Posts Tagged henry ford museum

1938 Massey-Harris Model 20 Self-Propelled Combine in Henry Ford Museum of American Innovation. / THF110572

Combines loom large on the floor of Henry Ford Museum of American Innovation, but they loom even larger on the physical and historical landscape of America’s agricultural heartland. Standing high on the horizon, combines both symbolize and represent the reality of the mechanization of modern agriculture. The 1938 Massey-Harris Model 20 self-propelled combine, a designated landmark of American agricultural engineering, was the first commercially successful self-propelled combine to make its way through an American harvest.

1930s, 20th century, Henry Ford Museum, food, farms and farming, farming equipment, by Jim McCabe, agriculture

What We Wore: Shoes

From practical footwear to eye-catching fashion statements, Henry Ford Museum of American Innovation’s current What We Wore exhibit is all about shoes. On display are 30 pairs of men’s, women’s and children’s shoes dating from the 1780s to the 2000s.

Each pair offers a bit of footwear history — and, for some perhaps, a familiar style once found in their own closet!

Shoes will be on display until May 24. Here’s a peek at a few examples.

Men’s Boudoir Slippers, 1855-1860 / THF31115

Men's embroidered slippers were very popular in the mid-1800s. Ladies magazines often included embroidery patterns for house slippers that a woman might make for her husband as a gift.

Men’s Wingtip Oxfords, 1945-1955, Gift of Richard Glenn / THF370088

The low-sided oxford came into fashion for men’s footwear in the 1910s, along with wingtips (a toe cap in the shape of a bird’s wing embellished with a perforated pattern). White shoes were for summer.

Reebok Pump AXT Cross-Training Shoes, circa 1990 / THF370066

In the 1970s, athletic shoes became big business as the popularity of running and more relaxed dress codes in workplaces and schools led to a boom in the market. Manufacturers developed high-tech features designed for more support and stability. Reebok introduced the Reebok Pump in 1990, a shoe that used inflatable chambers that pumped-up for a custom fit.

Women’s Shoes, 1785-1789, Gift of American Textile History Museum / THF370062

Before shoemaking became a mechanized industry in the mid-1800s, shoes were made by hand. Amos Boardman created these silk shoes — undoubtedly for a prosperous client— in one of the many small shoemaking home-shops that flourished in late 1700s New England.

Women's Boots, 1867, Gift of Cora D. Maggini, Worn by Angeline (Anna) Duckworth when she married Rufus Larkin in Posey County, Indiana, in September 1867 / THF158262

Sandals from ancient Greece or Rome inspired these 1860s shoes — footwear designed to reveal pretty-colored silk stockings beneath!

Women’s Platform Shoes, 1945-1950, Gift of American Textile History Museum, Donated to ATHM by Sharon and Phil Ferraguto / THF370078

Introduced in the late 1930s, platform shoes remained popular through the 1940s. These eye-catching examples sport cherry red, ivory and gray reptile leather.

Women’s Glitter Jelly Sandals, circa 1990 / THF172055

Jelly shoes were a favorite among young women in the 1980s and 1990s. Made of PVC plastic, the shoes came in a rainbow of colors. Sandals were the most popular.

Girls’ Slippers, circa 1850 / THF156007

In the mid-1800s, girls wore slippers with ribbon ties for formal occasions. For everyday? Low boots.

Boys’ Boots, circa 1865 / THF156008

Children’s clothing has increasingly included images that have appeal for a child. These are an early example — Civil War-era boots with a figure of a dashing Zouave soldier.

Saddle Oxfords, 1955-1965, Gift of Randolph C. and Nancy M. Carey / THF78930

The saddle shoe, with its contrasting color leather “saddle,” is a style icon. Worn by uniformed schoolkids since the 1930s and by “bobby soxer” teens in the 1940s and 1950s, the saddle shoe has an enduring link to youth culture.

Jeanine Head Miller is curator of domestic life at The Henry Ford.

What We Wore, Henry Ford Museum, fashion, by Jeanine Head Miller, 20th century

The Hitchcock Chair: An American Innovation

Side Chair, Created by Lambert Hitchcock, 1825-1835. / THF81928

Many people believe that mass production started with Henry Ford and the Model T. But the ideas that led to this breakthrough were already being put into practice back in the early 1800s, in mills and manufactories dotting the countryside across New England.

It was there that Lambert Hitchcock applied early mass-production techniques to turn out chairs by the thousands — uniform, durable, attractive, affordable and, for a time, wildly popular.

Julia Barton Hunting of Pine Plains, New York, sat on a Hitchcock chair while posing for this portrait by Ammi Phillips, about 1830. / THF95303

Invention was in the air in New England during the early 1800s. Burgeoning industries like firearms, clocks and textiles were experimenting with new machinery — to increase production and make up for labor shortages — and with new factory arrangements that integrated materials and activities under one roof.

Furniture making had a long tradition of handcraftsmanship, and manufacturers varied in their adoption of machine production over generations-old hand processes. Handcrafted pieces were made to order, resulting in low production and fairly high costs. With water- or steam-powered machines to rough out the pieces, furniture makers could turn out more products at lower costs to sell to a wider market. Neither of these processes was right or wrong — the choice was essentially a business decision.

Lambert Hitchcock chose machine over hand production, inspired by the bustling firearms and clock industries in his home state of Connecticut. He had started out learning the craft of fine furniture making. But Hitchcock dreamed of manufacturing affordable furniture, using uniform parts that were quickly and cheaply made by machine and easy to assemble.

In 1818, Hitchcock chose a site in northwestern Connecticut where two fast-moving rivers came together. There, using the rivers’ power to operate his machinery, Hitchcock produced a line of chairs that was so affordable he basically created a brand-new market. Before long, Hitchcock’s chair factory — in the newly named village of Hitchcocks-ville — was turning out some 15,000 chairs per year.

The price, ranging from 45 cents to $1.75 (about $10.15 to $39.40 today), certainly appealed to people. Also appealing was the idea that machines could be harnessed to produce sturdy, functional chairs that everyone could enjoy. But Hitchcock did not ignore aesthetics. His characteristic stenciling across the back chair rails served as an attractive substitute to the hand carving on more expensive custom-made chairs.

In 1825, Hitchcock went one step further. He erected a three-story factory, arranged into sections, in which specific tools and materials were associated with logical steps in the assembly process. The ground floor held areas for rough-cutting work, like sawing, turning and planing. On the second floor, the chair parts were bonded together with glue, then dried in a kiln until their joints were firm. On the third floor, the chairs were painted and decorated, using precut stencils and prearranged patterns. Each of these stencils, designed to create a different part of the overall composition, was positioned on the chair back, then carefully rubbed with bronze powders to achieve the special tone and shading.

Lambert Hitchcock’s innovative factory in Hitchcocks-ville (now Riverton), Connecticut, as depicted in a 1955 Hitchcock Chair Company trade catalog. / Detail, THF626707

Professional male stencilers probably cut the stencils and lent their expertise, but women did much of the actual stenciling at Hitchcock’s factory. Many had learned this skill as young women at female academies that were popular in New England at the time. There they practiced the art of theorem painting — that is, creating stylized pictures of fruits and flowers that similarly used precut stencils, metallic powders and prearranged patterns.

An example of a theorem painting, created in 1835 by Caroline Bennett, a young woman who would have attended a female academy. / THF119757

Women also worked as seat rushers and caners, while children often did the painting and striping. At its peak of production in the late 1820s and early 1830s, Hitchcock employed over 100 workers.

Lambert Hitchcock was innovative in his manufacturing techniques: integrated work processes, division of labor, and application of fast and inexpensive, yet still attractive, decorative techniques. Hitchcock was also an assertive salesman, opening retail stores in Hitchcocks-ville and Hartford (the state capital), selling chairs wholesale to dealers and store owners and distributing his chairs far and wide through the network of itinerant Yankee peddlers.

Unfortunately, Lambert Hitchcock also made some costly mistakes. He located his factory in a very isolated area, with deplorable roads to Hartford and other markets. In 1844, Hitchcock moved his factory to a town called Unionville, banking on the construction of a new canal. But, alas, the canal construction was halted, and a new railroad bypassed the town. For his tremendous contributions, Hitchcock died at the age of 57 with few assets to his name.

But Hitchcock’s name and his chairs lived on. The chairs were so popular during their heyday that many competitors tried to imitate both their aesthetics and production techniques. To this day, chairs of this general style are referred to as Hitchcock (or Hitchcock-type) chairs. Hitchcock chairs were also painstakingly reproduced by succeeding generations of artisans, a tribute to the genius and foresight of Lambert Hitchcock, a true American innovator.

Generations of artisans continued producing Hitchcock chairs and a range of other furniture, as shown in this 1955 brochure. / THF626710

Donna R. Braden is senior curator and curator of public life at The Henry Ford. This post originally ran in March 2008 as part of our Pic of the Month series.

Additional Readings:

- Made in America: Manufacturing

- The Changing Nature of Sewing

- The Henry Ford’s Ingersoll Milling Machine and Mass Production at Highland Park

- Build a Model T: Make, Build, Engineer

decorative arts, Connecticut, 1830s, 1820s, 1810s, 19th century, manufacturing, home life, Henry Ford Museum, furnishings, entrepreneurship, by Donna R. Braden

Ferris Bueller’s Faux Ferrari: A Replica with Real History

Like an actor cast in a role, this 1985 Modena Spyder California was chosen to play the part of a Ferrari 250 GT California Spyder in the movie Ferris Bueller’s Day Off. / Photo by Matt Anderson

For those who haven’t visited Henry Ford Museum of American Innovation in recent months, we have a wonderful new display space created in partnership with the Hagerty Drivers Foundation. Each year, we’ll share a couple of significant automobiles included on the foundation’s National Historic Vehicle Register. The (currently) 32 vehicles on the register each made a lasting mark on American history—whether through influence on design or engineering, success on the race track, participation in larger national stories, or starring roles on the silver screen.

Our first display vehicle is Hollywood through and through. It’s a “1961 Ferrari 250 GT California Spyder” (those quotes are intentional) used in the 1986 Gen-X classic Ferris Bueller’s Day Off. Those who’ve seen the film know that the car is a crucial part of the plot—ferrying Ferris, Sloane Peterson, and Cameron Frye around Chicago; threatening to expose their secret skip day; and forcing a difficult conversation between Cameron and his emotionally distant father.

In true movie fashion, though, not all is what it appears to be.

This 1958 Ferrari 250 GT California is the real thing, as featured in Henry Ford Museum’s Sports Cars in Review exhibit in 1965. / THF139028

The Ferrari 250 is among the most desirable collector cars in the world. GT street versions sell at auction for millions of dollars. And GTO competition variants—well, the sky’s the limit. Even in the mid-1980s, these autos were too pricey for film work—particularly when the plot calls for the car to be (spoiler alert) destroyed. Instead, Ferris Bueller director John Hughes commissioned three replicas for the shoot: two functional cars used for most scenes, and a non-runner destined to fly out the back of Mr. Frye’s suburban Chicago garage.

Replica cars were nothing new in the 1980s. For years, enterprising manufacturers had been offering copies of collector cars that were no longer in production and too expensive for most enthusiasts. The coveted Duesenberg Model J is a prime example, having been copied by replica manufacturers for decades. Some replica cars were more about convenience than cost. Glassic Industries of West Palm Beach, Florida, produced fiberglass-bodied copies of the Ford Model A with available niceties like automatic transmissions and tape decks. Occasionally, the line between “real” and “replica” got blurry. Continuation cars like the Avanti II (based on Studebaker’s original) or post-1960s Shelby Cobras (based on Carroll Shelby’s racing sports cars) were sometimes built with formal permission or participation from the original automakers.

So, if the Ferris Bueller car at The Henry Ford isn’t a real Ferrari, then what is it?

The replica’s builder, Modena Design & Development, was founded in the early 1980s by Californians Neil Glassmoyer and Mark Goyette. When John Hughes read about Modena in a car magazine, he called the firm. As the story goes, Glassmoyer initially hung up on the famous writer/director—believing that it had to be a prank. Hughes phoned again, and Modena found itself with a desirable movie commission. Paramount Pictures, the studio behind Ferris Bueller, leased one car and bought two others.

The Modena replicas featured steel-tube frames and Ferrari-inspired design cues like hood scoops, fender vents, and raked windshields. While the genuine Ferrari bodies used a blend of steel and aluminum components, Modena’s bodies were formed from fiberglass—purportedly based on a British MG body and then fine-tuned for a more Ferrari-like appearance.

The replica Ferrari’s V-8 was sourced from a 1974 Ford Torino, not too different from these 1973 models. / THF232097

The most obvious differences were under the cars’ skin. Rather than a 180-cubic-inch Ferrari V-12, the Modena at The Henry Ford features a 302-cubic-inch Ford V-8 (originally sourced from a 1974 Ford Torino). While the Ford engine was rated at 135 horsepower from the factory, this one has been rebuilt and refined—surely capable of greater output now. And instead of the original Ferrari’s four-speed manual gearbox, the Modena has a Ford-built three-speed automatic transmission. (According to lore, actor Matthew Broderick wasn’t comfortable driving a manual.)

After filming wrapped, the leased car was sent back to Modena’s El Cajon, California, facility. After some work to repair damage from a stunt scene, the car was sold to the first in a series of private owners. By 2003, this beloved piece of faux Italiana/genuine Americana had been relocated to the United Kingdom. The current owner purchased it at auction in 2010 and repatriated the car to the United States. The Modena was much modified over the years, so the current owner had it carefully restored and returned to its on-screen appearance—as you see it today.

Imitation can be the sincerest form of flattery, but it can also be the quickest route to a lawsuit. Following the release of Ferris Bueller’s Day Off, Ferrari sued Modena Design & Development (along with other replica builders). The matter was settled out of court when Modena agreed to make some minor changes per the Italian automaker’s specifications. Replica production then resumed for a few more years.

The Modena Spyder California may not be a real Ferrari, but it’s certainly a real pop-culture icon. That’s reason enough to include it on the National Historic Vehicle Register, and to celebrate it at The Henry Ford.

Matt Anderson is Curator of Transportation at The Henry Ford.

Henry Ford Museum, Europe, 1980s, 20th century, Illinois, California, by Matt Anderson, popular culture, movies, cars

Bonnie Cashin: Innovative and Influential

Our latest installation of What We Wore: Bonnie Cashin. / THF191461

The current What We Wore exhibit in Henry Ford Museum of American Innovation features clothing by Bonnie Cashin. American designer Bonnie Cashin’s ideas, radical when introduced, have become timeless.

Who was Bonnie Cashin? An inscription in her senior yearbook provided a hint of things to come: “To a kid with spark—may you set the world on fire.” She did. By the 1950s, Cashin had become “a mother of American sportswear” and one of the most influential fashion designers of the 20th century.

Born in 1908 in California, Bonnie Cashin apprenticed in her mother’s custom dress shop. At 16, she began designing chorus costumes for a Hollywood theater. Next stop—the Roxy Theatre in New York City, where the 25-year-old was the sole designer. The street clothes Cashin designed for a fashion-themed revue led to a job at the prestigious ready-to-wear firm Adler & Adler in 1937. Cashin left for California in 1943, where she spent six years at 20th Century Fox, designing costumes for approximately 60 films.

Cashin’s designs for the 1944 movie Laura were the most influential of her 20th Century Fox creations. Motion pictures of the 1940s tended to showcase female stars as wealthy and glamorous women. Cashin’s designs for actress Gene Tierney suggested clothing chosen by the character of Laura herself, rather than costumes worn for an actress’s role. A revolutionary concept for the time, the garments reflected Cashin's real-life views. / THF700871

Cashin and actress Olivia de Haviland look over costumes created for the motion picture The Snake Pit in 1948. / THF703254

In 1949, back in New York, Cashin created her first ready-to-wear collection under her own name. Cashin designed for “the woman who is always on the go, who is doing something.” She introduced the concept of layering, with each piece designed to work in an ensemble, alone, and in different combinations. The fashion world took notice. In 1950, Cashin won both the prestigious Coty American Fashion Critics’ Award and the Neiman Marcus Fashion Award.

This 1952 ad dates from the year Bonnie Cashin opened her own design studio. It captures the spirit of Cashin’s intended customers—women always on the go. / THF701655

In 1952, Cashin opened her own one-woman firm, Bonnie Cashin Designs. Cashin insisted on total creative control as she worked with the manufacturers who produced her designs. Cashin chose craftsmanship over commercial success. She never wavered in her artistic vision—functional simplicity and elegant solutions.

Jacket (Wool, Brown Leather Binding, Brass Toggle Closures), 1965–1970, Designed by Bonnie Cashin and Made by Philip Sills & Co., New York City. / THF188918

Trousers (Suede), 1955–1960, Designed by Bonnie Cashin and Made by Philip Sills & Co., New York City. / THF188947

Many Cashin designs were practical solutions to problems she herself experienced. Her tailored poncho was born after she cut a hole in a blanket to cope with temperature fluctuations while driving her convertible through the Hollywood Hills.

Coat (Mohair, Suede Bindings, Brass Clip Closure), 1955–1964, Designed by Bonnie Cashin and Made by Philip Sills & Co., New York City. / THF188928

Sweater (Cashmere, Brass Buttons), 1955–1964, Designed by Bonnie Cashin, New York City, and Made by Ballantyne, Innerleithen and Peebles, Scotland. / THF188908

Trousers (Leather, Brass Toggle Closures), 1965–1970, Designed by Bonnie Cashin and Made by Philip Sills & Co., New York City. / THF188945

Cashin is most well-known for her innovative use of leather, mohair, suede, knits, and nubby fabric, as well as heavy hardware used as fastenings. Cashin had a deep love of color and texture—she personally selected, designed, or commissioned her fabrics.

In this 1972 ad for Singer sewing machines, examples of Bonnie Cashin’s favored textiles—suede, leather, knits, and nubby tweeds—appear on the shelves behind her. / THF700873

Traveling widely during her career, Cashin closely studied the traditional clothing of other cultures. Her international focus and attention to refining traditional shapes down to their most modern and mobile forms led to her distinctive “Cashin Look.”

Jacket (Mohair Bouclé, Leather Bindings, Brass Sweater Guard Closure), about 1965, Designed by Bonnie Cashin and Made by Philip Sills & Co., New York City; Fabric Made by Bernat Klein, Galashiels, Scotland. / THF188913

Bonnie Cashin created dazzling costumes for the stage and screen—then excelled at exquisite minimalism in her sportwear. The intersection? Cashin’s garments always moved with the wearer and were designed to be set against a backdrop—whether a theatrical scene or contemporary life.

Coat (Wool, Leather Binding), 1965–1972, Designed by Bonnie Cashin and Made by Philip Sills & Co., New York City. / THF188933

Trousers (Leather, Brass Toggle Closures), 1965–1972, Designed by Bonnie Cashin and Made by Philip Sills & Co., New York City. / THF188943

Jacket (Leather, Brass Toggle Closures), 1965–1972, Designed by Bonnie Cashin and Made by Philip Sills & Co., New York City. / THF188938

Innovative and influential, Cashin continued to design until 1985. Following her death in 2000, among the handwritten notes jotted on scraps of paper in her apartment was one that read, “How nice for one voice to ignite the imaginations of others.”

Jeanine Head Miller is Curator of Domestic Life at The Henry Ford.

20th century, California, New York, women's history, What We Wore, movies, making, Henry Ford Museum, fashion, entrepreneurship, design, by Jeanine Head Miller

Behind Every Object Is a Story

The author at his desk at The Henry Ford. / Photo by Jeanine Head Miller

I grew up on Detroit’s far west side, just north of Dearborn, during the 1950s and 1960s. History was always my favorite subject, and I fondly remember school field trips to what was then called Henry Ford Museum and Greenfield Village. I can trace my interest in American history to those visits and remember thinking how great it would be to work there someday.

I graduated from the University of Michigan at Ann Arbor in 1975 with a bachelor's degree in history. My original intention was to become a history teacher, but with teaching positions few and far between in those days, I ended up accepting a position in the mortgage department of Comerica Bank and stayed there for nearly 30 years.

I retired in 2008 and became a volunteer at The Henry Ford. After three years of doing computer data entry in the marketing department and helping at special events like Maker Faire, Old Car Festival, and Motor Muster, I met Jeanine Head Miller, Curator of Domestic Life at The Henry Ford. Jeanie was looking for a volunteer curatorial research assistant to work with her in the Historical Resources department. She was willing to take a chance on me, even though my professional life had been spent in banking, not historical research. The learning curve was steep, but with Jeanie’s knowledge and patience, I learned the ropes.

My primary focus as a volunteer has been to research the lives of some of the people who owned, made, or used the objects in The Henry Ford’s collection. Most of them were ordinary people, using these objects as part of their everyday activities.

Uncovering People’s Stories

I first look for clues in the object’s accession file—a file that contains whatever information we know about the object. Sometimes I find letters from the donor, often a descendent of the original owner, providing some family history and information about the maker or owner of the object, or how it may have been used. More often, though, there may be only a few clues—a name or a place. From these clues, I start my search to learn more about the background of the individual or family and the context of the object.

The advent of the Internet and genealogy websites like Ancestry.com—with access to census records, city directories, birth and death records, and other information—make researching the life of someone born more than a hundred years ago much easier. The census records are a particularly valuable tool in my research. They provide information about a person’s occupation, age, place of birth, marital status, immigration status, place of residence, home ownership, and more. The census also lists all the people living in the same home and their relationship to the head of the household.

Sites like Newspapers.com, with its access to many newspapers nationwide, can provide a wealth of information. I often find marriage and birth announcements, obituaries, and other information. Local historical societies are also a great research resource. I encounter other dedicated volunteers willing to search local records for information on people I am searching for—information not available online.

Conrad Hoffman’s Violin

Violin used by Conrad Ambrose Hoffman, 1793. / THF180694

A few years ago, The Henry Ford acquired a violin used by Conrad Ambrose Hoffman (1839–1916), a musician and teacher from Pontiac, Michigan. The violin had been made in 1793 by Czech violin maker Johann Michael Willer (1753–1826). The family not only donated Hoffman’s violin and bow, but also related archival materials, including concert programs, sheet music and librettos, calling cards, and stationery.

These materials helped provide some information about Hoffman. But further research in sources like Ancestry.com, Newspapers.com, and the Palmer Family Papers: 1853–1940 at University of Michigan’s Bentley Historical Library helped me enrich Hoffman’s story.

The United States census records for Conrad Hoffman revealed that he was born in New York in 1839, but moved to Oakland County, Michigan, with his family by 1840. His father, Ambrose D. Hoffman (1806–1881), made his living as a farmer and cooper. The 1870 census revealed that 31-year-old Hoffman was employed as a music teacher and was living at the family home in Pontiac, Michigan, with his parents and two sisters.

Most of the information I discovered about Hoffman’s life as a musician and teacher came from a biography that I found on Google Books, Biographical Sketches of Leading Citizens of Oakland County, Michigan, published in 1903. The account recalled Hoffman’s early interest in music, the musical abilities of his mother and sisters, and his study of the violin as a young boy—including his traveling to Dresden, Germany, to study music at the Dresden Conservatorium.

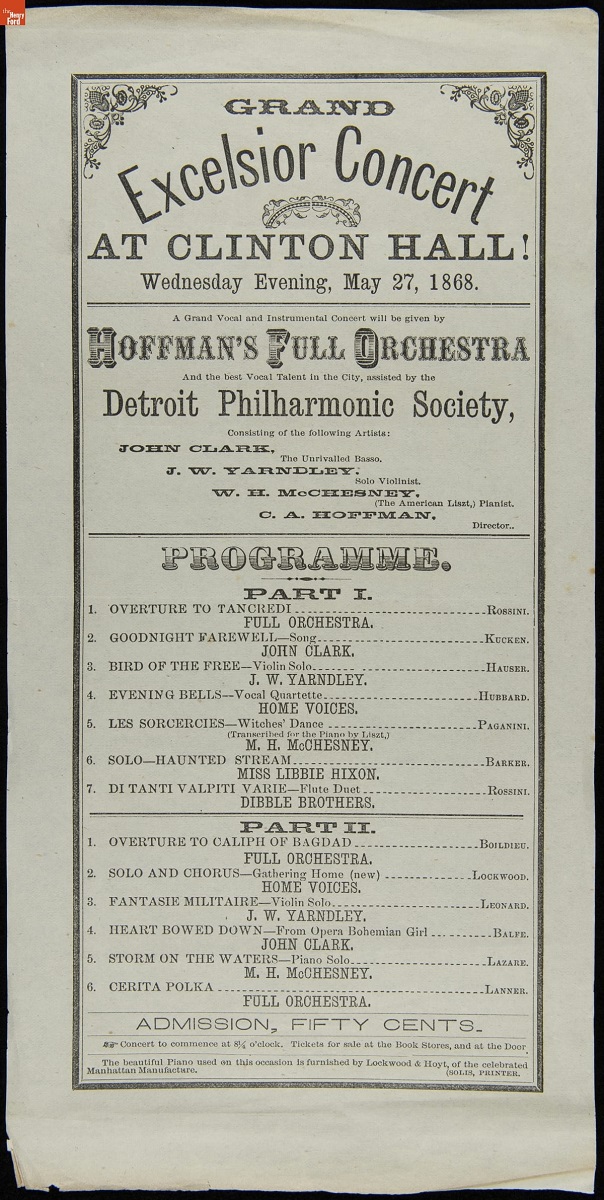

Hoffman and his orchestra performed at Clinton Hall in Pontiac, Michigan, on May 27, 1868. / THF279100

Hoffman’s biography also revealed that he served in the Union Army during the Civil War as a musician with the 15th Michigan Volunteer Infantry. In the years following the war, Hoffman organized an orchestra in the Pontiac area.

Conrad Hoffman performed at this concert at the Music Hall in Holly, Michigan, on May 24, 1866. / THF279106

Concert programs from the 1860s and 1870s document Hoffman’s performances in places like Birmingham, Holly, and Pontiac, Michigan. He performed as a solo violinist, as well as a conductor.

I discovered through a marriage announcement, published in the Detroit Free Press on September 25, 1900, that Conrad Hoffman married for the first time at the age of 60. His bride was childhood friend and pianist Philomela Cowles Palmer (1851–1930). Philomela was the daughter of Charles Henry Palmer (1814–1887) of Pontiac, an entrepreneur who was instrumental in helping develop Michigan’s copper industry.

Conrad Hoffman died in 1916. His obituary, found on Newspapers.com, was published in the Detroit Free Press on December 9, 1916. The obituary described Mr. Hoffman as a well-known violinist, the owner of a collection of old violins, and the instructor of several of the best-known Michigan violinists and violin teachers.

Audrey Wilder’s Dress

Audrey Wilder’s blue 1920s dress is second from the right.

In the fall of 2019, Jeanie Miller asked me to find out what I could about the life of Audrey Kenyon Wilder (1896–1979) of Albion, Michigan. Jeanie planned to use Wilder’s 1920s dress for an exhibit called What We Wore: A Matter of Emphasis in Henry Ford Museum of American Innovation. My task was to find out as much as I could about Wilder to help tell the story of the dress and the woman who wore it.

The donor correspondence in the accession file for Wilder’s dress provided just a few clues—her name and place of residence. I guessed Audrey Wilder’s birth date would be about 1900, based on the age of the dress. I was able to find four-year-old Wilder in the 1900 U.S. Census, living with her parents at the home of her paternal grandparents in Albion, Michigan. Her father was the owner of a lumber yard in Albion.

Yearbooks from high schools and colleges, which I found on Ancestry.com, provided information about Wilder’s education and career. I learned that she graduated from Albion High School in 1914, Albion College in 1918, and earned a master's degree from Columbia University in 1921. Wilder began teaching English at Albion College that same year.

In 1928, Audrey Wilder left Albion College to serve as Dean of Women at Ohio Northern University in Ada, Ohio. I was able to find an article written about her on Google Books, which shed some light on Audrey’s life and activities during this period of her life. The November 1935 issue of her college sorority newsletter, Anchora of Delta Gamma, published a story about Audrey’s life and career, entitled “Audrey Kenyon Wilder, Ohio Northern’s Dynamic Dean.” She is described as a woman “of exquisite grooming” and as having established the first social hall for women on the Ohio Northern campus, providing a setting for the female students on campus to hold teas, receptions, and co-ed dinners.

Dress owned by Audrey Wilder, 1927–1929 / THF177877

Tying an object to the story of its owner is the goal of my research. It is not hard to imagine Audrey Kenyon Wilder, the dynamic dean of exquisite grooming, attending a campus social function wearing the dress which is now part of the collection at The Henry Ford.

“Shopping” for the Collection

At times, I have assisted the curatorial staff in locating items for the museum’s collection. The curators identify a desired object and I then search eBay and other Internet sites to try to locate one in good condition. I then show the possibilities to the curator or curators, who select and acquire the object. These Internet sites make the search easier, but it often requires patient searching—sometimes for months.

Amelia Earhart brand overnight case made by the Orenstein Trunk Company, 1943–1950. / THF169109

One example is an Amelia Earhart brand suitcase. Earhart endorsed various products, including a line of luggage, in order to finance her aviation activities. I searched for six months and found one in like-new condition with the original price tag and keys! Though this example dates from the decade following Earhart’s disappearance, it attests to the staying power of the Earhart brand—this luggage line sold well for decades. This suitcase is on display in the museum’s Heroes of the Sky exhibit, in the section dedicated to Amelia Earhart.

I could not have asked for a more rewarding and interesting way to spend some of my time during my retirement years. I was finally able to find that “job” that I thoroughly enjoy and never get tired of. With millions of artifacts in the collection at The Henry Ford, there is always another life to explore and, for me, another adventure.

Gil Gallagher is Curatorial Research Volunteer at The Henry Ford.

Heroes of the Sky, women's history, Henry Ford Museum, What We Wore, fashion, Michigan, music, musical instruments, violins, The Henry Ford staff, #Behind The Scenes @ The Henry Ford, by Gil Gallagher, research

Hallmark Keepsake Ornaments: Curator Q&A

We are quickly drawing closer to the November 20 opening of our newest permanent exhibit in Henry Ford Museum of American Innovation: Miniature Moments: A Journey Through Hallmark® Keepsake Ornaments. With just a few weeks to go, we checked in with Jeanine Head Miller, Curator of Domestic Life, and Donna R. Braden, Senior Curator and Curator of Public Life, to collect their thoughts on our collection of nearly 7,000 Hallmark Keepsake Ornaments. Check out their answers below.

What is the oldest Hallmark Keepsake Ornament in The Henry Ford’s collection?

One of Hallmark’s first ornaments from 1973, designed by artist Betsey Clark. / THF178137

Jeanine Head Miller (JHM): The ornaments in this collection date back to the first year that Hallmark produced Christmas ornaments—1973. That year, the company offered six decorated ball ornaments and twelve yarn ornaments. While the shape of Hallmark’s ball ornaments was traditional, the artwork, printed on a plastic sleeve and then heat-shrunk to the ornament, was an innovation. Hallmark’s simple yarn figures evoked nostalgic visions of Christmases long ago—the years leading up to America’s American Revolution Bicentennial celebration saw an increased interest in “early American” traditions.

Hallmark’s 1973 yarn ornament series included this colorful toy soldier. / THF177677

What is the newest Hallmark Keepsake Ornament in The Henry Ford’s collection?

JHM: The newest ornaments are the 269 made in 2009. (Yes—the number of ornaments released by Hallmark each year has grown!) These later ornaments reflect the increasing complexity of Hallmark’s designs. The vast majority of the company’s ornaments by this time were figurals (shapes that represent objects), with many being highly detailed. Ornaments sporting traditional Christmas themes were joined by an ever-evolving array of popular culture and technology-themed decorations. Customers appreciated the way that Hallmark’s designs helped them “personalize” their tree—a growing trend in Christmas tree decorating—using ornaments that reflected their own interests and experiences.

Hallmark’s 2009 "Ralphie's Pink Nightmare" ornament from the movie A Christmas Story depicts an unhappy Ralphie dressed in Aunt Clara’s pink bunny suit gift. / THF177263

Hallmark’s 2009 "Wired for Fun" teenage reindeer multitasks as he entertains himself with up-to-date digital technology—an MP3 player and a wireless video game. / THF358063

For the passionate culinary wizard, Hallmark’s 2009 "Snow Much Fun to Cook" ornament. / THF357697

What is the most common Hallmark Keepsake Ornament in The Henry Ford’s collection?

Donna R. Braden (DRB): This is a bit of a difficult question to answer. There is no easily available information on ornaments that were either produced or purchased in the greatest quantities, or those that are the easiest to find today. However, we might assume that those might align with the categories of ornaments that tend to be produced in the greatest number and variety. This varies over the years, but today—according to the 2022 Dream Book (and probably characteristic of the more recent years of our collection)—they are ornaments with classic Christmas themes, series favorites, Disney ornaments, meaningful moments and milestones, and popular culture characters, including Star Wars, Star Trek, superheroes, Harry Potter, toys, Peanuts, and Barbie.

What is the rarest Hallmark Keepsake Ornament in The Henry Ford’s collection?

DRB: Again, this is difficult to pin down. Lots of eBay listings for Hallmark Keepsake Ornaments say “extremely rare,” but these don’t necessarily cost a lot of money. Rarity can be based on the look, the artist, the date, the number in the series (especially firsts), and the popularity of the topic. Five rare ornaments I’ve seen listed follow below. The 1973 Betsey Clark ornament Jeanie notes as one of the earliest in our collection also seems to be rare.

"Mary's Angels Series: Buttercup,” 1988, is the first in its series. / THF182250

“Santa's Motorcar,” 1979, is the first in the Here Comes Santa series. / THF176990

"Tin Locomotive,” from 1982, is also rare. / THF177179

Another rare listing is “Miss Piggy” from 1983. / THF177327

"Starship Enterprise" is rare, even though it’s less than 40 years old. / THF177369

What is the largest Hallmark Keepsake Ornament in The Henry Ford’s collection?

JHM: Over the years, many Hallmark ornaments have grown in size—some five inches high or more—and complexity, adding narrative embellishment through visual detail, light, motion, and sound effects. Some—designed to be displayed on a flat surface—are more like figurines.

This large 2006 “Letters to Santa” ornament—about 5 ½ inches high and made to be hung on the tree—not only brims with charming detail, it offers motion and sound features. Pulling the bell below this battery-powered ornament causes several toys around Santa’s desk spring to life, as eight humorous recordings of children reading their letters to Santa are heard. / THF362217

This 1994 “Beatles Gift Set,” four inches high, commemorates the 30th anniversary of the Beatles’ 1964 appearance on the Ed Sullivan Show—one of the first times Hallmark Keepsake Ornaments had attempted likenesses of real people. / THF352350

The 2002 scene “The Family Room”—five inches high—was a group effort, with details of this homey design contributed by 19 Hallmark artists. / THF362466

What is the most valuable Hallmark Keepsake Ornament in The Henry Ford’s collection?

DRB: This is difficult to pin down, as it varies by changing collectability over the years—and The Henry Ford doesn’t collect based on monetary value, but instead on historical significance. However, the one ornament that shows up over and over is a 2009 ornament representing Cousin Eddie’s RV from the movie National Lampoon's Christmas Vacation.

Hallmark "National Lampoon's Christmas Vacation: Cousin Eddie's RV" Christmas Ornament, 2009. / THF361864

What is your favorite Hallmark Keepsake Ornament in The Henry Ford’s collection?

JHM: Hmmm… while I admit being partial to Hallmark’s small buildings, my favorite ornament—if I had to choose just one—is "Christmas Cookies!" from 2004. Why do I love it? This tiny stove with its charming cooking-making details immediately immerses me into happy childhood memories of baking Christmas cookies with my mother and sisters. A few years ago, my husband located one of these nearly 20-year-old ornaments online and gave it to me as a Christmas gift.

Hallmark’s "Christmas Cookies!" ornament, 2004. The lights inside the oven glow, and a fragrance insert emits the sweet scent of cookies “baking.” / THF177744

DRB: “Baby’s First Christmas,” from 1990, is my favorite ornament for personal reasons. My daughter Caroline was born that year. We were not big Hallmark ornament purchasers yet (that mushroomed later), but we saw this and it really “spoke” to us as a perfect symbol of this important milestone in our lives. We imagined being able to relive the memories of that milestone every year. And we do! More than 30 years later, it still occupies a prominent place on our Christmas tree every year.

Baby’s First Christmas, 1990. / THF177026

Jeanine Head Miller is Curator of Domestic Life at The Henry Ford, Donna R. Braden is Senior Curator and Curator of Public Life at The Henry Ford, and Ellice Engdahl is Digital Collections & Content Manager at The Henry Ford.

Additional Readings:

- Miniature Moments: A Journey Through Hallmark® Keepsake Ornaments

- Hallmark "Our Family Photo Holder" Christmas Ornament, 2006

- Through the Years with Hallmark Ornaments

- Digitizing Our Collection of Hallmark Keepsake Ornaments: A Collection Management Perspective

2000s, 21st century, 1990s, 1980s, 1970s, 20th century, popular culture, Miniature Moments, home life, holidays, Henry Ford Museum, Hallmark, Christmas, by Jeanine Head Miller, by Ellice Engdahl, by Donna R. Braden

A Horse-Drawn Recycler: The Manure Spreader

International Harvester Manure Spreader, circa 1905 / THF89810

The act of farming draws nutrients from the soil. If the nutrients are not returned, the soil will become depleted and lose productivity. One of the best ways to restore the soil is to recycle what was removed from it by spreading manure. Manure spreaders made this dirty job not-so-dirty.

Caring for the Land: Forgotten—Then Rediscovered

To Europeans living in the American colonies, the availability of land in North America seemed limitless. Farmers paid little attention to caring for the soil, quickly abandoning the fertilizing activities they had practiced in Europe. These farmers felt it more cost effective to simply move on to new land when the soil lost productivity, rather than put in the effort to restore its fertility.

By the 1800s, this strategy had begun to run its course. As land went fallow—first in the east, and later in the Midwest and plains—American farmers had to rediscover the soil stewardship practices they had lost generations earlier. Since much of the grain grown on a farm is fed to livestock, farmers began to gather up barnyard manure from cows, horses, pigs, and other animals and spread it on their fields to restore the soil’s fertility.

This short-handled manure fork (dated 1875-1890) could be used in a stall, wagon, or other confined area. / THF173108

The Dirtiest of the Dirty Jobs

Spreading manure is one of the most unpleasant and labor-intensive jobs on a farm. It requires a lot of effort and a strong constitution to scoop up raw manure and straw bedding from the barnyard and stalls into a wagon, and then fork it out evenly over many acres of fields. David C. Voorhees, a farmer in Somerset, New Jersey, wrote in his diary of spreading 215 loads of manure in September 1875 following the harvest. Spreading manure needs to be done properly to be effective. Too much manure in one spot can “burn” the soil, so clumps need to be broken up before they are tossed on the field.

If ever there was a farm task that was ripe for mechanization, it was spreading manure. Throughout the 1800s, dozens upon dozens of patents were issued for manure spreaders. By the 1870s, the design of manure spreaders had been sufficiently refined, and the manufacturing process had developed enough to make manure spreaders both effective and affordable.

This pamphlet for a Kemp & Burpee Manufacturing Co. manure spreader described its operation and included many testimonials. The company was absorbed by International Harvester in 1906. / THF125272

How to Make the Manure Fly

The more successful manure spreaders had two key design features: a continuously moving apron, or floor, which automatically moved manure toward the back of the wagon to be spread; and a beater at the back of the spreader to pulverize manure and spread it evenly across the field. With a good manure spreader, one person could do the work of five or more—and those other people were surely happy to do some other job.

The beater on this circa 1905 manure spreader broke the manure up into small pieces and spread it evenly on the field. / THF89816

A Remarkable Survivor

If spreading manure was hard on farmers, it was even harder on farm equipment, since manure rapidly corrodes and rots manure spreader parts. Consequently, early manure spreaders rarely survived to be passed on to the next generation, much less make it into a museum.

The Henry Ford’s circa 1905 International Harvester manure spreader is one of these very rare survivors. It is all the more extraordinary because it retains its original paint and parts. It is an excellent example of the prevailing manure spreader design of the early 1900s.

A Sustainability Hero

In many ways, farm practices can work against nature. The manure spreader is a great example of a tool that helped farmers reestablish the natural cycle by recycling the bounty of the soil back into the soil. The manure spreader does the dirtiest job on the farm—but it is a key part of making farming a sustainable undertaking.

Jim McCabe is former Collections Manager/Acting Curator of Agriculture and the Environment at The Henry Ford.

Additional Readings:

- 1975 Sperry-New Holland Combine

- Horse Power

- Getting Seeds in the Ground: Urgent Business

- Mechanizing the Tomato Harvest

Henry Ford Museum, horse drawn transport, environmentalism, farms and farming, farming equipment, agriculture, by Jim McCabe

Barney Korn: Tether Car Craftsman

Barney Korn’s work is featured in The Henry Ford’s exhibit Driven to Win: Racing in America. / Photo by Matt Anderson

In the 1930s and 1940s, race fans who didn’t have the budget or the bravery for full-size auto racing could find big thrills in small scale through the world of tether cars. These gas-powered model cars were raced by adults in organized competition. The models either raced against the clock, running in circles while tethered to a pole, or they raced against each other on a scaled-down board track fitted with guide rails.

The fastest tether cars topped 100 miles per hour—real miles, not scale miles—which explains another name given to them: spindizzies. (Imagine watching a little car zooming around a pole and the name makes perfect sense.) Though they look like toys, these models could be expensive. By the time you bought the car, the engine, the tools, and the accessories, you could be looking at more than $100—at a time when you could by a Ford DeLuxe Convertible for well under $1,000. At the hobby’s peak, some 25 major manufacturers and hundreds of individual builders produced tether cars. But few makers matched the skill and craftsmanship of Barney Korn.

Barney Korn’s skill was apparent from his high school days, as when he built this working engine in shop class. / THF160779

Bernard Barney Korn was born in Los Angles on April 24, 1903. He showed his modeling talents at an early age, building an elaborate water-cooled model engine as a project for his high school shop class. After high school, Korn honed his skills in part by working as a machinist for aviation innovator Howard Hughes, whom he joined in 1924.

One of Barney Korn’s “Indianapolis” models, with the hood removed to expose the single-cylinder gas engine. / THF157084

As tether cars became more popular, Barney Korn joined the booming business and formed B.B. Korn Specialty Manufacturing Company in 1939. His first production model, the “Meteor,” was also his rarest. Only 18 examples are known to have been made. The following year, Korn began production of his best-known and, many would say, best-looking model: the “Indianapolis.” Based on real Indianapolis 500 race cars of the time, Korn’s “Indianapolis” was handsome and well proportioned. It was a big model, with an overall length over 20 inches. Many were also exceptionally detailed. The “Liberty Special” car even had a working compass in its dashboard! But the “Indianapolis” was rare too. It’s believed that Korn produced fewer than 70 examples in total. Most featured rear-wheel drive trains and aluminum bodies, though a few had lightweight magnesium bodies. When materials were restricted during World War II, Korn mixed and matched aluminum and magnesium components as needed.

Korn’s working dynamometer measured engine performance in his model cars. / THF159749

Barney Korn used precision tools, molds, and patterns to build his model cars. In a particularly impressive feat, Korn even built a working dynamometer to test his cars’ performance. Like full-size dynamometers, Korn’s version was basically a treadmill for engines. It allowed a model car’s drive wheels to spin while the car itself remained stationary. Korn’s dyno measured the power and torque of the .60-cubic inch engine as it delivered power to the wheels. The little dynamometer was even adjustable to accommodate both front and rear-wheel drive models.

This unfinished Korn “Indianapolis 29” kit would have appealed to the budget-conscious tether car buyer. / THF162913

The B.B. Korn Manufacturing Company provided a few options for budget-conscious buyers. Instead of a standard “Indianapolis” model, they could purchase one of Korn’s “Indianapolis 29” cars. Everything about the “29” series was smaller—from the .29-cubic inch engines (source of the name), to the dimensions, to the all-important price tags. Those wanting to save even more could opt for an unassembled “Indianapolis 29” kit rather than a fully assembled car. With the kit, it was up to the buyer to finish rough edges on the balsa wood body, and to source an engine separately.

Barney Korn’s tether cars were beautifully made and carefully detailed, but that quality came at a price—in dollars and in performance. Korn’s models were too expensive for amateur hobbyists and too slow for serious racers. Poor sales made the B.B. Korn Manufacturing Company unsustainable, and it closed just a few years after it opened.

Barney Korn went on to a career in modelmaking for special effects work in films. His detailed miniatures can be seen in movies like To Please a Lady, a 1950 racing melodrama staring Clark Gable and Barbara Stanwyck, and Moby Dick, the 1956 adaptation of Herman Melville’s novel directed by John Huston. In the early 1980s, Korn even built a few improved versions of his original tether car designs.

Barney Korn died in Los Angeles on October 23, 1996, but his craftsmanship survives. Replicas of Korn’s models are readily available today, and originals are highly prized by collectors. It’s a proud legacy for a talented artist who some regard as the Leonardo da Vinci of the tether car hobby.

Explore Further

“Barney Korn: Tether Car Craftsman” expert set

“Tether Cars: Big Thrills in Small Scale” expert set

Driven to Win: Racing in America exhibit information

Artifacts related to tether cars in our Digital Collections

Matt Anderson is Curator of Transportation at The Henry Ford.

Additional Readings:

- 2016 Le Mans Class-winning Ford GT Race Car, On Loan from Ford Motor Company

- 1901 Ford "Sweepstakes" Race Car

- 1902 Ford "999" Race Car, Built by Henry Ford

- 1906 Locomobile "Old 16" Race Car

engineering, engines, making, Henry Ford Museum, Driven to Win, toys and games, by Matt Anderson, cars, racing

Celebrating the National Historic Vehicle Register

America’s car culture is a subject for music, movies, and postcards—and for serious study and preservation. / THF104062

There’s an exciting new changing exhibit in Henry Ford Museum of American Innovation. In partnership with our friends at the Hagerty Drivers Foundation, we’re spotlighting some of the nation’s most significant automobiles and trucks. Some of these vehicles introduced new ideas in engineering or design, others found glory on the race track, and a few lit up the silver screen. In all cases, these vehicles left a mark on American history important enough to earn them a place on the National Historic Vehicle Register.

We inaugurate this collaborative display with a car from the world of popular culture. For those of us who were teens in the 1980s, the movies of writer-director John Hughes were inescapable. Films like Sixteen Candles, The Breakfast Club, Weird Science, and Pretty in Pink captured the Reagan-era teenage zeitgeist—and timeless teenage angst—to a T. But for self-styled Gen-X slackers, one film in the Hughes catalog stands above the rest: Ferris Bueller’s Day Off.

There’s probably no need to summarize the well-known plot (see here if you disagree). Suffice it to say, high school senior Ferris (Matthew Broderick) convinces best friend Cameron (Alan Ruck) and girlfriend Sloane (Mia Sara) to join him on his own personal skip day through Chicago. The plot really gets rolling, so to speak, when Ferris convinces Cameron to let them take his father’s 1961 Ferrari 250 GT California on their adventures. It doesn’t end well. The Ferrari becomes the target of Cameron’s longstanding anger with his father, and its accidental destruction forces some serious interpersonal growth.

This (genuine) 1958 Ferrari 250 GT California was part of Henry Ford Museum’s 1965 Sports Cars in Review exhibit. / THF139028

We’re delighted to be able to exhibit that Ferrari. Well, not that Ferrari… the one that got destroyed. For that matter, what we’re showing isn’t even a Ferrari. It’s a 1985 Modena Spyder California—an authentic-looking replica built by Modena Design & Development in El Cajon, California. It’s one of three Modena replicas used in shooting the movie. (Even in the mid-1980s, a genuine Ferrari 250 GT was too valuable to risk in film work.) This beloved pop-culture car is a playful way to kick off our celebration of a serious project: the National Historic Vehicle Register.

The National Historic Vehicle Register has its roots in the Historic American Engineering Record (HAER). Established jointly in 1969 by the National Park Service, the American Society of Civil Engineers, and the Library of Congress, HAER documents significant sites and structures associated with America’s engineering and industrial history. According to established HAER guidelines, nominated structures are documented with written reports, photographs, and technical drawings. These materials are then deposited in the Library of Congress. Generally, a listing in the HAER does not, in itself, protect a structure from possible demolition. It does, however, “preserve” that structure for the future via HAER’s extensive documentary materials.

HAER has documented buildings, bridges, and even airplanes, but it’s never documented cars. Recognizing the need for some similar mechanism to record significant automobiles and trucks, the Historic Vehicle Association (HVA) was formed in 2009. Modeling itself on HAER, the HVA had four founding principles:

- To document and recognize significant vehicles in a national register

- To establish and share best practices for the care and preservation of significant vehicles

- To promote the historical and cultural importance of motor vehicles

- To protect automotive history through affiliations with museums and academic institutions, through educational programs, and through support of relevant legislation

The Historic Vehicle Association, in collaboration with the U.S. Department of the Interior, established the National Historic Vehicle Register (NHVR) in 2013 and, in January 2014, it added the first car to its list. HVA selected a 1964 Shelby Cobra Daytona Coupe, one of six built by Carroll Shelby and his Shelby American team to compete in sports car races. Apart from Mr. Shelby himself, the Cobra Daytona Coupe was also developed with legendary racing figures like Pete Brock, Ken Miles, and Phil Remington.

CSX2287, the first Shelby Cobra Daytona Coupe, won the 12 Hours of Sebring in 1964. Fifty years later, it became the first entry on the National Historic Vehicle Register. / THF130368

We should pause to note that, of necessity, the National Historic Vehicle Register contains individual cars. The register does not list the Cobra Daytona Coupe as a model. Rather, it specifically includes chassis number CSX2287—the first of the six built, and the only one built completely at Shelby American’s Venice, California, shop. CSX2287 won the GT class at the 1964 Sebring 12-Hour race, competing as number 10, with drivers Dave MacDonald and Bob Holbert. The car later set 27 national and international land speed records at the Bonneville Salt Flats, with Craig Breedlove at the wheel. CSX2287 is now in the collections of the Simeone Foundation Automotive Museum in Philadelphia, Pennsylvania.

Following its selection, the Cobra Daytona Coupe—like all subsequent vehicles on the register—was thoroughly documented for the NHRV. Specialists researched the car through written documents and spoken interviews, they photographed it from multiple angles, and they measured the car using sophisticated laser scanners. (You can learn more about the scanning process in this clip from The Henry Ford’s Innovation Nation.) The resulting materials were then sent to the Library of Congress for long-term preservation.

The Historic Vehicle Association was founded with philanthropic support from Hagerty, the world’s largest specialist insurance provider for historic vehicles. In more recent years, the work of the HVA has been folded into the Hagerty Drivers Foundation, which manages the National Historic Vehicle Register with the U.S. Department of the Interior.

The Marmon Wasp driven by Ray Harroun, winner of the 1911 Indianapolis 500. / THF229391

To date, more than 30 vehicles have been added to the National Historic Vehicle Register. There are celebrated race cars like the 1907 Thomas Flyer that won the 1908 New York to Paris Automobile Race, the 1911 Marmon Wasp that won the first Indy 500, and one of NASCAR’s “Fabulous Hudson Hornets” driven by Herb Thomas.

Volkswagen’s groundbreaking Type 2 Transporter is represented on the NHVR by a van that served a higher purpose: supporting Black Americans in the Civil Rights Movement. / THF105564

There are vehicles that participated in large national events, like a 1918 Cadillac employed by the U.S. Army in World War I, or a 1966 Volkswagen Transporter used in humanitarian efforts supporting Black Americans on Johns Island, South Carolina, during the Civil Rights Movement, or a 1969 Chevrolet Corvette driven by Apollo astronaut Alan Bean, who landed on the Moon in November 1969.

The 1964 Chevrolet Impala lowrider is a car culture icon, illustrated by this remote-controlled model. / THF151539

The wide world of American car culture is wonderfully represented by a 1932 Ford V-8 hot rod built by Bob McGee, a 1951 Mercury Coupe modified for Masato Hirohata by “King of Kustomizers” George Barris, and the pioneering 1964 Chevrolet Impala lowrider “Gypsy Rose,” customized by Jesse Valadez.

Preston Tucker’s 1948 Tucker 48 made a mark in life and on screen. / THF135047

The register doesn’t overlook the automobile’s contributions to popular culture. Apart from the replica Ferrari used in Ferris Bueller’s Day Off, the list includes a 1968 Ford Mustang driven by Steve McQueen during the influential car chase in Bullitt, and a 1981 DeLorean DMC-12 that carried Michael J. Fox’s Marty McFly to 1955 before returning him back to the future. Preston Tucker’s 1947 Tucker 48 prototype is something of a movie car too. Yes, it inspired a real-life production vehicle, but it also inspired the 1988 film Tucker: The Man and His Dream, starring Jeff Bridges.

The 15 Millionth Ford Model T traveled from Greenfield Village to the National Mall in April 2018, after it was added to the NHVR. / Photo courtesy Hagerty Drivers Foundation

Some of you may be wondering if anything from The Henry Ford’s collections is listed on the National Historic Vehicle Register. I’m happy to report that, yes, we are represented by (what else) a Ford Model T added to the list in 2018. It’s not just any T, of course, but the 15 Millionth Ford Model T, which was the ceremonial “last” Model T built before Ford ended production in favor of the 1928–1931 Model A. Like most of the vehicles added to the register, our 15 Millionth Model T traveled to Washington, D.C., where it was displayed on the National Mall—to honor the car, but also to draw attention to the NHVR and the importance of preserving America’s automotive heritage. The NHVR research team also produced a 23-minute documentary on the Ford Model T and its enormous influence.

The register continues to grow. Likewise, The Henry Ford will continue to display a rotating selection of register cars in the years ahead. It’s a fun way to celebrate America’s car culture, but it’s also an opportunity to recognize the important and ongoing work of the National Historic Vehicle Register.

Matt Anderson is Curator of Transportation at The Henry Ford.

Model Ts, race cars, racing, popular culture, movies, by Matt Anderson, Henry Ford Museum, cars