored its reputation, and repaid its government loan. But even then he didn’t really retire. With billionaire Las Vegas developer Kirk Kerkorian, Iacocca launched an unsuccessful takeover attempt of Chrysler in 1995. Ten years later, he returned to Chrysler – by then under German ownership as DaimlerChrysler – to shoot a few commercials, reprising his trademark “If you can find a better car…” slogan.

Lee Iacocca seemed to live two lifetimes in his 94 years. He enjoyed success at two car companies, and he fathered two groundbreaking vehicles. Iacocca lived to see the Mustang turn 50, and to see Chrysler fall into bankruptcy once more before remerging as a part of FCA. He will be remembered as long as there are people who love cars like he did.

Matt Anderson is Curator of Transportation at The Henry Ford.

Pennsylvania, Dearborn, Michigan, 21st century, 20th century, racing, Mustangs, in memoriam, Ford workers, Ford Motor Company, cars, by Matt Anderson

The Search for Home

Detroit Reacts to the Great Migration: Before the first World War, a majority of Detroit's African American population lived on the East Side and shared the area, known as Black Bottom, with white immigrant populations. At this time, relatively few African Americans, just 1.2% of the total population, called Detroit home. By 1930, the city’s African American population had grown by over 1,991%. The white immigrant population began to vacate the Black Bottom area and were quickly replaced with the growing population of African Americans attracted to the north by the promise of employment in Detroit’s booming auto industry and an escape from the rampant oppression of the south. As the African American population in Detroit increased, racial residential boundaries began to form, due in part to the stress on housing stock, as well as to outright discrimination in institutions such as employment and real estate.

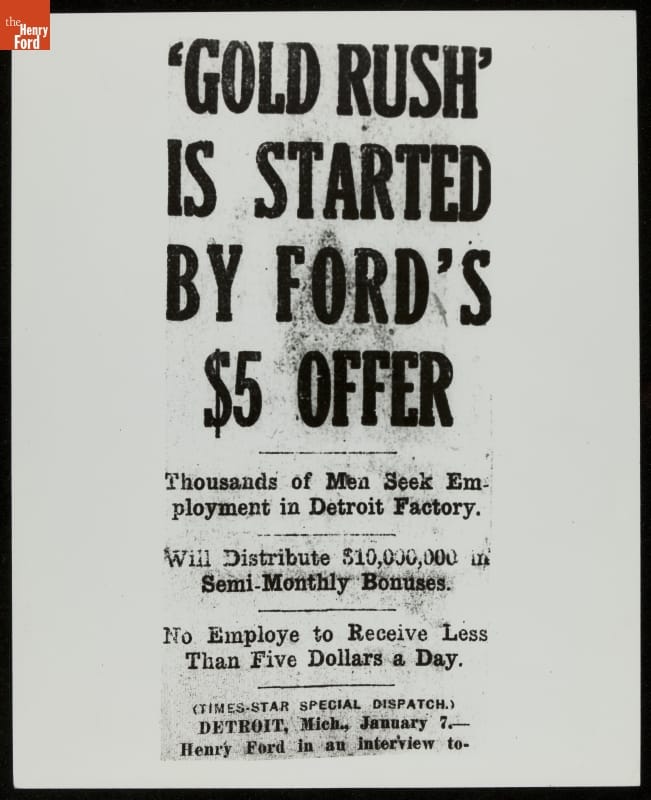

Photographic print - "Newspaper Article, "Gold Rush is Started by Ford's $5 Offer," January 7, 1914" - Ford Motor Company

The automobile industry and Henry Ford’s highly-publicized $5-a-day helped to draw people in great numbers to the Detroit area. However, for African American workers, reality often differed from their hopes and expectations in the north. While many of the automotive manufacturers did hire African Americans, it was almost always for the lowest paying jobs, such as in the janitorial department or the foundry. Ford Motor Company led the automotive industry in its hiring of African American workers by 1919. The company paid African American workers the same rate as their white counterparts and hired for a variety of positions, including skilled labor. Across the board, however, African American workers made less money than their white counterparts, and consequently, had less income for quality housing.

Photographic print - "Pickling Metal Crankcases and Other Parts to Remove Surface Impurities, Ford Rouge Plant, 1936" - Ford Motor Company Photographic Department

Discriminatory real estate practices played a significant role in the housing issues which plagued Detroit. Racially restrictive covenants, which legally ensured the sale of property to only white buyers, became increasingly common in Detroit. Even if a restrictive covenant was not in place, the Detroit Real Estate Board warned area realtors “not to sell to Negroes in a 100 percent white area,” thereby enforcing and perpetuating Detroit’s racial geography. Further, the practice of “redlining,” or the racial categorization of areas by their perceived financial risk in home insurance and mortgage lending, effectively shut out black homebuyers from the market. The practice extended to the lending of new mortgages, but also to home loans, leading to the inability to complete home repairs and, eventually, an abundance of blighted homes in black neighborhoods. In addition, real estate agents erroneously reported to white homeowners that the presence of black families in their neighborhoods would lower their property values. White homeowners, even those without ingrained prejudices against African Americans, certainly did not want their property values to lower, so rallied against any attempt by an African American homebuyer purchasing in their neighborhoods. The infamous story of African American Physician Dr. Ossian Sweet exemplifies the discrimination and mob violence experienced by those who attempted to move into white neighborhoods.

Discrimination in the workplace meant that African Americans, as a whole, made significantly less money than their white counterparts. Redlining practices forced them into racially-segregated neighborhoods and cemented their inability to access loans for mortgages or home repairs. Yet, the promise of the north continued to draw African Americans to Detroit. Without access to capital, increasingly-crowded neighborhoods became increasingly-deteriorated. At each turn, discriminatory systems excluded an entire population from quality housing. From these conditions, Charles H. Lawrence and his family departed Detroit in search of quality housing and a better life. He became the first African American to settle in Inkster, Michigan, and hundreds soon followed.

African Americans Settle in Inkster

The City of Inkster, also located in Wayne County, is approximately fourteen miles from downtown Detroit. Detroit Urban League President John Dancy fielded many housing inquiries from frustrated African American migrants to Detroit in the post-World War I period and beyond. Unable to locate sufficient housing in the City of Detroit, Dancy broadened his search outside the City with hopes that more rural areas would not have the same restrictive covenants and that lesser demand would persuade landowners to sell to African American buyers. In 1920, Dancy succeeded when he found amenable property owners in possession of 140 acres in rural Inkster. Although Inkster’s first African American residents’ settlement in Inkster preceded Dancy’s discovery, the 140 acres of available land enabled and impelled hundreds more African American families to move from Detroit to Inkster, despite the lack of a local government or basic public amenities like streetlights or sewer lines.

Clipping (Information artifact) - ""Henry Ford on Unemployment," 1932" - Detroit Free Press (Firm)

A Community Becomes a Project

Henry Ford was vocal about his disdain for institutionalized philanthropy. He wrote an entire chapter, entitled “Why Charity?” in an autobiography, and explained, “philanthropy, no matter how noble its motive, does not make for self-reliance…A philanthropy that spends its time and money in helping the world to do more for itself is far better than the sort which merely gives and thus encourages idleness.” Henry Ford’s brand of philanthropy was characterized by helping people help themselves. During the Great Depression, Henry Ford was called upon by the City of Detroit to provide aid because the City’s welfare offices were overwhelmed. Their argument, aside from civic responsibility, was that the City was not receiving taxes from Ford Motor Company (FMC’s factories were located outside Detroit) yet as many as “36 percent of the families receiving care from the City of Detroit were former Ford employees” in 1931. The public goodwill that Ford’s $5 a day policy brought was quickly dissipating. In 1931, Ford agreed to two philanthropic ventures; he provided a low-interest, short-term $5 million loan to the City of Detroit and essentially took the then-Village of Inkster under the Ford Motor Company’s auspices.

Photographic print - "Ford Motor Company Employee Home Improvement Project, Inkster, Michigan, 1930-1944" - Ford Motor Company

Photographic print - "Ford Motor Company Employee Home Improvement Project, Inkster, Michigan, 1930-1944" - Ford Motor Company

Photographic print - "Ford Motor Company Employee Home Improvement Project, Inkster, Michigan, 1930-1944" - Ford Motor Company

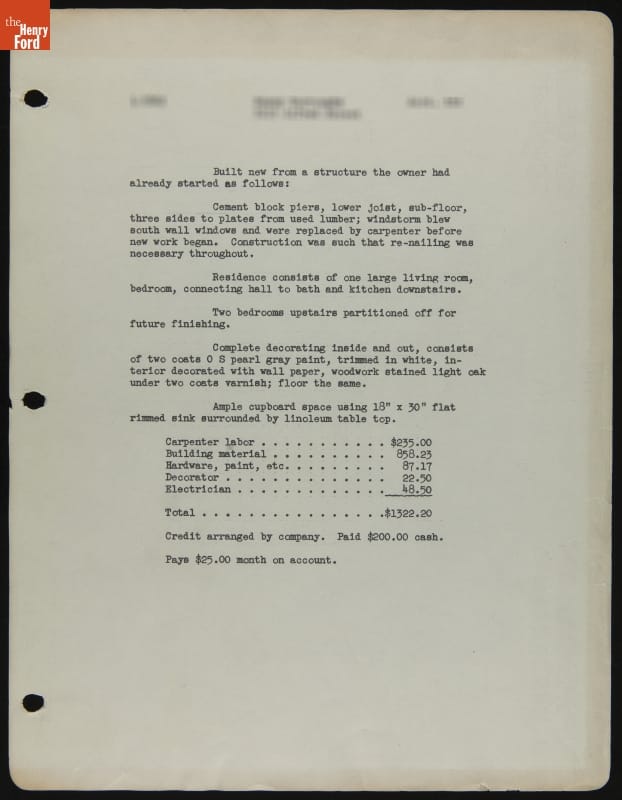

Report - "Ford Motor Company Employee Home Improvement Project, Inkster, Michigan, 1930-1944" - Ford Motor Company

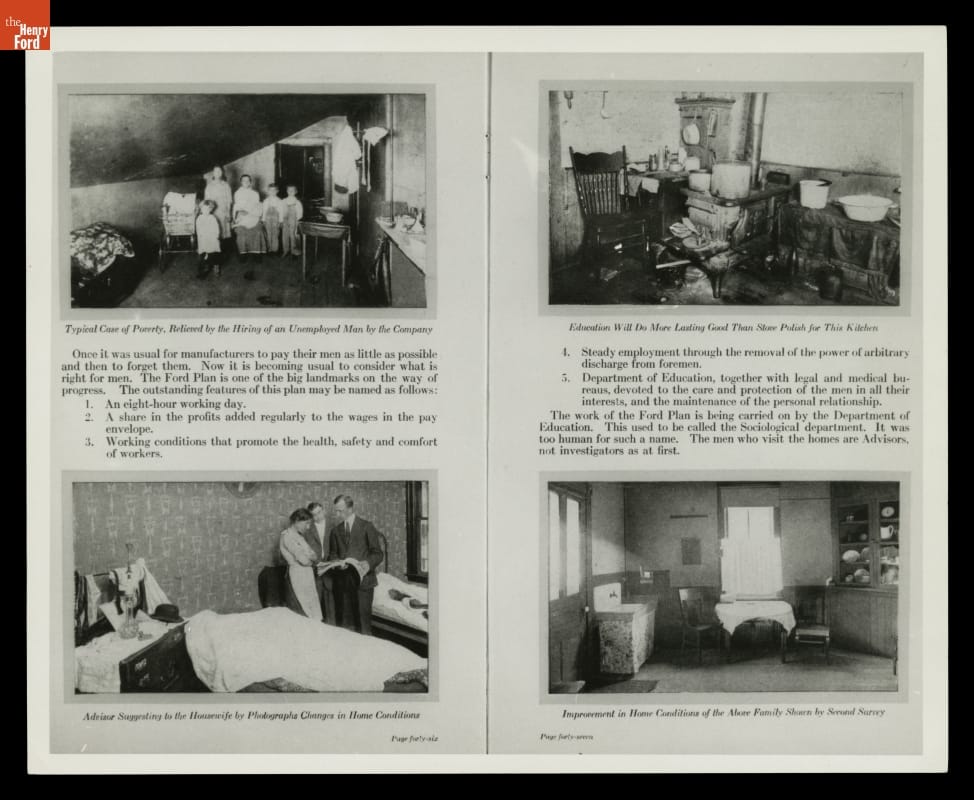

By 1931, a few years into the Great Depression’s hardships, the residents of Inkster were struggling. Unemployment and debt were high, public services had been cut, and many residences remained partially-completed, as the Great Depression halted progress in the young village. Controversially, Henry Ford placed FMC’s Sociological Department in charge of what became known as the Inkster Project. The Sociological Department was created in 1914 in order to manage the diverse workforce and ensure employee adherence to the company’s strict standards, which were paternalistic in nature and often crossed the home life-work life boundary. In Inkster, the Sociological Department immediately began implementing programs to comprehensively rehabilitate the village. A commissary, which sold high-quality, low-cost food and essential home goods, was established. Coal was distributed to those who needed it to heat their homes. Debtors were paid off, and a medical clinic and school were constructed. Homes deemed insufficient were rehabilitated. The inability to pay for these services was irrelevant; a type of “I.O.U,” repayable through Ford-provided work and wages, was enough to access all life’s necessities.

Photographic print - "Checking on Ford Employees Home Conditions, Views from "Factory Facts From Ford," 1917"

The Legacy of the Inkster Project

Although the Inkster Project was generally highly-regarded at the time, the FMC Sociological Department’s role was often overreaching. When agreeing to Ford’s aid, an Inkster resident was also agreeing to running their household as preferred by Henry Ford. Although his funds undoubtedly helped Inkster during the Great Depression, Ford’s motives were not entirely altruistic. Besides the much-needed public relations boost he received from the Inkster Project, he also was able to assert his influence and ideals on a community that largely had no choice but to accept his aid -- with all strings attached.

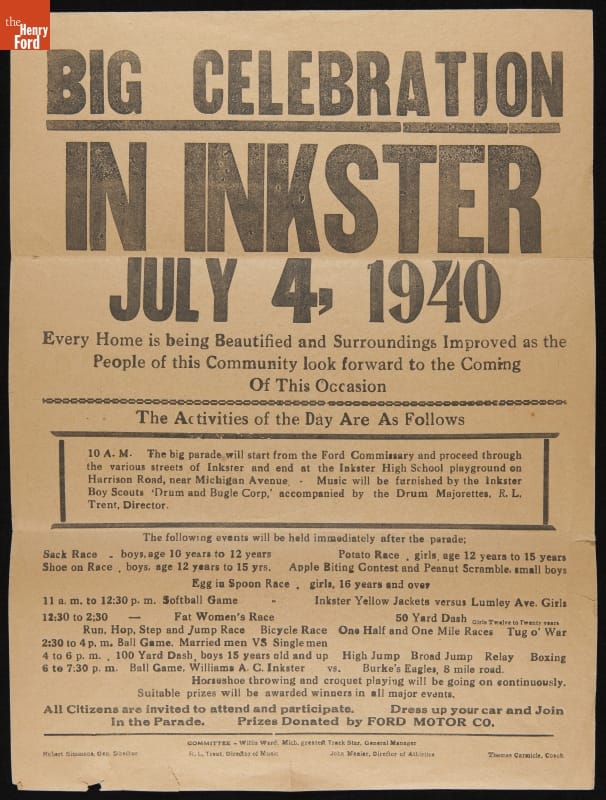

Broadside (Notice) - "Big Celebration in Inkster," July 4, 1940"

The Inkster Project’s legacy is complicated; many historians criticize Henry Ford’s paternalistic nature and the perhaps forceful imposition of his will onto the desperate, but others, including former residents of Inkster, praise Henry Ford for his aid. In her reminiscences, Georgia Ruth McKay explains that Inkster became a “jungle village changed into a city” during this period and that, “without his [Henry Ford’s] help, many would not have survived.” The Inkster Project was slowly phased out, but continued to operate in Inkster until 1941 when all programs were withdrawn.

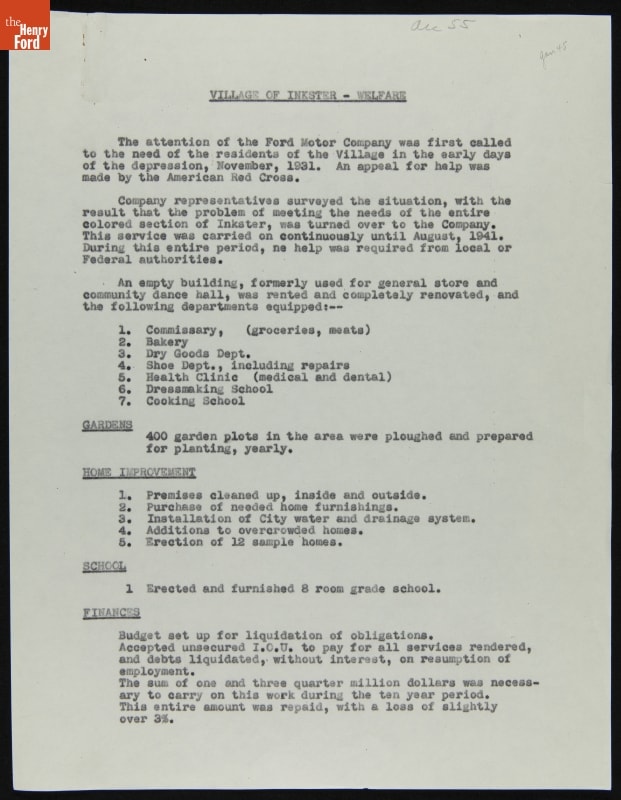

Progress report - "Village of Inkster Welfare Report, 1931-1941" - Ford Motor Company

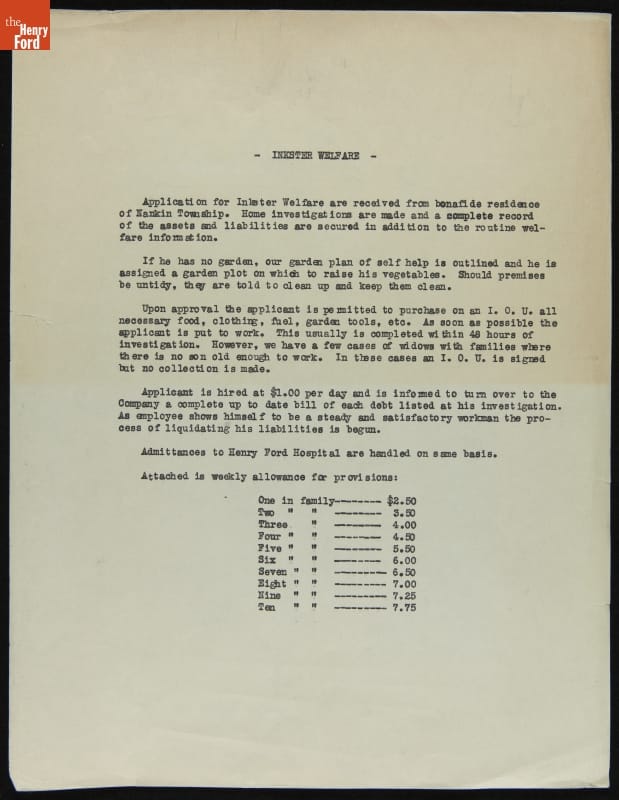

Report - "Village of Inkster Welfare Provision Report, circa 1936" - Ford Motor Company

Katherine White is Associate Curator, Digital Content, at The Henry Ford. In writing this piece, she appreciated the research and writings of Beth Tompkins Bates’ “The Making of Black Detroit in the Age of Henry Ford”, Thomas J. Sugrue’s “The Origins of the Urban Crisis; Race and Inequality in Postwar Detroit,”, and Howard O’Dell Lindsey’s dissertation, “Fields to Fords, Feds to Franchise: African American Empowerment in Inkster, Michigan.”

20th century, Michigan, labor relations, home life, Henry Ford, Ford workers, Ford Motor Company, Detroit, by Katherine White, African American history

Early Safety Innovations

What do Buster Keaton and Harold Lloyd have to do with Ford Motor Company? Well, besides the fact that Ford cars appear in a number of their films), the Ford Motor Company Safety Department. It’s strange to think of these two physical comedians as poster boys of safety, but through weekly films on safety issues the Safety Department used innovative techniques to prevent accidents by showing the right and wrong way of performing jobs and using machines and tools, often using Keaton and Lloyd films as comic examples of unsafe behavior. Safety, however, was taken very seriously at Ford and was seen as so important that early on in the 1910s the role of safety engineering and inspection was removed from the Medical Department and set up as a separate department.

Headed up by Robert Shaw, the department was established in 1914 and was responsible for machine safety, job safety, as well as hygienic safety (the full title of the department was the Safety and Hygiene Department). The first safety committee included P.E. Martin, C.E. Sorensen, C.W. Avery, the minutes stated: “it is the aim of the Safety Committee to reduce the number and serious nature of accidents. The assistance of every Ford man is needed in this work.” And assistance they got. By 1922, the department had around thirty inspectors, some general and some specialists, it also included a bacteriologist who examined areas in the factory to help stop the spread of disease, and a range of cleaners who sanitized, scrubbed, and scoured every inch of the factory to make sure the environment was as germ-free and clean for the workers as a factory could be.

Of the inspectors, some were general, and some specialized in specific areas or machines in the factory. John Wagner, who joined the department in 1922, worked on punch presses and noted when he started workers were losing an average of 16 fingers a month on press punches alone. Wagner designed several guards and safety mechanisms for machines, noting, “we never designed a guard like a pair of handcuffs that would pull men's hands back. I never approved of them. The men resented that type of guard. The sweep guard was not resented.” Shaw also noted that “we never liked harnessing a man to a machine.” Every machine in the factory was inspected and new guards or devices installed as necessary, any new machines had to be approved by the department, and they were consulted when new machines were being designed.

Shaw worked not only to fix machines that caused accidents, but also to heighten awareness of unsafe behavior and correct problems before they caused injury. Weekly safety bulletins were published, posters were posted, articles appeared in the Ford Man, and safety slogans and tips were printed on the back of each man’s timecard. Safety statistics for each department would be compiled monthly and distributed to all the departments for contests with departments competing against each other for the best safety record. The department hosted safety sessions where they showed movies, performed skits, and gave talks designed for individual departments and the safety hazards they faced. Safety rallies, parades, and picnics were hosted at different plants and branches in Detroit with the Ford Motor Company Band entertaining the crowd.

The department created safety cards for each job, which men has to read, sign, and turn in to the foreman who then carried them and used them to coach employees when they didn’t follow safety rules. Each new man was trained in safety procedures for his job before he started and was held accountable for complying with regulations. If a man was caught in violation of a safety regulation, such as running in the factory (with or without scissors), cleaning a machine while it was running, or using mushroom head tools that could catch and pull a man into a machine, they were sent up to the safety office to read through the safety bulletins and look at photos of industrial accidents from the plant. In rare cases of severe violation, a man was suspended, and if even more rarely, they were laid off for repeat safety offenses.

The pamphlet Factory Facts from Ford noted in 1917: “Safety work concerns not only the loss of fingers and injuries of this nature, but undertakes to protect the health of the men as well.” To this end the hygiene side of the department pumped in washed air “at just the right temperature for comfort and efficient work,” provided filtered and cooled water in drinking fountains that were sanitized multiple times a day, placed dust collection systems in dusty work areas, and scrubbed the floors at least once a week, boasting that cleaners swept “even the spaces which the average housewife passes over.”

Shaw extended the Ford safety program outside the company as well and was a founding member of the Detroit Industrial Safety Council. The council was composed of various Detroit area manufacturers and focused on reducing accidents through increased awareness, better machines and guards, and improving factory policies and environment.

Kathy Makas is a Reference Archivist for the Benson Ford Research Center at The Henry Ford. The Benson Ford Research Center is open Monday-Friday 9:00-5:00. Set up an appointment in our reading room or AskUs a question here.

labor relations, by Kathy Makas, Ford workers, manufacturing, Ford Motor Company

All Dolled Up for Christmas

Dressing Goodfellows dolls has been a Christmas tradition in Detroit since 1924, and the Ford Motor Company Girls’ Club was a major participant in dressing Goodfellows dolls for underprivileged children in Detroit for many years. Starting in 1946 by dressing 65 dolls, the club’s peak donation was 3,000 dresses in 1967, 1969, and 1970, and they averaged between 1,500 to 3,000 dolls most years.

The Ford Girls’ Club was started in 1946 under the Recreation Section of Ford Motor Company. Every female employee – salaried, or hourly – was automatically a member (though active membership did cost $1.00 per year). Any immediate female family member of a club member could join, as could the wives of Ford male employees. The club was primarily social, meeting once a month in addition to dinners, picnics, dances, lectures, and workshops. Members were also service oriented - they held dances for returning veterans, gave gifts and visited veterans in hospitals, and each Christmas they participated in clothing dolls for the Goodfellows to distribute, making thousands and thousands of handmade dresses over the years.

Dolls were usually handed out at the annual November service meeting. The club’s first foray into dress making was in 1946, when women of the club made 65 handmade dresses for dolls. The next year they jumped up to 290, with the dresses being displayed in the Administration Building cafeteria before being sent to the Goodfellows. As more women joined the club, interest grew in this Christmas service project and the club dressed more and more dolls each year, with their finished projects being displayed in various Ford Motor Company buildings’ lobbies, and offices, as well as the Dearborn Virginia Dare storefront window in 1949. The number of dresses made continued to climb each year reaching to almost one thousand in 1954, and the dolls were displayed for the first time at the Rotunda Christmas Fantasy. The next few years were dress-making bonanzas, and in 1957 2,500 dolls were dressed and displayed at the Rotunda for visitors to view before they were distributed to girls in the Detroit area on Christmas Eve. The Girl’s Club maintained a high production rate in the years to come - between 1,750 and 2,000 dresses were made annually and displayed at the Rotunda or Ford Motor Company buildings. In 1966 production saw another jump when the club made almost 3,000, a number they reached the next year and continued to reach or come close to for the next four years.

The handmade dresses were made of all kinds of fabric, from cotton to organdy, satin and lace. Women also knit and crocheted dresses, from wool to angora. Dolls dressed as nurses, astronauts, drum majorettes, hula dancers, Girl Scouts, flying nuns, ballerinas, and ice skaters complete with skates, graced the displays, as did brides, baby dolls, and all kinds of different ethnic dresses. Women could make any type of dress they wanted, but prizes were given by the Goodfellows, and later Ford, in specific categories:

- Bride

- Fancy dress

- Baby doll

- Character doll

- Sensible doll

- Costume

- Tailored

- Knit and crocheted

Goodfellows prizes ranged from $1 for a dress placing in a particular division to a grand prize of $10. Ford soon began judging the Girls’ Club’s work and awarding prizes as well, with the dresses usually judged by the wives of the Goodfellows’ president and executive officers. Early on prizes were cash, but when the displays headed to the Rotunda the stakes were raised. Grand prize in the 1950s and early 1960s was a sewing machine and console, second prize being a portable sewing machine, and third prize was a sewing cabinet.

The prizes, of course, were always of secondary importance in the Girls’ Club work with the Goodfellows' goal of “no child without a Christmas.” Over a 27-year period, 1946-1972, the Ford Girls’ Club donated over 45,000 hand-made dresses to the Detroit Goodfellows' organization to distribute to area children. The Ford employee newsletter The Rouge News and later Ford World carried stories and photos of the club’s donations every year, urging members of the club and others in the Ford organization to participate. We lose track of the Ford Girls’ Club here in the archive at about 1973, when Ford World ceased publishing stories on the yearly donation of dolls. However, judging from the 1972 output of 2,000 dolls, it seems likely the club continued the annual service drive for some years after.

The Goodfellows still distribute dolls and people in the metro Detroit area continue to provide dresses each year.

Kathy Makas is Reference Archivist at The Henry Ford.

Dearborn, 1970s, 1960s, 1950s, 1940s, 20th century, women's history, toys and games, philanthropy, Michigan, making, holidays, Ford workers, Ford Motor Company, Detroit, Christmas, childhood, by Kathy Makas

Remembering Richard Jeryan

The Henry Ford has lost a wonderful friend and colleague. Master Weaver Richard Jeryan passed away on June 25. Richard was an extraordinary individual— not only for his enormous professional contributions, but for his unique personal gifts that he so generously shared. Brilliant, gifted, generous, wise, and caring, Richard will be sorely missed by all who knew him.

Richard grew up in the Philadelphia area. He received a BS in Mechanical Engineering from Drexel University in 1967 and his MS in Mechanical Engineering and Heat Transfer from Massachusetts Institute of Technology in 1969.

Richard had a long and illustrious career at Ford Motor Company before coming to The Henry Ford, retiring as Senior Technical Specialist/Technical Leader in 2006 after 42 years. During his years at Ford, Richard used his vast expertise in lightweight automotive structural materials including aluminum and glass/carbon-fiber composites to research, develop, and create production applications for vehicles ranging from Ford passenger cars and trucks to Formula One race cars, America’s Cup yachts, and the 2005 Ford GT. Richard’s expertise was widely recognized among his colleagues in the field--he served first as Chairman and then on the Board of Directors of the Automotive Composites Consortium for nearly 20 years.

Richard was truly a Renaissance man—someone with wide interests and expertise in many areas. Richard always seemed to know something about everything—and sought out a wide variety of life experiences. (A little known fact: Richard had a number of non-singing roles in Michigan Opera Theatre productions, including Katisha’s beleaguered servant in a 1991 production of Gilbert and Sullivan’s The Mikado.) Perhaps most importantly for us at The Henry Ford, Richard studied, mastered, and then generously shared his knowledge of handweaving.

Richard and his wife Chris brought their weaving expertise to The Henry Ford in 2006—and a new era dawned in Greenfield Village’s Weaving Shop. Here, Richard’s mechanical engineering and weaving skills came together to transform our weaving program. Richard and Chris worked with Historic Operating Machinery’s Tim Brewer to get our historic weaving machinery working again and keep it well maintained. Richard led the team in reactivating our Jacquard loom in 2007—the 600-warp thread loom that had not run for decades—discovering along the way that Henry Ford had commissioned this Jacquard reproduction during the 1930s for the Weaving Shop and had it built by his workers. It is one of only three working Jacquard looms in North American museums.

Richard and Chris also took the lead on organizing and designing the textile projects, assisting Crafts and Trades manager Larry Watson. Improved, as well as new, items rolled off the looms as the weaving staff worked under the Jeryans’ guidance. Firestone Farmhouse received new, sturdier rag rugs for the everyday parlor; various village buildings got period correct handwoven towels for use in foodways programs and in historic kitchen installations, though most of these towels are eagerly snatched up by visitors to our Liberty Craftworks store; weaving products based on traditional coverlet weaving patterns appeared in our holiday catalog; and, soon, scarfs woven on our historic knitting machine will be offered as well. Richard often donated materials to be used for weaving, even prowling estate sales for desirable yarn.

Richard not only helped “behind the scenes” by researching, making the machinery run, designing the textile products, and teaching the staff to weave, but also frequently demonstrated weaving and interpreted our Weaving Shop stories for our visitors as well. Watching Richard present was truly memorable—his passion was contagious and he made it so clear how these stories of the past connect to our lives today. Richard often lent his expertise in coverlets and other historic woven textiles to curator Jeanine Head Miller. He provided invaluable assistance in evaluating and problem solving some of the issues we have had with the Dymaxion House. Richard and Chris were also co-chairs of our annual employee/volunteer fund drive for many years. And they did all of all of this as members of our unpaid staff. For these generous gifts of knowledge, skill, and time we are most grateful.

Richard’s knowledge of weaving and historic textiles benefited not only The Henry Ford, but other organizations as well. From 2008 to 2013, Richard served on the Board of Directors of the National Museum of the American Coverlet in Bedford, Pennsylvania. Here he did everything from strategic planning to teaching to painting the walls. More recently, Richard was elected the President of the Complex Weavers, an international guild of weavers dedicated to expanding the boundaries of handweaving and the sharing of information and innovative ideas.

There are so very many things we will always remember about Richard. Among them: his leadership, his ability to recognize and nurture hidden talent in those around him, his way of teaching and inspiring others, his keen perception and sense of humor, and his passion for The Henry Ford and its stories.

Richard Jeryan did so incredibly much in his 70 years. He was a truly extraordinary man who chose to use his talents to make the world a much better place.

You will continue to inspire us, Richard--and we will miss you.

The Henry Ford staff, Pennsylvania, Michigan, 21st century, 20th century, making, in memoriam, Greenfield Village, Ford workers, Ford Motor Company, engineering

The Ford Motor Company Medical Department

From “a bottle of liquid soap, a few bandages, and a pair of scissors” in a small wooden box by the timecards, the Ford Motor Company Medical Department grew to include over 100 physicians, assistants, and other employees. In 1914, Ford Motor Company instituted the five dollar day and with it a number of improvements to their programs for workers. One such program, was to expand and build up the Medical Department, first at Highland Park, where a 23-room state-of-the-art medical facility was built, and then expanding to the Rouge and other factories across the Ford empire. Let’s take a look at what the Medical Department looked like around 1916.

By 1916, the Medical Department included six divisions: Tuberculosis, Roentgenology, Dermatology, Dentistry, Corps. of the First Aid, and Ophthalmology, as well as various surgeons and support staff, counting over 100 people in all. It was headed up by Dr. J.E. Mead, who was assisted by Dr. N.L. Woodry, and Dr. W.R. McClure, and included ten other physicians, mainly from Detroit College of Medicine. In the twelve months before July 1917, these doctors were kept busy handling 558,869 cases including: 278,692 surgical cases, 120,309 medical cases, 5,044 minor operations, 2,473 x-rays, and 1,111 dental exams.

The Emergency Medical Hospital, situated between the Paymaster’s Office and Employment Office at Highland Park, was prepared for all manner of medical needs with x-ray machines, dressing tables and chairs for injuries to the head and “uppers;” and benches, foot rests, and tubs for “foot cases;” a well-supplied stock of pharmaceuticals; and a full operating room (as well as an additional operating room in the Blast Furnace area). There were also six first aid stations around the factory that functioned 24 hours a day manned by assistants who provided basic first aid and referred any cases such as infections, foreign bodies in the eye, or those requiring minor surgery, to the main hospital.

Any injury, no matter if it was just a scratch, was expected to be reported and had to be attended to at a first aid station, and if it warranted further attention, at the Emergency Hospital. Bulletins, posters, articles in the factory papers and Ford Times, as well as lectures, and on the job coaching alerted men to the danger of leaving an injury untreated. Images portraying infected eyes and hands alerted employees to the importance of proper medical attention. A booklet of “Helpful hints” issued to employees included medical tips such as: “All foreign bodies lodged in the eye should be removed by the doctor or first-aid man, and not by a fellow employee, because serious complications may result and probably cause blindness,” and “Do not try to lift anything beyond your strength, as you are liable to rupture yourself,” as well as “Do not wear loose-fitting or ragged clothing, as you are liable to be caught and pulled into a machine and seriously injured” (to say the least).

The Medical Department also played a large role in the hiring process and job placement of employees. Each new hire at Ford had to undergo a medical examination, and doctors determined what jobs they were physically and mentally best suited for, in 1916-17 they examined 13,055 applicants. The doctors would then turn their reports over to the employment office to process. The employment office kept detailed records of the exact physical requirements needed for jobs in the factory, and matched a new hire to a suitable job. Ford boasted that this method allowed them to hire many workers with disabilities in their factories, “there are probably 5,000 jobs at the Ford factories that do not require full physical capacity, and a surprisingly large number of these may be performed by men for whom steady work was at one time considered physically impossible.” Even workers with tuberculosis were hired and put to work, active cases in a separate “Lungers camp” on Oakland Avenue where they sorted and reclaimed scrap outside in fresh air (in line with the prevailing treatment method of the time). In fact, even when workers were convalescing in hospital they were given whatever light work was possible in the form of occupational therapy. There was also a Medical Transfer Division within the department that examined men and recommended transfers or certain adaptions to their workflow after an injury or illness.

As you can see from the above photo from Willow Run in 1942, the Medical Department continued to expand to include hospitals at the Rouge, Northern Michigan operations, and beyond. The department worked, in its own words, “solely for the aid and benefit of the employees; to see that they are in proper physical condition for their work and, if not, to do all that can be done in order that they may be in the best condition possible for the fulfillment of their duties.”

More resources on the Medical Department:

To learn even more about the Ford Medical Department, visit our Benson Ford Research Center. Its open Monday-Friday 9:30 am to 5:00 pm. You can set up an appointment in our reading room or ask us a question here.

Kathy Makas is Reference Archivist at The Henry Ford.

20th century, 1940s, 1910s, Michigan, healthcare, Ford workers, Ford Motor Company, by Kathy Makas