Monthly Archives: October 2021

Women and Farm Work, 1790s-1930s

“The Farmer Is the Man That Feeds Us All.” The words of that folk tune became indelibly imprinted on U.S. popular culture when Alan Lomax included it as the 66th out of the 317 songs in Folk Songs of North America (in the English Language) (1960). In fact, linking “the farmer” to “the man” tells only half the story!

Women in classical dress, 1790-1810 / THF152522

Plenty of popular images of women in agriculture exist. The painting above, rendered by a girl in Massachusetts in the early years of the new nation, shows a woman holding a cornucopia. This likely represented either Ceres, the Roman goddess of agriculture, or Copia, the Roman goddess of abundance. The goddess to the far right, holding a branch, might represent Pax, the Roman goddess of peace.

Mode of Spinning and Weaving by the Pueblo Indians, 1857 / THF621691

Abundance and peace marked a stable and secure agricultural society. Yet, farms throughout the expanding United States flourished on lands that matrilineal indigenous societies had managed for centuries before colonization. The Henry Ford acknowledges these matrilineal indigenous societies as stewards of the lands that sustained them for centuries.

Hillsboro County Agricultural and Mechanical Fair Badge, 1852 / THF154922

The popular depictions of goddesses of agriculture, grains, harvest, and fertility continued in U.S. popular culture for decades. The agricultural fair badge above depicts either the Greek goddess, Demeter; the Roman goddess, Ceres; or America’s Lady Liberty—all matrons of agriculture.

In contrast, illustrations in The Farmers and Dairymans Almanac, published the same year (1852), featured only men engaged in the practice of growing crops and rearing livestock. The work fit the seasons—flailing grain, building fence, spreading manure, and bringing in the sheaves—but emphasized that men did agricultural work and ran the business of farming as well.

Male authority over business ventures, including farming, stemmed from legal traditions based in English common law. These included the precedent of feme covert—that married women had no legal civil identity separate from their husbands. Married women were civilly dead. Thus, only single adult women or widows could negotiate the legally binding contracts required to operate farms. Married women could not—their husbands alone had the legal authority to do so. State laws began chipping away at feme covert during the 1820s by granting married women authority over their wages, recourse if abandoned by a husband, or the privilege of parental authority. It took decades, however, before most states afforded married women authority over their property and finances.

Woman milking a cow, circa 1890 / THF228504

Women acted as farmers, nonetheless. They performed many tasks routinely, including milking cows and tending chickens.

Farm scene showing Norwegian women at work in fields off Merrick Road, 1890-1915 / THF38397

Women worked in the fields, too, especially when crops needed planting, cultivating, or harvesting. Sometimes they did this work as a member of a gang of laborers. The companionship might have eased some of the tedium of hoeing around seedlings to reduce competition from weeds, but it did not ease the physical demands of the labor. The women shown above, described as Norwegian by the photographer, work in farm fields near Brooklyn, New York.

Workers in an Onion Field, H. J. Heinz Company, circa 1910 / THF291590

Perishable commodities required everyone to pitch in. The above photograph shows girls and boys, as well as women and men, busy in an onion field under contract to the H. J. Heinz Company.

In a Great Pine Forest, Collecting Turpentine, North Carolina / THF278800

During harvest seasons, farming needs often took precedence over domestic routines and women worked alongside men to get work done as quickly as possible. This included harvesting turpentine from long-leaf pine forests—yes, forestry work is a branch of agricultural work.

Women operated some machinery, too. Illustrated Industries and Geography of America (1882) features women and children raking hay. One illustration (page 96) shows a woman operating a Wheeler & Melick Co. rake, but this and others like it might have been pure advertising ploys, emphasizing ease of operation and celebrating the notion that “many hands make light work.” The description for the Coates Lock-Lever Hay and Grain Rake in Illustrated Industries and Geography of America (page 231) explains that “twenty acres is a fair day’s work, and as any boy or girl who can guide a horse can work it, it will readily be seen how great a labor-saver it is.”

Illustrated Industries and Geography of America (1882), pg. 240 / THF277183

The need to get hay in dry provided opportunities for girls and women to contribute their labor. The 1882 illustration above shows a girl and a boy on horses that generate the power to raise the loaded hay fork and run it along the track to dump hay in the barn. The same illustration shows a woman at work in the dirtiest job, distributing the dumped hay in the mow.

A Rice Raft with Plantation Hands, Near Georgetown, South Carolina, 1901-1909 / THF278804

The work completed by women and children often contributed to the economic solvency of the family farm. They “gleaned” by walking through harvested fields and picking up grain and straw missed by the work crews. The photograph above shows laborers after a day at work in rice fields in South Carolina. The raft transported them and their grain and straw back home, where they hulled the grain for family use or to sell and used the straw as forage or bedding for their livestock.

Other important farm work occurred in domestic spaces. This “women’s work” should not be discounted among farm work. Women and girls ensured food security and kept farms running by raising, processing, and preserving food crops and processing animal products (eggs, dairy, meat). Several farm homes in Greenfield Village tell these critical stories.

Daggett Farm in Greenfield Village, September 2007 / Photographed by Michelle Andonian / THF53544

The Daggett family, of Daggett Farmhouse, had a very set routine of farm and household management tasks. Samuel Daggett ran the business side of the farm. He had to ensure harvests of enough hay to keep the cattle herd healthy, and enough small grains to satisfy family consumption needs and market income. Anna Bushnell Daggett, on the other hand, oversaw the kitchen garden, to ensure harvests adequate to feed the family. The Daggett family raised food they needed for the entire year on their farmland. They had to plan the quantity and quality of plants and vegetables they needed to grow and harvest to ensure family survival. They then had to preserve the crops by pickling, storing (in a root cellar), fermenting, or drying them to ensure a supply throughout the winter months and into the next season.

Illustrated Historical Atlas of the County of Wayne, Michigan, 1876, page 34, detail / THF126026

The Ford farmhouse functioned well under the oversight of Henry Ford’s mother, Mary Litogot Ford. She maintained the busy farmstead while ensuring that her young and growing family was well fed and healthy. She, with the help of neighboring farmgirls, milked the cattle and tended chickens. She may also have helped with pressing seasonal farm work like bringing in the hay crop, but her young family probably consumed most of her attention on the farm. Mary unfortunately passed away on March 29, 1876, and it’s hard to imagine the historical farmstead operating without her at the center (distinctive in her dress in the illustration above, published in 1876) standing with children and chickens.

Firestone Farm in Greenfield Village, September 2007, Photographed by Michelle Andonian / THF52966

Firestone Farmhouse provides insight into the question, “What does it take to put a meal on the table?” This work drove a farm woman’s working day as she prepared three meals each day, 365 days every year. Morning activities focused on the repetitive and time-consuming tasks of preparing, consuming, and cleaning up after breakfast, while also preparing farm-grown produce, eggs, and meat for the noon meal. Other chores, including work in the kitchen garden, processing of dairy products, and tending to the chicken flock, in addition to household chores and childcare, consumed afternoons and evenings. Evenings involved additional preparation for the same tasks repeated the next day, and so on. Disruptions to these routines included celebrations like weddings, somber events such as funerals, and the haste of harvest which increased the farm workload for all.

Mattox Family Home in Greenfield Village, 1991 / THF45318

The center of many farm women’s lives revolved around the backyards of farm homes. Grace Mattox, her ancestors and her children, spent countless hours over decades keeping the backyard of the Mattox Family Home swept. This area, with its nearby brush arbor, provided additional space to get work done, and to visit with relatives and neighbors while they did it. The Mattox children remembered their hardscrabble existence, consisting of constant work to keep the garden cultivated, ripe vegetables processed, and food on the table.

The Henry Ford’s collections and these historic farmsteads in Greenfield Village provide a glimpse into the routines of farm women’s work. Their labor, from sun-up to sun-down, was essential to ensure the health and wellbeing of their families, as well as the smooth operation of their farms. These routines changed by the mid-twentieth century, as processed foods reduced the work required to maintain the family food supply and new farm implements replaced laborers. Often, women pursued off-farm work, but they remained essential to farm operations as their earnings helped family farms make ends meet.

Debra A. Reid is Curator of Agriculture and the Environment at The Henry Ford and Kathleen Johnson is a student at Henry Ford Academy.

Daggett Farmhouse, Greenfield Village buildings, Greenfield Village, home life, food, women's history, farms and farming, agriculture, by Kathleen Johnson, by Debra A. Reid, #THFCuratorChat

FMC Cascade Tomato Harvester in Use, circa 1985 / THF146505

FMC Cascade Tomato Harvester in Use, circa 1985 / THF146505

The adoption of mechanical tomato harvesters in the 1960s both industrialized tomato production and ushered in a countermovement of small growers and local food advocates. How could one machine prompt such contradictory but real changes in agriculture? The full story spans decades and reveals complex relationships of supply and demand—for both agricultural products and the people who grow and harvest them.

Shortage and Struggle

California’s labor shortage threatened the supply of processing tomatoes for ketchup, sauces, tomato juice, canned tomatoes, and other products. Can label, "Del Monte Brand Spanish Style Tomato Sauce," circa 1930. / THF294183, detail

To meet rising demand for processing tomatoes (to be made into ketchups, sauces, tomato juice, canned tomatoes, and other products) in the early 20th century, growers needed laborers to pick them. Those laborers, in turn, needed living wages. Tensions between growers and laborers came to a head during the New Deal era of the 1930s, when government policies promised minimum wages, maximum hours, and workers’ compensation. Yet, lobbyists working for growers and agricultural processers convinced policy makers to exempt agricultural workers from these protections.

Laborers voted with their feet, seeking employment beyond farm fields. This caused a critical labor shortage that became even more acute during World War II for growers raising tomatoes and other crops in California and beyond. To meet demand, the United States and Mexican governments negotiated the Mexican Farm Labor Agreement. This guest labor program brought millions of farmworkers, known as braceros, from Mexico to work in the United States for short periods of time between 1942 and 1964.

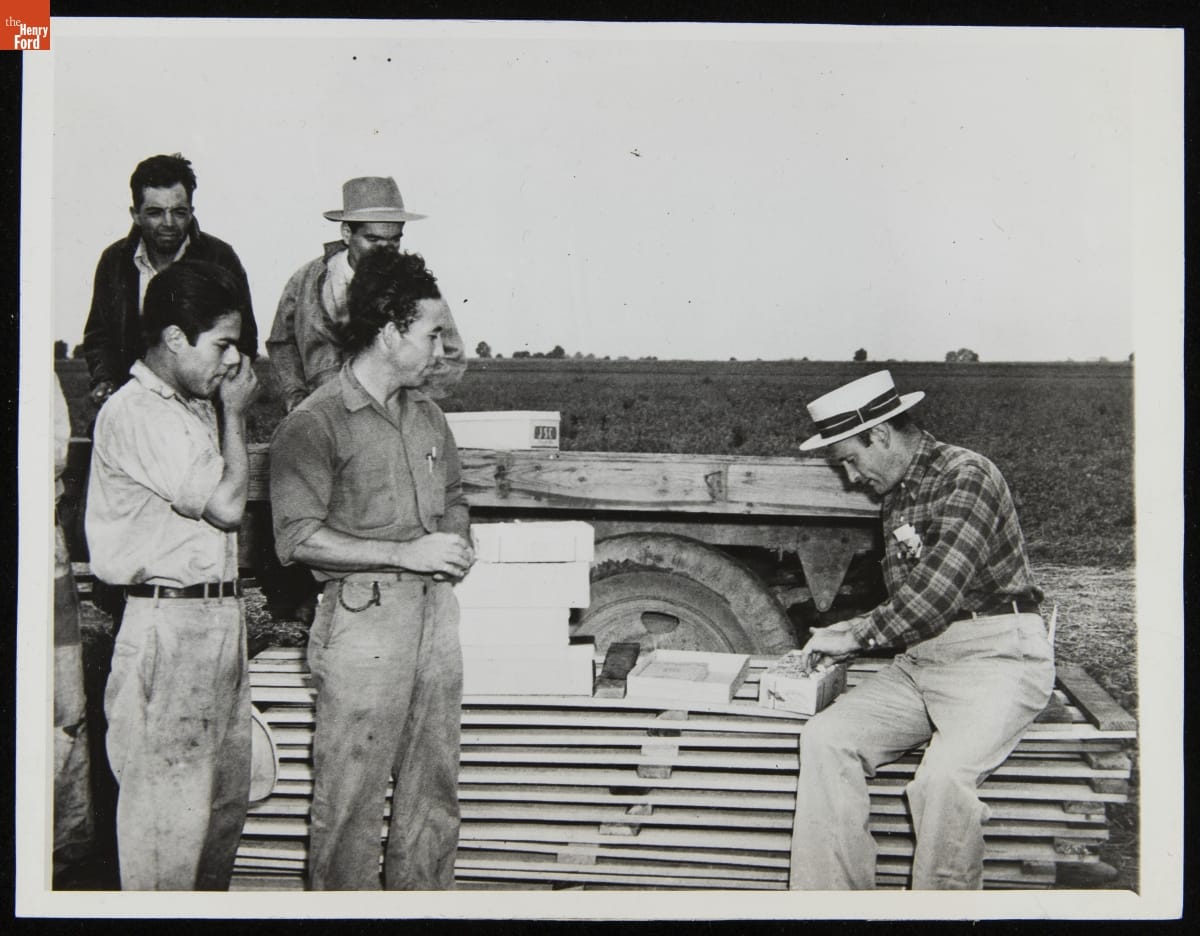

This photograph illustrated a news report on braceros resuming the tomato harvest near Danville, Illinois, in August 1945. / THF147934

A chain of events during the 1960s called attention to the plight of agricultural laborers. Edward R. Murrow’s television documentary Harvest of Shame (1960) highlighted the precarious existence of migrant laborers who worked picking perishable fruits and vegetables in the Midwest and along the East Coast. The Bracero Program expired in 1964, reducing the number of available laborers and increasing growers’ dependence on the existing labor pool. Congress passed the Civil Rights Act of 1964, which, along with other anti-poverty and housing legislation, made it clear that migratory and seasonal laborers had the right to humane treatment.

On the West Coast, Filipino laborers organized as part of the Agricultural Workers Organizing Committee. Seeking better wages and a more favorable rate of payment, they launched a grape strike that expanded into Delano, California, in 1965. The National Farm Workers Association, consisting mostly of Mexican migratory workers, joined the cause. This coordinated effort resulted in a new organization, the United Farm Workers (UFW), with Cesar Chavez as president.

The organizing efforts of groups like the United Farm Workers to secure better wages and living conditions for agricultural laborers in California gained national attention in the 1960s. United Farm Workers flag, circa 1970. / THF94392

The UFW devised innovative solutions to increase pressure on growers, and—especially due to the efforts of co-founder Dolores Huerta—built the Delano grape strike into a national boycott. This focused attention on basic needs for migratory and seasonal laborers. In addition to ensuring some protections for individuals, the coordinated effort secured the right for migratory and seasonal laborers as a class to collectively bargain.

Engineering a Solution to Labor Shortages

Tomato growers, keen on getting their crop planted, cultivated, and harvested at the optimum times, were interested in mechanical solutions that could address labor shortages. Mechanizing the harvest of this perishable commodity, however, proved to be a time-consuming challenge.

Scientists at the University of California, Davis (UC Davis), sought a labor shortage solution through mechanical and biological engineering. Research and development begun in the 1940s finally resulted in the successful design of both a mechanical tomato harvester (created in partnership with Blackwelder Manufacturing Company) and a tomato that could withstand mechanical harvesting (the VF145).

Top: UC Davis vegetable crops researcher Gordie “Jack” Hanna developed the machine-harvestable VF145 tomato. Bottom: An early mechanical tomato harvester underway. Images from the 1968 USDA Yearbook, Science for Better Living. / THF621133 and THF621134

By 1961, Blackwelder had released a commercial harvester and recommended the VF145 tomato for optimum mechanical harvesting. FMC Corporation released a competing harvester by 1966. Manufacturers touted the labor-saving value of mechanical harvesters at a time when the supply of laborers was too small to meet demand, and the adoption of this new technology was swift. In 1961, 25 mechanical harvesters picked about one-half of one percent of California’s tomato crop. Between 1965 and 1966, the number of harvesters doubled from 250 to 512 and the percentage of mechanically harvested tomatoes in California rocketed from 20 percent to 70 percent. By 1970, the transition was complete, with 99.9 percent of California’s tomato crop harvested mechanically. (For more, see Mark Kramer’s essay, "The Ruination of the Tomato," in the January 1980 issue of The Atlantic.)

Contradictory Impact

Some might claim mechanical harvesters helped save California’s processed tomato industry—by 1980, California growers produced 85 percent of that crop. But a closer look reveals a more complicated cause-and-effect. While growers could theoretically save their crop by replacing some labor with machines, many small-scale growers could not save their businesses from large-scale competition. By 1971, the number of tomato farmers had dropped by 82 percent. (This consolidation was mirrored elsewhere in the industry, as just four companies—Del Monte, Heinz, Campbell, and Libby’s—processed 72 percent of tomatoes by 1980.)

Tomato harvester advertisements promised farmers could save their businesses by replacing scarce laborers with machines, but many small-scale growers could not save themselves from large-scale competitors. Advertisement for FMC Corporation Tomato Harvester, circa 1966. / THF610767

A group of growers sued UC Davis, challenging the school for investing so much to develop the tomato harvester without spending comparable resources to address the needs of small farmers. In response, UC Davis opened its Small Farm Center, an advocacy center for alternative farmers, in 1979. These events coincided with wider efforts to hold the United States Department of Agriculture accountable for unequal distribution of support, resulting in increased attention at the national level to economically disadvantaged and ethnically diverse farmers. Around this same time, food activist Alice Waters raised awareness through her advocacy of locally sourced foods. Her restaurant, Chez Panisse, founded in Berkeley, California, in 1971, became an anchor for the burgeoning Slow Food movement.

So, while mechanical tomato harvesters—like the one on exhibit in Henry Ford Museum of American Innovation—represent large-scale scientific and industrial advances, they also offer insight into this country’s complex labor history and help tell stories about small-scale farmers and their connections to communities, customers, and all of us who eat.

Debra A. Reid is Curator of Agriculture & the Environment at The Henry Ford. Adapted by Saige Jedele, Associate Curator, Digital Content, at The Henry Ford.

Additional Readings:

- Agriculture and the Environment

- Bringing in the Beans: Harvesting a New Commodity

- Women in Agricultural Work and Research

- As Ye Sow So Shall Ye Reap: The Bickford & Huffman Grain Drill

farming equipment, research, labor relations, Hispanic and Latino history, food, farms and farming, by Saige Jedele, by Debra A. Reid, agriculture

THF610382

For as long as I can remember, I have been a fan of Charles Schulz's comic strip Peanuts. And It's the Great Pumpkin, Charlie Brown is one of my favorite animated holiday specials. Each year, I set aside time to relive the experiences of the Peanuts characters—and it doesn't grow old. Maybe because it first aired the year I started grade school, or because I also loved Halloween when I was growing up, my memories have kept It's the Great Pumpkin fresh and alive. It could also be the imaginative story, animation, and music encapsulated in a simple format that draws me back year after year, now that I am sadly well beyond the age of trick-or-treating. Or maybe it is a combination of all of these, the artistic creativity playing off deep-seated childhood memories, that makes me look forward to watching this animated classic every autumn.

It’s the Great Pumpkin, Charlie Brown, written by Charles Schulz, is a simple story of imagination, belief, and the joys of childhood. The main story centers on Linus, whose faith in and devotion to the Great Pumpkin reminds us of the fragile childhood innocence we all experienced—and hopefully still resides in us in some form. Within this larger story, Schulz weaves scenes reminiscent of his multi-framed comic strips. Each of these reminds us why we love his characters. The dismay of Linus at watching Lucy carve the pumpkin he brought home into a jack-o-lantern. The attempt by Charlie Brown to kick a football held by Lucy, who we all know will pull it away at the last minute. The help Snoopy gives to Charlie Brown with putting leaves in a pile. The eagerness of Linus to jump into that same pile of leaves—later philosophizing that he should not have done it holding a wet sucker. The joy of trick-or-treaters discovering what they got after dashing from house to house on Halloween night. Or the imagination of Snoopy concocting an epic battle with the Red Baron and his escape through no man's land. Childhood, even with its setbacks, never seemed better.

THF610396

It’s the Great Pumpkin, Charlie Brown is masterfully animated by Bill Melendez. Melendez made Schulz's static comic strip characters move. And it is Melendez who made Snoopy fly. His color palette reminds me of the clear October days when I played in the backyard. And the backgrounds of blotchy blue and purple skies are reminiscent of those blustery Halloween nights when my cousins and I tromped through the neighborhood trick-or-treating.

Finally, where would the Peanuts gang be without the score by Vince Guaraldi? His somber, flute-accompanied themes instill a sense of eerie-ness as trick-or-treaters glide through the streets, Snoopy maneuvers through no man's land, and Linus waits in anticipation in the shadowed pumpkin patch.

| Schulz, Melendez, and Guaraldi (along with producer Lee Mendelson) were the same talented team that helped make A Charlie Brown Christmas so successful the year before, 1965. Learn more about that Peanuts animated holiday classic in this 2015 blog post, Good Grief! "A Charlie Brown Christmas” Turns 50. |

These colorful impressions, these musical moods, these familiar storylines—these snippets of autumnal life—still resonate with me 55 years after the program first aired.

Andy Stupperich is Associate Curator, Digital Content, at The Henry Ford. You will find him on Halloween night watching this animated classic on DVD before he heads out to wait for the Great Pumpkin in the sincerest pumpkin patch he can find.

20th century, 1960s, TV, popular culture, holidays, Halloween, childhood, by Andy Stupperich

Sustainability Through Invention at Invention Convention U.S. Nationals

One of those students was Emma Kaipainen, an 11th grader from Michigan. Emma created the Walking Shipping Container Home and won the Zero Hunger | Zero Waste Award presented by the Kroger Co. Zero Hunger | Zero Waste Foundation. Emma wanted to solve the problem of homes being destroyed by receding shorelines. Her invention is a house comprised of shipping containers, which uses electric rod actuators to power “legs” which allow the house to “walk” away from the shoreline.

The team of Nicolette Buonora and Lauren Strechay, two 9th graders from Massachusetts, were also focused on sustainability. Nicolette and Lauren created the Battery Swap and won the Most Energy Sustainable Award presented by the Avangrid Foundation. Battery Swap is a flashlight with a unique design—it has an extra switch that can divert power between two battery packs. This invention, designed with police officers in mind, solves the problem of a flashlight unexpectedly running out of power. With the Battery Swap, when the flashlight turns off, the user is able to switch to the back-up battery.

Thanks to The Kroger Co. Zero Hunger | Zero Waste Foundation and the Avangrid Foundation for funding these awards and the curriculum enhancements which helped students unlock their full invention potential!

To learn more about these inventions and our other award winners, check out the full awards ceremony below.

Continue Reading

women's history, power, environmentalism, by Mitch Hufnagel, education, innovation learning, Invention Convention Worldwide, inventors, philanthropy, childhood

Mechanizing the Tomato Harvest

Machine-harvesting new tomato varieties, as depicted in the 1968 USDA Yearbook, Science for Better Living. / detail, THF621132

For millennia, people have domesticated plants and animals to ensure survival—this process is agriculture. And while most of us neither grow crops nor raise livestock, agriculture affects all our lives, every day: through the clothes we wear, the food we eat, and the fuel we use to move from place to place.

But agriculture is also the changing story of how this work is done. At every step, people have created new technology and tools to challenge nature’s limitations and to reduce the physical labor required to plant, cultivate, and harvest.

People produced much of what they ate until processed foods became big business in the United States during the late 1800s. As market demand increased, and commercial growing and canning grew, it prompted changes in farming. Take the tomato. Canning required ample quantity to guarantee supply, and vast fields of perishable crops required rapid harvest to ensure delivery of the best crop to processors.

Workers harvest tomatoes by hand at a Heinz farm in 1908. / THF252058

But mechanizing the tomato harvest required changing the crop—the tomato itself—so it could tolerate mechanical harvesting. During the 1940s and 1950s, crop scientists cross-pollinated tomatoes to create uniform sizes and shapes that matured at the same time, and with skins thick enough to withstand mechanical picking.

Agricultural engineers developed harvesting machines that combined levers and gears to dislodge tomatoes from the stalk and stem. But humans remained part of the harvesting process. At least eight laborers rode along on the machines and removed debris from the picked fruit.

In 1969, the first successful mechanical harvester picked tomatoes destined for processing as sauce, juice, and stewed tomatoes.

The 1968 United States Department of Agriculture Yearbook, Science for Better Living, depicted new machine-harvestable tomato varieties that “all ripen near same time, come from vine easily, and are firm fruited.” The oblong shape reduced rolling and bruising. / THF621135

Today, all processed tomatoes—the canned products you find on grocery store shelves—make their way from field to table via the levers, gears, and conveyor belts of a mechanical harvester. But you can still buy a hand-picked tomato at your local farmers’ market—or grow your own.

The process of growing food still involves planting and nurturing a seed. But exploring agriculture in all its complexity helps us recognize the many effects of human interference in these natural processes—an ever-changing story that affects all our daily lives.

Adapted by Saige Jedele, Associate Curator, Digital Content, from a film in Henry Ford Museum of American Innovation’s Agriculture and the Environment exhibit. The team that wrote and refined the film script included Debra Reid, Curator of Agriculture & the Environment; Ryan Jelso, Associate Curator, Digital Content; Ellice Engdahl, Manager, Digital Collections & Content; and Aimee Burpee, Associate Registrar—Special Projects.

Additional Readings:

- Agriculture and the Environment

- Horse Power

- #InnovationNation: Agriculture & Environment

- Biomimicry: Making Mother Nature Our Muse

Henry Ford Museum, farming equipment, food, farms and farming, by Saige Jedele, agriculture

Collecting Mobility: Insights from Ford Motor Company

Similar to the World War II “Arsenal of Democracy” effort, Ford Motor Company joined “Arsenal of Health” efforts through its Project Apollo to fight COVID-19 and serve the community. What Ford practices (or values) helped the company shift gears quickly to ramp up Project Apollo?

For 118 years and counting, Ford has had a culture of innovation and service, which enabled the team to respond quickly and nimbly to the personal protective equipment (PPE) shortages caused by the COVID-19 pandemic.

This Ford Transit van, on display in Collecting Mobility in Henry Ford Museum of American Innovation until January 2, 2022, is one of four converted into mobile test units in spring 2020, early in America's COVID-19 pandemic, by Ford Motor Company and Troy Design & Manufacturing. The vehicles collected genetic samples in the field and transported them to labs for testing. Free tests were given to first responders, nursing home residents, and people at substance abuse centers and community shelters in Michigan. / THF188109

How fast did Project Apollo ramp up? How many products did you make?

The earliest seeds of Project Apollo began in mid-March 2020, when concerns around the safety of healthcare workers faced with a shortage of PPE were first raised. Project Apollo has produced face shields, multiple types of masks, gowns, powered air purifying respirators (PAPRs), ventilators, air filtration kits, and mobile testing/vaccination units.

What were some of the unexpected improvisations that happened turning car parts into useful medical products?

Working with 3M, the team was able to use off-the-shelf parts like vehicle ventilator fans and power tool batteries for a PAPR, or airbag material for washable gowns.

Level 1 isolation gowns protect wearers from contaminants in minimal-risk situations. This gown is made from the same fabric used in automobile airbags. Ford set a goal to produce 1.3 million gowns during the COVID-19 pandemic—each one washable up to 50 times. / THF186847

What is a new way of working that came out of Project Apollo that you think will influence manufacturing innovation in the next 10 years?

The team being very clear on a compelling purpose and mission—there was a common mission that was crystal-clear, very ambitious: to build 50,000 ventilators, 20 million face shields, 32,000 PAPRs, 100 million face masks… and more. On a normal day, this would feel like a Herculean task for each individual item—but to do all of it at the same time was a stretch goal. Ford had a mindset of aim high, fail fast, learn, pivot, adjust—but stay focused on that goal, that mission.

Early in America's COVID-19 pandemic, Ford Motor Company converted a portion of its Rawsonville Components Plant to produce more than 51,000 medical ventilators. These critical machines helped patients with the most serious COVID-19 infections to breathe. This unit, the last one off the Rawsonville assembly line, was signed by some of the 1,100 Ford employees involved in the effort. / THF185919

Teams were empowered. In many cases, the teams set their own goals—it often wasn’t a matter of Ford leadership asking, employees stepped up across the company with ideas on how Ford could help. And everyone played a role in eliminating constraints that were getting in the way of the team mission to serve the greater good.

Cynthia Jones is General Manager of Innovation Experiences at The Henry Ford. Ted Ryan is Ford Motor Company Archives and Heritage Brand Manager and Jim Baumbick is Vice President, Enterprise Product Line Management, Strategy, and Planning, at Ford Motor Company. Ford Motor Company is a global company based in Dearborn, Michigan, that is committed to helping build a better world, where every person is free to move and pursue their dreams. See Collecting Mobility for yourself in Henry Ford Museum of American Innovation from October 23, 2021, through January 2, 2022.

Additional Readings:

- Ingersoll Milling Machine Used at Ford Motor Company Highland Park Plant, 1912

- The Wool Carding Machine

- Collecting Mobility: Insights from Hagerty

- “Female Operatives Are Preferred”: Two Stories of Women in Manufacturing

Ford workers, healthcare, manufacturing, COVID 19 impact, Ford Motor Company, by Jim Baumbick, by Ted Ryan, by Cynthia Jones

“Donation - Crash Test Dog” isn’t the type of subject line you typically see on an email. Yet just after Thanksgiving in 2019, that’s exactly what landed in the Benson Ford Research Center’s email queue. Sleepypod, makers of safety-conscious pet carriers and other related pet products, wanted to know if The Henry Ford would be interested in the donation of MAX2, one of the early crash test dogs they had designed to simulate a live pet in a series of crash tests used to demonstrate the increased safety of Sleepypod pet carriers. For the curator’s consideration, Sleepypod provided photos of MAX2, as well as a brief history of how and why he was developed.

Sleepypod “MAX 2” Crash-Test Dog, 2012 / THF185385

The offer went off to Curator of Transportation Matt Anderson. Intrigued, Matt wanted to follow up on a few questions with the folks at Sleepypod. Of first concern: would Sleepypod be able to hold on to MAX2 until the new year? With just over a month left in 2019, there would be very little time to get MAX2 on site, develop a comprehensive write-up, present it to The Henry Ford’s Collections Committee for approval, and get a deed of gift sent off to—and returned by—Sleepypod. Thankfully, Sleepypod was happy to hold onto MAX2 for us.

Matt was also interested in knowing if the donation would include one of Sleepypod’s pet carriers, and if there was any associated press or marketing material they would be willing to include. Collecting these additional items would help us tell a more complete story about the company and their innovation. Sleepypod responded that not only would they be happy to offer MAX2 with a carrier and marketing material, they would also be interested in donating CLEO 1.0, their first crash test cat. Matt eagerly accepted their offer.

Sleepypod “CLEO” Crash-Test Cat, 2015 / THF185386

In January 2020, MAX2 and CLEO made it to their new home at The Henry Ford, by way of arrival at our relatively new Main Storage Building (MSB). In previous years, objects would arrive at the curatorial offices in the Benson Ford Research Center, where they would be deposited in a small holding room until formally approved and accessioned; they would then be taken elsewhere for storage. MSB, however, is equipped with two rooms dedicated to new acquisitions—one where objects can be examined by our conservation staff to make sure they do not pose a risk to other objects (via issues like insect infestations), and another where “clean” objects can be stored on compacting shelving until they are accessioned and assigned a permanent location, typically within the same building. Utilizing MSB in this way not only helps us keep better track of pending acquisitions, but also saves time and effort on behalf of our Collections Management team, as they have less distance to move objects after they have been accessioned.

Matt began prepping MAX2, CLEO, the carrier, and associated material for presentation to Collections Committee, the group responsible for approving all additions to the collections of The Henry Ford. In order to make his case for adding these crash pets to the collection—after all, “adorableness” is in the eye of the beholder, and not an adequate justification for acquisition—Matt pulled together information on Sleepypod’s history, the development of MAX2 and CLEO, and the historical significance of a pet carrier designed with safety in a moving car in mind (an advancement that shows the next evolution of transportation safety, now that human lives have benefited from crash test technology). All of this was distilled into a short write-up, intended to give the committee a broad overview of the potential acquisition and the rationale behind suggesting it.

Sleepypod Pet Carrier, 2019 / THF185389

Collections Committee—likely won over by a combination of Matt’s thorough and engaging write-up, and the surprise guest appearance of MAX2 and CLEO as meeting attendees—approved adding MAX2, CLEO, the Sleepypod carrier, and the associated marketing material to the collection. The group of items was assigned an accession number—2020.31, denoting that it was the 31st accession group brought into the collection in 2020—and the registrars assigned each of the 3D objects a number within that group: 2020.31.1 for the Sleepypod pet carrier, 2020.31.2 for MAX2, and 2020.31.3 for CLEO. The photography studio photographed MAX2, CLEO, and the carrier, so that the objects would be ready to go up on our Digital Collections page, which provides photos and information for over 100,000 items (and growing) in The Henry Ford’s collection.

After the Collections Committee meeting, there was one final step to officially transfer ownership of MAX2 and CLEO to The Henry Ford: completion of deed of gift paperwork. Generated by the Registrar office for all donations that become part of the collection, the deed of gift serves as a legal document that formally transfers ownership of an object to The Henry Ford. It also provides an opportunity for donors to indicate how they would like to be credited if the object is ever exhibited, published, or otherwise presented to the public. Once this paperwork is completed by a donor and returned to The Henry Ford, the acquisition process comes to an end.

CLEO relaxing, waiting to be moved to her new home by her new owners / Photo courtesy Sophia Kloc

Although MAX2 and CLEO are certainly unique objects, the process by which they came to be part of The Henry Ford’s collection is the same one that every object must take. Although some acquisition offers (like the Sleepypod donation) result in a quick turnaround, others require more thought and research; while the process itself remains the same, the timeline is unique from object to object.

Without the wide variety of offers that The Henry Ford receives, our collection would not be what it is today. Sometimes the most interesting items we acquire are ones we would not have thought to look for, had someone not sought us out with an opportunity. Although we cannot accept everything—over 90 years of collecting means that many things are already represented in the collection, and other items just may not be a good fit for one reason or another—we always take the time to review the offers we are sent, never knowing when the next exciting acquisition may appear.

If you, too, are interested in providing an addition to the collections of The Henry Ford, information on how to start the process can be found here.

Rachel Yerke is Curatorial Assistant at The Henry Ford.

collections care, philanthropy, cars, by Rachel Yerke, #Behind The Scenes @ The Henry Ford

Collecting Mobility: Insights from Hagerty

What aspect of mobility history (artifacts, topics, or themes) preserved at The Henry Ford feels the most significant in the current moment?

The Henry Ford’s amazing collection of self-propelled transportation machinery ranges from the diminutive 1896 Ford Quadricycle runabout that weighs just 500 pounds with an engine making four horsepower, to the Chesapeake & Ohio Railway’s gargantuan 1941 Allegheny steam locomotive weighing in at an unimaginable 1.2 million pounds and making 7,500 horsepower.

Of all these, however, the most powerful is an unassuming lime, white, and gold bus that powered the country out of its dark past of segregation into a future where laws would not discriminate against the nation’s citizens simply on the color of their skin. Especially when viewed through the prism of current events such as the Black Lives Matter movement, the 1948 General Motors (GM) bus where Rosa Parks made her stand against racial discrimination by sitting down is the most significant piece of mobility history in The Henry Ford’s collection.

The Rosa Parks Bus, on exhibit in With Liberty and Justice for All in Henry Ford Museum of American Innovation, is Hagerty’s pick for the most significant artifact from The Henry Ford’s collections in the current moment. / THF14922

What cars are popular with collectors right now that might eventually make their way into museum collections?

Definitely include the Tesla Roadster as the start of an incredible story about Elon Musk. It’s also the first vehicle to make electrics cool. The McLaren P1 hybrid supercar was important for establishing electrification as a must-have feature in the supercar class, making every other supercar seem outdated. Any current Formula One car, as their complex hybrid powerplants are achieving formerly unheard-of efficiency rates of over 50 percent, which is the future of the internal combustion engine … assuming it has a future. The Chevy Bolt will be remembered as the turning point for General Motors’ reputation and the industry as a whole, transforming GM from the company that notoriously “killed the electric car” (the EV1) to one of the technology’s chief proponents. The same holds true for a Volkswagen diesel, circa 2010—an enormously influential moment in which the world’s largest automaker was forced by its own actions to pivot to fully embracing electric tech, thus spurring the industry as a whole to commit to electrification.

One of Hagerty’s suggestions for cars that might make their way into museum collections is a Tesla Roadster—like this one, photographed in 2008 and owned by Elon Musk himself (photographed by Michelle Andonian). / THF55832

Are there vehicle(s), innovator stories, or mobility technologies you think The Henry Ford should add to its collections right now? Why?

An early fuel-cell vehicle, either a Honda Clarity or Toyota Mirai or Hyundai Tucson FCEV, would represent how the industry has placed bets on various technologies—and how at that moment in time, it wasn’t clear which would win out (one could debate whether it is clear even now). Obviously, a Tesla Model S with autopilot tells the story of Silicon Valley’s attempt to disrupt the auto industry through fast-paced innovation common in big tech, but unknown in the historically cautious and slow-moving auto industry. A retired Waymo or GM Cruise taxi studded with LiDAR sensors would be an example of the first attempts to commercialize autonomous vehicles.

What mobility artifacts, innovator stories, or technologies do you think The Henry Ford will be collecting in 10 years? 50 years? 100 years?

Batteries are the new frontier, as are electric motors—and the relentless drive for efficiency in both. Nothing else defines this era so aptly. Also, semiconductor manufacturing. We have seen how beholden the industry is to a component that wasn’t even used in cars just a few decades ago. The cars of today and tomorrow are just the boxes that computers come in; every automaker is turning itself into a tech company whose primary competitive advantage will be in software.

By 1990, computer engine controls were nearly universal on American automobiles. This GM computer module controlled a gasoline engine's ignition firing sequence. Hagerty notes that “The cars of today and tomorrow are just the boxes that computers come in.” / THF109463

Aluminum construction is important, too. The 2015 Ford F-150, the first aluminum-body truck, is a watershed moment for aluminum in high-volume vehicles. It is an open question now whether aluminum will spread beyond that experiment, but no automaker has made such a high-stakes gamble as Ford with the F-150. New materials and manufacturing methods are coming as the battle to reduce weight continues into the electrification era.

What aspects of mobility is Hagerty paying the most attention to right now?

The act of getting behind the wheel, twisting the key, and hitting the road is an act of personal freedom, and we believe anyone and everyone who wants to experience that should be able to. Our longstanding Hagerty Driving Experience has put thousands of young people all over North America behind the wheels of classic cars, alongside passionate owners, to teach the basics of operating a manual transmission. Through the nonprofit Hagerty Drivers Foundation, we launched the “License to the Future” program, which provides financial assistance to kids ages 14–18 to cover the expense of driver’s training. And the Hagerty Driving Academy partners with Skip Barber Racing School at dozens of events around the country to teach safe, proficient driving skills in a variety of situations.

Ensuring young people have access to driver training is important. In this 1940 photo, a young man takes a driver’s test as part of the Ford Motor Company Good Drivers League at the New York World’s Fair. / THF216125

We also regularly report on developments taking place in the realm of autonomous vehicles as a trusted voice to assure our members that this beloved activity that connects us—driving—is under no threat from the far-off future.

Will the future make owning classic vehicles more difficult or less difficult? Servicing older vehicles is already becoming harder, due to shortages in knowledge and parts, but will new technologies such as 3D printing or electric conversion mean that older vehicles will have new lives and relevance in the future?

Ellice Engdahl is Digital Collections & Content Manager at The Henry Ford. Aaron Robinson is Editor-at-Large, Kirk Seaman is Senior Editor, and Stefan Lombard is Executive Editor at Hagerty. Hagerty is an automotive enthusiast brand and the world's largest membership organization for car lovers everywhere. See Collecting Mobility for yourself in Henry Ford Museum of American Innovation from October 23, 2021, through January 2, 2022.

Additional Readings:

- Henry’s Assembly Line: Make, Build, Engineer

- The Hitchcock Chair: An American Innovation

- The Changing Nature of Sewing

- Collecting Mobility: Insights from Ford Motor Company

autonomous technology, education, manufacturing, alternative fuel vehicles, African American history, Rosa Parks bus, technology, cars, by Stefan Lombard, by Kirk Seaman, by Aaron Robinson, by Ellice Engdahl

Collecting Mobility: Insights from General Motors

Our new limited-engagement exhibit, Collecting Mobility: New Objects, New Stories, opening to the public October 23, 2021, takes you behind the scenes at The Henry Ford to show you how we continue to grow our vast collection of more than 26 million artifacts. One key question the exhibit asks is why we collect the items we collect. To get more insight on the artifacts on exhibit and future trends that may impact our collecting, we reached out to several of our partners. In this post from that series, our friends at General Motors (GM), donors of the General Motors first-generation self-driving test vehicle in the exhibit and contributors to our Driven to Win: Racing in America exhibit, tackle questions about autonomous vehicles (AVs), electric vehicles (EVs), and racing.

Our latest permanent exhibit, Driven to Win: Racing in America, is presented by General Motors. How has GM’s racing program evolved over time?

GM’s Chevrolet and Cadillac brands have both had long, storied histories in motorsports. Racing is a fundamental part of what we do—from transferring technology learned on the track to help us build better vehicles to connecting with consumers through something they love.

Racing driver Louis Chevrolet co-founded GM’s Chevrolet brand with William C. Durant in 1911. / THF277330

Chevrolet has been successful in professional motorsports in the United States and around the globe, capturing many manufacturer, driver, and team championships in NASCAR, IndyCar, IMSA, and the NHRA. From stock cars to advanced prototypes, Cadillac Racing has a rich history—more than half a century—of racing around the world and around the clock on some of the world’s notably challenging circuits.

Off the track, our racing programs have evolved with the help of our GM facilities. In 2016, General Motors opened the doors to the all-new GM Powertrain Performance and Racing Center—a state-of-the-art facility designed to enhance the development processes for the company’s diverse racing engine programs.

In 2021, General Motors broke ground on the new Charlotte Technical Center, a 130,000-square-foot facility that will expand GM’s performance and racing capabilities. The facility is a $45 million investment for GM and it will be a strong hub for the racing and production engineering teams to collaborate, share resources, and learn together, delivering better results more quickly, both on the racetrack and in our production vehicles.

The Chevrolet Corvette has a long, proud history in professional and amateur sports car racing. This pair of Corvettes is seen at a Sports Car Club of America race in Maryland in 1959. / THF135778

Engineering has become incredibly advanced over time, and leveraging tools between racing and production has become extremely important. We use tools like computational fluid dynamic models, which uses applied mathematics, physics, and computational software to visualize how a gas or liquid flows. These CFD models help us predict things like powertrain performance and aerodynamics.

Also, our Driver-in-the-Loop simulator allows us to test vehicles on courses virtually. It is the combination of two technologies: a real-time computer (with vehicle hardware) and a driving simulator. The driving simulator allows our development engineers to drive and test the real-time computer simulation and added hardware system on a virtual track, just like they would a physical prototype. The simulator was used extensively during the development of the mid-engine Corvette C8.R race car.

The 2001 C5-R Corvette is currently on loan from General Motors and can be seen by guests inside Driven to Win: Racing in America. Why was this vehicle selected to go on display inside Henry Ford Museum of American Innovation?

The Corvette C5-R made its debut in 1999 at the Rolex 24 at Daytona and was a fixture of global GT racing for the next five years. From 1999–2004, Corvette Racing and the C5-R set the standard for racing success with 31 victories in the American Le Mans Series, along with an overall victory at the Rolex 24 in 2001.

During six years of competition, Corvette Racing—the first factory-backed Corvette team in the car’s history—led the C5.R to an overall victory at the Daytona 24-hour race and three 1-2 finishes in the GTS class at the 24 Hours of Le Mans. During the 2004 season, Corvette Racing won every race the team entered and captured every pole position in the American Le Mans Series.

2001 C5-R Corvette, on loan from General Motors Heritage Center and currently on exhibit in Driven to Win: Racing in America in Henry Ford Museum of American Innovation. / THF185966

This specific car raced 17 times from August 2000 through June 2002 with 10 wins. It brought home the first win for the factory Corvette Racing program—Texas 2000 in the ALMS’ GTS class. Then it went on to become 2001 overall winner at Rolex 24, which was quite an accomplishment for a GT car. The car went on to win its class at Le Mans 24 in both 2001 and 2002. The modern era of Corvette’s factory racing program continues today, after over 20 years and 4 generations (C5/C6/C7/C8).

The success of this C5-R essentially started it all and we are proud to have it on display.

General Motors' donation of the 2016 GM First-Generation Self-Driving Test Vehicle was our first self-driving car acquisition. Why was it important to have this car join more than 300 others—including GM landmarks like the 1927 LaSalle and the 1997 EV1 Electric—in the collections of The Henry Ford?

This vehicle represents a huge step forward on the journey to fully autonomous driving. With Cruise, our majority-owned subsidiary, we’re determined to commercialize safe, autonomous, and electric vehicles on our way to a driverless future—one with zero crashes.

General Motors tested a series of autonomous vehicles in San Francisco, California, and Scottsdale, Arizona, in 2016. These cars used a combination of cameras, radar and lidar sensors, cellular and GPS antennas, and powerful computers to drive themselves on public streets in both cities. GM donated this one, now on exhibit in Driving America in Henry Ford Museum of American Innovation, to The Henry Ford in 2018. / THF173551

Cruise was the first AV company permitted to give rides to the public in its current driverless vehicles in the San Francisco area. Expansion of our real-world test fleet will help ensure that our self-driving vehicles meet the same strict standards for safety and quality that we build into all of our vehicles.

GM became the first company to assemble self-driving test vehicles in a mass-production facility when its next generation of self-driving Chevrolet Bolt EV test vehicles began rolling off of the line at Orion Township, Michigan, in January 2017.

The self-driving Chevrolet Bolt EVs feature an array of equipment, including LIDAR, cameras, sensors, and other hardware designed to accelerate development of a safe and reliable fully autonomous vehicle.

Reshaping cities and the lives of those who live in them has tremendous societal implications. Since we believe that all AVs will be EVs, these efforts will clearly advance our vision of zero crashes, zero emissions, and zero congestion, and help us build a more sustainable and accessible world.

This vehicle was really the first of its kind and its display is a sneak peek at the future of autonomy.

By 2025, General Motors plans to offer more than 30 electric vehicles globally. What does an all-electric future look like for Generation E?

For electric vehicles to make an impact, we need consumers to embrace them in mass numbers. So earlier this year, General Motors introduced the world to EVerybody In.

This is our brand commitment toward advancing a world with zero crashes, zero emissions, and zero congestion. EVerybody In is more than a brand campaign, it's a global call to action for everybody to join us on the road to an all-electric future.

GM introduced the EV1 in 1997. It was among the most sophisticated electric cars built during the 20th century. / THF91060

GM wants to put everyone in an EV. Thanks to Ultium, our EV architecture, GM is able to reimagine the vehicles it produces today as electric vehicles with equivalent power, excellent range, and a manufacturing cost different that is expected to diminish as EV production increases.

Not only will our EVs be fun to drive and cost less to own, they will also provide an outstanding customer experience. This is how we will encourage and inspire mass consumer adoption of EVs. GM has the technology, talent, scale, and manufacturing expertise to do it.

The all-electric future we are creating goes beyond our vehicles, it is inspiring us to do even more to help mitigate the effects of climate change. We plan to source 100 percent renewable energy to power our U.S. sites by 2025, and to become carbon neutral in our global vehicles and operations by 2040.

General Motors wants to impact society in a positive way and these are some of the steps we are taking to make it happen.

General Motors is committed to electrification—what types of current EV projects from the company might we expect to see in the museums of tomorrow?

With more than 30 EVs being introduced by 2025, we have a lot of exciting vehicles coming. From sedans, to trucks, to full-size SUVs, we will have a wide range of offerings in terms of size and design.

We are entering an inflection point in the transportation industry, a transformation the industry has not seen in decades—the mass adoption of electric vehicles. The first of any of these entries will be a sight to see in the museums of tomorrow for generations to come.

Lish Dorset is Marketing Manager, Non-Admission Products, at The Henry Ford. Todd Christensen is Strategy and Operations Manager, Chevrolet Motorsports Marketing & Activation, and Gina Peera is Corporate Strategy and Executive Communications at General Motors. General Motors is a global automotive manufacturer, driving the world forward with the goal to deliver world-class customer experiences at every touchpoint and doing so on a foundation of trust and transparency. See Collecting Mobility for yourself in Henry Ford Museum of American Innovation from October 23, 2021, through January 2, 2022.

Additional Readings:

- Driven to Win: Sports Car Performance Center

- A Lesson in Safety: Salt Walther’s Race Car

- I Would Drive 500 Miles: Scottish Drivers at the Indy 500

- 2001 Chevrolet Corvette C5-R. On Loan from General Motors Heritage Center.

engineering, manufacturing, Henry Ford Museum, Driving America, Chevrolet, alternative fuel vehicles, technology, autonomous technology, Driven to Win, race cars, racing, cars, by Gina Peera, by Todd Christensen, by Lish Dorset

Collecting Mobility: Insights from Michigan Department of Transportation

Our new limited-engagement exhibit, Collecting Mobility: New Objects, New Stories, opening to the public October 23, 2021, takes you behind the scenes at The Henry Ford to show you how we continue to grow our vast collection of more than 26 million artifacts. One key question the exhibit asks is why we collect the items we collect. To get more insight on the artifacts on exhibit and future trends that may impact our collecting, we reached out to several of our partners. In this post from that series, our friends at the Michigan Department of Transportation (MDOT) and the Michigan Economic Development Corporation (MEDC) tackle questions about the infrastructure of mobility.

Our cars are increasingly "connected," whether for navigation, communication, or entertainment. What challenges does this pose for our current infrastructure, and what improvements are most urgently needed to keep pace with technology?

MDOT:

First, the balance between data-sharing and privacy. The Michigan Department of Transportation leads all our efforts with safety first. Our agency looks to find opportunities to solve modern traffic challenges as cars become increasingly connected with technology that meets the need for navigation, communication, and/or entertainment.

Due to today’s connectivity, MDOT has the means to share data and asset information relevant to roadway users—for example, wrong-way driving alerts and information directly connected to infrastructure, vehicles, and other devices. But as more consumers purchase connected vehicles, there are increased opportunities for exploitation by hackers using cellular networks and/or wi-fi. Therefore, software vulnerabilities, privacy, and other cybersecurity concerns must be addressed as quickly as the technology progresses.

Early standalone consumer GPS units, like this 1998 Garmin “Personal Navigator” system, had limited or no integration with the rest of a car. As vehicles become increasingly connected, potential safety and security concerns increase too. / THF150113

Second, leaving room for solutions, opportunities, and collaboration. It is imperative to remain technology-agnostic and interoperability is critical. Today’s vehicles meet many needs and should be able to work with many devices and operating systems.

A recent decision by the Federal Communications Commission (FCC) to reallocate a portion of the radio spectrum from public safety to commercial use has been the most significant impact to date. This introduces the potential of not having enough spectrum to operate the technology to improve safety and mobility. Continued collaboration with other governmental agencies, private companies, and academia leads to a safer, better user experience for motorists.

Challenges in allocating limited radio spectrum frequencies aren’t new. In 1977, at the height of the CB radio craze, the FCC yielded to popular demand by expanding the number of citizens band channels from 23 to 40. / THF106547

MEDC:

The increase in connectivity between vehicles challenges our current infrastructure because infrastructure upgrades are not able to happen as quickly as the vehicle technology is advancing. First, we need to make sure our current infrastructure is maintained and suitable for the vehicles we do have on the roads. The next improvements would be continuing to implement vehicle-to-everything (V2X) technology on our roadways, and to explore connected infrastructure projects, such as a public-private partnership to establish and manage a connected roadway corridor.

Navigation apps like Waze leverage user data and intelligent transportation systems (ITS) to provide real-time updates, helping drivers avoid construction and other traffic congestion. Does MDOT have its own advanced technologies and services to enhance these platforms and keep Michigan drivers safe and on the move?

MDOT:

MDOT utilizes a variety of methods to reach out to our citizens to provide traveler information. Drivers can access our Mi-Drive link for detailed information regarding construction projects, etc. Our traffic operations centers post information for incidents and rerouting on our dynamic message signs located on our freeway system.

This 2018 Waze beacon, on display in Collecting Mobility through January 22, 2022, eliminated dead spots in GPS navigation by placing battery-powered beacons in tunnels where GPS satellite signals couldn't reach. / THF188371

As vehicles and roadways transition to the future state of connectivity, there will continue to be many vehicles on the road that are not equipped with these technologies. How will the new systems accommodate older or non-connected vehicles?

MDOT:

MDOT works with industry partners on that transition, and as new technologies are implemented, we are always considering the users and amount of saturation for vehicles to take advantage of them. For example, MDOT provides information on our dynamic message boards, and we can also provide that information into connected vehicles. It would be difficult to remove those dynamic message signs currently, as the number of connected vehicles on the road today is not high enough. The technologies will become more prevalent as drivers get new vehicles and aftermarket technologies are implemented on older vehicles. Systems already exist on vehicles coming off the assembly line that are improving safety, such as blind spot and forward collision warnings, and adaptive cruise control.

The coming transitional period, in which connected cars share roads with non-connected vehicles, will mirror the mobility transition of the early 20th century, when horse-drawn vehicles coexisted with automobiles. / THF200129

MEDC:

It’s important to note that connected roadways will not cancel out the use of non-connected vehicles—there will be a transitional period where a lot of non-connected vehicles will use aftermarket Internet of Things (IoT) solutions that allow them to take advantage of the connected roadways. The non-connected vehicles may not be able to take advantage of all the benefits of the connected roadways, like communication and navigation, but there will be solutions to upgrade their vehicles to accommodate them.

We've long depended on gasoline taxes to finance road construction and maintenance. But as the percentage of electric vehicles (EVs) grows, gas tax revenues decrease. Should we be looking at new funding methods? What alternatives should we consider?

MDOT:

This will be an important public policy discussion going forward. In Michigan, road funding legislation signed by then-Governor Rick Snyder in 2015 included increased registration fees for EVs. Roads in Michigan are primarily funded through registration fees and fuel taxes. More creative mechanisms will be necessary to continue to maintain our roads and bridges. Legislation in Michigan tasked MDOT with conducting a statewide tolling study, which is ongoing. New public-private partnerships will be vital to creating and maintaining charging infrastructure.

Gas taxes won’t pay for roads in an electric-vehicle world. This modern problem could be solved in part with an ancient solution: toll roads. Learn more about highway funding challenges in our “Funding the Interstate Highway System” expert set. / THF2033

States could look to local governments and other state agencies to encourage charging infrastructure inclusion in building codes and utility company build-out plans. There is also uncertainty at the moment around what federal programs might be created as a result of the draft infrastructure plan being debated by Congress.

MEDC:

Yes, absolutely. With more electric vehicles coming to market, there is an opportunity for more creative ways to finance roads while ensuring no more of a burden on electric vehicle drivers than on gasoline vehicle drivers. Some alternatives include a VMT (vehicle miles traveled)–based fee that electric vehicle owners could opt into. The fee would be based on a combination of the vehicle’s metrics and miles driven, to accurately reflect road usage and the gas taxes that gasoline vehicle owners pay. This is also a policy recommendation in the Michigan Council on Future Mobility and Electrification’s annual report, which will be published in October 2021.

In the 1950s, there were experiments with guidewire technology that enabled a car to steer itself by following a wire embedded in the pavement. Today we're experimenting with roads that can charge electric vehicles as they travel. Is it time to rethink the road itself—to connect it directly with our cars?

MDOT:

Thankfully, infrastructure continues to become “smarter” due to intelligent transportation systems, smart signals, and more—for example, the simplification of the driving environment for connected autonomous vehicles (CAVs). In 2020, MDOT established a policy to increase the width of lane lines on freeways from four to six inches to support increasing use of lane departure warning and lane keeping technologies.

Our roadways evolve with our technologies. This 1956 brochure promotes the proposed Interstate Highway System—which was then a brand-new idea, not yet implemented. / THF103981

Similarly, the roadway can be evolved to optimize travel in EVs. The development of a wireless dynamic charging roadway in Michigan is a step forward in addressing range anxiety and will accelerate better understanding of infrastructure needs moving forward. This inductive vehicle charging pilot will deploy an electrified roadway system that allows electric buses, shuttles, and vehicles to charge while driving. The pilot will help to accelerate the deployment of electric vehicle infrastructure in Michigan and will create new opportunities for businesses and high-tech jobs.

Some of Michigan’s “smart infrastructure.” / Infographic courtesy MDOT

MEDC:

It is time to rethink the road itself—as new advancements in mobility and electrification roll out for vehicles, it’s only natural to rethink the infrastructure these vehicles operate on. As computers got smaller and more compact over time, so did their chargers. It’s a similar thing with vehicles and their infrastructure. As vehicles get smarter and more connected, the infrastructure will have to follow suit.

Matt Anderson is Curator of Transportation at The Henry Ford, Michele Mueller is Sr. Project Manager - Connected and Automated Vehicles at Michigan Department of Transportation, and Kate Partington is Program Specialist - Office of Future Mobility and Electrification at Michigan Economic Development Corporation (MEDC). The Michigan Department of Transportation is responsible for Michigan's 9,669-mile state highway system, and also administers other state and federal transportation programs for aviation, intercity passenger services, rail freight, local public transit services, the Transportation Economic Development Fund, and others. The Michigan Office of Future Mobility and Electrification within the MEDC was created in February 2020 to bring focus and unity in purpose to state government’s efforts to foster electrification, with a vision to create a stronger state economy through safer, more equitable, and environmentally conscious transportation for all Michigan residents. See Collecting Mobility for yourself in Henry Ford Museum of American Innovation from October 23, 2021, through January 2, 2022.

autonomous technology, alternative fuel vehicles, Michigan, technology, roads and road trips, cars, by Kate Partington, by Michele Mueller, by Matt Anderson